- DL manuals

- ABB

- DC Drives

- ACS150 series

- User Manual

ABB ACS150 series User Manual

Summary of ACS150 series

Page 1

Acs150 user’s manual acs150 drives (0.37…4 kw, 0.5…5 hp) quote or buy online www.Inverterdrive.Co.Uk.

Page 3: User’S Manual

Acs150 drives 0.37…4 kw 0.5…5 hp user’s manual 3afe68576032 rev a en effective: 7.12.2005 © 2005 abb oy. All rights reserved..

Page 5: Safety

Safety 5 safety what this chapter contains the chapter contains the safety instructions which you must follow when installing, operating and servicing the drive. If ignored, physical injury or death may follow, or damage may occur to the drive, motor or driven equipment. Read the safety instructions...

Page 6: Operation And Start-Up

Safety 6 warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment. • the drive is not field repairable. Never attempt to repair a malfunctioning drive; contact your local abb representative or authorized service center for replacement. • make sure t...

Page 7: Table of Contents

Table of contents 7 table of contents safety what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 use of warning symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 8

Table of contents 8 electrical installation what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 9

Table of contents 9 10 start/stop/dir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 11 reference select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 12 const...

Page 10

Table of contents 10 efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 11: About The Manual

About the manual 11 about the manual what this chapter contains the chapter describes the intended audience, compatibility and contents of this manual. It contains a flowchart of steps for checking the delivery and installing and commissioning the drive. The flowchart refers to chapters/sections in ...

Page 12

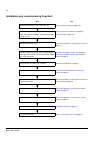

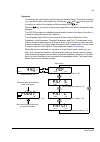

About the manual 12 installation and commissioning flowchart task see identify the frame size of your drive: r0…r2. Technical data : ratings on page 109 plan the installation: select the cables, etc. Check the ambient conditions, ratings and required cooling air flow. Planning electrical installatio...

Page 13: Hardware Description

Hardware description 13 hardware description what this chapter contains the chapter describes the construction and type code information in short. Overview the acs150 is a wall or cabinet mountable drive for controlling ac motors. The construction of frame sizes r0…r2 varies to some extent. 5 9 8 6 ...

Page 14

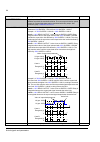

Hardware description 14 overview: connections and switch the diagram shows the connections and switch of the acs150. U1 v1 w1 brk+brk- u2 v2 w2 m ~3 pe l1 l2 l3 t° ac power line brake resistor motor analog input 0(2)…+10 vdc or 0(4)…+20 ma relay output 250 vac / 30 vdc five digital inputs di5 also u...

Page 15: Type Code

Hardware description 15 type code the type code contains information on the specifications and configuration of the drive. You find the type code on the type designation label attached to the drive. The first digits from the left express the basic configuration, for example acs150-03e- 08a8-4. The e...

Page 16

Hardware description 16.

Page 17: Mechanical Installation

Mechanical installation 17 mechanical installation what this chapter contains the chapter describes the mechanical installation procedure of the drive. Unpacking the drive the drive (1) is delivered in a package that also contains the following items (frame size r0 shown in the figure): • plastic ba...

Page 18: Before Installation

Mechanical installation 18 delivery check check that there are no signs of damage. Notify the shipper immediately if damaged components are found. Before attempting installation and operation, check the information on the type designation label of the drive to verify that the drive is of the correct...

Page 19: Mounting The Drive

Mechanical installation 19 free space around the drive the required free space for cooling above and below the drive is 75 mm (3 in.). No free space is required on the sides of the drive, so they can be mounted side by side. Mounting the drive mount the drive note: make sure that dust from drilling ...

Page 20

Mechanical installation 20 fasten clamping plates 1. Fasten the clamping plate to the plate at the bottom of the drive with the provided screws. 2. Fasten the i/o clamping plate to the clamping plate with the provided screws. 1 1 2 2.

Page 21: What This Chapter Contains

Planning electrical installation 21 planning electrical installation what this chapter contains the chapter contains the instructions that you must follow when selecting the motor, cables, protections, cable routing and way of operation for the drive. If the recommendations given by abb are not foll...

