- DL manuals

- Badger Meter

- Measuring Instruments

- ModMAG M1000

- Installation And Operation Manual

Badger Meter ModMAG M1000 Installation And Operation Manual

Summary of ModMAG M1000

Page 1

® badger meter europa gmbh modmag ® m1000 installation and operation manual february 2018 mid_m1000_ba_02_1802.

Page 2

Contents page 1. Basic safety precautions ................................................................................................ 1 2. System description ......................................................................................................... 2 3. Installation ................

Page 3

Basic safety precautions page 1/47 mid_m1000_ba_02_1802 1. Basic safety precautions before installing or using this product, please read this instruction manual thoroughly. Only qualified personnel should install and/or repair this product. If a fault appears, contact your distributor. Installation ...

Page 4

System description page 2/47 mid_m1000_ba_02_1802 2. System description the electromagnetic flow meters are intended for the metering of all fluids with electric conductivity of at least 5 µs/cm (20 µs/cm for demineralized water). These series of meters is characterized by a high degree of accuracy....

Page 5

Installation page 3/47 mid_m1000_ba_02_1802 nameplate look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate..

Page 6

Installation page 4/47 mid_m1000_ba_02_1802 3. Installation warning: • installation instructions given in the following are to be observed in order to guarantee a perfect functioning and a safe operation of the meter. 3.1 general information 3.1.1 temperature ranges caution: • in order to prevent a ...

Page 7

Installation page 5/47 mid_m1000_ba_02_1802 > 3-5 x dn > 2 x dn m 1000- 18 3.1.3 transport caution: • use lifting lugs when lifting meter flow tubes that are 150 in diameter or larger. • do not lift meter on measuring amplifier or on detector’s neck. • do not lift meter with a fork lift on the jacke...

Page 8

Installation page 6/47 mid_m1000_ba_02_1802 m 1000- 15 h > 2 x d n m 1000 -1 6 > 3- 5 x dn > 2 x d n m 10 00 -1 4 m 10 00 -1 7 3.2.3 meter location caution: • do not install the detector on the suction sides of pumps. This could damage the liner (in particular ptfe liners). • verify that the pipelin...

Page 9

Installation page 7/47 mid_m1000_ba_02_1802 m ax .8 ° m 10 00 -1 3 3.2.4 pipe reducer requirements with pipe reducers as per din 28545 detectors can be mounted in larger pipelines. You can determine the occurring pressure drop by using the shown nomogram (only applicable to liquids with similar visc...

Page 10

Installation page 8/47 mid_m1000_ba_02_1802 m 1000 -1 2 3.2.5 separate version provide a separate version in the following cases: note: • detector protection class ip 68 • medium temperature > 100 °c • strong vibrations caution: • do not install the signal cable close to power cables, electric machi...

Page 11

Installation page 9/47 mid_m1000_ba_02_1802 "x" m 100 0- 20 "x" m4:1 6 mm² cu m 1000- 21 "x" m4:1 "x" 6 mm² cu m1000 -2 2 "x" m4:1 "x" 3.2.7 plastic or lined pipelines if non-conductive pipelines or pipelines lined with non-conductive material are used, install an additional grounding electrode or g...

Page 12

Installation page 10/47 mid_m1000_ba_02_1802 6 mm² cu m1000 -1 1 "x" m4:1 "x" pe 3.2.9 electrically disturbed environment if the pipe material is in an electrically disturbed environment or if metallic pipelines that are not grounded are used, we recommend a groundring as shown in the following pict...

Page 13

Power connections page 11/47 mid_m1000_ba_02_1802 m1000 -1 9 4. Power connections caution: • for the 2 x m20 cable inlets only use flexible electric cables. • use separate cable inlets for auxiliary power, signal and input/output cables. 4.1 auxiliary power warning: • do not connect meter under impr...

Page 14

Power connections page 12/47 mid_m1000_ba_02_1802 4.2 separate version caution: • connect or separate signal connection cable only when the unit has been switched off. Connection in the measuring amplifier 1. Loosen both fixing screws of the connection cover and remove cover. 2. Loosen upper and low...

