- DL manuals

- ABB

- Transformer

- Relion 615 series

- Installation Manual

ABB Relion 615 series Installation Manual

Summary of Relion 615 series

Page 1

Relion ® protection and control 615 series installation manual.

Page 3

Document id: 1mrs756375 issued: 2012-05-11 revision: k product version: 4.0 © copyright 2012 abb. All rights reserved.

Page 4

Copyright this document and parts thereof must not be reproduced or copied without written permission from abb, and the contents thereof must not be imparted to a third party, nor used for any unauthorized purpose. The software or hardware described in this document is furnished under a license and ...

Page 5

Disclaimer the data, examples and diagrams in this manual are included solely for the concept or product description and are not to be deemed as a statement of guaranteed properties. All persons responsible for applying the equipment addressed in this manual must satisfy themselves that each intende...

Page 6

Conformity this product complies with the directive of the council of the european communities on the approximation of the laws of the member states relating to electromagnetic compatibility (emc directive 2004/108/ec) and concerning electrical equipment for use within specified voltage limits (low-...

Page 7

Safety information dangerous voltages can occur on the connectors, even though the auxiliary voltage has been disconnected. Non-observance can result in death, personal injury or substantial property damage. Only a competent electrician is allowed to carry out the electrical installation. National a...

Page 9

Table of contents section 1 introduction.......................................................................5 this manual........................................................................................5 intended audience........................................................................

Page 10

Rack mounting the ied in a combiflex 19" equipment frame (type rhgt 19" 4u variant c)....................................................34 mounting lens sensors for an arc protection system...................36 replacing a strömberg sp_j40 series relay by a 615 series ied..............................

Page 11

Section 9 glossary.........................................................................73 table of contents 615 series 3 installation manual.

Page 12

4.

Page 13

Section 1 introduction 1.1 this manual the installation manual contains instructions on how to install the ied. The manual provides procedures for mechanical and electrical installation. The chapters are organized in chronological order in which the ied should be installed. 1.2 intended audience thi...

Page 14

The installation manual contains instructions on how to install the ied. The manual provides procedures for mechanical and electrical installation. The chapters are organized in chronological order in which the ied should be installed. The operation manual contains instructions on how to operate the...

Page 15

1.4 symbols and conventions 1.4.1 symbols the electrical warning icon indicates the presence of a hazard which could result in electrical shock. The warning icon indicates the presence of a hazard which could result in personal injury. The caution icon indicates important information or warning rela...

Page 16

The function can be enabled and disabled with the operation setting. • parameter values are indicated with quotation marks. The corresponding parameter values are "on" and "off". • ied input/output messages and monitored data names are shown in courier font. When the function starts, the start outpu...

Page 17

Section 2 environmental aspects 2.1 sustainable development sustainability has been taken into account from the beginning of the product design including the pro-environmental manufacturing process, long life time, operation reliability and disposing of the ied. The choice of materials and the suppl...

Page 18

Electronic waste. These handlers can sort the material by using dedicated sorting processes and dispose of the product according to the local requirements. Table 2: materials of the ied parts ied parts material case metallic plates, parts and screws steel plastic parts pc 1) , lcp 2) electronics plu...

Page 19

Section 3 unpacking, inspecting and storing 3.1 removing transport packaging ieds require careful handling. 1. Examine the delivered products to ensure that they have not been damaged during the transport. 2. Remove the transport packing carefully without force. 3. Attach the protective film (suppli...

Page 20

• check the ied to see if any damage occurred during transportation. If the ied has damaged during transportation, make a claim against the transport contractor, and notify the local abb representative. 3.2.4 returning an ied damaged in transit if damage has occurred during transport, appropriate ac...

Page 21

Section 4 mounting 4.1 checking environmental conditions and mounting space the mechanical and electrical environmental conditions at the installation site must be within the limits described in the technical manual. • avoid installation in dusty, damp places. Avoid places susceptible to rapid tempe...