Page 22

Planning electrical installation 22 thermal overload and short-circuit protection the drive protects itself and the input and motor cables against thermal overload when the cables are dimensioned according to the nominal current of the drive. No additional thermal protection devices are needed. Warn...

Page 23: Selecting The Power Cables

Planning electrical installation 23 selecting the power cables general rules dimension the input power and motor cables according to local regulations. • the cable must be able to carry the drive load current. See chapter technical data for the rated currents. • the cable must be rated for at least ...

Page 24

Planning electrical installation 24 motor cable shield to function as a protective conductor, the shield must have the same cross-sectional area as the phase conductors when they are made of the same metal. To effectively suppress radiated and conducted radio-frequency emissions, the shield conducti...

Page 25: Of Inductive Loads

Planning electrical installation 25 protecting the relay output contact and attenuating disturbances in case of inductive loads inductive loads (relays, contactors, motors) cause voltage transients when switched off. Equip inductive loads with noise attenuating circuits [varistors, rc filters (ac) o...

Page 26: Routing The Cables

Planning electrical installation 26 a double-shielded cable is the best alternative for low-voltage digital signals, but a single-shielded or unshielded twisted multipair cable (figure b) is also usable. However, for frequency input, always use a shielded cable. Run the analog signal and digital sig...

Page 27

Planning electrical installation 27 a diagram of the cable routing is shown below. Control cable ducts 90 ° min. 500 mm (20 in.) motor cable input power cable control cables min. 200 mm (8 in.) min. 300 mm (12 in.) motor cable power cable drive 230 v 24 v 24 v 230 v lead 24 v and 230 v control cable...

Page 28

Planning electrical installation 28.

Page 29: Electrical Installation

Electrical installation 29 electrical installation what this chapter contains the chapter describes the electrical installation procedure of the drive. Warning! The work described in this chapter may only be carried out by a qualified electrician. Follow the instructions in chapter safety on page 5 ...

Page 30

Electrical installation 30 connecting the power cables connection diagram input output u1 v1 w1 3 ~ motor u1 v1 w1 1) u2 v2 w2 brk- l1 l2 l3 pe drive pe for alternatives, see section supply disconnecting device on page 21 . Optional brake resistor 1) ground the other end of the pe conductor at the d...

Page 31

Electrical installation 31 procedure 1. On it (ungrounded) systems and corner grounded tn systems, disconnect the internal emc filter by removing the screw at emc. For 3-phase u-type drives (with type code acs150-03u-), the screw at emc is already removed at the factory and replaced by a plastic scr...

Page 32

Electrical installation 32 connecting the control cables i/o terminals the figure below shows the i/o connectors. The default connection of the control signals depends on the application macro in use, which is selected with parameter 9902 . See chapter application macros for the connection diagrams....

Page 33

Electrical installation 33 procedure 1. Analog signal (if connected): strip the outer insulation of the analog signal cable 360 degrees and ground the bare shield under the clamp. 2. Connect the conductors to the appropriate terminals. 3. Connect the grounding conductor of the used pair in the analo...

Page 34

Electrical installation 34.

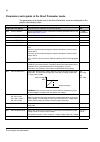

Page 35: Installation Checklist

Installation checklist 35 installation checklist checklist check the mechanical and electrical installation of the drive before start-up. Go through the checklist below together with another person. Read chapter safety on the first pages of this manual before you work on the drive. Check mechanical ...

Page 36

Installation checklist 36.

Page 37: What This Chapter Contains

Start-up and control with i/o 37 start-up and control with i/o what this chapter contains the chapter instructs how to: • do the start-up • start, stop, change the direction of rotation and adjust the speed of the motor through the i/o interface. Using the control panel to do these tasks is explaine...

Page 38

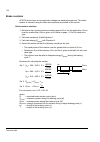

Start-up and control with i/o 38 3. Press . The display shows a parameter of the short parameter mode. 4. Find the appropriate parameter with keys / . 5. Press and hold for about two seconds until the parameter value is shown with under the value. 6. Change the value with keys / . The value changes ...

Page 39

Start-up and control with i/o 39 set constant speeds (drive output frequencies) 1, 2 and 3 (parameters 1202 , 1203 and 1204 ). Set the minimum value (%) corresponding to the minimum signal for ai(1) (parameter 1301 ). Set the maximum limit for the drive output frequency (parameter 2008 ). Select the...

