- DL manuals

- Bad Boy

- Lawn Mower

- Outlaw XP 5400

- Owner's, Service & Parts Manual

Bad Boy Outlaw XP 5400 Owner's, Service & Parts Manual

Summary of Outlaw XP 5400

Page 1

Zero-turn mower owner’s, service & parts manual for additional information, please see us at www.Badboymowers.Com bad boy, inc. 102 industrial drive batesville, arkansas 72501 ©2015 12-11 outlaw xp models.

Page 2: Table of Contents

Table of contents basic information ................................................................................................ Section 1 (page 4) bad boy safety guidelines ............................................................................. Section 2 (pages 5–8) operation ...............

Page 3

This manual applies to the following equipment: bad boy outlaw xp series outlaw xp 5400 54˝ 852cc kawasaki fx-850 outlaw xp 6100 61˝ 852cc kawasaki fx-850 outlaw xp 7200 72˝ 852cc kawasaki fx-850 outlaw xp 6100 61˝ 993cc vanguard outlaw xp 7200 72˝ 993cc vanguard page 3 pump belt deck belt 54" blade...

Page 4: Section 1:

Section 1: basic information congratulations on the purchase of your new bad boy mower! The purpose of this manual is to assist operators in maintaining and operating their machine. The information and instructions in this manual can help you attain years of performance from your new bad boy. Also, ...

Page 5: Section 2:

Section 2: mower safety guidelines never allow untrained people to operate this machine. It is the owner’s responsibility to get training and see to it that anyone who has permission to use your machine receives the proper training. Do not mow around people. The factory discharge chute is designed t...

Page 6: Slope Operation

Slope operation slopes are a major factor related to loss of control and tip over accidents, which can result in severe injury or death. Operation on all slopes requires extra caution. If you cannot back up the slope, or you feel uneasy on it, do not mow it. 2.22 mow up and down slopes, not across. ...

Page 7: Service:

Service: safe handling of gasoline to avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive. 2.45 extinguish all cigarettes, cigars, pipes, and all other sources of ignition. 2.46 use only an approved gasoline co...

Page 8: Safety Interlock System

2.69 always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel. 2.70 park machine ...

Page 9: Section 3:

Section 3: mower operation never operate the machine with faulty equipment. Always be alert of sudden changes in landscape, as the mower will react differently on slopes or embankments than it will on flat surfaces. Never operate the mower with the discharge chute open. Do not cross terrain, other t...

Page 10: Section 4:

Section 4: mower maintenance first every 50 every 100 every daily 8 hours or hours or 250 section maintenance hours annually* annually* hours check and add engine oil ● section 3 section 2 ● (pump) 6 (deck) check condition of blades ● section 6 check for fule and oil leakage ● section 3 initial oil ...

Page 11

Page 11 performed: performed performed: performed performed performed: performed performed: performed performed performed: performed: performed performed performed performed performed: performed: performed: performed: performed: date: hours: date: hours: date: hours: date: hours: date: hours: date: ...

Page 12: Section 5:

Section 5: mower storage & transportation 5.1 keep machine from collecting debris by storing in a covered area while not in use. 5.2 fuel can harm your machine if left for more than 30 days without changing, especially if the fuel contains ethanol. Never use fuel with more than 10% ethanol by volume...

Page 13: Section 6:

Section 6: troubleshooting 6.1 q: how do i prevent an uneven cutting pattern and increase the quality of cut? 6.1 a: check tire pressure, check blade sharpness (replace blades or sharpen at least once per year or when needed), make sure blades are tightened properly, check spring and belt tension, c...

Page 14: Section 7:

Section 7: controls 7.1 ignition switch—bad boy mowers have a three position ignition switch: off, run, and start. With key inserted, rotate it clockwise to start position and release key when engine starts. Switch will automatically return to he run position. 7.2 throttle control—a cable is connect...

Page 15: Section 8:

Section 8: moving inoperable mower 8.1 do not tow machine. Use a winch to load on a trailer for transporting. 8.2 attention: return bypass valves to operating position before running mower following repairs. 8.3 if it is necessary to move mower when the engine is inoperable, the hydraulic drive pump...

