- DL manuals

- ABB

- Servo Drives

- ACS880-04 drive modules

- Hardware Manual

ABB ACS880-04 drive modules Hardware Manual

Summary of ACS880-04 drive modules

Page 1

Abb industrial drives hardware manual acs880-04 drive modules (200 to 710 kw, 300 to 700 hp).

Page 2

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. This qr code opens an online...

Page 3: Hardware Manual

Hardware manual acs880-04 drive modules (200 to 710 kw, 300 to 700 hp) 3aua0000128301 rev g en effective: 2017-02-17 2017 abb oy. All rights reserved. 1. Safety instructions 6. Installation instructions table of contents 10. Start-up.

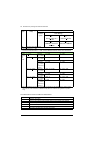

Page 5: Table Of Contents

5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1. Safety instructions contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 use...

Page 6

6 layout example, door closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 layout example, door open (standard drive module configuration) . . . . . . . . . . . . . 47 layout example, door open (option +h391) . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

7 additional us requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 armored cable / shielded power cable . . . . . . . . ...

Page 8

8 motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 brake resistor and resistor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 checking the compatibility with it (ungrounded) systems . . . ...

Page 9

9 installing i/o extension, fieldbus adapter and pulse encoder interface modules . . . 120 wiring the optional modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 7. Installation example of the standard drive module configuration contents of this chapter . ....

Page 10

10 11. Fault tracing contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151 leds with options +j410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151 warning and fault messages . . ....

Page 11

11 high speed mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 fuses (iec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181 ultrarapid (ar) fuses . . . . . . . . . . . . . ....

Page 12

12 r11 with options +0b051+e208+h356+0h371 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209 r11 with options +e208+h356+h381+j414+p905 . . . . . . . . . . . . . . . . . . . . . . . . . . . 210 r11 with options +0b051+c173+e208+h356+0h354+0h371 . . . . . . . . . . . . . . . . . . 211 f...

Page 13

13 protecting the resistor cable against short-circuits . . . . . . . . . . . . . . . . . . . . . . . . . . 236 mechanical installation of external brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236 electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 14

14.

Page 15: Safety Instructions

Safety instructions 15 1 safety instructions contents of this chapter this chapter contains the safety instructions which you must obey when you install and operate the drive and do maintenance on the drive. If you ignore the safety instructions, injury, death or damage can occur. Use of warnings an...

Page 16

16 safety instructions general safety in installation, start-up and maintenance these instructions are for all personnel that install the drive module and do maintenance work on it. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • use pro...

Page 17

Safety instructions 17 • to prevent the drive module from falling, attach its top lifting lugs with chains to the cabinet frame before you push the module into the cabinet and pull it from the cabinet. Work carefully preferably with help from another person as shown below. Keep a constant pressure w...

Page 18

18 safety instructions electrical safety in installation, start-up and maintenance precautions before electrical work these warnings are for all personnel that do work on the drive, motor cable or motor. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipmen...

Page 19

Safety instructions 19 additional instructions and notes warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • if you are not a qualified electrician, do not do installation or maintenance work. • do not install a drive with emc filter option ...

Page 20

20 safety instructions grounding these instructions are for all personnel who are responsible for the grounding of the drive. Warning! Obey these instructions. If you ignore them, injury or death, or equipment malfunction can occur, and electromagnetic interference can increase. • if you are not a q...

Page 21

Safety instructions 21 additional instructions for permanent magnet motor drives safety in installation, start-up and maintenance these are additional warnings concerning permanent magnet motor drives. The other safety instructions in this chapter are also valid. Warning! Obey these instructions. If...

Page 22

22 safety instructions.

Page 23: Introduction To The Manual

Introduction to the manual 23 2 introduction to the manual contents of this chapter this chapter describes the intended audience and contents of the manual. It contains a flowchart of steps in checking the delivery, installing and commissioning the drive. The flowchart refers to chapters/sections in...

Page 24

24 introduction to the manual contents of the manual this manual contains the instructions and information for the basic drive module configuration. The chapters of the manual are briefly described below. Safety instructions gives safety instructions for the installation, commissioning, operation an...

Page 25

Introduction to the manual 25 step-by-step drawings for a flat installation example in rittal ts 8 600 mm wide cabinet shows how to install the drive module in a rittal ts 8 cabinet. Step-by-step drawings for option +h391 installation example in rittal ts 8 600 mm wide cabinet shows how to install d...

Page 26

26 introduction to the manual standard drive modules • install the additional components into the cabinet: for example, main disconnector, main contactor, main ac fuses, etc.. • install the drive module into the cabinet. • connect the motor cables to the drive module terminals. • connect the brake r...

Page 27

Introduction to the manual 27 terms and abbreviations connect the external control cables to the drive control unit. Connecting the control cables to the terminals of the control unit (page 107 ) check the installation. Installation checklist (page 145 ) commission the drive. Start-up (page 149 ) co...

Page 28

28 introduction to the manual fena-21 optional high performance ethernet/ip™, modbus/tcp and profinet io adapter module, 2-port fepl-01 optional ethernet powerlink fieldbus adapter module fio-01 optional digital i/o extension module fio-11 optional analog i/o extension module flon-01 optional lonwor...

Page 29: Operation Principle And

Operation principle and hardware description 29 3 operation principle and hardware description contents of this chapter this chapter describes the operating principle and construction of the drive module..

Page 30

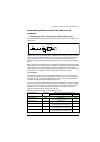

30 operation principle and hardware description product overview the acs880-04 is a drive module for controlling asynchronous ac induction motors, permanent magnet motors, ac induction servomotors and abb synchronous reluctance motors (synrm motors). The main circuit of the drive module is shown bel...

Page 31

Operation principle and hardware description 31 layout standard drive module configuration with option +e208 the assembled standard drive module configuration with option +e208 is shown below. 1 drive module 5 optional common mode filter (+e208) 2 upper front cover 6 pedestal 3 lower front cover 7 e...

Page 32

32 operation principle and hardware description 1 clear plastic shroud to be attached onto the drive module input power cabling (a). Lead- through shroud for side cabling (b). 11 fiber optic cables 2 clear plastic shrouds to be attached onto the drive module output power cabling 12 pe (ground) termi...

Page 33

Operation principle and hardware description 33 drive module for flat mounting (option +c173) front view of an assembled drive module for flat mounting is shown below. Option +c173 adds flat mounting brackets to the standard drive module configuration. Option +0h354 removes the pedestal and option +...

Page 34

34 operation principle and hardware description drive module with full power cabling panels (option +h381) accessories assembled drive module 1 input power cabling panel 7 rubber grommet 2 side guides 8 input power cabling panel to be attached to the drive cabinet 3 output power cabling panel 9 outp...

Page 35

Operation principle and hardware description 35 drive module without full-size output cable connection terminals (option +0h371) and ip20 shrouds (option +0b051) 1 lifting lugs 2 fastening bracket 3 input cable connection busbars (l1/u1, l2/v1, l3/w1) and dc+ and dc- busbars (udc+, ucd- with option ...

Page 36

36 operation principle and hardware description drive module configuration with power cable connection terminals on the right-hand side of the drive module (option +h391) 1 lifting lugs 2 fastening bracket 3 input cable connection busbars (l1/u1, l2/v1, l3/w1) and dc+ and dc- busbars (udc+, ucd- wit...