Page 40

Start-up and control with i/o 40 acceleration/deceleration times set the acceleration time 1 (parameter 2202 ). Set the deceleration time 1 (parameter 2203 ). Final check the start-up is now completed. Check that there are no faults or alarms shown in the display. The drive is now ready for use. Loc...

Page 41

Start-up and control with i/o 41 how to control the drive through the i/o interface the table below instructs how to operate the drive through the digital and analog inputs when: • the motor start-up is performed, and • the default (standard) parameter settings are valid. Preliminary settings if you...

Page 42

Start-up and control with i/o 42.

Page 43: Control Panel

Control panel 43 control panel what this chapter contains the chapter describes the control panel keys and display fields. It also instructs in using the panel in control, monitoring and changing the settings. Integrated control panel the acs150 works with the integrated control panel, which provide...

Page 44

Control panel 44 overview the following table summarizes the key functions and displays on the integrated control panel. No. Use 1 lcd display – divided into five areas: a. Upper left – control location: loc: drive control is local, that is, from the control panel rem: drive control is remote, such ...

Page 45

Control panel 45 operation you operate the control panel with the help of menus and keys. You select an option (e.G. Operation mode or parameter) by scrolling the and arrow keys until the option is visible in the display and then pressing the key. With the key, you return to the previous operation l...

Page 46

Control panel 46 how to do common tasks the table below lists common tasks, the mode in which you can perform them and the page number where the steps to do the task are described in detail. Task mode page how to switch between local and remote control any 47 how to start and stop the drive any 47 h...

Page 47

Control panel 47 how to start, stop and switch between local and remote control you can start, stop and switch between local and remote control in any mode. To be able to start or stop the drive, the drive must be in local control. How to change the direction of the motor rotation you can change the...

Page 48

Control panel 48 how to set the frequency reference you can set the local frequency reference with the integrated potentiometer in any mode when the drive is in local control if parameter 1109 loc ref source has the default value 0 (pot). If parameter 1109 loc ref source has been changed to 1 (keypa...

Page 49

Control panel 49 output mode in the output mode, you can: • monitor actual values of up to three group 01 operating data signals, one signal at a time • start, stop, change direction, switch between local and remote control and set the frequency reference. You get to the output mode by pressing the ...

Page 50

Control panel 50 reference mode in the reference mode, you can: • view and set the frequency reference • start, stop, change direction and switch between local and remote control. How to view and set the frequency reference you can set the local frequency reference with the integrated potentiometer ...

Page 51

Control panel 51 parameter modes there are two parameter modes: short parameter mode and long parameter mode. Both function identically, except that the short parameter mode shows only the minimum number of parameters typically required to set up the drive (see section parameters and signals in the ...

Page 52

Control panel 52 how to select the monitored signals 6. Use keys and to select the parameter value. When you have changed the parameter value, starts flashing. • to save the displayed parameter value, press . • to cancel the new value and keep the original, press . Step action display 1. You can sel...

Page 53

Control panel 53 changed parameters mode in the changed parameters mode, you can: • view a list of all parameters that have been changed from the macro default values • change these parameters • start, stop, change direction, switch between local and remote control and set the frequency reference. H...

Page 54

Control panel 54.

Page 55: Application Macros

Application macros 55 application macros what this chapter contains the chapter describes the application macros. For each macro, there is a wiring diagram showing the default control connections (digital and analog i/o). Overview of macros application macros are preprogrammed parameter sets. While ...

Page 56

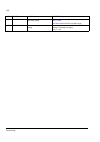

Application macros 56 summary of i/o connections of application macros the following table gives the summary of the default i/o connections of all application macros. 1) the frequency reference comes from the integrated potentiometer when hand is selected. Input/output macro abb standard 3-wire alte...

Page 57: Abb Standard Macro

Application macros 57 abb standard macro this is the default macro. It provides a general purpose i/o configuration with three constant speeds. Parameter values are the default values given in chapter actual signals and parameters , starting from page 63 . If you use other than the default connectio...

