- DL manuals

- ABB

- Servo Drives

- ACS880-07

- Hardware Manual

ABB ACS880-07 Hardware Manual

Summary of ACS880-07

Page 1

Abb industrial drives hardware manual acs880-07 drives (560 to 2800 kw).

Page 3: Hardware Manual

Hardware manual acs880-07 drives (560 to 2800 kw) table of contents 1. Safety instructions 4. Mechanical installation 6. Electrical installation 9. Start-up © 2017 abb oy. All rights reserved. 3aua0000143261 e en effective: 2017-06-05.

Page 5: Table Of Contents

Table of contents 1 safety instructions 15 contents of this chapter ........................................................................... 15 use of warnings and notes ....................................................................... 16 general safety in installation, start-up and mainten...

Page 6

46 cooling air intake through bottom of cabinet (option +c128) ............................ 46 channeled air outlet (option +c130) ......................................................... 46 marine construction (option +c121) ......................................................... 46 ul listed (o...

Page 7

64 moving the unpacked drive cabinet .......................................................... 64 lifting the cabinet with a crane ........................................................... 65 moving the cabinet on rollers ............................................................. 65 moving the...

Page 8

86 relay cable type ................................................................................ 86 control panel cable length and type ......................................................... 86 routing the cables ...................................................................................

Page 9

106 wiring the pt100 relays (option +nl514) ................................................ 107 powering the heating and lighting equipment (options +g300, +g301 and +g313) ....................................................................................... 108 wiring ground fault monitoring for...

Page 10

141 warnings ............................................................................................ 141 checklist ............................................................................................. 9 start-up 143 contents of this chapter .................................................

Page 11

177 ratings .............................................................................................. 179 definitions ....................................................................................... 179 derating ...............................................................................

Page 12

13 dimensions 205 cabinet line-up dimensions ....................................................................... 206 dimension tables ............................................................................... 212 weights .........................................................................

Page 13

247 sine filter (+e206) cubicle, 1000 mm, bottom cable exit (no +h353) ............... 248 sine filter (+e206) cubicle, 1000 mm, top cable exit (+h353) ........................ 249 units with common motor terminal cubicle (option +h359) .............................. 249 cubicle width 300 mm, bottom...

Page 14

269 protecting the brake system against thermal overload ................................... 270 thermal protection of the resistors ....................................................... 270 protecting the resistor cable against short-circuits ........................................ 270 mechanica...

Page 15: Safety Instructions

Safety instructions contents of this chapter this chapter contains the safety instructions which you must obey when you install and operate the drive and do maintenance on the drive. If you ignore the safety instructions, injury, death or damage can occur. Use of warnings and notes warnings tell you...

Page 16

General safety in installation, start-up and maintenance these instructions are for all personnel that install and commission the drive, and do maintenance work on it. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • keep the drive in its...

Page 17

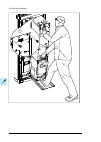

• secure the module extraction/installation ramp carefully. • push the module into the cabinet and pull it from the cabinet carefully preferably with help from another person. Keep a constant pressure with one foot on the base of the module to prevent the module from falling on its back. Keep your f...

Page 18

• when the control location is set to remote in the control panel, the stop key on the control panel will not stop the drive. • only authorized persons are allowed to repair a malfunctioning drive. 18 safety instructions.

Page 19

Electrical safety in installation, start-up and maintenance ■ electrical safety precautions these electrical safety precautions are for all personnel who do work on the drive, motor cable or motor. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can ...

Page 20

• if you are not a qualified electrician, do not do electrical installation or maintenance work. • do not install the drive if the electrical power network, motor/generator, or environmental conditions do not agree with the drive data. • do not install a drive with emc filter (option +e200 or +e202)...

Page 21

• connect the power cable shields to protective earth (pe) of the drive to make sure of personnel safety. • make a 360° grounding of the power and control cable shields at the cable entries to suppress electromagnetic disturbances. • in a multiple-drive installation, connect each drive separately to...

Page 22

22.

Page 23: Contents Of This Chapter

Introduction to the manual contents of this chapter this chapter describes the manual. It contains a flowchart of steps in checking the delivery, installing and starting up the drive. The flowchart refers to chapters/sections in this manual and to other manuals. Target audience this manual is intend...

Page 24

Control units of the drive contains the default i/o connection diagrams, descriptions of the terminals and technical data for the control units of both the supply and inverter units. Installation checklist contains a list for checking the mechanical and electrical installation of the drive. Start-up...

Page 25

Quick installation, commissioning and operation flowchart see task guidelines for planning the electrical install- ation (page 75) plan the electrical installation and acquire the accessories needed (cables, fuses, etc.). Check the ratings, required cooling air flow, input power connec- tion, compat...

Page 26: Terms And Abbreviations

Terms and abbreviations description term/ abbreviation type of control unit bcu frequency converter for controlling ac motors. The drive consists of a rectifier and an inverter connected together by the dc link. In drives up to approximately 500 kw, these are integrated into a single module (drive m...

Page 27

3aua0000119910 user’s manual for prevention of unexpected start-up (+q957) for acs880-07/17/37 drives 3aua0000119908 user’s manual for emergency stop, stop category 0 (+q963) for acs880-07/17/37 drives 3aua0000119909 user’s manual for emergency stop, stop category 1 (+q964) for acs880-07/17/37 drive...

Page 28

28.

Page 29: Description

Operation principle and hardware description contents of this chapter this chapter briefly describes the operation principle and construction of the drive. Operation principle the acs880-07 is an air-cooled cabinet-installed drive for controlling asynchronous ac induction motors, permanent magnet sy...

Page 30

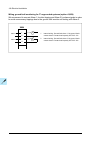

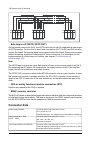

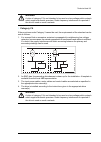

■ overview circuit diagram of the drive m 3~ 1 2 3 4 6 8 12 13 7 7 6 5 10 9 11 ac supply *main switch-disconnector (q1.1) 1 *ac fuses. 2 frames 1×d8t + 2×r8i (6-pulse), 2×d7t + 2×r8i (12-pulse), 2×d8t + n×r8i(12-pulse) have ac fuses installed in the incoming cubicle (icu) only. Frames 2×d8t + 2×r8i ...

Page 31

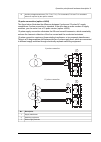

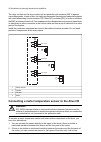

Auxiliary voltage transformers (t21, t101, t111). T21 is standard; t101 and t111 are added whenever required by the options ordered. 13 12-pulse connection (option +a004) the figure below illustrates the difference between 6-pulse and 12-pulse ac supply connections. 6-pulse connection is standard. I...

Page 32

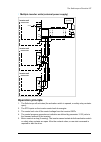

Cabinet line-up and layout examples ■ frame 1×d8t + 2×r8i a b c d 1 2 3 4 cabinet line-up example auxiliary control cubicle (acu). Contains control electronics and customer i/o connections. See section auxiliary control cubicle (acu) layout (page 40) . A incoming cubicle (icu). Contains the power in...

Page 33

1 8 2 9 11 10 5 3 4 6 a 7 cabinet layout example auxiliary control cubicle (acu). See section auxiliary control cubicle (acu) layout (page 40) . A input cable lead-throughs, pe busbar 1 input terminals 2 main switch-disconnector (q1.1) 3 grounding (earthing) switch (q9.1) (optional) 4 ac fuses 5 mai...

Page 34

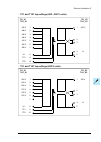

■ frame 2×d7t + 2×r8i (12-pulse connection, option +a004) a b c d 1 2 3 4 cabinet line-up example auxiliary control cubicle (acu). Contains control electronics and customer i/o connections. See section auxiliary control cubicle (acu) layout (page 40) . A incoming cubicle (icu). Contains the power in...

Page 35

1 7 2 8 10 9 4 3 5 a 6 cabinet layout example auxiliary control cubicle (acu). See section auxiliary control cubicle (acu) layout (page 40) . A input cable lead-throughs, pe busbar 1 input terminals 2 main switch-disconnector (q1.1) 3 ac fuses 4 main contactors (q2.1 and q2.2) (optional) 5 auxiliary...

Page 36

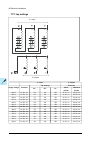

■ frame 2×d8t + 3×r8i a b c d 1 2 3 4 cabinet line-up example auxiliary control cubicle (acu). Contains control electronics and customer i/o connections. See section auxiliary control cubicle (acu) layout (page 40) . A incoming cubicle (icu). Contains the power input cable terminals and switchgear. ...