Page 37

Operation principle and hardware description 37 control unit see section standard drive module configuration with option +e208 on page 31 . Control panel in the standard drive module configuration, the control panel is located in the control panel holder of the external control unit. The control pan...

Page 38

38 operation principle and hardware description overview of power and control connections the diagram shows the power connections and control interfaces of the drive module. 1 2 3 analog and digital i/o extension modules, feedback interface modules and fieldbus communication modules can be inserted ...

Page 39

Operation principle and hardware description 39 external control connection terminals the layout of the external control connection terminals on the drive module control are shown below. Description xpow external power input xai analog inputs *) xao analog outputs *) xd2d drive to drive link xro1 re...

Page 40

40 operation principle and hardware description external control unit connection cables the cables that are delivered with the drive module for connecting the drive module and control panel to the external control unit are shown below. See sections connecting the external control unit to the drive m...

Page 41

Operation principle and hardware description 41 type designation key the type designation contains information on the specifications and configuration of the drive module. The first digits from left express the basic configuration. The optional selections are given thereafter, separated by plus sign...

Page 42

42 operation principle and hardware description h381 full power cabling panels to be attached to a cabinet. The drive module can be pulled from the cabinet for maintenance without disconnecting the power cables. Degree of protection ip20. (not to be used with options +0b051, +c173, 0h354 and 0h371.)...

Page 43

Operation principle and hardware description 43 l521 fse-31 pulse encoder interface module. Requires option +q972. L525 faio-01 analog i/o extension module l526 fdio-01 digital i/o extension module l536 fptc-01 thermistor protection module l537 fptc-02 atex-certified thermistor protection module. Re...

Page 44

44 operation principle and hardware description.

Page 45: Cabinet Installation

Guidelines for planning the cabinet installation 45 4 guidelines for planning the cabinet installation contents of this chapter this chapter guides in planning drive cabinets and installing the drive module into a user- defined cabinet. The chapter gives cabinet layout examples and free space requir...

Page 46

46 guidelines for planning the cabinet installation planning the layout of the cabinet plan a spacious layout to ensure easy installation and maintenance. Sufficient cooling air flow, obligatory clearances, cables and cable support structures all require space. Place the control board(s) away from: ...

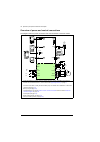

Page 47

Guidelines for planning the cabinet installation 47 layout example, door open (standard drive module configuration) 1 supporting frame of the cabinet 8 motor cable including the protective ground conductor of the drive module 2a 2b vertical (2a) and horizontal (2b) air baffles that separate the cool...

Page 48

48 guidelines for planning the cabinet installation layout example, door open (option +h391) 1 supporting frame of the cabinet 8 motor cable including the protective ground conductor of the drive module 2a 2b vertical (2a) and horizontal (2b) air baffles that separate the cool and hot areas (leak- p...

Page 49

Guidelines for planning the cabinet installation 49 layout example, door open (option +0b051) this diagram shows a layout example for drive modules with no ip20 shrouds (option +0b051) or no cabling panels (option +h381 not included). 1 supporting frame of the cabinet 8 motor cable including the pro...

Page 50

50 guidelines for planning the cabinet installation note 1 : the power cable shields can also be grounded to the drive module grounding terminals. Note 2: see also section required free space , page 60 . Arranging the grounding inside the cabinet arrange the grounding of the drive module by leaving ...

Page 51

Guidelines for planning the cabinet installation 51 planning the cabinet placement on a cable channel note the following when you plan to place the cabinet on a cable channel: • the cabinet structure must be sturdy enough. If the whole cabinet base is not supported from below, the cabinet weight wil...

Page 52

52 guidelines for planning the cabinet installation • we recommend 360° high frequency grounding of the motor cable shields at their entries. The grounding can be implemented by a knitted wire mesh screening as shown below. • we recommend 360° high frequency grounding of the control cable shields at...

Page 53

Guidelines for planning the cabinet installation 53 • make sure that the air inlets and outlets are large enough to allow sufficient air flow in and out of the cabinet. This is critical for proper cooling of the drive module. Minimum air inlets are four rittal air filters (sk 3243.200 for a 600 mm w...

Page 54

54 guidelines for planning the cabinet installation preventing the recirculation of hot air prevent hot air circulation outside the cabinet by leading the outcoming hot air away from the area where the inlet air to the cabinet is taken. Possible solutions are listed below: • gratings that guide air ...

Page 55

Guidelines for planning the cabinet installation 55 bookshelf mounting (standard drive module configuration) this diagram shows the air baffle position inside an example cabinet. For dimensions of the baffle, see page 215 . 1a air flow to the drive module, max. 40 °c (104 °f) 4 disconnector and fuse...

Page 56

56 guidelines for planning the cabinet installation bookshelf mounting (option +0b051) this diagram shows air baffle positions inside an example cabinet. For the descriptions, see the next page. 1a 7 l1/u1 l2/v1 l3/w1 pe t3/w2 t2/v2 t1/u2 3 3 c c c – c b b a a 2a 2c b - b a - a 2c 3 2a 2a 3 2d 2a 4 ...

Page 57

Guidelines for planning the cabinet installation 57 bookshelf mounting (option +h381) see chapter step-by-step drawings for installing full cabling panels (option +h381) in a rittal ts 8 400 mm wide cabinet on page 247 and dimension drawings on page 216 . 1a air flow to the drive module, max. 40 °c ...

Page 58

58 guidelines for planning the cabinet installation flat mounting (option +c173) this diagram shows air baffle positions inside an example cabinet. For dimensions of the baffle, see page 215 . 1a air flow to the drive module, max. 40 °c (104 °f) 5 contactor 1b air inlet to the drive circuit boards a...

Page 59

Guidelines for planning the cabinet installation 59 flat mounting (option +c173+0b051) this diagram shows air baffle positions inside an example cabinet. 1a air flow to the drive module, max. 40 °c (104 °f) 4 disconnector and fuses 1b air inlet to the drive circuit boards and dc and output busbars 5...

Page 60

60 guidelines for planning the cabinet installation required free space free space around the drive module is needed for ensuring that sufficient cooling air flows through the module and the module cools correctly. Free space at the top of the drive module the required free space at the top of the d...

Page 61

Guidelines for planning the cabinet installation 61 planning the placement of the control panel note the following alternatives when you plan the placement of the control panel: • when the control unit is inside the drive module (option +p905), the control panel can be integrated in the drive module...

Page 62

62 guidelines for planning the cabinet installation.

Page 63: Electrical Installation

Guidelines for planning the electrical installation 63 5 guidelines for planning the electrical installation contents of this chapter this chapter contains the instructions that you must obey when you select the motor, cables, protections, cable routing and way of operation for the drive system. Lim...

Page 64

64 guidelines for planning the electrical installation selecting the supply disconnecting device install a hand-operated input disconnecting device between the ac power source and the drive. The disconnecting device must be of a type that can be locked to the open position for installation and maint...

Page 65

Guidelines for planning the electrical installation 65 protecting the motor insulation and bearings the drive uses modern igbt inverter technology. Regardless of frequency, the drive output has pulses of approximately the drive dc bus voltage with a very short rise time. Up to twice bus voltage can ...

Page 66

66 guidelines for planning the electrical installation the abbreviations used in the table are defined below. Hdp consult the motor manufacturer. * manufactured before 1.1.1998 ** for motors manufactured before 1.1.1998, check for additional instructions with the motor manufacturer. Non-abb motors r...