Page 16: Section 10:

Section 10: mower blade maintenance 10.1 check mower blades after each use. This is essential for maintaining well-groomed turf. Keep the blades sharp. If a dull blade is used for cutting, the grass will tear rather than cut. This could damage the grass leaving a brown frayed top on the grass within...

Page 17

How to choose the right blade essentially there are only two basic styles of mowing blades used or approved for use on our current products: 1) the standard style of mowing blade is essentially designed for cutting grass and effectively discharging the clippings out from the deck to fall onto the la...

Page 18: Mowing Tips:

Mowing tips: • mow header strips at the ends of the lawn and around flower beds first. Make them wide enough that you can turn the mower around in the already mown section. Then mow back and forth between these header strips overlapping each lap by about 1/8 the width of the mower’s deck. • don’t cu...

Page 19: Service Section

Service section section 1: hydrostatic system page 19 the hydraulic reservoir tank on the outlaw xp model is located on each side of rear cover. There is a dipstick that indicates the current hydraulic oil level. Use only 20w-50 motor oil in this tank. Conventional or synthetic oil may be used. Bad ...

Page 20

5) fill the new hydraulic oil filters with 20w-50 motor oil. Only use bad boy replacement filters. 6) place the hydraulic return lines back onto the hydrogear pumps. Fill each hydraulic reservoir tank until the oil level reaches the bubble on the dipstick. Be careful not to overfill the hydraulic re...

Page 21

When adjusting the tracking on the mower, the length of the pushrods can be changed by screwing the pivot joint in or out on the ends of the rods. Shortening the overall length of the rod slows the pump down. Lengthening the rod will increase the speed of the pump. Page 21.

Page 22: Section 2: Drive Belt

Section 2: drive belt page 22 shown on the right is the tensioner for your pump belt. Adjusting this will either increase or decrease tension on the belt. Use a ¾” wrench to loosen the jam nuts and either tighten for more belt tension or loosen for less belt tension. The belt tension should be set t...

Page 23: Section 3: Engine

Section 3: engine page 23 kawasaki fx850v this machine has an oil drain hose installed on the engine to allow for easier oil changes. Bad boy recommends that the oil and filter be changed at intervals of 50 usage hours or yearly, whichever occurs first. The oil capacity is 2 quarts. Bad boy 10w-30 s...

Page 24

4) apply a thin film of clean oil to rubber gasket on new filter 5) refer to instructions on oil filter for proper installation. 6) fill crankcase with approximately 2 quarts of new oil. Level should top of indicator on dipstick. 7) reinstall oil fill/dipstick and tighten securely. 8) start engine; ...

Page 25

The air cleaner is the engine’s only defense against damaging foreign particles. It is very important that the air cleaner element is inspected prior to each use. Remove the element and tap its sides in order to remove debris. Do not blow the filter out using compressed air. Doing so will greatly re...

Page 26

3.4 changing the spark plugs and checking the spark plug gap: 1) remove the wire on the spark plug and use a 13/16” socket to remove the spark plug. 2) check the gap on the spark plug to verify that it is 0.03 in using a feeler gauge. 3) if the spark plug is worn, overheated, wet or carbon fouled re...

Page 27: 993Cc Vanguard

993cc vanguard this machine has an oil drain hose installed on the engine to allow for easier oil changes. Bad boy recommends that the oil and filter be changed at intervals of 50 usage hours or yearly, whichever occurs first. The oil capacity is 2 quarts. Bad boy 10w-30 synthetic blend engine oil i...

Page 28

The fuel filter is located in the fuel line about 12˝ from the carburetor on the side of the engine. Replace the filter yearly. Prior to the removal of the old filter, note the direction of fuel flow as indicated on the filter. Have towels readily available in order to quickly remove any fuel leakag...

Page 29

The air cleaner is the engine’s only defense against damaging foreign particles. It is very important that the air cleaner element is inspected prior to each use. Remove the element and tap its sides in order to remove debris. Do not blow the filter out using compressed air. Doing so will greatly re...