Page 37

1 8 6 7 10 9 11 12 3 a 2 3 4 5 cabinet layout example auxiliary control cubicle (acu). See section auxiliary control cubicle (acu) layout (page 40) . A input cable lead-throughs, pe busbar 1 input terminals 2 main switch-disconnector (q1.1) 3 grounding (earthing) switch (q9.1) (optional) 4 common ac...

Page 38

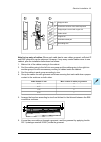

■ frame 3×d8t + 4×r8i (with main breaker, option +f255) a b c d 1 2 3 4 e cabinet line-up example auxiliary control cubicle (acu). Contains control electronics and customer i/o connections. See section auxiliary control cubicle (acu) layout (page 40) . A incoming cubicle (icu). Contains the power in...

Page 39

1 4 5 8 7 9 10 6 9 10 2 a 3 cabinet layout example auxiliary control cubicle (acu). See section auxiliary control cubicle (acu) layout (page 40) . A input cable lead-throughs, pe busbar 1 input terminals 2 incoming cubicle cooling fans 3 main breaker (q1) (option +f255) 4 auxiliary voltage switch (q...

Page 40

■ auxiliary control cubicle (acu) layout a layout example of the auxiliary control cubicle (acu) is shown below. On the left: swing-out frame closed, detachable mounting plates in place. On the right: swing-out frame open, without detachable mounting plates. 40 operation principle and hardware descr...

Page 41

24 v dc power supply for cabinet lighting (op- tion +g301) 26 temperature monitoring relays (options +l505 and +l506). The terminals (x506) are located on the back of the detachable mounting plate. 8 auxiliary voltage transformer t101 (at the back of the cubicle, not visible). Supplies ip54, brake c...

Page 42

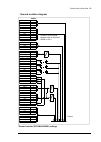

Overview of power and control connections the diagram shows the power connections and control interfaces of the drive. L1 l2 l3 pe u2 v2 w2 m 3 ~ l1 l2 l3 pe fxx slots 1, 2 and 3 1 7 .... .. .. .. .... .. .. .. ...... .... .... .... .. .. .. . .. .. . 6 . . . . . . 10 .. ... .. .. . .. ... .. .. . 4...

Page 43: Door Switches And Lights

Terminal blocks for customer connections installed in the drive cabinet. For the locations, see section auxiliary control cubicle (acu) layout (page 40) . 10 supply unit (consisting of one or more supply modules) 11 dc intermediate link 12 inverter unit (consisting of two or more inverter modules) 1...

Page 44

■ main disconnecting device (q1.1) depending on the configuration of the drive, the main disconnecting device of the drive is either a switch-disconnector or a main circuit breaker. Units with a switch-disconnector also have a main contactor. The main disconnecting device switches the main supply to...

Page 45: Descriptions Of Options

The control panel can be removed by pulling it forward by the top edge and reinstalled in reverse order. For the use of the control panel, see acx-ap-x assistant control panel user’s manual (3aua0000085685 [english]) and the firmware manual. Control by pc tools there is a usb connector on the front ...

Page 46

Ip42 (option +b054) this option provides the degree of protection of ip42 (ul type 1). The air inlet gratings are covered with a metallic mesh between the inner and outer metallic gratings. Ip54 (option +b055) this option provides the degree of protection of ip54 (ul type 12). It provides the cabine...

Page 47

• main (air circuit) breaker when available for the particular drive type. ■ plinth height (options +c164 and +c179) the standard height of the cabinet plinth is 50 mm. These options specify a plinth height of 100 mm (+c164) or 200 mm (+c179). ■ seismic design (option +c180) the option involves seis...

Page 48

• section powering the heating and lighting equipment (options +g300, +g301 and +g313) (page 107) • circuit diagrams delivered with drive for the actual wiring. ■ cabinet lighting (option +g301) this option contains led lighting fixtures in each cubicle (except joining and brake resistor cubicles) a...

Page 49

■ a-meter in one phase (option +g335) the option contains an ammeter that reads the current flowing through one input phase. ■ additional wire markings (options +g340 and +g342) standard wire markings as standard, wires and terminals are marked as follows: • plug-in connectors of wire sets: connecto...

Page 50

Power and control cable entries at the floor of the cabinet. The entries are equipped with grommets and 360° grounding hardware. For non-ul listed units, bottom entry/exit is the default cabling arrangement. ■ top cable entry/exit (options +h351 and +h353) for non-ul listed units, the default input ...

Page 51

■ additional terminal block x504 (option +l504) the standard terminal blocks of the drive control unit are wired to the additional terminal block at the factory for customer control wiring. The terminals are spring loaded. Cables accepted by the terminals: • solid wire 0.08 to 4 mm2 • stranded wire ...

Page 52

+l536, +l537 an alternative to a thermistor relay option is the fptc-01 (option +l536) or fptc-02 (+l537, also requires +q971) thermistor protection module. The module mounts onto the inverter control unit, and has reinforced insulation to keep the control unit pelv-compatible. The connectivity of t...

Page 53

Manual reset required by ex/atex regulations must be implemented using drive parameters. For more information, see atex-certified motor thermal protection functions for cabinet-built acs880 drives (options +l513+q971 and +l514+q971) user's manual (3axd50000014979 [english]). See also • firmware manu...

Page 54: Type Designation Label

Type designation label the type designation label includes ratings, appropriate markings, a type designation and a serial number, which allow the identification of each unit. A sample label is shown below. Quote the complete type designation and serial number when contacting technical support. 1 4 5...

Page 55

Description code 380…415 v ac. This is indicated in the type designation label as typical input voltage level (3~ 400 v ac) 3 380…500 v ac. This is indicated in the type designation label as typical input voltage levels (3~ 400/480/500 v ac) 5 525…690 v ac. This is indicated in the type designation ...

Page 56

Description code ready light on door, white g327 run light on door, green g328 fault light on door, red g329 halogen-free wiring and materials g330 v-meter with selector switch g334 a-meter in one phase g335 additional wire markings. See section descriptions of options (page 45) . G340 g342 cabling ...

Page 57

Description code fen-11 ttl absolute encoder interface module l518 fse-31 pulse encoder interface module l521 faio-01 analog i/o extension module l525 fdio-01 digital i/o extension module l526 fptc-01 thermistor protection module l536 fptc-02 atex-certified thermistor protection module l537 starter ...

Page 58

Description code emergency stop (configurable for category 0 or 1) with fso-xx safety functions module, by activating the safe torque off function q979 profisafe with fso-xx safety functions module and fena-21 ethernet adapter module q982 full set of printed manuals in the selected language note: th...

Page 59: Mechanical Installation

Mechanical installation contents of this chapter this chapter describes the mechanical installation procedure of the drive. Examining the installation site examine the installation site: • the installation site is sufficiently ventilated or cooled to transfer away the drive losses. See the technical...

Page 60: Necessary Tools

Do not install the drive on an elevated platform or a recess. The module extraction/installation ramp included with the drive is only suitable for a height difference of 50 mm maximum (ie. The standard plinth height of the drive). Necessary tools the tools required for moving the unit to its final p...

Page 61

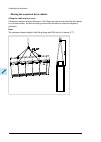

Moving and unpacking the drive move the drive in its original packaging to the installation site as shown below to avoid damaging the cabinet surfaces and door devices. When you are using a pallet truck, check its load capacity before you move the drive. The drive cabinet is to be moved in the uprig...

Page 62

Lifting the crate with a crane max 20 b a lifting point a optimal position for the lifting sling: as close to the traverse board as possible b 62 mechanical installation.

Page 63

Moving the crate with a forklift mechanical installation 61 moving the crate with a forklift 750 mm (29.5'') ■ removing the transport package remove the transport package as follows: 1. Undo the screws that attach the wooden parts of the transport crate to each other. 2. Remove the wooden parts. 3. ...

Page 64

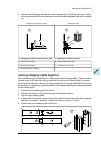

■ moving the unpacked drive cabinet lifting the cabinet with a crane lift the drive cabinet using its lifting eyes. The lifting eyes can be removed after the cabinet is in its final position, but their mounting holes must be blocked to retain the degree of protection. Note: the minimum allowed heigh...

Page 65

Moving the cabinet on rollers warning! Do not move marine versions (option +c121) on rollers. Lay the cabinet on the rollers and move it carefully until close to its final location. Remove the rollers by lifting the unit with a crane, forklift, pallet truck or jack. Moving the cabinet on its back wa...

Page 66: (Non-Marine Units)

Final placement of the cabinet move the cabinet into its final position with a slate bar (spud bar). Place a piece of wood between the edge of the cabinet and the bar to protect the cabinet frame. Fastening the cabinet to the floor and wall or roof (non-marine units) ■ general rules • the drive must...