Page 67

Guidelines for planning the electrical installation 67 additional requirements for explosion-safe (ex) motors if you use an explosion-safe (ex) motor, obey the rules in the requirements table above. In addition, consult the motor manufacturer for any further requirements. Additional requirements for...

Page 68

68 guidelines for planning the electrical installation additional data for calculating the rise time and the peak line-to-line voltage the diagrams below show the relative peak line-to-line voltage and rate of change of voltage as a function of the motor cable length with and without a d u /d t filt...

Page 69

Guidelines for planning the electrical installation 69 selecting the power cables general rules select the input power and motor cables according to local regulations: • select a cable capable of carrying the drive nominal current. See section ratings (page 175 ) for the rated currents. • select a c...

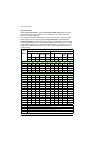

Page 70

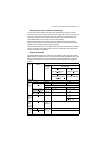

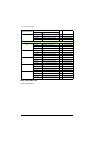

70 guidelines for planning the electrical installation typical power cable sizes the table below gives copper and aluminum cable types with concentric copper shield for the drives with nominal current. See also terminal and lead-through data for the power cables on page 184. 1) the cable sizing is b...

Page 71

Guidelines for planning the electrical installation 71 alternative power cable types the recommended and not allowed power cable types to be used with the drive are presented below. Recommended power cable types power cable types for restricted use not allowed power cable types symmetrical shielded ...

Page 72

72 guidelines for planning the electrical installation motor cable shield if the motor cable shield is used as the sole protective earth conductor of the motor, make sure that the conductivity of the shield is sufficient. See subsection general rules on page 69 , or iec 61800-5-1. To effectively sup...

Page 73

Guidelines for planning the electrical installation 73 planning the braking system see chapter resistor braking . Selecting the control cables shielding all control cables must be shielded. Use a double-shielded twisted pair cable for analog signals. We recommend this type of cable for the pulse enc...

Page 74

74 guidelines for planning the electrical installation a diagram of the cable routing is shown below. Separate control cable ducts lead 24 v and 230 v (120 v) control cables in separate ducts unless the 24 v cable is insulated for 230 v (120 v) or insulated with an insulation sleeving for 230 v (120...

Page 75

Guidelines for planning the electrical installation 75 implementing thermal overload and short-circuit protection protecting the drive and input power cable in short-circuits protect the drive with fuses (a) and the input cable with fuses (b) or a circuit breaker as shown below: size the fuses or th...

Page 76

76 guidelines for planning the electrical installation 1) maximum allowed rated conditional short-circuit current (iec 61800-5-1) of the electrical power network 2) contact your local abb representative warning! Due to the inherent operating principle and construction of circuit breakers, independen...

Page 77

Guidelines for planning the electrical installation 77 protecting the drive and the input power and motor cables against thermal overload the drive protects itself and the input and motor cables against thermal overload when the cables are dimensioned according to the nominal current of the drive. N...

Page 78

78 guidelines for planning the electrical installation implementing the emergency stop function for safety reasons, install the emergency stop devices at each operator control station and at other operating stations where emergency stop may be needed. You can implement the emergency stop function us...

Page 79

Guidelines for planning the electrical installation 79 implementing the power loss ride-through function implement the power loss ride-through function as follows: 1. Check that the power-loss ride-through function of the drive is enabled with parameter 30.31 undervoltage control in the acs880 prima...

Page 80

80 guidelines for planning the electrical installation using a contactor between the drive and the motor implementing the control of the output contactor depends on how you select the drive to operate. See also section implementing a bypass connection on page 80 . When you have selected to use dtc m...

Page 81

Guidelines for planning the electrical installation 81 example bypass connection an example bypass connection is shown below. Switching the motor power supply from drive to direct-on-line 1. Stop the drive and the motor with the drive control panel (drive in the local control mode) or the external s...

Page 82

82 guidelines for planning the electrical installation switching the motor power supply from direct-on-line to drive 1. Stop the motor with s42. 2. Switch the motor power supply from direct-on-line to the drive with s40. 3. Close the main contactor of the drive with switch s11 (-> turn to position s...

Page 83

Guidelines for planning the electrical installation 83 implementing a motor temperature sensor connection warning! Iec 60664 requires double or reinforced insulation between live parts and the surface of accessible parts of electrical equipment which are either non-conductive but not connected to th...

Page 84

84 guidelines for planning the electrical installation note : the inaccuracy of the drive analog inputs for pt100 sensors is 10 °c (18 °f). If a better accuracy is needed, use the faio-01 analog i/o extension module (option +l525). Example circuit diagram see page 219 . Fptc- xx reinforced insulatio...

Page 85: Installation Instructions

Installation instructions 85 6 installation instructions contents of this chapter this chapter contains the general installation instructions for the drive module. The chapter refers to the installation example chapters which contain instructions that depend on the selected drive configuration. Safe...

Page 86

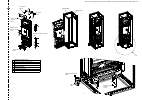

86 installation instructions moving and unpacking the unit warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. Move the transport package by pallet truck to the installation site. Unpack the package as foll...

Page 87

Installation instructions 87 package drawings transport package contents 1 with standard drive module configuration: clear plastic shrouds. With option +h381: input cabling panel parts. See below for the box contents. 2 with standard drive module configuration: output cable connection terminals. Wit...

Page 88

88 installation instructions 3axd10000407466 1 2 3 4 option +h391: top and bottom brackets and handle 1 top bracket 2 bottom bracket 3 handle 4 screw package 3axd50000009484 3 4 8 7 1 12 10 6 2 5 9 11 14 13 15 box b1 contents (standard drive module configuration) 1 paper fill 2 clear plastic shroud ...

Page 89

Installation instructions 89 2 6 9 2 8 2 2 2 5 7 8 3aua0000121817 4 1 6 9 10 3 box b1 contents with option +h381: input power cabling panel parts 1 screw package 2 paper fill 3 grounding busbar to be connected to the input power cabling panel and the drive module 4 cardboard tray 5 top cardboard cov...

Page 90

90 installation instructions 3axd50000010005 1 2 3 ramp box contents 1 screw package 2 telescopic extraction and insertion ramp 3 cardboard box 1 3aua0000100915 3 4 5 2 accessories box contents 1 screw package, includes also spacers for fso module installation 2 rubber grommets for control unit cabl...

Page 91

Installation instructions 91 checking the delivery check that all items listed in section moving and unpacking the unit are present. Check that there are no signs of damage. Before attempting installation and operation, check the information on the type designation label of the drive to verify that ...

Page 92

92 installation instructions checking the insulation of the assembly drive do not make any voltage tolerance or insulation resistance tests on any part of the drive as testing can damage the drive. Every drive has been tested for insulation between the main circuit and the chassis at the factory. Al...

Page 93

Installation instructions 93 brake resistor and resistor cable check the insulation of the brake resistor assembly (if present) as follows: 1. Stop the drive and do the steps in section precautions before electrical work on page 18 before you start the work. 2. Check that the resistor cable is conne...

Page 94

94 installation instructions standard drive module configuration (bookshelf mounting) for an installation example on how to install the drive module with clear plastic shrouds into a rittal ts 8 cabinet, see chapter installation example of the standard drive module configuration on page 121 . See al...

Page 95

Installation instructions 95 install the metallic shroud with ground bar as shown below. Drive module with full cabling panels (option +h381) for an installation example of the drive module with full cabling panels (option +h381) into a rittal cabinet including power cable connection procedure, see ...