Page 30

3.4 changing the spark plugs and checking the spark plug gap: 1) remove the wire on the spark plug and use a 5/8” socket to remove the spark plug. 2) check the gap on the spark plug to verify that it is 0.03 in using a feeler gauge. 3) if the spark plug is worn, overheated, wet or carbon fouled repl...

Page 31: Section 4: Electrical System

Section 4: electrical system page 31 this mower is equipped with one protective fuse: a 30 amp main fuse (pictured to the right). A blown fuse usually indicates a problem within the electrical system or an electrical component. Ensure the battery terminals are tightly fastened. Never replace a fuse ...

Page 32

Page 32.

Page 33: Section 5: Frame

Section 5: frame page 33 the front fork nuts require a torque of 40ft-lbs. First remove the dust cap. While applying this torque, turn the fork itself to ensure no damage is done to the bearing. This operation is only necessary if a repair requires it. Torque rear wheel lugs to 65-75 ft. Lbs. Re-tor...

Page 34

The pump belt tensioner is located under the engine and has a grease fitting at its pivot point. Grease at every engine oil change. The deck belt tensioner is located at the rear of the deck and has a grease fitting on its pivot point. Grease at every engine oil change. The control arm blocks have g...

Page 35: Section 6: Cutting Deck

Section 6: cutting deck page 35 deck belt removal 1) remove ignition key. 2) raise the deck to its highest position. 3) remove the right pulley cover. 4) while lifting up on the belt (as shown in the photograph), rotate the pulley until the belt is free of the pulley. Exercise caution while performi...

Page 36

Page 36 leveling the deck 1) start on a flat level surface and set the air pressure in all four tires to 12 psi. 2) get two 2x4s and make sure that the wider sides are similar length. 3) take off the foot pedal and raise the floor plate. 4) lower the deck onto the 2x4s and pin the deck into its top ...

Page 37

The deck spring tension is critical. If the tension is too high, premature failure of the deck belt and blade spindles can occur. If the tension is too low, the belt can ‘jump off’ or slip on the pulleys. This results in reduced cut quality and early belt failure. Spring tension adjustments can be m...

Page 38

Blade removal: to change blades, it may be easier to use a piece of wood to keep the blade from turning so that the bolt can be loosened. Use a 15/16” socket and impact drill, or a wrench and an extension to gain more leverage. You might need to put a ¾” wrench on top of the pulley bolt to keep the ...

Page 39: Parts Section

Parts section page 39 parts list description part number qty item suspension fork top/side combo 023-0020-00 1 1 suspension fork - bottom left 023-0012-00 1 2 suspension fork - bottom right 023-0013-00 1 3 front suspension fork spindle 037-0010-00 1 4 1/2" flange nut 013-5300-00 2 5 1/2" x 1" hex bo...

Page 40

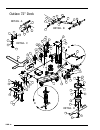

Page 40 25 30 27 8 18 17 8 9 8 26 20 18 17 7 6 4 28 24 15 15 11 21 13 10 23 22 16 12 14 29 oultaw xp drive arms 31 2 3 1 3 19 welded to frame 34 2 32 3 1 5 3 34 33.

Page 41

Page 41 parts list description part number qty item drive lever spring 034-8025-00 4 1 bushing for 2012 drive arms 032-5055-00 4 2 .515 id nylon shoulder washer 019-8027-00 8 3 1/4" press in grease fitting 024-6034-00 2 4 1/2-13 nylon flange nut 013-8050-00 2 5 5/16" nut 013-8043-00 2 6 5/16" x 3/4"...

Page 42

Page 42 detail a detail b a b 36 35 16 17 17 15 17 16 16 20 35 10 21 25 24 23 22 28 29 26 33 30 27 32 34 34 7 8 9 6 3 2 19 14 13 15 14 13 13 14 11 12 4 5 7 8 9 1 31 18 outlaw xp gas tank assemblies 37.