Page 67

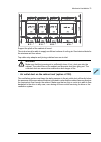

A b 120° w > 400 mm (15.75”) note 1: any height adjustment must be done before fastening the units or shipping splits together. Height adjustment can be done by using metal shims between the cabinet bottom and floor. Note 2: if the lifting eyes are removed, refasten the bolts to retain the degree of...

Page 68: Units)

Fastening top to wall clamping bottom to floor m16 ■ alternative 2 – using the holes inside the cabinet 1. Fasten the cabinet to the floor through the bottom fastening holes with m10 to m12 (3/8” to 1/2”) bolts. The recommended maximum distance between the front edge fastening points is 800 mm (31.5...

Page 69

3. Remove the lifting lugs and bolt the corner brackets (d) to the lifting lug holes. Fasten the corner brackets to the rear wall and/or roof with suitable hardware such as u-brackets (e). Fastening to wall fastening to floor with a clamp m16 3 e d a b c 2 3. Fastening the cabinet at the top 2. Clam...

Page 70

6. Connect the pe busbars using the m10 bolts and nuts included. Tighten to 35…40 n·m (25…30 lbf·ft). B a c a 35…40 n·m (25…30 lbf·ft) a plain washer b spring washer c bolt and nut 7. Remove the shroud covering the dc busbars in the joining cubicle. 8. Use the joint pieces to connect the dc busbars....

Page 71

Warning! Make sure you install the washers in the correct order as shown. For example, placing an unpassivated zinc-coated spring washer directly against the joint piece will cause corrosion. Warning! Do not use any joining parts other than those delivered with the unit. The parts are carefully sele...

Page 72: Miscellaneous

Miscellaneous ■ cable duct in the floor below the cabinet a cable duct can be constructed below the 500 mm wide middle part of the cabinet. The cabinet weight lies on the two 50 mm wide transverse sections which the floor must carry. Prevent the cooling air flow from the cable duct to the cabinet by...

Page 73

Support the plinth of the cabinet all round. The air duct must be able to supply a sufficient volume of cooling air. See technical data for the minimum air flow values. Top cable entry adapter and joining cubicles have no air inlet. Warning! Make sure that the incoming air is sufficiently clean. If ...

Page 74

Calculating the required static pressure difference the required static pressure difference between the exit air duct and the drive installation room can be calculated as follows: Δ p s = (1.5…2) · p d where p d = 0.5 · ρ · v m v m = q / a c dynamic pressure p d air density (kg/m 3 ) ρ average air v...

Page 75: Installation

Guidelines for planning the electrical installation contents of this chapter this chapter contains instructions for planning the electrical installation of the drive. Some instructions are mandatory to follow in every installation, others provide useful information that only concerns certain applica...

Page 76

Examining the compatibility of the motor and drive use an asynchronous ac induction motor, permanent magnet synchronous motor or ac induction servomotor with the drive. Several induction motors can be connected to the drive at a time. Select the motor size and drive type from the rating tables on ba...

Page 77

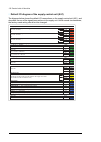

This table shows the requirements when an abb motor is in use. Requirement for nominal ac supply voltage motor type abb du/dt and common mode filters, insulated n-end motor bearings motor insula- tion system p n ≥ 350 kw or frame size ≥ iec 400 100 kw ≤ p n kw or iec 315 ≤ frame size p n and frame s...

Page 78

This table shows the requirements when a non-abb motor is in use. Requirement for nominal ac supply voltage motor type abb du/dt and common mode filters, insulated n-end motor bearings motor insula- tion system p n ≥ 350 kw or frame size ≥ iec 400 100 kw ≤ p n kw or iec 315 ≤ frame size p n and fram...

Page 79

Availability of du/dt filter and common mode filter by drive type availability of common mode filter (cmf) availability of du/dt filter product type standard standard acs880-07 additional requirements for explosion-safe (ex) motors if you will use an explosion-safe (ex) motor, follow the rules in th...

Page 80

Additional requirements for non-abb high-output and ip23 motors the rated output power of high-output motors is higher than what is stated for the particular frame size in en 50347 (2001). If you plan to use a non-abb high-output motor or an ip23 motor, consider these additional requirements for pro...

Page 81

Additional data for calculating the rise time and the peak line-to-line voltage if you need to calculate the actual peak voltage and voltage rise time considering the actual cable length, proceed as follows: • peak line-to line voltage: read the relative Û ll / u n value from the diagram below and m...

Page 82

Selecting the power cables ■ general rules select the input power and motor cables according to local regulations. Obey these rules: • select a cable capable of carrying the drive nominal current. • select a cable rated for at least 70 °c maximum permissible temperature of conductor in continuous us...

Page 83

■ alternative power cable types recommended power cable types this section presents the recommended cable types. Check with local / state / country electrical codes for allowance. Use as motor cabling use as input power cabling cable type yes. Yes. Pe symmetrical shielded cable with three phase cond...

Page 84

Power cable types for limited use use as motor cabling use as input power cabling cable type no yes pe a four-conductor system: three phase conductors and a pe conduct- or on a cable tray only with phase conductor cross section less than 10 mm 2 (8 awg) or motors yes emt corrugated cable with three ...

Page 85

1 3 4 5 2 insulation jacket 1 helix of copper tape or copper wire 2 copper wire screen 3 inner insulation 4 cable core 5 ■ additional us requirements use type mc continuous corrugated aluminum armor cable with symmetrical grounds or shielded power cable for the motor cables if metallic conduit is no...

Page 86: Routing The Cables

Use a double-shielded twisted pair cable for analog signals. This type of cable is recommended for the pulse encoder signals also. Employ one individually shielded pair for each signal. Do not use common return for different analog signals. A double-shielded cable (figure a below) is the best altern...

Page 87

Min 200 mm (8 in.) 90 ° min 500 mm (20 in.) min 300 mm (12 in.) drive 1 2 3 1 4 motor cable 1 input power cable 2 power cable 3 control cable 4 ■ separate control cable ducts lead 24 v and 230 v (120 v) control cables in separate ducts unless the 24 v cable is insulated for 230 v (120 v) or insulate...

Page 88

The fuses will protect the input cable in short-circuit situations, restrict drive damage and prevent damage to adjoining equipment in case of a short-circuit inside the drive. ■ protecting the motor and motor cable in short-circuits the drive protects the motor cable and motor in a short-circuit si...

Page 89: Function

Implementing the emergency stop function you can order the drive with a category 0 or category 1 emergency stop function. For safety reasons, install the emergency stop devices at each operator control station and at other operating stations where emergency stop may be needed. Note: pressing the sto...

Page 90

The settings of the fso-xx are at default when delivered from the factory. The wiring of the external safety circuit and configuration of the fso-xx module are the responsibility of the machine builder. The fso-xx reserves the standard safe torque off (sto) connection of the inverter control unit. S...

Page 91: Motor

Warning! Never connect the drive output to the power line. The connection may damage the drive. Supplying power for the auxiliary circuits the drive is equipped with an auxiliary control voltage transformer which supplies control voltage, for example, for the control devices and cabinet fan(s). The ...

Page 92

The relay contacts on the drive control unit are protected with varistors (250 v) against overvoltage peaks. In spite of this, it is highly recommended that inductive loads are equipped with noise attenuating circuits (varistors, rc filters [ac] or diodes [dc]) in order to minimize the emc emission ...

Page 93

Connected to the drive's digital and analog inputs (typically low-voltage circuits) are protected against contact and insulated with basic insulation from other low-voltage circuits. The insulation must be rated for the same voltage level as the drive main circuit. 3. You can connect the sensor to a...

Page 94

94.

Page 95: Electrical Installation

Electrical installation contents of this chapter this chapter gives instructions on the wiring of the drive. Warnings warning! Only qualified electricians are allowed to carry out the work described in this chapter. Follow the safety instructions on the first pages of this manual. Ignoring the safet...

Page 96

2. Measure the insulation resistance between each phase conductor and the protective earth conductor using a measuring voltage of 1000 v dc. The insulation resistance of an abb motor must exceed 100 mohm (reference value at 25 °c or 77 °f). For the insulation resistance of other motors, consult the ...

Page 97

■ t21 and t101 tap settings (400…500 v units) 500 v 1 480 v 2 460 v 3 440 v 4 415 v 5 400 v 6 380 v 7 u1 8 tp1 9 tp2 10 t21_x1 t101_x1 t21_x2 t101_x2 1 230 v 2 3 4 n 5 Ĭ ■ t21 and t101 tap settings (690 v units) 690 v 1 660 v 2 600 v 3 575 v 4 540 v 5 525 v 6 7 u1 8 tp1 9 tp2 10 t21_x1 t101_x1 t21_x...