Page 96

96 installation instructions drive module without pedestal (option +0h354) the drive module without pedestal can be mounted on a wall or a cabinet with four screws through the fastening holes at the top and bottom of the module. Make sure that the cabinet mounting plate and frame are strong enough t...

Page 97

Installation instructions 97 alternatives for grounding the drive module you can ground the drive module from its top back to the cabinet frame with these alternatives: 1. From the grounding hole 2. To a rittal punched section: with the fastening bracket. 1 2 tapping screw m6×12 torx t30 (hex) 9 n·m.

Page 98

98 installation instructions installing the bottom grille for ip20 degree of protection if ip20 degree of protection is needed from the bottom side, install the bottom grille as shown below. Installing the emc filter (option +e202) see arfi-10 emc filter installation guide (3afe 68317941 [english). ...

Page 99

Installation instructions 99 power cable connection diagram 1 for alternatives, see section selecting the supply disconnecting device on page 64. In the installing example of this chapter, the disconnecting device is not in the same cubicle with the drive module. 2 if a shielded cable is used (not r...

Page 100

100 installation instructions power cable connection procedure warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. Warning! Apply grease to stripped aluminum conductors before attaching them to non-coated a...

Page 101

Installation instructions 101 removing the control panel holder from the external control unit 1. Disconnect the control panel cable from connector x13 on the control unit. 2. Loosen the mounting screws of the control panel holder and take the holder off. 1 x13 x13 2 2 2 2.

Page 102

102 installation instructions fastening the control cable clamp plate fasten the control cable clamp plate either to the top or base of the control unit with four screws as shown below. Note : if you install the fso-xx safety functions module above the control unit, fasten the control cable clamp pl...

Page 103

Installation instructions 103 connecting the external control unit to the drive module warning! Handle the fiber optic cables with care. When unplugging optic cables, always grab the connector, not the cable itself. Do not touch the ends of the fibers with bare hands as the fiber is extremely sensit...

Page 104

104 installation instructions connections to the control unit connect the fiber optic, power supply and bgdr cables to the external control unit as follows: 1. Thread the cables inside the back frame of the control unit. 2. Connect the cables to the zbib board terminals. 3. Connect the bpow cable gr...

Page 105

Installation instructions 105 mounting the external control unit the drive control unit can be fastened on a mounting plate through the fastening holes in its back or by using a din rail. Mounting the external control unit to wall 1. Fasten the fastening screws in the wall. 2. Lift the unit onto the...

Page 106

106 installation instructions mounting the external control unit vertically on a din rail 1. Fasten the latch (a) to the back of the control unit with three screws. 2. Click the control unit to the rail as shown below (b). Mounting the control unit horizontally on a din rail 1. Fasten the latches (a...

Page 107

Installation instructions 107 connecting the control cables to the terminals of the control unit 1. Route the cables to the control unit as shown below. 2. Ground the shields of the control cables at the clamp plate. The shields should be continuous as close to the terminals of the control unit as p...

Page 108

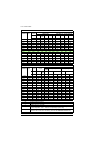

108 installation instructions default i/o connection diagram relay outputs xro1…xro3 ready 250 v ac / 30 v dc 2 a no 13 com 12 nc 11 running 250 v ac / 30 v dc 2 a no 23 com 22 nc 21 faulted(-1) 250 v ac / 30 v dc 2 a no 33 com 32 nc 31 external power input xpow 24 v dc, 2 a gnd 2 +24vi 1 reference ...

Page 109

Installation instructions 109 notes: 1) current [0(4)…20 ma, r in = 100 ohm] or voltage [0(2)…10 v, r in > 200 kohm] input selected by jumper j1. Change of setting requires reboot of control unit. 2) current [0(4)…20 ma, r in = 100 ohm] or voltage [0(2)…10 v, r in > 200 kohm] input selected by jumpe...

Page 110

110 installation instructions ai1 and ai2 as pt100, pt1000, ptc and kty84 sensor inputs (xai, xao) three pt100, pt1000 or ptc sensors or one kty84 sensor for motor temperature measurement can be connected between an analog input and output as shown below. Do not connect both ends of the cable shield...

Page 111

Installation instructions 111 di6 (xdi:6) as ptc sensor input a ptc sensor can be connected to this input for motor temperature measurement as follows. The sensor resistance must not exceed the threshold resistance of the digital input at the motor normal operating temperature. Do not connect both e...

Page 112

112 installation instructions the following diagram shows the wiring of the drive-to-drive link. Safe torque off (xsto) for the drive to start, both connections (out1 to in1 and in2) must be closed. By default, the terminal block has jumpers to close the circuit. Remove the jumpers before connecting...

Page 113

Installation instructions 113 connecting the control cables to the internal control unit (option +p905) 1. Ground the outer control cable shields 360 degrees at the cabinet lead-through plate (recommendation). 2. Remove the middle front cover of the drive module (view of standard drive module config...

Page 114

114 installation instructions connecting the control cables to the internal control unit (options +p905 and +0b051) 1. Remove the middle front cover of the drive module. 2. Fasten the clamp plate to the control unit with two screws from front, see fastening the control cable clamp plate on page 102 ...

Page 115

Installation instructions 115 connecting a control panel with external control unit and control panel holder mounted on the drive module (option +j414), put the control panel on the control panel holder. With door mounting kit (option +j410)), connect the control panel to the control unit as follows...

Page 116

116 installation instructions controlling several drives from one control panel through panel bus one control panel (or pc) can be used to control several drives by constructing a panel bus. 1. Connect the panel to one drive using an ethernet (eg. Cat5e) cable. • use menu – settings – edit texts – d...

Page 117

Installation instructions 117 connecting a pc you need a control panel to connect a pc to the drive module. Connect the control panel to the drive control unit as described in section connecting a control panel on page 115 . Warning! Do not connect the pc directly to the control panel connector of t...

Page 118

118 installation instructions case 1: fso safety functions module on slot 2 warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section precautions before electrical wo...

Page 119

Installation instructions 119 case 2: fso safety functions module above the control unit warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section precautions before ...

Page 120

120 installation instructions installing i/o extension, fieldbus adapter and pulse encoder interface modules see page 38 for the available slots for each module. Warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can...

Page 121: Installation Example Of The

Installation example of the standard drive module configuration 121 7 installation example of the standard drive module configuration contents of this chapter in this chapter, the drive module is installed in a 600 mm wide rittal ts 8 cabinet in a bookshelf way of mounting. The module is placed in a...

Page 122

122 installation example of the standard drive module configuration required parts required tools • set of screw drivers (torx and pozidriv) • set of metric magnetic-end hexagon sockets • torque wrench • step drill bit for drilling the holes in the clear plastic shroud for input power cables. Overal...

Page 123

Installation example of the standard drive module configuration 123 installing the drive module into a cabinet see a video of the installation at youtube: http://www.Youtube.Com/watch?V=ihkosx3hmzq see appendix step-by-step drawings for an installation example of standard drive configuration with op...

Page 124

124 installation example of the standard drive module configuration 7 connect the phase t2/v2 conductors to the t2/v2 connection terminal. 8 install the t1/u2 connection terminal to the insulators. See the warning in step 4. 9 connect the phase t1/u2 conductors to the t1/u2 terminal. 10 remove the p...

Page 125

Installation example of the standard drive module configuration 125 installing the roof and door (rittal parts) this drawing shows a layout tested by abb. 1 door 2 install these gratings as close to each other as possible. Remove the filter mats. Rittal 7967.000 3aua0000145776 2 1 592 [23.31] 1978 [...

