Bacchus BCS2000 Installation Manual

Installation Manual

BCS2000/3000

Supplies Needed for Installation

1. 3/8” and 5/8” copper tubing.

2. 1/4” copper water supply

3. 1/4” condensate vinyl drain tube/tube clamps

4. Provide 120v 15A circuit for indoor evaporator, and 120v/230v 30A, single or three

phase

(dependent upon your condensing unit) for outdoor condensing unit.

Check local codes.

5. 18-2 stat wire; to be used to extend temperature sensor, humidity sensor cable,

keyboard,

and master to slave control jumper.

6. Condensing unit pad

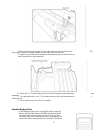

Condensing Unit Set Up

1. Place a (suggested model) on a firm level location (pad) for outdoor applications, or

add 4

anti-vibration pads to each corner of the condensing unit for indoor use. Place

in an area with adequate air flow.

2. Braze in suction and liquid lines to condensing unit.

3. Bring 3/8” copper tubing from the liquid line of the condensing unit to a spot

equidistant to both evaporators and solder that line into the run side of a 3/8” x 3/8” x

3/8” tee.

4. Braze both the 3/8” line to the liquid line of each evaporator from the run and branch

of the

tee.

1