Page 98: T111 Tap Settings

■ t111 tap settings 96 electrical installation t111 tap settings 3~ input 3~ output supply voltage terminals tap settings terminals a1– b1– c1– 400 v (50 hz) 320/340 v (60 hz) 690 v a1, b1, c1 c2 a2 b2 a1, b1, c1 a2, b2, c2 660 v a1, b1, c1 c2 a2 b2 a1, b1, c1 a2, b2, c2 600 v a1, b1, c1 c3 a3 b3 a1...

Page 99

Connecting the control cables see chapter control units of the drive (page 129) for the default i/o connections of the inverter unit (with the acs880 primary control program). The default i/o connections can be different with some hardware options, see the circuit diagrams delivered with the drive f...

Page 100

Grounding the outer shields of the control cables at the cabinet lead-through ground the outer shields of all control cables 360 degrees at the emi conductive cushions as follows: 1. Loosen the tightening screws of the emi conductive cushions and pull the cushions apart. 2. Cut adequate holes to the...

Page 101: •

98 electrical installation note 1 : keep the shields continuous as close to the connection terminals as possible. Secure the cables mechanically at the lead-through strain relief. Note 2: if the outer surface of the shield is non-conductive: • cut the shield at the midpoint of the bare part. Be care...

Page 102

Routing the control cables inside the cabinet use the existing trunking in the cabinet wherever possible. Use sleeving if cables are laid against sharp edges. When running cables to or from the swing-out frame, leave enough slack at the hinge to allow the frame to open fully. 102 electrical installa...

Page 103

Connecting to the inverter control unit (a41) connect the conductors to the appropriate terminals of the control unit or terminal block x504 (option +l504). Connect the inner twisted pair shields and all separate grounding wires to the grounding clamps below the control unit. The drawing below repre...

Page 104

Connecting a 230/115 v ac auxiliary voltage supply (ups, option +g307) wire the external control voltage to terminal block x307 at the back side of the mounting plate as shown below. 1 2 pe 4 5 n l x307 pe 1 internal wiring of ups supervision: circuit breaker or fuse off/fault = contact open. 1 conn...

Page 105

Wiring the ptc thermistor relay(s) (options +l505, +2l505, +l513 and +2l513) the external wiring of option +2l505 and +2l513 (two thermistor relays) is shown below. For example, one relay can be used to monitor the motor windings, the other to monitor the bearings. The maximum contact load capacity ...

Page 106

Wiring the pt100 relays (option +nl506) external wiring of eight pt100 sensor modules is shown below. Contact load capacity 250 v ac 10 a. For the actual wiring, see the circuit diagram delivered with the drive. 1 2 3 4 5 6 … 22 23 24 25 26 27 28 29 30 x506 1 × pt100 t … … t t sensor 1 sensor 2 sens...

Page 107

Powering the heating and lighting equipment (options +g300, +g301 and +g313) see the circuit diagrams delivered with drive. Connect the external power supply wires for the cabinet heater and lighting to terminal block x300 at the back of the mounting plate. 104 electrical installation powering the h...

Page 108

Wiring ground fault monitoring for it ungrounded systems (option +q954) we recommend to connect alarm 1 for drive tripping and alarm 2 for alarm signals in order to avoid unnecessary trippings due to the ground fault monitor self testing with alarm 2. Electrical installation 105 wiring ground fault ...

Page 109

Connecting the motor cables (units without common motor terminal cubicle or sine output filter) on units without a common motor terminal cubicle or a sine output filter, the motor cables connect to busbars located behind the inverter module(s). The location and dimensions of the busbars are visible ...

Page 110

Pe u2 v2 w2 u2 v2 w2 m 3~ u1 w1 v1 pe inverter unit cubicle(s) ■ motor connection diagram (with option +h366) with option +h366, the output busbars of the inverter modules within the same cubicle are connected by bridging busbars. The bridging balances the motor current between the modules, which al...

Page 111

■ procedure removing the inverter module(s) to allow more room for cabling work, the inverter modules can be removed completely instead of only the fan carriages. Refer to the drawings below. Warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or dama...

Page 112

Electrical installation 109 5 6 4 3 112 electrical installation.

Page 113

110 electrical installation 7 8 8 electrical installation 113.

Page 114

Electrical installation 111 9 10 114 electrical installation.

Page 115

Removing and reinstalling the fan carriage of an inverter module refer to the drawings below. Warning! Obey the instructions in chapter safety instructions (page 15) . If you ignore them, injury or death, or damage to the equipment can occur. 1. Do the steps in section electrical safety precautions ...

Page 116

Electrical installation 113 4 5 3 6 7 116 electrical installation.

Page 117

Connecting the motor cables refer to the drawings below. Warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Do the steps in section electrical safety precautions (page 19) before you start the work. 2. Remove ...

Page 118

2 11 b pe 10 7 5 6 8 a 360° grounding detail 118 electrical installation.

Page 119

Re-installing the fan carriage of an inverter module (if the inverter module was removed completely instead of only the fan carriage, proceed to section re-inserting the inverter module into the cubicle below). The re-installation of the fan carriage is the removal procedure in reverse. See section ...

Page 120

■ connection diagram u2 v2 w2 pe m 3~ u1 w1 v1 pe inverter unit cubicle common motor terminal or sine filter cubicle the recommended cable types are given in chapter technical data . ■ procedure warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or d...

Page 121

9. At the motor, connect the cables according to instructions from the motor manufacturer. Pay special attention to the phase order. For minimum radio-frequency interference, ground the cable shield 360 degrees at the lead-through of the motor terminal box, or ground the cable by twisting the shield...

Page 122

■ connection diagram, 12-pulse units acs880-07 incoming unit (icu) 1) 1l1 1l2 1l3 2) pe 2l1 2l2 2l3 pe 1) fuses or other protection means. 2) 360-degree grounding is recommended if shielded cable is used. Ground the other end of the input cable shield or pe conductor at the distribution board. Note:...

Page 123

Warning! Aluminum-aluminum contact apply grease to stripped aluminum conductors before attaching them to non-coated aluminum cable lugs. Obey the grease manufacturer's instructions. Aluminum-aluminum contact can cause oxidation in the contact surfaces. Pe pe 6. If fire insulation is used, make an op...

Page 124: Connecting A Pc

8. Attach the conductive sleeves to the cable shields with cable ties. Tie up the unused conductive sleeves with cable ties. 9. Seal the slot between the cable and mineral wool sheet (if used) with sealing compound (eg. Csd-f, abb brand name dxxt-11, code 35080082). 10. Connect the twisted shields o...

Page 125: Connecting A Pc

122 electrical installation connecting a pc a pc (with eg. The drive composer pc tool) can be connected to the inverter unit as follows: 1. Connect an acs-ap-i control panel to the inverter control unit either by using an ethernet (eg. Cat5e) networking cable, or by inserting the panel into the pane...

Page 126: Installing Option Modules

• with an fdpi-02 module, move termination switch s2 into the terminated position. Make sure that bus termination is off on all other drives. 4. On the control panel, switch on the panel bus functionality (options - select drive - panel bus). The drive to be controlled can now be selected from the l...

Page 127

Unit, which is the standard with factory-installed fso-xx modules. For instructions, see the fso-xx manual.) 1. Fasten the module onto slot 3 of the inverter control unit (a41) with four screws. Electrical installation 125 mechanical installation of an fso-xx safety functions module this procedure d...

Page 128

128.

Page 129: General

Control units of the drive what this chapter contains this chapter • describes the connections of the control units used in the drive, • contains the specifications of the inputs and outputs of the control units. General the acs880 drive utilizes bcu-x2 control units. The bcu-x2 consists of a bcon-1...

Page 130

■ control unit layout and connections description i/o terminals (see following diagram) i/o i/o extension, encoder interface or fieldbus adapter module connection. (this is the sole location for an fdpi-02 diagnostics and panel interface.) slot 1 i/o extension, encoder interface or fieldbus adapter ...

Page 131

Description analog inputs xai analog outputs xao digital inputs, digital input interlock (diil) xdi digital input/outputs xdio drive-to-drive link xd2d +24 v output (for digital inputs) xd24 ethernet port (eg. For pc communication) xeth external power input xpow relay output ro1 xro1 relay output ro...

Page 132

■ default i/o diagram of the supply control unit (a51) the diagram below shows the default i/o connections on the supply control unit (a51), and describes the use of the signals/connections in the supply unit. Under normal circumstances, the factory-made wiring should not be changed. Relay outputs x...

Page 133

■ default i/o diagram of the inverter control unit (a41) drive-to-drive link xd2d drive-to-drive link 1) b 1 a 2 bgnd 3 shield 4 rs485 connection x485 not in use b 5 a 6 bgnd 7 shield 8 relay outputs xro1…xro3 ready 250 v ac / 30 v dc 2 a nc 11 com 12 no 13 running 250 v ac / 30 v dc 2 a nc 21 com 2...