Page 126

126 installation example of the standard drive module configuration installing the roof and door (abb air filters and roof) this drawing shows a layout tested by abb. 3axd50000016652 abb 3aua0000125202 (ip20) abb 3aua0000114971 (ip42) abb 3aua0000117003 (ip20) abb 3aua0000117008 (ip42).

Page 127

Installation example of the standard drive module configuration 127 removing the protective covering from the drive module air outlet warning! Remove the protective covering from the top of the drive module after the installation. If the covering is not removed, the cooling air cannot flow freely th...

Page 128

128 installation example of the standard drive module configuration.

Page 129

Installation example with full cabling panels (option +h381) 129 8 installation example with full cabling panels (option +h381) contents of this chapter in this chapter, the drive module is installed in a 400 mm wide rittal ts 8 cabinet in a bookshelf way. The module is placed in an upright position...

Page 130

130 installation example with full cabling panels (option +h381) required parts the parts are used in this installation example: required tools • set of screw drivers (torx and pozidriv) • set of metric magnetic-end hexagon sockets • torque wrench with a 500 mm (20 in.) or 2 × 250 mm (2 × 10 in.) lo...

Page 131

Installation example with full cabling panels (option +h381) 131 overall flowchart of the installation process installing the mechanical accessories into the cabinet install the mechanical accessories into the cabinet as shown in appendix step-by-step drawings for installing full cabling panels (opt...

Page 132

132 installation example with full cabling panels (option +h381) connecting the power cables connection diagram 1 for alternatives, see section selecting the supply disconnecting device on page 64. In the installing example of this chapter, the disconnecting device is not in the same cubicle with th...

Page 133

Installation example with full cabling panels (option +h381) 133 power cable connection procedure warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Run the motor cables from the motor to the cabinet. G...

Page 134

134 installation example with full cabling panels (option +h381) an example installation is shown below. Warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. View without cabinet side plate in place. A) 360-...

Page 135

Installation example with full cabling panels (option +h381) 135 installing the drive module into the cabinet warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. Handle the drive module carefully. Make sure...

Page 136

136 installation example with full cabling panels (option +h381) 4. Attach the drive module lifting lugs to the cabinet frame with chains. 5. Push the drive module carefully into to the cabinet preferably with the help from another person. 6. Attach the grounding busbar that has been previously atta...

Page 137

Installation example with full cabling panels (option +h381) 137 2 7a 7b 5 3 3 7a 7b 8a 8b 8b 4.

Page 138

138 installation example with full cabling panels (option +h381) assembly drawing of installing the drive module to the cabinet (frame r10) 3a u a 000 01320 78.

Page 139

Installation example with full cabling panels (option +h381) 139 assembly drawing of installing the drive module to the cabinet (frame r11) 3a u a 0000 13206 2.

Page 140

140 installation example with full cabling panels (option +h381) assembly drawing of installing the roof and door this drawing shows a layout tested by abb. If you use abb air filters, place them vertically in the positions shown in the drawing on page 126 . 1 door 2 install these gratings as close ...

Page 141

Installation example with full cabling panels (option +h381) 141 removing the protective covering from the drive module air outlet warning! Remove the protective covering from the top of the drive module after the installation. If the covering is not removed, the cooling air cannot flow freely throu...

Page 142

142 installation example with full cabling panels (option +h381) installing the rubber grommet to get ip20 degree of protection for the drive module, install the input power cables through the rubber grommet. Install the grommet as follows: 1. Cut adequate holes into the grommet for the input power ...

Page 143

Installation example with full cabling panels (option +h381) 143 modular design of rittal ts8 cabinets the design of the drive module with optional cabling panels (+h381) is optimized to the rittal ts 8406.510 cabinet. To make space for the additional components, connect two or more ts8 cabinets tog...

Page 144

144 installation example with full cabling panels (option +h381).

Page 145: Installation Checklist

Installation checklist 145 9 installation checklist contents of this chapter this chapter contains a list for checking the mechanical and electrical installation of the drive module. Installation checklist go through the checklist below together with another person. Warning! Obey the safety instruct...

Page 146

146 installation checklist drive option modules and other components type and number of option modules and other equipment is correct. Option modules and other equipment are not damaged. Optional modules and terminals are labelled correctly. The placement of optional modules and other equipment insi...

Page 147

Installation checklist 147 installation of the cabinet the drive cabinet has been attached to floor and also from top to the wall or roof. The ambient operating conditions agree with the specifications given in chapter technical data . The cooling air will flow freely in and out of the dri...

Page 148

148 installation checklist.

Page 149: Start-Up

Start-up 149 10 start-up contents of this chapter this chapter describes the start-up procedure of the drive. Start-up procedure 1. Only qualified electricians are allowed to start-up the drive. 2. Make sure that the installation of the drive module has been checked according to the checklist in cha...

Page 150

150 start-up • for drives with resistor braking (option +d151), see also section start-up on page 236 . • for option +n7502, see also acs880 drives with synrm motors (option +n7502) supplement (3aua0000145506 [english]). • for drives with abb du/dt filter, check that bit 13 of parameter 95.20 hw opt...

Page 151: Fault Tracing

Fault tracing 151 11 fault tracing contents of this chapter this chapter describes the fault tracing possibilities of the drive. Leds with options +j410 warning and fault messages see the firmware manual for the descriptions, causes and remedies of the control program warning and fault messages. Whe...

Page 152

152 fault tracing.

Page 153: Maintenance

Maintenance 153 12 maintenance contents of this chapter this chapter contains maintenance instructions of the drive modules. Maintenance intervals the tables below show the maintenance tasks which can be done by the end user. The complete maintenance schedule is available on the internet ( www.Abb.C...

Page 154

154 maintenance descriptions of symbols recommended annual maintenance actions by the user abb recommends these annual inspections to ensure the highest reliability and optimum performance. Recommended maintenance intervals after start-up cabinet cleaning the interior of the cabinet warning! Obey th...

Page 155

Maintenance 155 heatsink the module heatsink fins pick up dust from the cooling air. The drive runs into overtemperature warnings and faults if the heatsink is not clean. Cleaning the interior of the heatsink warning! Obey the safety instructions in chapter safety instructions . If you ignore them, ...

Page 156

156 maintenance fans the actual lifespan depends on the running time of the fan, ambient temperature and dust concentration. See the firmware manual for the actual signal which indicates the running time of the cooling fan. For resetting the running time signal after a fan replacement, please contac...

Page 157

Maintenance 157 replacing the main cooling fans warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section precautions before electrical work on page 18 before you sta...

Page 158

158 maintenance replacing the standard drive module note : the replacement module must be of the same type as the original module: same type code and same option codes. Warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipm...

Page 159

Maintenance 159 6 5.

Page 160

160 maintenance replacing the drive module with option +h381 note : the replacement module must be of the same type as the original module: same type code and same option codes. Warning! Obey the safety instructions in chapter safety instructions . If you ignore them, injury or death, or damage to t...

Page 161

Maintenance 161 8. Disconnect the power supply cable and the fiber optic cables from the external control unit and coil them on the top of the drive module. For drive modules with an internal control unit (option +p905): detach the control unit from the drive module by undoing the fastening screws b...