Page 58: 3-Wire Macro

Application macros 58 3-wire macro this macro is used when the drive is controlled using momentary push-buttons. It provides three constant speeds. To enable the macro, set the value of parameter 9902 to 2 (3-wire). For the parameter default values, see section default values with different macros o...

Page 59: Alternate Macro

Application macros 59 alternate macro this macro provides an i/o configuration adapted to a sequence of di control signals used when alternating the rotation direction of the drive. To enable the macro, set the value of parameter 9902 to 3 (alternate). For the parameter default values, see section d...

Page 60: Motor Potentiometer Macro

Application macros 60 motor potentiometer macro this macro provides a cost-effective interface for plcs that vary the speed of the drive using only digital signals. To enable the macro, set the value of parameter 9902 to 4 (motor pot). For the parameter default values, see section default values wit...

Page 61: Hand/auto Macro

Application macros 61 hand/auto macro this macro can be used when switching between two external control devices is needed. To enable the macro, set the value of parameter 9902 to 5 (hand/auto). For the parameter default values, see section default values with different macros on page 63 . If you us...

Page 62

Application macros 62.

Page 63: What This Chapter Contains

Actual signals and parameters 63 actual signals and parameters what this chapter contains the chapter describes the actual signals and parameters used in the short and the long parameter modes. See section parameter modes on page 51 for how to select the parameter mode. Terms and abbreviations defau...

Page 64

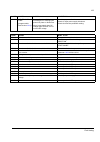

Actual signals and parameters 64 parameters and signals in the short parameter mode the parameters and signals used in the short parameter mode are displayed on the panel in the following order. No. Name/value description 99 start-up data application macro. Definition of motor set-up data. Def 9902 ...

Page 65

Actual signals and parameters 65 04 fault history fault history (read-only) 0401 last fault fault code of the latest fault. See chapter fault tracing for the codes. 0 = fault history is clear (on panel display = no record). - 11 reference select maximum reference 1105 ref1 max defines the maximum va...

Page 66

Actual signals and parameters 66 20 limits maximum frequency 2008 maximum freq defines the maximum limit for the drive output frequency. Eur: 50 / us: 60 0.0…500.0 hz maximum frequency 21 start/stop stop mode of the motor 2102 stop function selects the motor stop function. 1 = coast 1 = coast stop b...

Page 67

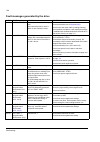

Actual signals and parameters 67 parameters and signals in the long parameter mode the following table includes the complete parameter and signal list, i.E. Parameters and signals used in the long parameter mode. No. Name/value description 01 operating data basic signals for monitoring the drive (re...

Page 68

Actual signals and parameters 68 0403 fault time 2 time at which the latest fault occurred. Format: time elapsed after power-on in 2 second ticks (minus the whole days stated by signal 0402 fault time 1). 30 ticks = 60 seconds. E.G. Value 514 equals 17 minutes and 8 seconds (= 514/30). 0404 speed at...

Page 69

Actual signals and parameters 69 index name/selection description 10 start/stop/dir the sources for external start, stop and direction control def 1001 ext1 commands defines the connections and the source for the start, stop and direction commands for external control location 1 (ext1). 2 = di1,2 0 ...

Page 70

Actual signals and parameters 70 1010 jogging sel defines the signal that activates the jogging function. The jogging function is typically used to control a cyclical movement of a machine section. One push button controls the drive through the whole cycle: when it is on, the drive starts, accelerat...

Page 71

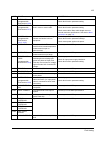

Actual signals and parameters 71 -1 = di1(inv) inverted digital input di1. 1 = jogging inactive, 0 = jogging active. -2 = di2(inv) see selection di1(inv). -3 = di3(inv) see selection di1(inv). -4 = di4(inv) see selection di1(inv). -5 = di5(inv) see selection di1(inv). 11 reference select panel refer...

Page 72

Actual signals and parameters 72 3 = ai1/joyst analog input ai1 as joystick. The minimum input signal runs the motor at the maximum reference in the reverse direction, the maximum input at the maximum reference in the forward direction. Minimum and maximum references are defined by parameters 1104 r...