Page 22

A070577 v4 en figure 1: detaching a plug-in unit from the case the ied features an automatic short-circuit mechanism in the ct connector. Therefore, detaching the plug-in unit will not open the secondary circuit of the ct which could cause dangerously high voltages. Do not touch terminals inside the...

Page 23

Before fitting the plug-in unit into the case, check that the unit and the case have the same serial number. 1 guid-bce48661-e92a-460e-8e72-4f0ea261fb9e v1 en figure 2: serial number in the case 1 rating label with serial number forcing a non-suitable plug-in unit into the case can break both the pl...

Page 24

A071115 v5 en figure 3: installing a plug-in unit into the case 4.2.3 sealing the plug-in unit the front panel of the ied has an integrated sealing screw. By default the screw is screwed all the way in and is not used when installing or detaching the plug-in unit. 1. Open the sealing screw about nin...

Page 25

1 2 guid-8158c704-bd99-42eb-a495-6bd015c240cd v1 en figure 4: sealing screw 1 sealing screw 2 sealing wire and seal 4.2.4 securing the handle the front panel of the ied has an integrated sealing screw. By default, the screw is screwed all the way in and not used when installing or detaching the plug...

Page 26

1 2 guid-10d2039e-4c58-4372-b0b2-edff0c2a451c v1 en figure 5: sealing screw with spacer 1 spacer 2 sealing screw 4.3 mounting the ied 4.3.1 required tools • t25 torx screwdriver for mounting the case • t20 torx screwdriver for connecting the protective earthing only use adjustable torque screwdriver...

Page 27

4.3.2 flush mounting the ied all the mounting elements are integrated in the ied. Requirements for installation: • panel cut-out of 165.5 x 161.5 mm • depth behind the panel 153 mm an ied equipped with optical connections requires a minimum depth of 180 mm. The allowed minimum bending radius has to ...

Page 28

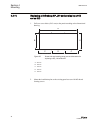

A b 1 1 a070581 v4 en figure 6: flush mounting a case into a panel cut-out a 165.5 ±1 mm 1 m5 fixing screws b 161.5 ±1 mm 3. Tighten the m5 (t25) screws. The allowed range for the fixing screws’ tightening torque is 0.7...1 nm. Section 4 1mrs756375 k mounting 20 615 series installation manual.

Page 29

A070582 v4 en figure 7: flush mounted case, tightening the m5 fixing screws 4. Install the plug-in unit into the case. 1mrs756375 k section 4 mounting 615 series 21 installation manual.

Page 30

A b d e f g c a070584 v4 en figure 8: flush mounted case and plug-in unit a 177 mm b 177 mm c 164 mm d 201 mm e 153 mm f 48 mm g 160 mm 4.3.3 semi-flush mounting the ied a mounting kit is needed for semi-flush mounting the ied. In addition to the detailed mounting instructions, the mounting kit incl...

Page 31

• raising frame • gasket • screws requirements for installation: • panel cut-out of 165.5 x 161.5 mm with mounting holes • depth behind the panel 103 mm • when ip 54 degree of protection (according to iec 60529) is required for the front side, a gasket has to be used in the installation. 1. Mount th...

Page 32

A070590 v4 en figure 10: mounting the case 4. Tighten the m5 screws. The allowed range for the fixing screws’ tightening torque is 0.7...1 nm. 5. Install the plug-in unit into the case. Section 4 1mrs756375 k mounting 24 615 series installation manual.

Page 33

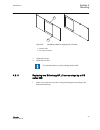

A b c d e f a070591 v4 en figure 11: semi-flush mounted ied a 186 mm b 177 mm c 201 mm d 103 mm e 98 mm f 160 mm check the allowed minimum bending radius from the optical cable manufacturer. 4.3.4 semi-flush mounting the ied inclined a mounting kit is needed for semi-flush mounting the ied inclined....