Page 43

Page 43 parts list description part number qty item 2016 outlaw seat bracket 080-5116-00 1 1 5/16-18 x 1 carriage bolts zinc 018-8065-00 4 2 .360 id plastic washer 019-6042-00 4 3 3/8" nylock flange nut 013-5202-00 2 4 3/8" x 1 1/4" carriage bolt 018-5043-00 2 5 5/16-18 nylon insert flange nut zinc ...

Page 44

Page 44 detail a detail b detail c a b c 65 1 2 36 38 33 34 35 37 39 20 16 13 12 12 11 13 18 18 18 17 15 21 17 19 67 22 23 7 6 9 10 8 3 4 5 3 44 54 55 52 56 49 50 53 48 51 26 28 27 26 47 26 31 30 29 32 40 42 43 41 44 24 25 60 59 58 57 61 26 62 53 26 27 28 46 71 43 45 69 70 14 64 63 68 66.

Page 45

Page 45 parts list description part number qty item 1/4" x 5/8" bs c/s 18-8 ss 018-8064-00 1 1 floor board cable w/ swivel ends 064-2006-00 1 2 5/16" nylock flange nut zinc 013-8049-00 3 3 5/16" x 1" carriage bolt 018-8065-00 2 4 .360 id plastic washer 019-6042-00 2 5 #10 x 1/2" self tapping screw 0...

Page 46

Page 46 detail a detail b a b 1 16 17 18 45 47 53 54 55 51 46 49 48 52 50 11 66 12 13 10 65 28 31 29 32 13 12 11 14 67 48 57 56 4 6 5 9 7 64 3 2 19 8 25 21 25 24 20 23 22 9 62 15 40 42 41 43 35 35 44 33 39 39 36 60 38 37 34 26 27 30 63 61 68 6 58 59 69.

Page 47

Page 47 parts list description part number qty item 2015 xp frame 070-5380-00 1 1 3/8" x 1 1/4" carriage bolt 018-5043-00 4 2 3/8 nylock nut 013-5041-00 4 3 1/4-20 x 1-1/4 gr 5 hex bolt 018-4702-00 2 4 14" rubber bumper 029-7037-00 1 5 1/4" flat washer 019-7040-00 4 6 2015 outlaw rear plate 026-2180...

Page 48

Page 48 detail b detail c b c 18 17 22 66 15 23 12 13 37 9 4 21 42 54 4 39 40 36 38 9 47 38 55 3 6 7 1 51 50 48 55 32 52 53 33 45 46 9 5 4 43 14 16 15 19 6 15 13 44 25 26 2 8 30 29 28 27 20 21 6 31 41 6 21 24 10 68 70 69 67 72 71 11 4 9 9 5 57 4 5 9 56 58 62 61 59 21 60 63 35 64 65 34 49 24 20 21 6 ...

Page 49

Page 49 parts list description part number qty item 2016 outlaw seat bracket 080-5116-00 1 1 outlaw cooler cover 014-2100-00 1 2 2016 seat plate outlaw 026-2016-00 1 3 5/16" x 1" carriage bolt 018-8065-00 10 4 .360 id plastic washer 019-6042-00 8 5 3/8" nylock flange nut 013-5202-00 10 6 3/8" x 1 1/...

Page 50

Page 50 parts list description part number qty item kawasaki engine fx-850-v-cs09r 015-0031-00 1 1 4 3/4 motor pulley 033-5035-00 1 2 pump belt 041-8411-00 1 3 3/8" set screw 030-6029-00 1 4 1/4 x 2 square key stock 042-5020-00 1 5 3/8 x 1 1/8 bolt 018-1075-00 4 6 oil drain 015-5404-00 1 7 black boo...

Page 51

Page 51 993cc vanguard description part number qty item 1/4" x 1" key 042-6030-00 1 1 5/16 set screw 030-0050-00 1 2 ground cable 086-0005-00 1 3 5/16" lock washer 019-8051-00 1 4 5/16" nut 013-8043-00 1 5 black boot for ground cable 103-5400-00 1 6 5/16" x 1 3/4" hex bolt 018-8059-00 1 7 3/8 x 1 1/...