Page 73

Actual signals and parameters 73 1104 ref1 min defines the minimum value for external reference ref1. Corresponds to the minimum setting of the used source signal. 0 0.0…500.0 hz minimum value. Example: analog input ai1 is selected as the reference source (value of parameter 1103 ref1 select is ai1)...

Page 74

Actual signals and parameters 74 12 constant speeds constant speed selection and values. It is possible to define seven positive constant speeds. Constant speeds are selected with digital inputs. Constant speed activation overrides the external speed reference. Constant speed selections are ignored ...

Page 75

Actual signals and parameters 75 -5 = di5(inv) speed defined by parameter 1206 const speed 5 is activated through inverted digital input di5. 0 = active, 1 = inactive. -7 = di1,2 (inv) constant speed selection through inverted digital inputs di1 and di2. 1 = di active, 0 = di inactive. -8 = di2,3 (i...

Page 76

Actual signals and parameters 76 13 analog inputs analog input signal processing 1301 minimum ai1 defines the minimum %-value that corresponds to minimum ma/(v) signal for analog input ai1. When used as a reference, the value corresponds to the reference minimum setting. 0...20 ma 0...100% 4...20 ma...

Page 77

Actual signals and parameters 77 8 = suprv 1 over status according to supervision parameters 3201 ... 3203 . 9 = suprv 1 under see selection suprv 1 over. 10 = suprv 2 over status according to supervision parameters 3204 ... 3206 . 11 = suprv 2 under see selection suprv 2 over. 12 = suprv 3 over sta...

Page 78

Actual signals and parameters 78 2 = di2 see selection di1. 3 = di3 see selection di1. 4 = di4 see selection di1. 5 = di5 see selection di1. -1 = di1(inv) external signal required through inverted digital input di1. 0 = run enable. If run enable signal is switched on, the drive will not start or coa...

Page 79

Actual signals and parameters 79 1606 local lock disables entering local control mode or selects the source for the local control mode lock signal. When local lock is active, entering the local control mode is disabled (loc/rem key of the panel). 0 = not sel 0 = not sel local control is allowed. 1 =...

Page 80

Actual signals and parameters 80 1803 filter freq in defines the filter time constant for frequency input, i.E the time within 63% of a step change is reached. 0.1 0.0…10.0 s filter time constant 20 limits drive operation limits 2003 max current defines the allowed maximum motor current. 1.8 · i 2n ...

Page 81

Actual signals and parameters 81 21 start/stop start and stop modes of the motor 2101 start function selects the motor starting method. 1 = auto 1 = auto frequency reference ramps immediately from 0 hz. 2 = dc magn the drive pre-magnetises the motor with dc current before the start. The pre-magnetis...

Page 82

Actual signals and parameters 82 2106 dc curr ref defines the dc braking current. See parameter 2104 dc hold ctl. 30 0…100% value in percent of the motor nominal current (parameter 9906 motor nom curr) 2107 dc brake time defines the dc braking time. 0 0.0…250.0 s time 2108 start inhibit enables the ...

Page 83

Actual signals and parameters 83 2112 zero speed delay defines the delay for the zero speed delay function. The function is useful in applications where a smooth and quick restarting is essential. During the delay the drive knows accurately the rotor position. Zero speed delay can be used e.G. With ...

Page 84

Actual signals and parameters 84 2202 acceler time 1 defines the acceleration time 1 i.E. The time required for the speed to change from zero to the speed defined by parameter 2008 maximum freq. - if the speed reference increases faster than the set acceleration rate, the motor speed will follow the...

Page 85

Actual signals and parameters 85 2205 acceler time 2 defines the acceleration time 2 i.E. The time required for the speed to change from zero to the speed defined by parameter 2008 maximum freq. See parameter 2202 acceler time 1. Acceleration time 2 is used also as jogging acceleration time. See par...

Page 86

Actual signals and parameters 86 25 critical speeds speed bands within which the drive is not allowed to operate. A critical speeds function is available for applications where it is necessary to avoid certain motor speeds or speed bands because of e.G. Mechanical resonance problems. The user can de...