Page 34

• panel cut-out of 167 x 203 mm with mounting holes • depth behind the panel 107 mm • when ip 54 degree of protection (according to iec 60529) is required for the front side, a gasket has to be used in the installation. 1. Mount the angle frame into the panel cut-out with four m4 screws. A b c d e f...

Page 35

A b c g 1 2 3 4 5 d e f a071314 v4 en figure 13: ied semi-flush mounted inclined a 25 ° 1 m4 screws b 221 mm 2 gasket c 9 mm 4 case d 107 mm 3 angled frame e 133 mm 5 plug-in unit f 230 mm g 190 mm 4.3.5 rack mounting the ied a mounting kit is needed for rack mounting the ied. In addition to the det...

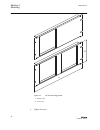

Page 36

A b a070580 v3 en figure 14: 19” rack mounting panels a 482.6 mm (19") b 177 mm (4u) 4. Tighten the screws. Section 4 1mrs756375 k mounting 28 615 series installation manual.

Page 37

The allowed range for the fixing screws’ tightening torque is 0.7...1 nm. 5. Install the plug-in unit into the case. A070579 v4 en figure 15: rack mounted ied 4.3.6 wall mounting the ied a mounting kit is needed for wall mounting the ied. In addition to the detailed mounting instructions, the wall m...

Page 38

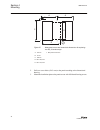

A a070593 v4 en figure 16: wall mounting the ied a 430 mm 6. Tighten the screws. The allowed range for the fixing screws’ tightening torque is 0.7...1 nm. Section 4 1mrs756375 k mounting 30 615 series installation manual.

Page 39

A b c a070592 v4 en figure 17: wall mounted ied a 214 mm b 177 mm c 270 mm minimum of 50 mm space is needed between two kits. When connecting the wires, a wall-mounted ied can be pulled out and turned 45° (or 90°) degrees downwards or upwards. • to release the ied for pulling it out, push the locks ...

Page 40

A a070594 v4 en figure 18: wall mounted ied in rotated position a 455 mm minimum of 50 mm space is needed above and below the frame for rotating. 4.3.7 rack mounting the ied and test switch rtxp to a 19” equipment frame a mounting kit is needed for rack mounting the ied in a 19" equipment frame. In ...

Page 41

• mounting panel • metallic frame for mounting the rtxp 18 or 24 test switch to the panel an ied equipped with optical connections requires a minimum depth of 180 mm. The allowed minimum bending radius has to be checked from the optical cable manufacturer. To rack mount the ied into a 19" equipment ...

Page 42

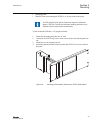

A070588 v4 en figure 20: ied and the test switch rtxp 18 mounted into a 19" equipment panel 4.3.8 rack mounting the ied in a combiflex 19" equipment frame (type rhgt 19" 4u variant c) a mounting bracket is needed for rack mounting the ied into a combiflex 19" equipment frame, a different bracket is ...

Page 43

1 2 3 a070576 v4 en figure 21: mounting the ied into a 19" combiflex equipment frame 1 rhgt 19" 4u equipment frame, variant c, with support frame 2 tapping screw st3.5x13 3 mounting bracket 6. Install the optional rtxp 18 or 24 test switch. 1mrs756375 k section 4 mounting 615 series 35 installation ...

Page 44

1 2 3 a070575 v4 en figure 22: ied and the test switch 1 rhgt 19" 4u equipment frame, variant c, with support frame 2 tapping screw st3.5x13 3 mounting bracket for mounting with test switch rtxp 18 4.3.9 mounting lens sensors for an arc protection system arc protection is used to detect arc situatio...

Page 45

A b c d a040183 v2 en figure 23: dimensions of the lens sensor a 3.5 mm b 10 mm c ∅ 9.5 mm d 19 mm 2. Fit the lens sensor into the hole and fasten it with a self-tapping m3 screw. Alternatively, the lens sensor can be fastened with a cable tie. To do this, secure the cable tie to a suitable point of...

