Installation & operating guide bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the operating manual, or to view the illustrated parts catalog, programming manual, or service manual, ple...

Page 2 41167.1 051910 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) co...

Page 3 41167.1 051508 contents warranty .............................................................................................................2 introduction ........................................................................................................3 user notices ....................

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. Refer to data plate on the brewer, and local/national electrical codes to determine circuit requirements. Electrical hook-up caution – improper electrical installation wi...

Page 5 plumbing requirements these brewers must be connected to a cold water system with operating pressure between 20 and 90 psi (138 and 620 kpa) from a ½˝ or larger supply line. A shut-off valve should be installed in the line before the brewer. Install a regulator in the line when pressure is gr...

Page 6 -1000 213.8 101.0 200 93.3 -500 212.9 100.5 200 93.3 0 212.0 100.0 200 93.3 500 211.1 99.5 200 93.3 1000 210.2 99.0 200 93.3 1500 209.3 98.5 200 93.3 2000 208.4 98.0 200 93.3 2500 207.4 97.4 200 93.3 3000 206.5 96.9 199 92.8 3500 205.6 96.4 198 92.2 4000 204.7 95.9 197 91.7 4500 203.8 95.4 19...

Page 7 41167.1 041410 coffee brewing 1. Place cup under brew chamber fig 8-1. (slide booster out for small cups) fig 8-3. 2. Press the open/close switch to open pod door fig 8-2. 3. Press fresh pod firmly down into pod holder fig 8-3. 4. Press the open/close switch to close pod door fig 8-2. 5. Pres...

Page 8 sprayhead 1. Open the pod door with the "open/close" switch. 2. Disconnect brewer from power source and allow to cool. 3. Unscrew sprayhead counterclockwise (looking from below). Fig 8-1 4. Remove sprayhead and seal from holder. 5. Check and clean the sprayhead. The sprayhead holes must alway...

Page 9 tank draining factory blowout 1. Disconnect the power and water supply to brewer. Allow brewer to cool before proceeding. 2. Remove 2 screws that secure the top cover. Remove the cover. Place brewer next to a sink. 3. Disconnect the hose from (top) center hose barb of each tank. Connect a pie...

Page 10 hidden switch step forward through screens open/close "no" or (-) large brew (a) "done" hot water "yes" or (+) small brew (b) step backwards through screens programming switches hidden switch press until display reads "brew lockout" 41167.1 051508.

Page 11 program overview brew lockout (yes/no) setting to "yes" will only allow brews at or above the "set ready" temp screen. Brew type (a/b) (tea/coffee) tea setting provides less "purge" after brew cycle. Brew oz. (a/b) (1-16) adjust brew volume. Brew meter (a/b) (1-5) simplified pulse brew adjus...

Page 12 adjustments & optional settings brew oz a: 8.0 (-) done (+) enter password 0 0 0 brew lockout ? No done yes units metric done eng set language ? No yes enter service #? No yes brew type a tea done coffee brew meter a: 2 - + brew oz b: 6.0 (-) done (+) brew type b tea done coffee set password...

Page 13 air time a: 17.0 (-) done (+) air pump power 4 (-) done (+) enabl energysavr no done yes brews to empty (-) 25 (+) drip t i m e a: 5 (-) done (+) setpulsebrew a ? No done yes adjustments & optional settings (cont.) calibrate flow ? No yes brew count ## reset next brew count ## no yes air tim...

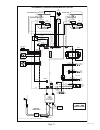

Page 14 schematic wiring diagram autopod grn chassis ground earth ground blk wht blk wht power cord hw brew flow meter yel blk red whi/gry whi/orn whi/vio (sig) (gnd) (+12v) (sig) (gnd) (+12v) vio vio red brn whi blu/blk heater j7 j4 index sensor pressure sw nc no c j3 j11 j1 1 1 j2 1 1 4 j6 3 2 1 4...

Page 15 schematic wiring diagram autopod grn/yel chassis ground brn blu hw brew flow meter yel blk red whi/gry whi/orn whi/vio (sig) (gnd) (+12v) (sig) (gnd) (+12v) vio vio red brn whi blu/blk heater j7 j4 index sensor pressure sw nc no c j3 j11 j1 1 1 j2 1 1 4 j6 3 2 1 4 3 2 1 grn blk whi red displ...