Page 87

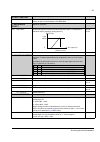

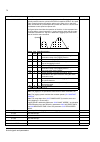

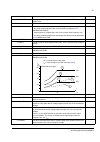

Actual signals and parameters 87 2603 ir comp volt defines the output voltage boost at zero speed (ir compensation). The function is useful in applications with high break-away torque. To prevent overheating, set ir compensation voltage as low as possible. The figure below illustrates the ir compens...

Page 88

Actual signals and parameters 88 2608 slip comp ratio defines the slip gain for the motor slip compensation control. 100% means full slip compensation, 0% means no slip compensation. Other values can be used if a static speed error is detected despite of the full slip compensation. Example: 35 hz co...

Page 89

Actual signals and parameters 89 3005 mot therm prot selects how the drive reacts when motor overtemperature is detected. The drive calculates the temperature of the motor on the basis of the following assumptions: 1) the motor is in the ambient temperature of 30°c when power is applied to the drive...

Page 90

Actual signals and parameters 90 3008 zero speed load defines the load curve together with parameters 3007 mot load curve and 3009 break point freq. 70 25.…150% allowed continuous motor load at zero speed in percent of the nominal motor current 3009 break point freq defines the load curve together w...

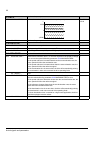

Page 91

Actual signals and parameters 91 3012 stall time defines the time for the stall function. See parameter 3010 stall function. 20 10…400 s time 3013 underload func selects how the drive reacts to underload. The protection wakes up if - the motor torque falls below the curve selected by parameter 3015 ...

Page 92

Actual signals and parameters 92 3017 earth fault selects how the drive reacts when an earth (ground) fault is detected in the motor or the motor cable. The protection is active only during start. An earth fault in the input power line does not activate the protection note: changing this parameter s...

Page 93

Actual signals and parameters 93 3105 ar overvoltage activates/deactivates the automatic reset for the intermediate link overvoltage fault. Automatically resets the fault (dc overvolt, code: f0002) after the delay set by parameter 3103 delay time. 0 = disable 0 = disable inactive 1 = enable active 3...

Page 94

Actual signals and parameters 94 32 supervision signal supervision. The drive monitors whether certain user selectable variables are within the user-defined limits. The user may set limits for speed, current etc. Supervision status can be monitored with relay output. See parameter group 14 relay out...

Page 95

Actual signals and parameters 95 3202 superv 1 lim lo defines the low limit for the first supervised signal selected by parameter 3201 superv 1 param. Supervision wakes up if the value is below the limit. - x…x setting range depends on parameter 3201 setting. - 3203 superv 1 lim hi defines the high ...

Page 96

Actual signals and parameters 96 3304 drive rating displays the drive current and voltage ratings. 0x0000 0x0000…0xffff (hex) value in format xxxy: xxx = nominal current of the drive in amperes. An “a” indicates decimal point. For example if xxx is 8a8, nominal current is 8.8 a. Y = nominal voltage ...

Page 97

Actual signals and parameters 97 3404 output1 dsp form defines the format for the displayed signal selected by parameter 3401 signal1 param. 9 = direct 0 = +/-0 signed/unsigned value. Unit is selected by parameter 3405 output 1 unit. Example pi (3.14159): 1 = +/-0.0 2 = +/-0.00 3 = +/-0.000 4 = +0 5...

Page 98

Actual signals and parameters 98 3408 signal2 param selects the second signal to be displayed on the control panel in display mode. See parameter 3401 signal1 param. 104 0, 102…162 parameter index in group 01 operating data . E.G. 102 = 0102 speed. If value is set to 0, no signal is selected. If par...

Page 99

Actual signals and parameters 99 3421 output3 max sets the maximum display value for the signal selected by parameter 3415 signal3 param. See parameter 3402 signal1 min. - x…x setting range depends on parameter 3415 setting. - 99 start-up data application macro. Definition of motor set-up data. 9902...

Page 100

Actual signals and parameters 100 9908 motor nom speed defines the nominal motor speed. Must be equal to the value on the motor rating plate. Type dependent 50…30000 rpm speed 9909 motor nom power defines the nominal motor power. Must equal the value on the motor rating plate. P n 0.2…3.0 · p n kw/h...