Page 46

4.3.10 replacing a strömberg sp_j40 series relay by a 615 series ied 1. Drill new screw holes ( ∅4.5 mm) to the panel according to the dimensional drawing. E c d c b a guid-c7ca77aa-74ea-40d2-b98e-84735bcadda2 v1 en figure 25: screw hole and existing panel cut-out dimensions for replacing a sp_j40 s...

Page 47

1 2 guid-b5a98f9f-e10d-4f92-a1ed-73d9b7719916 v1 en figure 26: installation plates for replacing sp_j40 relay 1 installation plate 2 torx head screw m5x10 3. Tighten the screws. 4. Mount the new ied. For ordering numbers, see the ordering number table. 4.3.11 replacing two strömberg sp_j3 series rel...

Page 48

1 d e a b c a guid-7d44f5de-6452-455a-8076-2a67fd463cc7 v1 en figure 27: new panel cut-out and screw hole dimensions for replacing two sp_j3 series relays a 155 mm 1 new panel cut-out line b 15 mm c 196 mm d min. 165,5 mm e min. 161,5 mm 2. Drill new screw holes ( ∅4.5 mm) to the panel according to ...

Page 49

1 2 guid-24cf4d5d-1eae-487a-a1de-557df59658b0 v1 en figure 28: installation plate for replacing two sp_j3 relays 1 installation plate 2 torx head screw m5x10 4. Tighten the screws. 5. Mount the new ied. For ordering numbers, see the ordering number table. 4.3.12 replacing a strömberg sp_j3/j6 series...

Page 50

D a c b guid-f1b5da9a-05ed-419f-a795-6fd6e2a4cf95 v1 en figure 29: screw hole and existing panel cut-out dimensions for replacing a sp_j3/j6 series relay a 446 mm b 196 mm c 460 mm d 114,5 mm section 4 1mrs756375 k mounting 42 615 series installation manual.

Page 51

1 2 3 guid-90bdc1ba-f671-4178-8136-8e8d9e56a7a3 v1 en figure 30: installation plates for replacing sp_j3/j6 relay in 19" rack 1 installation plate 2 torx head screw m6x20 3 hexagon nut m6 2. Tighten the screws. 3. Mount the new ied with the mounting frame to the installation plate. For ordering numb...

Page 52

D c b a guid-57fa3f1b-c6eb-43a4-80e8-5d13cd08d9ff v1 en figure 31: screw hole and existing panel cut-out dimensions for a sp_j6 series relay a 186 ± 1 mm b 186 ± 1 mm c 196 mm d 196 mm 2. Mount the installation plate to the existing panel cut-out with m5 thread forming screws. Section 4 1mrs756375 k...

Page 53

11 22 guid-2b059f45-1287-4d8d-92a6-e6583b0adaeb v1 en figure 32: installation plate for replacing sp_j6 relay 1 installation plate 2 torx head screw m5x10 3. Tighten the screws. 4. Mount the new ied. For ordering numbers, see the ordering number table. 4.3.14 replacing three bbc s_ series relays by ...

Page 54

A b c c d guid-a309a8c4-5ab1-4859-91d2-cd8c4556ba7f v1 en figure 33: existing panel cut-out and screw hole dimensions for three bbc s_ series relays a 92 mm b 234 mm c 100 mm d 250 mm section 4 1mrs756375 k mounting 46 615 series installation manual.

Page 55

1 guid-fec7a3b8-7a65-4acf-bdeb-dd8bb2bf5f57 v1 en figure 34: new panel cut-out for replacing bbc s_ series relays 1 new panel cut-out line 2. Mount the installation plate to the panel cut-out with m5 screws, nuts and washers. Use the existing screw holes. 1mrs756375 k section 4 mounting 615 series 4...