Page 162

162 maintenance capacitors the drive intermediate circuit employs several electrolytic capacitors. Their lifespan depends on the operating time of the drive, loading and ambient temperature. The lifespan of the capacitor can be prolonged by lowering the ambient temperature. It is not possible to pre...

Page 163

Maintenance 163 replacing the control unit battery stop the drive and do the steps in section precautions before electrical work on page 18 before you start the work. To replace the control unit battery: 1. Stop the drive and do the steps in section precautions before electrical work on page 18 befo...

Page 164

164 maintenance replacing the memory unit when a drive module is replaced, the parameter settings can be retained by transferring the memory unit from the defective drive module to the new module. The memory unit is located in the control unit, see page 38 . Warning! Do not remove or insert the memo...

Page 165: Ordering Information

Ordering information 165 13 ordering information contents of this chapter this chapter gives ordering information on additional components available from abb for the drive module installation. Notes: • this chapter only lists the installation accessories available from abb. All other parts must be s...

Page 166

166 ordering information the control panel can be mounted on the cabinet door with the help of a door mounting kit. Brake resistors see section safur resistors on page 238 . Output (du/dt) filters see section du/dt filters on page 239 . Sine filters see section sine filters on page 240 . Type descri...

Page 167

Ordering information 167 cabinet ventilation air inlet kits mounting screws are included. Enclosure width / degree of protection kit code ordering code illustration 400 mm / ip20 a-4-x-021 3aua0000117002 instruction code: 3aua0000116879 400 mm / ip42 a-4-x-024 3aua0000117007 instruction code: 3aua00...

Page 168

168 ordering information 600 mm / ip20 a-6-x-022 3aua0000117003 instruction code: 3aua0000116880 600 mm / ip42 a-6-x-025 3aua0000117008 instruction code: 3aua0000116874 600 mm / ip54 a-6-x-028 3axd50000009185 instruction code: 3axd50000009990 800 mm / ip20 a-8-x-023 3aua0000117005 instruction code: ...

Page 169

Ordering information 169 air outlet kits note: the fan is to be ordered separately. 800 mm / ip42 a-8-x-026 3aua0000117009 instruction code: 3aua0000116875 800 mm / ip54 a-8-x-029 3axd50000009186 instruction code: 3axd50000010001 enclosure width / degree of protection qty kit code ordering code illu...

Page 170

170 ordering information 400 mm / ip42 1 a-4-x-060 3aua0000114968 instruction code: 3aua0000115290 note: fan to be ordered separately 800 mm / ip42 2 600 mm / ip42 1 a-6-x-061 3aua00001149789 instruction code: 3aua0000115152 note: fan to be ordered separately 400 mm / ip54 (iec) 1 a-4-x-064 3axd5000...

Page 171

Ordering information 171 cooling fans one or two cooling fans are to be installed inside the air outlet compartment to ensure sufficient cooling of the cabinet. 600 mm / ip54 (iec) 1 a-6-x-065 3axd50000009189 instruction code: 3axd50000010004 note: fan to be ordered separately 600 mm / ip54 (ul) 1 a...

Page 172

172 ordering information emc filter arfi-10 order code: 68241561 800 mm / ip54 fan rb4c-355/170 2 3axd50000006934 capacitor msb mkp 6/603/e1679 2 3axd50000006959 connector spb2,5/7 (2.5 mm2, 12awg) 2 3axd50000000723 connector sc 2,5-rz/7 (2.5 mm2, 12awg) 2 3axd50000000724 ul 400 mm, 600 mm / ip20, i...

Page 173

Ordering information 173 fso accessories kit retrofit accessory kits * the drive module is delivered with full size cable connection terminals for output power cables as standard. They can be excluded with option +0h371. ** the drive module is delivered with ip20 shrouds for covering the input and m...

Page 174

174 ordering information.

Page 175: Technical Data

Technical data 175 14 technical data contents of this chapter this chapter contains the technical specifications of the drive, for example, the ratings, sizes and technical requirements, provisions for fulfilling the requirements for ce and other markings. Marine type-approved drives (option +c132) ...

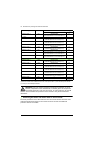

Page 176

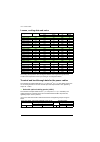

176 technical data 460a-5 r10 460 560 671 460 315 398 450 315 330 200 503a-5 r10 503 560 671 503 355 436 483 315 361 250 583a-5 r10 583 730 828 583 400 505 573 400 414 250 635a-5 r10 635 730 954 635 450 550 623 450 477 315 715a-5 r11 715 850 1100 715 500 619 705 500 566 400 820a-5 r11 820 1020 1100 ...

Page 177

Technical data 177 when is derating needed derate the continuous output current of the drive if • ambient temperature exceeds +40 °c (+104 °f) or • drive is installed higher than 1000 m (3280 ft) above sea level • switching frequency is other than default. Note: the final derating factor is a multip...

Page 178

178 technical data altitude derating at altitudes from 1000 to 4000 m (3300 to 13123 ft) above sea level, the derating is 1% for every 100 m (328 ft). If ambient temperature is below +40 °c (+104 .°f), the derating can be reduced by 1.5% for every 1 °c reduction in temperature. For a more accurate d...

Page 179

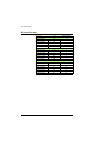

Technical data 179 with other than recommended sine filters (see section sine filters on page 240 ) and ex motors of other manufacturers, contact abb. Drive module type acs880-04- output ratings for special settings ex motor (abb ex motor) abb sine filter low noise mode nominal use light- duty use h...

Page 180

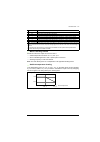

180 technical data high speed mode selection high speed mode of parameter 95.15 special hw settings improves control performance at high output frequencies. We recommend it to be selected with output frequency of 120 hz and above. This table gives the drive module ratings for 120 hz output frequency...

Page 181

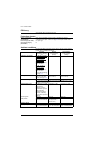

Technical data 181 fuses (iec) ar fuses for protection against short-circuit in the input power cable or drive are listed below. Note 1: see also implementing thermal overload and short-circuit protection on page 75 . Note 2: in multicable installations, install only one fuse per phase (not one fuse...

Page 182

182 technical data fuses (ul) ul fuses for branch circuit protection per nec are listed below. Check that the operating time of the fuse is below 0.1 seconds. The operating time depends on the fuse type, supply network impedance and the cross-sectional area, material and length of the supply cable. ...

Page 183

Technical data 183 dimensions, weights and free space requirements * approximate (depends on the selected options) the weight of the cabling panels of option +h381 is 30 kg (66 lb) additional depth with option +c173 when the mounting brackets are used: 18.5 mm (0.73 in.) for requirements of free spa...

Page 184

184 technical data losses, cooling data and noise the cooling air temperature rises 30 degrees celsius when it goes through the drive module if the temperature of the input cooling air is 40 degrees celsius. Terminal and lead-through data for the power cables the maximum accepted cable size is 4 × (...

Page 185

Technical data 185 units without full-size output cable connection terminals (+0h371) and with a common mode filter (+e208) it is possible to use the maximum cable size (4 × [3 × 240] mm2 or 4 ×[(3 × 500 awg]) only with special cable lugs and additional insulation. For more information, contact your...

Page 186

186 technical data dc connection data drive type i dc (a) capacitance (mf) u n = 400 v acs880-04-505a-3 640 14 acs880-04-585a-3 714 14 acs880-04-650a-3 870 14 acs880-04-725a-3 909 21 acs880-04-820a-3 1033 21 acs880-04-880a-3 1120 21 u n = 500 v acs880-04-460a-5 487 14 acs880-04-503a-5 640 14 acs880-...

