Bunn DUAL SH DBC Installation & Operating Manual

Other manuals for DUAL SH DBC:

Installation and operating manual, Installation & Operating Manual, Installation & Operating Manual, Installation & Operating Manual, Installation And Operaing Instructions, Operating Manual, Operating Manual, Operating Manual, Operating Manual, Installation & Operating Manual

Manual is about: WITH SMART FUNNEL

S/N DUAL068000 & UP

of

9

DUAL

®

SH DBC

®

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit

the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain

the latest catalog and manual updates. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain

a paper copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

29877.0005A 2/13 ©2013 Bunn-O-Matic Corporation

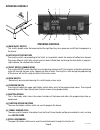

EN

AB

LE

ON

/ OF

F

BR

EW

EN

AB

LE

ON

/ OF

F

BR

EW

.5 & 1.0 Gallon