Page 56

2 3 4 11 guid-71136c37-e662-426d-b378-9bf21adfc51a v1 en figure 35: installation plate for replacing three bbc s_ relays 1 installation plate 2 torx head screw m5x16 3 hexagon nut m5 4 spring washer 3. Tighten the screws. 4. Mount the new ied. For ordering numbers, see the ordering number table. Sec...

Page 57

4.3.15 replacing a spa 300 series relay by a 615 series ied 1. Make a new panel cut-out to the existing mounting panel according to the dimensional drawing. B a e d c guid-f20d587e-5e99-4593-b9ee-a1b125a95524 v1 en figure 36: new panel cut-out and screw hole dimensions for replacing a spa 300 series...

Page 58

11 22 guid-a8741360-1066-494d-9340-3da0af81e778 v1 en figure 37: installation plate for replacing spa 300 relay 1 installation plate 2 torx head screw m5x10 4. Tighten the screws. 5. Mount the new ied. Use a raising frame if needed. For ordering numbers, see the ordering number table. 4.3.16 replaci...

Page 59

Section 5 connecting 5.1 required tools only use a screwdriver and insert bits for phillips (ph 1) cross-recessed head screws (m3.5) when handling ct/vt terminals (x120) of screw-compression type. A b a071178 v2 en figure 38: screwdriver for ct/vt terminals of screw-compression type a max ∅5.5 mm b ...

Page 60

See the application manual for product-specific connection diagrams. 5.2.1 connecting ring-lug type wires ring-lug type insulated terminal can be used for signal connector x120. The maximum outside diameter for the m4 ring-lug type terminals is 9 mm. 5.3 connecting protective earthing the earth lead...

Page 61

The earth lead should be as short as possible but notice that extra length is required for door mounting. Each ied must have its own earth lead connected to the earth circuit connector. 2. Connect the earth lead to the earth bar. Use either stripped wire screwed between a washer cup and the protecti...

Page 62

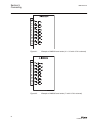

Guid-cc5faadb-60c3-43ef-a172-7572ff85fc44 v1 en figure 41: example of aim0004 card variant (4 i + 3 u with 1/5 a io channel) guid-cab8daaa-8a15-4af6-afc7-ca232d253f3d v3 en figure 42: example of aim0005 card variant (7 i with 1/5 a io channel) section 5 1mrs756375 k connecting 54 615 series installa...

Page 63

Guid-7fc759cb-afc5-4029-972a-bfc8677763f9 v3 en figure 43: example of aim0006 card variant (5 u) guid-7473ceba-aa9c-4f58-8091-f9717aee7f3a v1 en figure 44: example of aim0013 card variant (4 i + 3 u with 0.2/1 a io channel) 1mrs756375 k section 5 connecting 615 series 55 installation manual.

Page 64

A071228 v4 en figure 45: example of aim0016 card variant (4 i with 1/5 a io channel) a071232 v4 en figure 46: example of aim0017 card variant (4 i with 0.2/1 a io channel) section 5 1mrs756375 k connecting 56 615 series installation manual.

Page 65

A071230 v4 en figure 47: example of aim0018 card variant (4 i + uo with 1/5 a io channel) a071234 v4 en figure 48: example of aim0019 card variant (4 i + uo with 0.2/1 a io channel) 1mrs756375 k section 5 connecting 615 series 57 installation manual.

Page 66

5.4.2 connecting rtd and ma inputs connect the wires from the transducers to the correct device according to the connection diagram. Each terminal for rtds and ma inputs is dimensioned for one 0.5...2.5 mm 2 wire or for two 0.5...1.0 mm 2 wires. See the specific card variant from the application man...

Page 67

5.5 connecting binary signals connect the wires for the binary signals to the correct device according to the connection diagram. Each terminal for binary input and output signal is dimensioned for one 0.5...2.5 mm 2 wire or for two 0.5...1.0 mm 2 wires. See the specific card variant from the applic...