Page 187

Technical data 187 control unit connection data (zcu-14) power supply (xpow) 24 v (±10%) dc, 2 a external power supply in. With some drive module sizes, not used as the control unit is supplied from the drive module. Connector pitch 5 mm, wire size 2.5 mm 2 relay outputs ro1…ro3 (xro1…xro3) connecto...

Page 188

188 technical data drive-to-drive link (xd2d) connector pitch 5 mm, wire size 2.5 mm 2 physical layer: rs-485 termination by jumper safe torque off connection (xsto) connector pitch 5 mm (0.2 in), wire size 2.5 mm2 (14 awg) input voltage range: -3…30 v dc logic levels: “0” 19 v for the drive to star...

Page 189

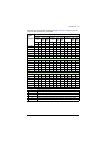

Technical data 189 ground isolation diagram) control panel type acs-ap-w assistant control panel xpow +24vi 1 gnd 2 xai +vref 1 -vref 2 agnd 3 ai1+ 4 ai1- 5 ai2+ 6 ai2- 7 xao ao1 1 agnd 2 ao2 3 agnd 4 xd2d b 1 a 2 bgnd 3 xro1, xro2, xro3 nc 1 com 2 no 3 nc 1 com 2 no 3 nc 1 com 2 no 3 xd24 diil 1 +2...

Page 190

190 technical data efficiency approximately 98% at nominal power level protection classes degree of protection (iec/en 60529) ip20, requires installation of bottom grille for standard drive module configuration and option +h0354, see page 98 . With option +0b051: ip00. Enclosure type (ul 508c) ul op...

Page 191

Technical data 191 vibration iec 60068-2-6:2007, en 60068-2-6:2008 environmental testing part 2: tests –test fc: vibration (sinusoidal) max. 0.1 mm (0.004 in.) (10 to 57 hz), max. 10 m/s 2 (33 ft/s 2 ) (57 to 150 hz) sinusoidal max. 1 mm (0.04 in.) (5 to 13.2 hz), max. 7 m/s 2 (23 ft/s 2 ) (13.2 to ...

Page 192

192 technical data ce marking a ce mark is attached to the drive to verify that the unit follows the provisions of the european low voltage, emc and rohs directives. The ce marking also verifies that the drive, in regard to its safety functions (such as safe torque off), conforms with the machinery ...

Page 193

Technical data 193 declaration of conformity.

Page 194

194 technical data.

Page 195

Technical data 195 compliance with en 61800-3:2004 definitions emc stands for e lectro m agnetic c ompatibility. It is the ability of electrical/electronic equipment to operate without problems within an electromagnetic environment. Likewise, the equipment must not disturb or interfere with any othe...

Page 196

196 technical data category c4 if the provisions under category c3 cannot be met, the requirements of the standard can be met as follows: 1. It is ensured that no excessive emission is propagated to neighboring low-voltage networks. In some cases, the inherent suppression in transformers and cables ...

Page 197

Technical data 197 • the cables located within the motor circuit must be rated for at least 75 °c (167 °f) in ul-compliant installations. • integral solid state short circuit protection does not provide branch circuit protection. The input cable must be protected with fuses. Suitable iec fuses are l...

Page 198

198 technical data disclaimers generic disclaimer the manufacturer shall have no obligation with respect to any product which (i) has been improperly repaired or altered; (ii) has been subjected to misuse, negligence or accident; (iii) has been used in a manner contrary to the manufacturer's instruc...

Page 199: Dimension Drawings

Dimension drawings 199 15 dimension drawings contents of this chapter this chapter contains dimension drawings of the drive modules with optional parts for rittal ts 8 cabinet assembly..

Page 200

200 dimension drawings r10 – standard configuration 3ax d5000002 5145.

Page 201

Dimension drawings 201 r10 with options +e208+h370+j414+p905 3a u a 00001399 00

Page 202

202 dimension drawings r10 with options +0b051+c173+e208+h356+0h354+0h371 3a u a 00 00139900

Page 203

Dimension drawings 203 r10 with options +0b051+e208+h356+0h371 3a u a 00001 39900

Page 204

204 dimension drawings r10 with options +e208+h356+h381+j414+p905 3a u a 00001399 00

Page 205

Dimension drawings 205 r10 – cabling panels (+h381) installed into a rittal ts 8 cabinet 3a u a 00001320 78.

Page 206

206 dimension drawings frame r10 with options +e208+h370+h391+0j400 3a u a 00 00139900

Page 207

Dimension drawings 207 r11 – standard configuration 3ax d5000002 5145.

Page 208

208 dimension drawings r11 with options +e208+h370+j414+p905 3a u a 00001392 02.

Page 209

Dimension drawings 209 r11 with options +0b051+e208+h356+0h371 3a u a 00 00139202.

Page 210

210 dimension drawings r11 with options +e208+h356+h381+j414+p905 3a u a 00001 39202.

Page 211

Dimension drawings 211 r11 with options +0b051+c173+e208+h356+0h354+0h371 3a u a 00 00139202.

Page 212

212 dimension drawings frame r11 – cabling panels (+h381) installed into a rittal ts 8 cabinet 3a u a 000013 2062.

Page 213

Dimension drawings 213 bottom plate for option +h381 in rittal ts 8 400 mm wide cabinet installation note: the bottom plate is not an abb part. 3aua0000082240 cable lead-through area put nut pem-s-m8-2 or equal (2 pcs).

Page 214

214 dimension drawings frame r11 with options +e208+h370+h391+0j400 3a u a 00 00139202.

Page 215

Dimension drawings 215 air baffles for the standard drive module and option +c173 this drawing shows the dimensions of the hole in the air baffle around the standard drive module and flat mounting option +c173. The drawing also shows the correct vertical location area of the air baffle as measured f...

Page 216

216 dimension drawings air baffles for option +h381 in rittal ts 8 400 mm wide cabinet installation note : these air baffles are not abb parts. 3a u a 00001 38986.

Page 217

Dimension drawings 217 external control unit 3axd50000011687.

Page 218

218 dimension drawings.

Page 219: Example Circuit Diagram

Example circuit diagram 219 16 example circuit diagram contents of this chapter this chapter shows an example circuit diagram for a cabinet-installed drive module..

Page 220

220 example circuit diagram example circuit diagram this diagram is an example for the main wiring of a drive cabinet. Note that the diagram includes components which are not included in a basic delivery (* plus code options, ** other options, *** to be acquired by the customer). **m otor t e m pera...

Page 221: Safe Torque Off Function

Safe torque off function 221 17 safe torque off function contents of this chapter this chapter describes the safe torque off (sto) function of the drive and gives instructions for its use. Description the safe torque off function can be used, for example, to construct safety or supervision circuits ...

Page 222

222 safe torque off function the function also corresponds to prevention of unexpected start-up as specified by en 1037:1995 + a1:2008 and uncontrolled stop (stop category 0) as specified in en 60204-1:2006 + ac:2010. Compliance with the european machinery directive see section compliance with the...

Page 223

Safe torque off function 223 maximum cable lengths: • 300 m (984 ft) between activation switch [k] and drive control unit • 60 m (200 ft) between multiple drives • 60 m (200 ft) between external power supply and first drive. Note that the voltage at the inx terminals of each control unit must be at ...