Page 101: Fault Tracing

Fault tracing 101 fault tracing what this chapter contains the chapter lists all alarm and fault messages including the possible cause and corrective actions. Safety warning! Only qualified electricians are allowed to maintain the drive. Read the safety instructions in chapter safety on the first pa...

Page 102

Fault tracing 102 alarm messages generated by the drive code alarm cause what to do a2001 overcurrent (programmable fault function 1610 ) output current limit controller is active. Check motor load. Check acceleration time ( 2202 and 2205 ). Check motor and motor cable (including phasing). Check amb...

Page 103

Fault tracing 103 a2026 input phase loss (programmable fault function 3016 ) intermediate circuit dc voltage is oscillating due to missing input power line phase or blown fuse. Alarm is generated when dc voltage ripple exceeds 14% of nominal dc voltage. Check input power line fuses. Check for input ...

Page 104

Fault tracing 104 fault messages generated by the drive code fault cause what to do f0001 overcurrent output current has exceeded trip level. Overcurrent trip limit for drive is 325% of drive nominal current. Check motor load. Check acceleration time ( 2202 and 2205 ). Check motor and motor cable (i...

Page 105

Fault tracing 105 f0015 ext fault 2 (programmable fault function 3004 ) external fault 2 check external devices for faults. Check fault function parameter setting. F0016 earth fault (programmable fault function 3017 ) drive has detected earth (ground) fault in motor or motor cable. Check motor. Chec...

Page 106

Fault tracing 106 f1000 par hzrpm incorrect speed/frequency limit parameter setting check parameter settings. Following must apply: 2007 2008 , 2007 / 9907 and 2008 / 9907 are within range. F1003 par ai scale incorrect analog input ai signal scaling check parameter group 13 analog inputs settings. F...

Page 107: Maintenance

Maintenance 107 maintenance what this chapter contains the chapter contains preventive maintenance instructions. Safety warning! Read the instructions in chapter safety on the first pages of this manual before performing any maintenance on the equipment. Ignoring the safety instructions can cause in...

Page 108: Capacitors

Maintenance 108 fan replacement (r1 and r2) only frame sizes r1 and r2 include a fan; frame size r0 has natural cooling. 1. Stop the drive and disconnect it from the ac power source. 2. Remove the hood if the drive has the nema 1 option. 3. Lever the fan holder off the drive frame with e.G. A screwd...

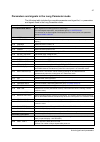

Page 109: Technical Data

Technical data 109 technical data what this chapter contains the chapter contains the technical specifications of the drive, e.G. The ratings, sizes and technical requirements as well as provisions for fulfilling the requirements for ce and other marks. Ratings current and power the current and powe...

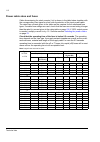

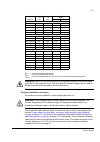

Page 110

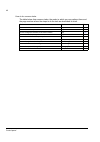

Technical data 110 symbols sizing the current ratings are the same regardless of the supply voltage within one voltage range. To achieve the rated motor power given in the table, the rated current of the drive must be higher than or equal to the rated motor current. Note 1:the maximum allowed motor ...

Page 111

Technical data 111 cooling air flow requirements the table below specifies the heat dissipation in the main circuit at nominal load and in the control circuit with minimum load (i/o not in use) and maximum load (all digital inputs in the on state and the fan in use). The total heat dissipation is th...

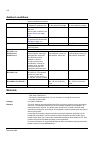

Page 112: Power Cable Sizes and Fuses

Technical data 112 power cable sizes and fuses cable dimensioning for rated currents (i 1n ) is shown in the table below together with the corresponding fuse types for short-circuit protection of the input power cable. The rated fuse currents given in the table are the maxima for the mentioned fuse ...

Page 113: Torques

Technical data 113 power cables: terminal sizes, maximum cable diameters and tightening torques input power, motor cable and brake resistor terminal sizes, accepted cable diameters and tightening torques are given below. Dimensions, weights and noise dimensions, weights and noise are given below in ...