Page 15

Power connections page 13/47 mid_m1000_ba_02_1802 ba 17 mi d weiß (45) braun (46) pink (40) schwarz (44) schwarz (44) gelb/grün (13) gelb (12) grün (11) 5 bis 300 m grün (11) gelb (12) pink (40) weiß (45) braun (46) schwarz (44) schwarz (44) gelb/grün (13) 5 to 50 m pink 4.2.1 signal cable specifica...

Page 16

Power connections page 14/47 mid_m1000_ba_02_1802 rs-interface m 10 00 -2 3 m 10 00 -24 dig. Out- and input analog output solid state relay 4.3 configuring input/output (i/o) input/output description terminal analog output* 0 - 20 ma 4 - 20 ma rl 0 - 10 ma 7 (+) 8 (-) 9 (gnd) digital output 1* open ...

Page 17

Power connections page 15/47 mid_m1000_ba_02_1802 4.3.1 in- and output cable connection for the normal i/os use shielded cables. Connect the shield of the cable to one of the grounding screw. Recommended cable liycy size min. 0,14 mm². Solid state output in case the second cable gland is used for th...

Page 18

Programming page 16/47 mid_m1000_ba_02_1802 5. Programming programming is accomplished by using the three functional buttons ▲, ► and exit/save. You can move from the measuring mode to the programming mode by pressing once the button exit/save. Meter setup main menu with the ▲ button you move downwa...

Page 19

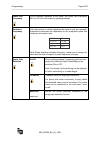

Programming page 17/47 mid_m1000_ba_02_1802 5.1 main menu the following menu items are available to you in the main menu: • meter setup • measurements • inputs and outputs • totalizer reset • communication • miscellaneous • information • pin 5.1.1 meter setup calibration diameter this figure is used...

Page 20

Programming page 18/47 mid_m1000_ba_02_1802 power line frequency for an optimum operation of the meter, set power line frequency 50 hz or 60 hz in this menu at operating location. Excitation frequency this value shows in which frequency the meter’s coils are operated. Supported frequencies are depen...

Page 21

Programming page 19/47 mid_m1000_ba_02_1802 5.1.2 measurement flow unit flow units let you select among the flow units mentioned below. Flow units are automatically converted into the selected unit. Totalizer unit this parameter establishes the units of measure for the totalizers: unit unit l/s lite...

Page 22

Programming page 20/47 mid_m1000_ba_02_1802 full scale flow this parameter sets the maximum flow the system is expected to measure. This parameter has influence on other system parameters like analog output or low flow cut-off. In terms of flow velocity, the meter’s limit are from 0.1 to 12 m/sec. T...

Page 23

Programming page 21/47 mid_m1000_ba_02_1802 moving average moving average filter (mav) smooth out short- term fluctuations. The value can be adjusted from 1 to 200 measuring periods. The delay is calculated: delay [s] = ( mav – 1) x t the time t is given by the adjusted excitation frequency of the m...

Page 24

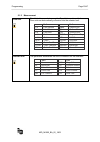

Programming page 22/47 mid_m1000_ba_02_1802 5.1.3 input and outputs analog output range this parameter establishes the range of the analog output signal: 0 to 100% (= full scale). The following cur- rent ranges are available to you: analog output active analog output passive note: in case that an er...

Page 25

Programming page 23/47 mid_m1000_ba_02_1802 digital input digital input lets you reset totalizers (remote reset), or interrupt flow measurement (poszeroreturn). If the function of the digital output 1 or 2 is selected as preselection meter, the function of the digital output is automatically set to ...

Page 26

Programming page 24/47 mid_m1000_ba_02_1802 digital outputs you can configure functional operation of the 2 digital outputs. You can select e.G “forward pulse” for the digital output and define the pulses per totalizer unit via “pulse scale”. Digital outputs 1 and 2 the two outputs can be operated a...