Page 134

3) 0 = acceleration/deceleration ramps defined by parameters 23.12/23.13 in use. 1 = acceleration/deceleration ramps defined by parameters 23.14/23.15 in use. 4) constant speed 1 is defined by parameter 22.26. 5) see section diil input (page 135) . 6) total load capacity of these outputs is 4.8 w (2...

Page 135

/ 630 v. The shield can also be grounded directly at both ends if they are in the same ground line with no significant voltage drop between the end points. Xai xao ain+ ain- aon agnd 1) 2) t t t 1 … 3 × pt100/pt1000/ptc or 1 × kty84 1) set the input type to voltage with the appropriate switch or jum...

Page 136: Connector Data

1 2 3 4 b a bgnd sh ie l d xd 2 d 1 2 3 4 b a bgnd sh ie l d xd 2 d 1 2 3 4 b a bgnd sh ie l d xd 2 d termination on termination on termination off ■ safe torque off (xsto, xsto out) on the inverter control unit (a41), the xsto input can be used to implement a safe torque off (sto) function. For the...

Page 137: Control Unit Connector Data

Connector pitch 5 mm, wire size 2.5 mm 2 digital inputs di1…di6 (xdi:1…xdi:6) 24 v logic levels: “0” 15 v r in : 2.0 kohm input type: npn/pnp (di1…di5), npn (di6) hardware filtering: 0.04 ms, digital filtering up to 8 ms di6 (xdi:6) can alternatively be used as an input for a ptc sensor. “0” > 4 koh...

Page 138

Connector pitch 5 mm, wire size 2.5 mm 2 safe torque off connection (xsto) input voltage range: -3…30 v dc logic levels: “0” 17 v. For the unit to start, both connec- tions must be “1”. Current consumption: 66 ma (continuous) per sto channel per r8i inverter module emc (immunity) according to iec 61...

Page 139

■ ground isolation diagram control units of the drive 137 ground isolation diagram xpow +24vi 1 gnd 2 +24vi 3 gnd 4 xai +vref 1 -vref 2 agnd 3 ai1+ 4 ai1- 5 ai2+ 6 ai2- 7 xao ao1 1 agnd 2 ao2 3 agnd 4 xd2d b 1 a 2 bgnd 3 shield 4 xro1, xro2, xro3 nc 11 com 12 no 13 nc 21 com 22 no 23 nc 31 com 32 no...

Page 140

Dicom=diognd: on all digital inputs share a common ground (dicom connected to diognd). This is the default setting. Dicom=diognd: off ground of digital inputs di1…di5 and diil (dicom) is isolated from dio signal ground (diognd). Isolation voltage 50 v. 140 control units of the drive.

Page 141: Installation Checklist

Installation checklist contents of this chapter this chapter contains an installation checklist which you must complete before you start up the drive. Warnings warning! Obey the safety instructions. If you ignore them, injury or death, or damage to the equipment can occur. Do the steps in section el...

Page 142

Check that … there is an adequately sized protective earth (ground) conductor between the motor and the drive, and the conductor has been connected to appropriate terminal, and the terminal have been tightened. (pull on the conductors to check.). Proper grounding has also been measured according to ...

Page 143: Start-Up

Start-up contents of this chapter this chapter contains the start-up procedure of the drive. Start-up procedure the tasks which are needed in certain cases only are marked with underlining, and option codes are given in brackets. Default device designations (if any) are given in brackets after the n...

Page 144

Action check that the main switch-disconnector (q1.1) is switched off, or main breaker (q1) racked out. Note: some 12-pulse units are equipped with two switch-disconnectors or breakers – check that both are open before you proceed. Check that the grounding switch (q9.1) (option +f259) is switched on...

Page 145

Action setting up the inverter unit parameters, and performing the first start set up the inverter control program. See the appropriate start-up guide and/or firmware manual. There is a separate start-up guide only for some control programs. Check that parameter 95.09 fuse switch control is disabled...

Page 146

146.

Page 147: Fault Tracing

Fault tracing contents of this chapter this chapter describes the fault tracing possibilities of the drive. Leds this table shows the leds visible on the control panel mounting platform on cabinet door (when panel has been removed), and on the bcu-xx control unit inside the cabinet. Indication color...

Page 148

148.

Page 149: Maintenance

Maintenance contents of this chapter this chapter contains maintenance instructions. Maintenance intervals the table below shows the maintenance tasks which can be done by the end user. The complete maintenance schedule is available on the internet ( www.Abb.Com/drivesservices ). For more informatio...

Page 150

Years from start-up component … 12 11 10 9 8 7 6 5 4 3 2 1 cooling r supply and inverter module main cooling fans r r r r sine filter (option +e206) cooling fan r r supply and inverter modules: cir- cuit board compartment fan r r internal cabinet cooling fans (intern- al, door and ip54) batteries r ...

Page 151: Cabinet

Cabinet ■ cleaning the interior of the cabinet warning! Obey the instructions in chapter safety instructions. If you ignore them, injury or death, or damage to the equipment can occur. Warning! Use a vacuum cleaner with an antistatic hose and nozzle, and wear a grounding wristband. Otherwise an elec...

Page 152

5. Reinstall the grating in reverse order. 1 2 3 3 4 5 ■ cleaning the outlet (roof) filters (ip54) the outlet (roof) filters in ip54 units can be accessed by pulling the gratings upwards. ■ replacing the outlet (roof) filters (ip54) 1. Remove the front and back gratings of the fan cubicle by lifting...

Page 153: Fans

Fans the lifespan of the cooling fans of the drive depends on the running time, ambient temperature and dust concentration. See the firmware manual for the actual signal which indicates the running time of the cooling fan. Reset the running time signal after fan replacement. Replacement fans are ava...

Page 154

5. Install the new fan in reverse order. 4a 3 4 3a 4b ■ replacing a roof fan (ip54/ul type 12) warning! Bey the instructions in chapter safety instructions. If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety prec...

Page 155

8. Install the new fan in reverse order. 2 3 4 2 3 3 5 6 6 6 6 ■ replacing a supply module (d7t) cooling fan warning! Only qualified electricians are allowed to do this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage t...

Page 156

9. Install the fan holder in reverse order to the above. 4 d 8 b e 6 3 c 5 a ■ replacing a supply module (d8t) or inverter module (r8i) cooling fan warning! Obey the instructions in chapter safety instructions. If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the dr...

Page 157

8. Install new fan in reverse order. 7 3 4 5 6 ■ replacing the circuit board compartment fan frame d8d supply and frame r8i inverter modules are equipped with a fan blowing air through the circuit board compartment. The fan is accessible from the front of the module. Warning! Obey the instructions i...

Page 158

5. Disconnect the fan cable. 3 4 5 6. Remove the four m3 (5.5 mm) nuts which hold the fan. 7. Remove the fan from the fan holder. 6 7 8. Put the fan onto the threaded studs on the fan holder with the airflow direction arrow pointing towards the fan holder. 9. Install and tighten the four nuts remove...

Page 159

12. Install and tighten the two m4×12 (t20) screws. 10 11 12 maintenance 159.

Page 160

Supply and inverter modules ■ replacing a frame d7t supply module warning! Only qualified electricians are allowed to do this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. Warning! Use extreme cauti...

Page 161

14. Remove the lifting chain from the old module and move the module away. 15. Install a new module in reverse order. 16. Close the cubicle door. 5 4 4a 4b 4 4a 4b maintenance 161.

Page 162

6 6a 6a 6b 7a 7b 7 8 8a 8b 162 maintenance.

Page 163

9 10 9a 9a 10a 11 ■ replacing a frame d8t supply module warning! Only qualified electricians are allowed to do this work. Read and obey the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. Warning! Use extreme cautio...

Page 164

Module to prevent the module from falling on its back. Keep your fingers away from the edges of the front flange of the module. 50 mm max. • do not tilt the module. It will overturn very easily because it is heavy and its center of gravity is high. Make sure that the module does not topple over when...

Page 165

10. To reinsert the module into the cubicle: • push the module back in and fasten. Tighten the fastening screws of the module to 22 n·m (16.2 lbf·ft) and the fastening bolts of the dc output busbars to 70 n·m (52 lbf·ft). • reconnect the wires and fiber optic cables to the module. • reinstall the sh...

Page 166

166 maintenance 6 6 7 8 7 166 maintenance.

Page 167: Replacing An Inverter Module

Maintenance 167 replacing an inverter module follow the module extraction and insertion procedures under connecting the motor cables (units without common motor terminal cubicle or sine output filter) (page 106 ). 9 ■ cleaning the heatsink the drive module heatsink fins pick up dust from the cooling...