Page 68

Guid-ed2ea005-c136-4db1-b71f-b828997a6edb v1 en figure 51: example of bio0006 card variant (6 bi + 3 bo) 5.6 connecting power supply the ied's auxiliary voltage is connected to terminals x100-1 and x100-2. The positive lead is connected to terminal x100-1. The permitted auxiliary voltage range of th...

Page 69

7 6 7 8 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 5 4 3 2 1 8 6 23 1 2 3 4 5 9 10 11 12 13 14 15 16 17 18 19 20 21 22 24 1 2 a070770 v1 en figure 52: connecting auxiliary voltage 5.7 connecting communication before connecting communication, check that the hw module has the correct communication...

Page 70

Before connecting the auxiliary power, check that the terminal strip is wired and placed correctly. Remove the protective film from the top side of the unit. Check that there is no debris visible in the ventilation holes. Guid-97a2d4ba-29fc-4e2f-8c4d-81ee5e77cf79 v1 en figure 53: removing the protec...

Page 71

Section 6 removing, repairing and exchanging 6.1 product lifecycle at some point of the product lifecycle, the ied will be upgraded to a next generation unit. When selecting the original product, already consider the upgrading and extension possibilities that the specific product offers for its whol...

Page 72

6.3 removing the ied 1. Turn off the power. 2. Detach the plug-in unit from the case. 3. Disconnect the wiring. 4. Loosen the four m5 fixing screws. A070582 v4 en 5. Detach the case from the panel cut-out. 6.4 sending the ied for repair in case of product problems, contact the nearest abb office or ...

Page 73

Section 7 technical data 7.1 case and hmi display variants 7.1.1 front side of the ied ieca070904 v3 en figure 54: small display 1mrs756375 k section 7 technical data 615 series 65 installation manual.

Page 74

Ieca070901 v3 en figure 55: large display table 3: small display character size 1) rows in the view characters per row small, mono-spaced (6x12 pixels) 5 20 large, variable width (13x14 pixels) 4 8 or more 1) depending on the selected language table 4: large display character size 1) rows in the vie...

Page 75

7.1.2 rear side of the ied a070596 v1 en figure 56: rear view of an 615 series ied with communication module 1mrs756375 k section 7 technical data 615 series 67 installation manual.

Page 76

7.2 dimensions a c d f e b guid-6ba24db4-935e-4b81-aee6-fd8b7fc4140f v2 en figure 57: 615 series main dimensions a 177 mm b 177 mm (4u) c 164 mm d 153 mm e 48 mm f 160 mm table 5: dimensions description value width frame 177 mm case 164 mm height frame 177 mm (4u) case 160 mm table continues on next...

Page 77

Description value depth 201 mm (153 + 48 mm) weight complete ied 4.1 kg plug-in unit only 2.1 kg 7.3 enclosure class table 6: degree of protection of flush-mounted ied description value front side ip 54 rear side, connection terminals ip 20 1mrs756375 k section 7 technical data 615 series 69 install...

Page 78

70

Page 79

Section 8 accessories and ordering data table 7: cables item order number cable for optical sensors for arc protection 1.5 m 1mrs120534-1.5 cable for optical sensors for arc protection 3.0 m 1mrs120534-3.0 cable for optical sensors for arc protection 5.0 m 1mrs120534-5.0 table 8: mounting accessorie...

Page 80

72.

Page 81

Section 9 glossary 615 series series of numerical ieds for low-end protection and supervision applications of utility substations, and industrial switchgear and equipment ct current transformer emc electromagnetic compatibility hmi human-machine interface iec international electrotechnical commissio...

Page 82

74.

Page 83

75.

Page 84

Contact us abb oy distribution automation p.O. Box 699 fi-65101 vaasa, finland phone +358 10 22 11 fax +358 10 22 41094 www.Abb.Com/substationautomation 1mrs756375 k © copyright 2012 abb. All rights reserved..