Page 27

Programming page 25/47 mid_m1000_ba_02_1802 digital outputs functional selection the following functions can be selected for the outputs 1 to 2 as well as for the solid state relay. The solid state relay function is linked with the func- tion of output 2. Off means digital output is switched off. Fo...

Page 28

Programming page 26/47 mid_m1000_ba_02_1802 pulse width this parameter establishes the “on” duration of the transmitted pulse. The configurable range ist from 0 msec to 2000 ms. If 0 ms is configured, pulse width is automatically adapted depending on pulse frequency (pulse/pause ratio 1:1). During t...

Page 29

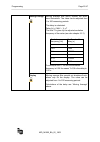

Programming page 27/47 mid_m1000_ba_02_1802 5.1.4 clear totals t2 the unidirectional totalizer t2 is reset within the menu manager. 5.1.5 communications interfaces modbus ® rtu rs232, rs485 and rs422 with modbus ® rtu. Mode can be configured by dip switches also if termination on or off. M-bus optio...

Page 30

Programming page 28/47 mid_m1000_ba_02_1802 ethernet modbus ® tcp/ip with meap-header ip address ipv4-address ip mask ipv4 subnetting reference ip gateway gateway address mac address media-access-control-address ade control on or off protocol 1 or 2 dial 4 to 9 resolution 0,001 / 0,01 / 0,1 / 1 / 10...

Page 31

Programming page 29/47 mid_m1000_ba_02_1802 5.1.6 miscellaneous log off, on and preset power up the number of times that the unit has been powered on. Settling time measures settling of coils and must be less than one quarter of excitation period. 0 ms in case no detector is connected. Language the ...

Page 32

Programming page 30/47 mid_m1000_ba_02_1802 datalog period the data logging period can be adjusted as following: every 15 min / 1 h / 6 h / 12 h / 24 h there is a 500 kb memory with about 30.000 data records for data logging available. The logging capacity is as following (uni-directional mode): per...

Page 33

Programming page 31/47 mid_m1000_ba_02_1802 5.1.8 pin the different menus and parameterings can be secured via three password levels. • administrator pin • service pin • user pin the password protection is a 6-digit pin which is parametered on [000000] and deactivated at the factory. At the first ti...

Page 34

Troubleshooting page 32/47 mid_m1000_ba_02_1802 6. Troubleshooting the following error messages can be displayed: description possible cause recommended action coil disconnected meter not connected. Connection to meter interrupted. Detector electronics or coils defective. Check if meter is connected...

Page 35

Troubleshooting page 33/47 mid_m1000_ba_02_1802 inaccurate measurement wrong parameters. Pipe not completely full. Check parameters (detector, amplifier and size) as per annexed data sheet check if measuring pipe completely full..

Page 36

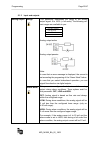

Troubleshooting page 34/47 mid_m1000_ba_02_1802 m 10 00 -2 3 m 10 00 -24 6.1 control led on the board there are several led to control the operation of the device. See below the leds and the meaning led1 coil loop (on = active / off loop open) led2 communication – receive (on = active) led3 communic...

Page 37

Troubleshooting page 35/47 mid_m1000_ba_02_1802 m 10 00 -2 3 6.2 replace meter’s electronics warning: • disconnect auxiliary power before opening body cover. 1. Pull out all plugs. Loosen screws s1-s4 and take out circuit board. 2. Insert new circuit board and fix it by fastening the screws s1-s4. P...

Page 38

Technical data page 36/47 mid_m1000_ba_02_1802 a b2 k d d2 x n dn m 10 00 -05 148 m20 (x2 ) 164 70,5 a 122 80 b1 120 k d d2 x n m 1000- 04 dn 80 164 148 249 60 Ø5.2 65 m2 0 (x 2) 7. Technical data 7.1 detector type ii technical data size dn 6 – dn 500 (1/4“ to 20“) process connections flange: din, a...