Page 168

2. Remove the drive module from the cabinet. 3. Remove the module cooling fan(s). See the separate instructions. 4. Blow dry, clean compressed air from bottom to top and simultaneously use a vacuum cleaner at the air outlet to trap the dust. Note: if there is a risk of dust entering adjoining equipm...

Page 169

• fasten the left/right sides of the baffle if wherever possible using m4 screws. (this depends on the location of the module in the cubicle.) tighten to 1…2 n·m (0.7 … 1.5 lbf·ft). 3 5 6. If the inverter control unit (a41) is powered from the faulty module, connect the power supply wiring using the...

Page 170: Capacitors

Returning the module 1. Install the module in reverse order. Use the following tightening torques: • dc busbar assembly to upper insulators (2 × m8): 9 n·m (6.6 lbf·ft) • dc busbar assembly to lower insulators (2 × m10): 18 n·m (13.3 lbf·ft) • fuses to dc busbars: 50 n·m (37 lbf·ft) (bussmann), 46 n...

Page 171: Fuses

Fuses ■ replacing the ac and dc fuses in cabinet this procedure instructs how to replace the drive ac and dc fuses inside the cabinet. The location of the fuses vary depending on the drive type and options. Locate the fuses to be replaced using the delivery-specific layout drawings and circuit diagr...

Page 172

8. Reinstall the shroud and close the door. 4 ■ replacing the supply module dc fuses (d7t and d8t) warning! Obey the instructions in chapter safety instructions. If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety...

Page 173

6. Reinstall the cover removed earlier and close the cubicle door. 4 4 d7t d8t maintenance 173.

Page 174: Control Panel

Control panel ■ replacing the control panel battery 1. Turn the lid on the back of the panel counter-clockwise until the lid opens. 2. Replace the battery with a new cr2032 battery. 3. Put the lid back and tighten it by turning it clockwise. 4. Dispose of the old battery according to local disposal ...

Page 175: Control Units

Control units ■ bcu control unit types there are three variants of the bcu control unit used in acs880 drives: bcu-02, bcu-12 and bcu-22. These have a different number of converter module connections (2, 7 and 12 respectively) but are otherwise identical. The three bcu types are interchangeable as l...

Page 176

Warning! Obey the instructions in chapter safety instructions. If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions (page 19) before you start the work. 2. Undo the fastening screw and remove the batter...

Page 177: Technical Data

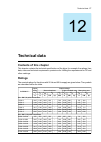

Technical data contents of this chapter this chapter contains the technical specifications of the drive, for example, the ratings, fuse data, sizes and technical requirements, provisions for fulfilling the requirements for ce and other markings. Ratings the nominal ratings for the drives with 50 hz ...

Page 178

Output ratings input rating acs880-07-… heavy-duty use light-overload use no-overload use p hd i hd p ld i ld s n p n i max i n i 1 hp kw a hp kw a kva hp kw a a a u n = 500 v, 6-pulse connection 700 560 800 900 710 1027 927 900 710 1391 1070 983 1070a-5 900 710 987 1000 900 1267 1143 1000 900 1716 ...

Page 179

■ definitions supply voltage range u n nominal rms input current i 1 nominal output current (available continuously with no over-loading) i n maximum output current. Available for 10 seconds at start, then as long as allowed by drive temper- ature. I max typical motor power in no-overload use. The h...

Page 180

Altitude derating at altitudes from 1000 to 4000 m (3300 to 13123 ft) above sea level, the output current derating is 1 pp for every 100 m (328 ft). If ambient temperature is below +40 °c (+104 °f), the derating can be reduced by 1.5 pp for every 1 °c (1.8 °f) reduction in temperature. For a more ac...

Page 181

Frame sizes and power module types inverter modules used supply module(s) used frame size acs880-07-… type qty type qty u n = 400 v, 6-pulse connection acs880-104-0640a-3 2 acs880-304-0980a-3+a018 1 1×d8t + 2×r8i 1140a-3 acs880-104-0640a-3 2 acs880-304-0650a-3+a018 2 2×d8t + 2×r8i 1250a-3 acs880-104...

Page 182

Inverter modules used supply module(s) used frame size acs880-07-… type qty type qty acs880-104-0600a-7 4 acs880-304-0570a-7+a018 4 4×d8t + 4×r8i 2300a-7+a004 acs880-104-0600a-7 5 acs880-304-0820a-7+a018 4 4×d8t + 5×r8i 2600a-7+a004 acs880-104-0600a-7 5 acs880-304-0820a-7+a018 4 4×d8t + 5×r8i 2860a-...

Page 183: Fuses

Fuses ■ ac fuses notes: • fuses with higher current rating than the recommended ones must not be used. • fuses from other manufacturers can be used if they meet the ratings and the melting curve of the fuse does not exceed the melting curve of the fuse mentioned in the table. Ultrarapid (ar) fuses a...

Page 184

Ultrarapid (ar) fuses at supply module input input cur- rent (a) acs880-07-… type manufacturer v a 2 s at 660 v a qty u n = 690 v, 12-pulse connection 170m6411 bussmann 690 300000 700 6 800 0800a-7+a004 170m6414 bussmann 690 945000 1000 6 950 0950a-7+a004 170m6414 bussmann 690 945000 1000 6 1160 116...

Page 185

Dc fuses at inverter module input acs880-07-… type manufacturer v a 2 s a qty 170m6417 bussmann 690 1) 2450000 1400 4 1320a-5+a004 170m6417 bussmann 690 1) 2450000 1400 4 1450a-5+a004 170m6417 bussmann 690 1) 2450000 1400 4 1580a-5+a004 170m6417 bussmann 690 1) 2450000 1400 6 1800a-5+a004 170m6417 b...

Page 186: Dimensions And Weights

■ brake chopper dc fuses optional (+d150) brake choppers have two dc fuses each. The fuse type is bussmann 170m8635 (630 a 1000 v). Dimensions and weights see chapter dimensions (page 205) free space requirements the values are as required by cooling. Also obey the general installation rules given u...

Page 187

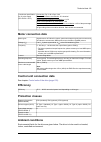

Noise heat dissipation air flow acs880-07-… db(a) kw ft 3 /min m 3 /h 74 27 3367 5720 1580a-5 75 32 4208 7150 1800a-5 75 36 4208 7150 1980a-5 u n = 500 v, 12-pulse connection 73 16 3367 5720 0990a-5+a004 74 22 3367 5720 1320a-5+a004 74 25 3367 5720 1450a-5+a004 74 27 3367 5720 1580a-5+a004 75 32 420...

Page 188: Sine Output Filter Data

Sine output filter data sine output filters are available as option +e206. The table below shows the types and technical data of the filters and filter cubicles used in drives. The standard filters listed require no current derating. For availability of sine output filters for other types, contact y...

Page 189: Input Cable Sizes

Input cable sizes the table below gives copper and aluminum cable types with concentric copper shield for nominal current. Us 2) iec 1) acs880-07-… ground wire size cu cable size cu cable size al cable size awg/kcmil awg/kcmil mm 2 mm 2 u n = 400 v 1/0 3 × 250 4 × (3 × 240 + 120) 6 × (3 × 150 + 41 c...

Page 190

Us 2) iec 1) acs880-07-… ground wire size cu cable size cu cable size al cable size awg/kcmil awg/kcmil mm 2 mm 2 2/0 6 × 300 8 × (3 × 240 + 120) 12 × (3 × 185 + 57 cu) 2300a-7+a004 4/0 11 × 400 9 × (3 × 240 + 120) 14 × (3 × 185 + 57 cu) 2600a-7 4/0 8 × 4/0 12 × (3 × 150 + 70) 12 × (3 × 240 + 72 cu)...

Page 191: Output Cable Sizes

Output cable sizes the table below gives copper and aluminum cable types with concentric copper shield for nominal current. Note: if the drive is not equipped with option common motor terminal cubicle (option +h359) or common output terminal (option +h366), each inverter module of the drive is to be...

Page 192

Us 2) iec 1) acs880-07-… cu cable size cu cable size al cable size awg/kcmil mm 2 mm 2 10 × 400 8 × (3 × 240 × 120) 12 × (3 × 185 + 57 cu) 2300a-7+a004 11 × 400 15 × (3 × 120 × 70) 15 × (3 × 150 + 41 cu) 2600a-7 2600a-7+a004 11 × 500 15 × (3 × 120 × 70) 15 × (3 × 185 + 57 cu) 2860a-7 2860a-7+a004 +a...