Page 224

224 safe torque off function single-channel connection +24 v out1 sgnd in2 k in1 inverter unit control unit notes : • both sto inputs (in1, in2) must be connected to the activation switch. Otherwise, no sil/pl classification is given. • pay special attention to avoiding any potential failure modes f...

Page 225

Safe torque off function 225 multiple drives (internal power supply) +24 v out1 sgnd in1 in2 acs880-04 out1 sgnd in1 in2 out1 sgnd in1 in2 acs880-04 acs880-04 k xsto control unit xsto control unit xsto control unit.

Page 226

226 safe torque off function multiple drives (external power supply) out1 sgnd in1 in2 out1 sgnd in1 in2 out1 sgnd in1 in2 acs880-04 +24 v acs880-04 control unit acs880-04 24 v dc – + k xsto control unit xsto control unit xsto.

Page 227

Safe torque off function 227 operation principle 1. The safe torque off activates (the activation switch is opened, or safety relay contacts open). 2. Sto inputs on the drive control unit de-energize. 3. The control unit cuts off the control voltage from the drive igbts. 4. The control program gener...

Page 228

228 safe torque off function close the disconnector and switch the power on. Test the operation of the sto function when the motor is stopped. • give a stop command for the drive (if running) and wait until the motor shaft is at a standstill. Ensure that the drive operates as follows: • open the sto...

Page 229

Safe torque off function 229 use 1. Open the activation switch, or activate the safety functionality that is wired to the sto connection. 2. Sto inputs on the drive control unit de-energize, and the drive control unit cuts off the control voltage from the drive igbts. 3. The control program generate...

Page 230

230 safe torque off function notes : • if a running drive is stopped by using the safe torque off function, the drive will cut off the motor supply voltage and the motor will coast to a stop. If this causes danger or is not otherwise acceptable, stop the drive and machinery using the appropriate sto...

Page 231

Safe torque off function 231 sto in a non-redundant manner, for example activating only one channel, will trigger the same reaction. See the drive firmware manual for the indications generated by the drive, and for details on directing fault and warning indications to an output on the control unit f...

Page 232

232 safe torque off function hft iec 61508 hardware fault tolerance mttf d en iso 13849-1 mean time to dangerous failure: (the total number of life units) / (the number of dangerous, undetected failures) during a particular measurement interval under stated conditions pfd avg iec 61508 average proba...

Page 233: Resistor Braking

Resistor braking 233 18 resistor braking contents of this chapter this chapter describes how to select, protect and wire brake choppers and resistors. The chapter also contains the technical data. Operation principle and hardware description the dive can be equipped with optional built-in brake chop...

Page 234

234 resistor braking which two standard resistors are connected in parallel, two in series. The e r value of the four-resistor assembly is four times the value specified for the standard resistor. Selecting a custom resistor if you use a resistor other than the default resistor, make sure that: 1. T...

Page 235

Resistor braking 235 minimizing electromagnetic interference obey these rules in order to minimize electromagnetic interference caused by the rapid current changes in the resistor cables: • shield the braking power line completely, either by using shielded cable or a metallic enclosure. Unshielded s...

Page 236

236 resistor braking a thermal switch (standard in abb resistors) is required for safety reasons. The thermal switch cable must be shielded and may not be longer than the resistor cable. Wire the switch to a digital input on the drive control unit as shown in the figure below. Protecting the resisto...

Page 237

Resistor braking 237 warning! If the drive is equipped with a brake chopper but the chopper is not enabled by the parameter setting, the internal thermal protection of the drive against resistor overheating is not in use. In this case, the brake resistor must be disconnected. Note : some brake resis...

Page 238

238 resistor braking p rcont continuous power (heat) dissipation of the resistor when placed correctly the ratings apply at an ambient temperature of 40 °c (104 °f). Safur resistors the degree of protection of safur resistors is ip00. The resistors are not ul listed. The thermal time constant of the...

Page 239: And Sine Filters

Du/dt and sine filters 239 19 d u /d t and sine filters contents of this chapter this chapter describes how to select d u /d t and sine filters for the drive. D u /d t filters when is a d u /d t filter needed? See section examining the compatibility of the motor and drive , page 64 ..

Page 240

240 du/dt and sine filters selection table d u /d t filter types for the drive modules are given below. Ordering codes description, installation and technical data of the foch filters see foch du/dt filters hardware manual (3afe68577519 [english]). Sine filters when is a sine filter needed? See sect...

Page 241

Du/dt and sine filters 241 ordering codes derating see section deratings for special settings in the drive control program  on page 180 . ï® description, installation and technical data of the sine filters see sine filters hardware manual  (3axd50000016814 [english]). for more inf...

Page 242

242 du/dt and sine filters.

Page 243

Step-by-step drawings for an installation example of standard drive configuration with option +e208 in rittal ts 8 600 mm wide cabinet 243 step-by-step drawings for an installation example of standard drive configuration with option +e208 in rittal ts 8 600 mm wide cabinet rittal 8606.500 rittal 861...

Page 244

244 step-by-step drawings for an installation example of standard drive configuration with option +e208 in rittal ts 8 600 mm wide cabinet combi screw m8×16 hex 20 n·m combi screw m12×25 hex 20 n·m combi screw m6×12 torx t25 8 n·m combi screw m12×25 hex 70 n·m hex screw m12×35 full thread 70 n·m was...

Page 245

Step-by-step drawings for an installation example of standard drive configuration with option +e208 in rittal ts 8 600 mm wide cabinet 245 combi screw m6×20 torx t25 2 n·m combi screw m4×10 torx t20 2 n·m hex screw m12×35 full thread 70 n·m washer m12 or equal hex nut m12 70 n·m washer m12 or equal ...

Page 246

246 step-by-step drawings for an installation example of standard drive configuration with option +e208 in rittal ts 8 600 mm wide cabinet.

Page 247

Step-by-step drawings for installing full cabling panels (option +h381) in a rittal ts 8 400 mm wide cabinet 247 step-by-step drawings for installing full cabling panels (option +h381) in a rittal ts 8 400 mm wide cabinet installation procedure see the dimension drawing on page 205 (frame r10) or pa...

Page 248

248 step-by-step drawings for installing full cabling panels (option +h381) in a rittal ts 8 400 mm wide cabinet 7. Install the output cabling panel. Note : after you have installed the output cabling panel, you can remove the support rail that lies under the panel if there is not enough space for c...

Page 249

Step-by-step drawings for a flat installation example in rittal ts 8 600 mm wide cabinet 249 step-by-step drawings for a flat installation example in rittal ts 8 600 mm wide cabinet tapping screw m6×12 torx t30 (hex) 9 n·m rittal 8612.160 abb parts 1 mounting bracket of flat mounting option +c173 - ...

Page 250

250 step-by-step drawings for a flat installation example in rittal ts 8 600 mm wide cabinet.

Page 251

Step-by-step drawings for option +h391 installation example in rittal ts 8 600 mm wide cabinet 251 step-by-step drawings for option +h391 installation example in rittal ts 8 600 mm wide cabinet rittal 8612.160 abb parts for option +h391 1 support for back top mounting bracket 2 handle 3 bottom mount...

Page 252

252 step-by-step drawings for option +h391 installation example in rittal ts 8 600 mm wide cabinet.

Page 253

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/searchcha...

Page 254

Contact us www.Abb.Com/drives www.Abb.Com/drivespartners 3aua0000128301 rev g (en) 2017-02-17.