Page 114: Input Power Connection

Technical data 114 input power connection voltage (u 1 ) 200/208/220/230/240 vac 1-phasefor 200 vac drives 200/208/220/230/240 vac 3-phasefor 200 vac drives 380/400/415/440/460/480 vac 3-phase for 400 vac drives ±10% variation from converter nominal voltage is allowed as default. Short-circuit capac...

Page 115: Control Connections

Technical data 115 control connections analog input x1a: 2 voltage signal, unipolar 0 (2)…10 v, r in > 312 kohm current signal, unipolar 0 (4)…20 ma, r in = 100 ohm resolution 0.1% accuracy ±1% auxiliary voltage x1a: 4 24 vdc ± 10%, max. 200 ma digital inputs x1a: 7…11 (frequency input x1a: 11) volt...

Page 116: Ambient Conditions

Technical data 116 ambient conditions environmental limits for the drive are given below. The drive is to be used in a heated indoor controlled environment. Operation installed for stationary use storage in the protective package transportation in the protective package installation site altitude 0 ...

Page 117: Ce Marking

Technical data 117 ce marking see the type designation label for the valid markings of your drive. A ce mark is attached to the drive to verify that the drive follows the provisions of the european low voltage and emc directives (directive 73/23/eec, as amended by 93/68/eec, and directive 89/336/ ee...

Page 118: Ul Marking

Technical data 118 ul marking see the type designation label for the valid markings of your drive. Ul checklist input power connection – see section input power connection on page 114 . Disconnecting device (disconnecting means) – see section supply disconnecting device on page 21 . Ambient conditio...

Page 119

Technical data 119 compliance with the iec/en 61800-3 (2004) the immunity performance of the drive complies with the demands of iec/en 61800-3, second environment (see page 118 for iec/en 61800-3 definitions). The emission limits of iec/en 61800-3 are complied with the provisions described below. Fi...

Page 120: Brake Resistors

Technical data 120 brake resistors acs150 drives have an internal brake chopper as standard equipment. The brake resistor is selected using the table and equations presented in this section. Brake resistor selection 1. Determine the required maximum braking power p rmax for the application. P rmax m...

Page 121

Technical data 121 r min = minimum allowed brake resistor r max = maximum allowed brake resistor p brmax = maximum braking capacity of the drive, must exceed the desired braking power. Warning! Never use a brake resistor with a resistance below the minimum value specified for the particular drive. T...

Page 122

Technical data 122 mandatory circuit protection the following setup is essential for safety – it interrupts the main supply in fault situations involving chopper shorts: • equip the drive with a main contactor. • wire the contactor so that it opens if the resistor thermal switch opens (an overheated...

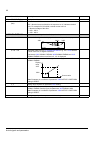

Page 123: Dimensions

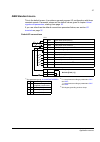

Dimensions 123 dimensions dimensional drawings of the acs150 are shown below. The dimensions are given in millimeters and [inches]..

Page 124

Dimensions 124 frame sizes r0 and r1, ip20 (cabinet installation) / ul open r1 and r0 are identical except for the fan at the top of r1. 3af e 6863790 2-a f rame siz e s r 0 and r1, i p 20 ( cabi net in st al lat ion) / ul open var emc.

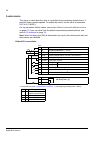

Page 125

Dimensions 125 frame sizes r0 and r1, ip20 / nema 1 r1 and r0 are identical except for the fan at the top of r1. 3a f e 68637929-a fr am e si zes r0 and r1, i p 20 / nem a 1 var emc.

Page 126

Dimensions 126 frame size r2, ip20 (cabinet installation) / ul open 3a f e 68613264-a fra m e si ze r2, ip20 ( cabi net i n st all a tio n ) / ul op en.

Page 127

Dimensions 127 frame size r2, ip20 / nema 1 3a f e 68633931-a f ra m e s iz e r 2 , ip 20 / n e m a 1.

Page 128

Dimensions 128.

Page 130

3a f e 68 576 032 rev a / e n ef f e ct ive : 7 .12. 200 5 abb oy ac drives p.O. Box 184 fi-00381 helsinki finland telephone +358 10 22 11 fax +358 10 22 22681 internet http://www.Abb.Com abb inc. Automation technologies drives & motors 16250 west glendale drive new berlin, wi 53151 usa telephone 26...