Page 193: Motor Connection Data

Connection: dy 11 d0 or dyn 11 d0 transformer specification for 12-pulse supply (iec 60076-1:2011) phase shift between secondaries: 30° electrical voltage difference between secondaries: short-circuit impedance of secondaries: > 5% short-circuit impedance difference between secondaries: ≤ 10% of the...

Page 194: Materials

Transportation in the protective package storage in the protective package operation installed for stationary use - - 0…2000 m (0…6562 ft) above sea level. For alti- tudes over 2000 m, contact abb. Installation site altitude output derated above 1000 m (3281 ft). -40 to +70 °c (- 40 to +158 °f) -40 ...

Page 195: Applicable Standards

Standard package: package • timber, polyethylene sheet (thickness 0.15 mm), stretch film (thickness 0.023 mm), pp tape, pet strap, sheet metal (steel) • for land and air transport when planned storage time is less than 2 months or when storage can be arranged in clean and dry conditions less than 6 ...

Page 196

Information standard enclosures for electrical equipment, non-environmental considerations ul 50 12th edition:2007 industrial control equipment csa c22.2 no. 14-13:2013 adjustable speed drives csa c22.2 no. 274- 13:2013 196 technical data.

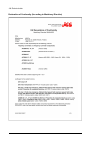

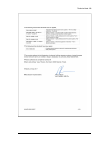

Page 197: Ce Marking

Ce marking a ce marking is attached to the product to signify that it conforms to all applicable european union legislation. ■ compliance with the european low voltage directive the compliance with the european low voltage directive has been verified according to appropriate european harmonized stan...

Page 198

Declaration of conformity (according to machinery directive) 198 technical data.

Page 199

Technical data 199.

Page 200

Compliance with en 61800-3:2004 ■ definitions emc stands for electromagnetic compatibility. It is the ability of electrical/electronic equipment to operate without problems within an electromagnetic environment. Likewise, the equipment must not disturb or interfere with any other product or system w...

Page 201

Warning! A drive of category c3 is not intended to be used on a low-voltage public network which supplies domestic premises. Radio frequency interference is expected if the drive is used on such a network. ■ category c4 if the provisions under category 3 cannot be met, the requirements of the standa...

Page 202: Ul And Csa Markings

Ul and csa markings the drive is c-ul-us listed (with option +c129) and csa certified (with option +c134). The approvals are valid with rated voltages up to 600 v. The appropriate marking is attached to the drive when either option is selected. ■ ul and csa checklist • use the drive in a heated, ind...

Page 203

Note torque size strength class 8.8 4 n·m (35 lbf·in) m5 strength class 8.8 9 n·m (6.6 lbf·ft) m6 strength class 8.8 22 n·m (16 lbf·ft) m8 strength class 8.8 42 n·m (31 lbf·ft) m10 strength class 8.8 70 n·m (52 lbf·ft) m12 strength class 8.8 120 n·m (90 lbf·ft) m16 ■ mechanical connections note max....

Page 204: Disclaimers

Disclaimers ■ generic disclaimer the manufacturer shall have no obligation with respect to any product which (i) has been improperly repaired or altered; (ii) has been subjected to misuse, negligence or accident; (iii) has been used in a manner contrary to the manufacturer’s instructions; or (iv) ha...

Page 205: Dimensions

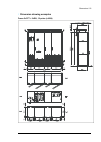

Dimensions cabinet line-up dimensions the drive consists of cubicles built into a cabinet line-up. The tables below show the composition of cabinet line-ups for each frame size and the standard combinations of options. The dimensions are in millimeters (for inches, divide by 25.4). Notes: • the side...

Page 206

■ dimension tables 1×d8t + 2×r8i – 6-pulse connection line-up width shipping split widths brake resistor 3 1) brake chopper 3 1) brake resistor 2 1) brake chopper 2 1) brake resistor 1 1) brake chopper 1 1) joining cubicle sine filter cu- bicle common motor terminal cubicle inverter module cubicle s...

Page 207

2×d7t + 2×r8i – 12-pulse connection (option +a004), without grounding switch (no option +f259) line-up width shipping split widths brake resistor 3 1) 1) brake chopper 3 brake resistor 2 1) brake chopper 2 1) brake resistor 1 1) brake chopper 1 1) joining cubicle sine filter cu- bicle common motor t...

Page 208

2×d7t + 2×r8i – 12-pulse connection (option +a004), with grounding switch (option +f259) line-up width shipping split widths brake resistor 3 1) brake chopper 3 1) brake resistor 2 1) brake chopper 2 1) brake resistor 1 1) brake chopper 1 1) joining cubicle sine filter cu- bicle common motor termina...

Page 209

2×d8t + 2×r8i – 6-pulse connection, 690 v line-up width shipping split widths brake resistor 3 1) brake chopper 3 1) brake resistor 2 1) brake chopper 2 1) brake resistor 1 1) brake chopper 1 1) joining cubicle sine filter cu- bicle common motor terminal cubicle joining cubicle inverter module cubic...

Page 210

2×d8t + 2×r8i – 12-pulse connection (option +a004), with grounding switch (option +f259) line-up width shipping split widths brake resistor 3 1) brake chopper 3 1) brake resistor 2 1) brake chopper 2 1) brake resistor 1 1) brake chopper 1 1) joining cubicle common motor terminal cubicle inverter mod...

Page 211

3×d8t + 4×r8i line-up width inverter module cu- bicle 2 common motor termin- al cubicle inverter module cu- bicle 1 supply mod- ule cubicle adapter for top cable entry incoming cu- bicle (icu) auxiliary control cu- bicle (acu) 3000 600 600 800 600 400 3200 600 600 800 200 600 400 3400 600 400 600 80...

Page 212

4×d8t + 5×r8i line-up width shipping split widths inverter module cubicle 1 common motor terminal cubicle inverter module cubicle 1 joining cubicle incoming cubicle (icu) 2 2) adapter for top cable entry 2 2) supply module cubicle 2 supply module cubicle 1 adapter for top cable entry 1 incoming cubi...

Page 213

■ dimension drawing examples frame 2×d7t + 2×r8i, 12-pulse (+a004) dimensions 213.

Page 214

Frame 1×d8t + 2×r8i (ip22) 214 dimensions.

Page 215

Frame 1×d8t + 2×r8i, ip54 (+b055) dimensions 215.

Page 216

Frame 1×d8t + 2×r8i with common motor terminal cubicle (+h359), 1/2 216 dimensions.

Page 217

Frame 1×d8t + 2×r8i with common motor terminal cubicle (+h359), 2/2 dimensions 217.

Page 218

Frame 1×d8t + 2×r8i with brake choppers and resistors (+d150 +d151), 1/2 218 dimensions.

Page 219

Frame 1×d8t + 2×r8i with brake choppers and resistors (+d150 +d151), 2/2 dimensions 219.

Page 220

Frame 1×d8t + 2×r8i with sine output filter (+e206), 1/2 220 dimensions.

Page 221

Frame 1×d8t + 2×r8i with sine output filter (+e206), 2/2 dimensions 221.

Page 222

Frame 2×d8t + 2×r8i, 12-pulse (+a004) with grounding switch (+f259) 222 dimensions.

Page 223

Frame 2×d8t + 3×r8i, 1/2 dimensions 223.

Page 224

Frame 2×d8t + 3×r8i, 2/2 224 dimensions.

Page 225

Frame 2×d8t + 3×r8i with common motor terminal cubicle (+h359), 1/2 dimensions 225.

Page 226

Frame 2×d8t + 3×r8i with common motor terminal cubicle (+h359), 2/2 226 dimensions.

Page 227

Frame 2×d8t + 3×r8i with top entry / top exit (+h351/+h353), 1/2 dimensions 227.

Page 228

Frame 2×d8t + 3×r8i with top entry/top exit, 2/2 228 dimensions.

Page 229

Frame 3×d8t + 4×r8i, 1/2 dimensions 229.

Page 230

Frame 3×d8t + 4×r8i, 2/2 230 dimensions.

Page 231

Frame 3×d8t + 4×r8i with common motor terminal cubicle (+h359), 1/2 dimensions 231.

Page 232

Frame 3×d8t + 4×r8i with common motor terminal cubicle (+h359), 2/2 232 dimensions.

Page 233

Frame 3×d8t + 4×r8i with top entry / top exit (+h351/+h353), 1/2 dimensions 233.

Page 234

Frame 3×d8t + 4×r8i with top entry / top exit (+h351/+h353), 2/2 234 dimensions.

Page 235

Frame 4×d8t + 5×r8i (6-pulse) with top entry/exit, ul listed (+c129), 1/2 dimensions 235.

Page 236

Frame 4×d8t + 5×r8i (6-pulse) with top entry/exit, ul listed (+c129), 2/2 236 dimensions.