Page 52

Page 52 detail a detail b detail c detail d a b c d 4 43 41 42 44 49 8 4 52 7 47 4 59 58 58 32 57 61 63 56 60 16 15 35 34 45 13 12 20 18 17 28 24 23 46 26 25 27 22 26 2 3 21 37 30 4 29 14 1 5 31 54 4 5 4 51 50 47 9 10 11 38 39 40 36 6 54 33 19 55 outlaw 54" deck 53 48 62 28.

Page 53

Page 53 parts list description part number qty item 2015 54" deck 060-5550-00 1 1 3/8" x 3/4" hex bolt 018-5250-00 3 2 3/8" flange nut 013-5201-00 3 3 1/2-13 nylon flange nut 013-8050-00 30 4 1/2 x 3 1/2 flange bolt grade 8 018-2018-00 3 5 .502 id x .750 od x 1.500 long spacer 025-5338-00 2 6 1/2 x ...

Page 54

Page 54 detail a detail b detail c detail d a b c d 8 50 7 53 4 42 45 43 44 4 4 58 57 48 60 57 33 56 63 55 59 14 4 30 31 38 1 37 26 27 3 22 2 28 23 24 25 29 47 5 32 61 4 5 6 61 9 10 11 4 52 51 40 41 39 17 20 34 19 18 12 13 21 46 36 35 15 16 54 outlaw 61" deck 48 49 62 29.

Page 55

Page 55 parts list description part number qty item 2015 61" deck 060-6150-00 1 1 3/8" x 3/4" hex bolt 018-5250-00 3 2 3/8" flange nut 013-5201-00 3 3 1/2-13 nylon flange nut 013-8050-00 32 4 1/2 x 3 1/2 flange bolt grade 8 018-2018-00 3 5 .502 id x .750 od x 1.500 long spacer 025-5338-00 2 6 1/2 x ...

Page 56

Page 56 detail a 56 detail b detail c detail d a b c d 33 30 29 28 32 27 12 18 31 11 45 4 36 62 4 5 3 62 10 9 8 3 2 46 50 39 38 15 3 17 16 34 35 1 20 19 21 61 44 26 13 14 24 23 22 25 6 52 3 3 48 7 41 3 42 40 43 3 58 57 46 57 37 60 64 55 59 54 49 outlaw 72" deck 51 53 47 63 33.

Page 57

Page 57 parts list description part number qty item 2015 72" deck 060-7250-00 1 1 5-3/4 idler pulley-don dye 033-7201-00 1 2 1/2-13 nylon flange nut 013-8050-00 32 3 1/2 x 3 1/2 flange bolt grade 8 018-2018-00 3 4 .502 id x .750 od x 1.500 long spacer 025-5338-00 2 5 1/2 x 2" carriage bolt 018-1050-...

Page 58

Page 58 parts list description part number qty item 4000 series spindle housing 037-4001-00 1 1 4000 series spindle spacer 037-4002-00 1 2 locking collar w/ 1/4"-20 set screw 037-9050-00 1 3 spindle dust cap 037-8002-00 2 4 zt-aos spindle shaft 037-6026-00 1 5 bearing - 6206 037-6023-00 4 6 5 4 6 6 ...

Page 59

Page 59.

Page 60

Notes: __________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ ____...

Page 61

Notes: __________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ ____...

Page 62: 2016 Limited Warranty

2016 limited warranty for bad boy commercial mower (stand on, diesel, outlaw, outlaw extreme, and outlawxp) 1. What this warranty covers, and for how long: bad boy, inc. Will, at its option, repair or replace, without charge, any part covered by the warranty which is found to be defective in materia...

Page 63: Warranty Registration

Bad boy, inc. 102 industrial drive batesville, ar 72501 www.Badboymowers.Com technical support: ............................................................Techsupport@badboymowers.Com warranty: .....................................................................................Warranty@badboymower...

Page 64: Www.Badboymowers.Com

For additional information, please see us at www.Badboymowers.Com bad boy, inc. 102 industrial drive batesville, arkansas 72501.