Page 39

Technical data page 37/47 mid_m1000_ba_02_1802 dn a std* a iso** b1 b2 ansi flanges din flanges ∅ d ∅ k ∅ d2xn ∅ d ∅ k ∅ d2xn 6 1/4” 170 --- 228 256 88,9 60,3 15,9 x 4 90 60 14 x 4 8 3/10” 170 --- 228 256 88,9 60,3 15,9 x 4 90 60 14 x 4 10 3/8” 170 --- 228 256 88,9 60,3 15,9 x 4 90 60 14 x 4 15 1/2”...

Page 40

Technical data page 38/47 mid_m1000_ba_02_1802 b1 120 122 80 a d dn m 100 0-06 80 164 148 249 60 Ø5.2 65 m2 0 (x2 ) b1 a 120 122 80 d dn m 1000- 08 80 164 148 249 60 Ø5.2 65 m 20 (x 2) 7.2 detector type food technical data size dn 10 – dn 100 (3/8“ to 4“) process connections tri-clamp ® , din 11851,...

Page 41

Technical data page 39/47 mid_m1000_ba_02_1802 b2 a d dn m 1000- 07 148 m 20 ( x2) 164 70,5 a b2 d dn m 100 0- 09 148 m 20 (x2 ) 164 70,5 process connection tri-clamp ® process connection din 11851 modmag ® m1000 mounted version modmag ® m1000 mounted version (in mm) (in mm) type food tri-clamp ® ty...

Page 42

Technical data page 40/47 mid_m1000_ba_02_1802 m 1000- 02 m 1000- 03 7.3 detector type iii technical data size dn 25 – dn 100 (1“ to 4“) process connections sandwich connection, (intermediate flange mounting) nominal pressure pn 40 protective class ip 67, ip 68 optional min. Conductivity 5 µs/cm (20...

Page 43

Technical data page 41/47 mid_m1000_ba_02_1802 m 100 0-01 80 164 148 m20 ( x2 ) 249 60 Ø5.2 65 7.4 meter type modmag ® m1000 technical data type modmag ® m1000 auxiliary power 92-275 vac (50 / 60 hz), 13 va optional 9-36 vdc, 4 w analog output 0/4 – 20 ma, ≤ 800 ohm flow direction is displayed via s...

Page 44

Technical data page 42/47 mid_m1000_ba_02_1802 7.5 error limits measuring range : 0,03 m/s to 12 m/s pulse output : ± 0,3% of m.V. ± 2 mm/s analog output : similar to pulse output plus ±0,01 ma reproducibility : ± 0,1% reference conditions: ambient and fluid temperature : 20 °c electr. Conductivity ...

Page 45

Technical data page 43/47 mid_m1000_ba_02_1802 7.6 size select 0,01 0,1 1 10 100 0,01 0,1 1 10 100 1.000 10.000 l/min m/s dn 6 - dn 100 0,01 0,1 1 10 100 dn 125 - dn 200 1 10 100 1000 10.000 100.0 m³/h.

Page 46

Program structure page 44/47 mid_m1000_ba_02_1802 8. Program structure.

Page 47

Program structure page 45/47 mid_m1000_ba_02_1802.

Page 48

Spare parts page 46/47 mid_m1000_ba_02_1802 9. Spare parts pos. Description part n° 1 92-275 vac amplifier assembly complete 592410 9-36 vdc amplifier assembly complete 592412 2 92-275 vac board 384528 9-36 vdc board 384529 3 92-275 vac board with ethernet 384585 9-36 vdc board with ethernet 384586 ...

Page 49

Return of goods for repair page 47/47 mid_m1000_ba_02_1802 10. Return of goods for repair please refer to our claims return form / harmlessness declaration under: http://www.Badgermeter.De/en/service/return-of-goods.Html.

Page 52: Hotline

Hotline phone +49-7025-9208-0 or -30 fax +49-7025-9208-15 ® badger meter europa gmbh subsidiary of badger meter, inc., usa nürtinger strasse 76 72639 neuffen (germany) e-mail: badger@badgermeter.De www.Badgermeter.De.