Page 237

■ dimensions of empty cubicles (options +c199, +c200, +c201) ip22/ip42 dimensions 237.

Page 238

Ip54 238 dimensions.

Page 239

Location and size of input terminals note: see the dimension tables as to which incoming cubicles are used with which drive type and options. ■ 400 mm, bottom cable entry ■ 400 mm, top cable entry dimensions 239.

Page 240

■ 600 mm, without main breaker, bottom cable entry (including 12-pulse units with grounding switch) ■ 600 mm, without main breaker, top cable entry (including 12-pulse units with grounding switch) 240 dimensions.

Page 241

■ 600 mm, 12-pulse units without grounding switch, bottom cable entry ■ 600 mm, 12-pulse units without grounding switch, top cable entry dimensions 241.

Page 242

■ 600 mm, with main breaker, bottom cable entry ■ 600 mm, with main breaker, top cable entry 242 dimensions.

Page 243

■ 1000 mm (ul/csa), top cable entry dimensions 243.

Page 244

■ 1000 mm (ul/csa), bottom cable entry 244 dimensions.

Page 245

Location and size of output terminals ■ units without common motor terminal cubicle (no option +h359) inverter module cubicle with two r8i modules, bottom cable exit (no +h353) 222 dimensions location and size of output terminals (units without common motor terminal cubicle) frame 1×r8i + 1×r8i (wit...

Page 246

Inverter module cubicle with three r8i modules, bottom cable exit (no +h353) dimensions 223 inverter module cubicle with two r8i modules, top cable exit inverter module cubicle with three r8i modules, bottom cable exit inverter module cubicle with three r8i modules, top cable exit (+h353) 224 dimens...

Page 247

Brake chopper cubicle sine filter (+e206) cubicle, 1000 mm, bottom cable exit (no +h353) dimensions 225 sine filter (+e206) cubicle, 400 mm, top cable exit sine filter (+e206) cubicle, 1000 mm, bottom cable exit xxxxx adg2 ei konffaa tällaista. Dimensions 247.

Page 248

Sine filter (+e206) cubicle, 1000 mm, top cable exit (+h353) 226 dimensions sine filter (+e206) cubicle, 1000 mm, top cable exit 248 dimensions.

Page 249: Motor Terminal Cubicle)

■ units with common motor terminal cubicle (option +h359) note: see the dimension tables to which common motor terminal cubicle width is used with which drive type. Cubicle width 300 mm, bottom cable exit dimensions 245 location and size of output terminals (units with common motor terminal cubicle)...

Page 250

Cubicle width 300 mm, top cable exit 246 dimensions cubicle width 300 mm, top cable exit cubicle width 300 mm (double-busbar version), top cable exit dimensions 229 cubicle width 300 mm (double-busbar version), top cable exit cubicle width 400 mm, bottom cable exit 250 dimensions.

Page 251

Cubicle width 400 mm, bottom cable exit dimensions 247 cubicle width 400 mm, bottom cable exit cubicle width 400 mm, top cable exit cubicle width 400 mm, top cable exit dimensions 247 cubicle width 400 mm, bottom cable exit cubicle width 400 mm, top cable exit dimensions 251.

Page 252

Cubicle width 600 mm, bottom cable exit 248 dimensions cubicle width 600 mm, bottom cable exit cubicle width 600 mm, top cable exit cubicle width 600 mm, top cable exit 248 dimensions cubicle width 600 mm, bottom cable exit cubicle width 600 mm, top cable exit 252 dimensions.

Page 253: Contents Of This Chapter

The safe torque off function contents of this chapter this chapter describes the safe torque off (sto) function of the inverter unit of the acs880-07 and gives instructions for its use. Description the safe torque off function can be used, for example, to construct safety or supervision circuits tha...

Page 254: Wiring

Name standard functional safety of electrical/electronic/programmable electronic safety- related systems – part 1: general requirements iec 61508-1:2010 functional safety of electrical/electronic/programmable electronic safety- related systems – part 2: requirements for electrical/electronic/program...

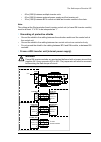

Page 255

• 60 m (200 ft) between multiple inverter units • 60 m (200 ft) between external power supply and first inverter unit • 30 m (100 ft) between bcu control unit and last inverter module in the chain. Note: the voltage at the inx terminals of each inverter control unit (or frame r8i inverter module) mu...

Page 256

■ multiple inverter units (internal power supply) the safe torque off function 235 multiple inverter units (internal power supply) +24 v out1 sgnd in1 in2 out1 sgnd in1 in2 out1 sgnd in1 in2 k xsto xsto xsto inverter unit control unit inverter unit control unit inverter unit control unit 256 the saf...

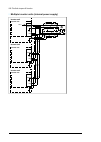

Page 257: Operation Principle

■ multiple inverter units (external power supply) 236 the safe torque off function multiple inverter units (external power supply) out1 sgnd in1 in2 out1 sgnd in1 in2 out1 sgnd in1 in2 +24 v 24 v dc – + k xsto xsto xsto inverter unit control unit inverter unit control unit inverter unit control unit...

Page 258

Start-up including acceptance test to ensure the safe operation of a safety function, validation is required. The final assembler of the machine must validate the function by performing an acceptance test. The acceptance test must be performed • at initial start-up of the safety function • after any...

Page 259: Use

Action close the disconnector and switch the power on. Test the operation of the sto function when the motor is stopped. • give a stop command for the drive (if running) and wait until the motor shaft is at a standstill. Ensure that the drive operates as follows: • open the sto circuit. The drive ge...

Page 260: Maintenance

Warning! The safe torque off function does not disconnect the voltage of the main and auxiliary circuits from the drive. Therefore maintenance work on electrical parts of the drive or the motor can only be carried out after isolating the drive from the main supply. Warning! The safe torque off funct...

Page 261: Fault Tracing

• when the safety integrity requirement for the safety function is sil 2 (hft = 1) or pl d (cat. 3), the proof test for the function must be performed at least every 12 months. The sto function of the drive does not contain any electromechanical components. In addition to proof testing, it is a good...

Page 262: Abbreviations

• the following temperature profile is used in safety value calculations: • 670 on/off cycles per year with Δ t = 71.66 °c • 1340 on/off cycles per year with Δ t = 61.66 °c • 30 on/off cycles per year with Δ t = 10.0 °c • 32 °c board temperature at 2.0% of time • 60 °c board temperature at 1.5% of t...

Page 263

Description reference abbr. Proof test interval. T1 is a parameter used to define the probabilistic failure rate (pfh or pfd) for the safety function or subsystem. Per- forming a proof test at a maximum interval of t1 is required to keep the sil capability valid. The same interval must be followed t...

Page 264

264.

Page 265: Resistor Braking

Resistor braking contents of this chapter this chapter tells how to select, protect and wire brake choppers and resistors. The chapter also contains the related technical data. Operating principle the brake chopper handles the energy generated by a decelerating motor. During the deceleration, motor ...

Page 266: Technical Data

Factory-installed brake choppers and resistors the following brake choppers (option +d150) and resistors (+d151) are available for the drive as factory-installed. It is also possible to use option +d150 with a custom resistor assembly. Brake resistor type (+d151) brake chopper type (+d150) acs880-07...

Page 267

Resistance of specified resistors (per chopper). This is also the minimum allowed resistance for the resistor assembly. R maximum short-term (1 min every 10 mins) braking power p brmax maximum continuous power rating p brcont maximum peak current i max maximum braking power for the specified duty cy...

Page 268

Custom resistor resistors other than those available as option +d151 can be used provided that • the resistance is not lower than the value given in the ratings table warning! Never use a brake resistor with a resistance below the value specified for the particular drive / brake chopper / resistor c...

Page 269

■ selecting and routing the cables of a custom resistor use the same cable type for the resistor cabling as for the drive input cabling to ensure that the input fuses also protect the resistor cable. Alternatively, a two conductor shielded cable with the same cross-sectional area can be used. Minimi...

Page 270

Thermal protection of the resistors the standard resistors available as option +d151 are equipped with a thermal switch. The switches of the resistors are wired in series and connected to the enable input of the brake chopper. The relay output of the chopper is wired to the supply control unit so th...

Page 271: Connection Procedure

• at the chopper end of the cable, connect the r+ and r- conductors of the resistor cable together. Measure the insulation resistance between the combined conductors and the pe conductor by using a measuring voltage of 1 kv dc. The insulation resistance must be higher than 1 mohm. 268 resistor braki...

Page 272

27 2.

Page 273

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/searchcha...

Page 274

Contact us www.Abb.Com/drives www.Abb.Com/drivespartners 3aua0000143261 e (en) effective 2017-06-05 3aua0000143261e.