- DL manuals

- Bunn

- Coffee Maker

- FMD-2

- Operating & Service Manual

Bunn FMD-2 Operating & Service Manual

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

www.bunnomatic.com

FMD-2

FMD-3

(prior to S/N FMD0013000)

HO

T

L I

Q

U

I D

RELEASE BUTTON WHEN CUP IS 2/3 FULL

PL

AC

E

CU

P H

ER

E

PLA

CE

CU

P H

ER

E

PL

AC

E

CU

P H

ER

E

!

WARNING

PU

SH

an

d H

OL

D B

UT

TO

N U

NT

IL C

UP

IS

2/3

FU

LL

, T

HE

N R

EL

EA

SE

28364.0000D 08/02 ©1998 Bunn-O-Matic Corporation

BUNN

®

Summary of FMD-2

Page 1

Operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com fmd-2 fmd-3 (prior to s/n fmd0013000) ho t l i q u i d release button when cup is 2/3 full pl ac e cu p h er e pla ce cu p h er e pl ...

Page 2

2 introduction this equipment dispenses hot beverages on demand from powdered product. It has two or three hoppers. The two and three hopper models may also dispense cold beverages from powdered product from their left dispense station. It is for indoor use only on a sturdy counter or shelf. Bunn-o-...

Page 3

3 00656.0000 00831.0000 user notices (cont.) release button when cup is 2/3 full place cup here place cup here fmd-2 28328.00003 fmd-3 28328.0000 heater 26527.0002 thermostat assembly bunn-o-matic corp temperature adjustment + - 160 ° 120vac ® 190 ° mechanical thermostat 28368.0000 electronic thermo...

Page 4

4 initial set-up 1. Locate the drip tray assembly beneath the dispenser nested in the packing material. 2. Remove the drip tray and the drip tray cover and set them aside. 3. Remove the water strainer assembly from the drip tray and set it aside. 4. Remove the four legs from the drip tray, apply non...

Page 5

5 plumbing hook-up 1. Securely attach the short piece of tubing on the water strainer assembly to the inlet fitting on the bottom of the dispenser. 2. Flush the water line and securely attach it to the flare fitting on the water strainer assembly. 3. Turn-on the water supply. Initial fill & heat cau...

Page 6

6 draining the hot water tank caution - the dispenser must be disconnected from the power source throughout these steps. 1. Disconnect the dispenser from the power source. 2. Open front door and place tank heater switch in the “off” (upper) position. 3. Shut-off and disconnect the incoming water sup...

Page 7

7 problem product will not dispense probable cause 1. No water 2. No power or incorrect voltage to the dispenser 3. Dispense switch 4. Dispense solenoid valve (hot or cold) 5. Solenoid valve (inlet) 6. Level control board and probe 7. Overflow protection switch 8. Auger drive remedy water lines and ...

Page 8

8 troubleshooting (cont.) problem product will not dispense (cont.) water is not hot spitting or excessive steaming probable cause 9. Water strainer 10. Lime build-up caution - tank and tank compo- nents should be delimed regularly depending on local water conditions. Excessive mineral build-up on s...

Page 9

9 troubleshooting (cont.) problem dripping from dispense tip water flows into tank continuously product overflows container probable cause 1. Lime build-up caution - tank and tank compo- nents should be delimed regularly depending on local water conditions. Excessive mineral build-up on stain- less ...

Page 10

10 troubleshooting (cont.) problem weak product probable cause 1. Water temperature 2. Whipper motor 3. Frother 4. Dispense solenoid valve (hot or cold) 5. Auger drive 6. Auger spring 7. Auger motor 8. Rinse/run switch remedy place an empty container beneath the dispense tip. Initiate a dispense cyc...

Page 11

11 troubleshooting (cont.) problem dispenser is making unusual noises excess dust display not lit probable cause 1. Plumbing lines 2. Water supply 3. Tank heater 1. Fan 2. Hopper delay board 1. Lamp 2. Lamp holder 3. Starter - lamp 4. Ballast remedy plumbing lines should not be rest- ing on the coun...

Page 12

12 service this section provides procedures for testing and replacing various major components used in this dispenser should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipment ...

Page 13

13 service auger drive components (cont.) 4. Disconnect the dispenser from the power supply. If voltage is present as described, proceed to #5. If voltage is not present as described, refer to the wir- ing diagrams and check the dispenser wiring harness. 5. With the wires removed from the motor to b...

Page 14

14 service (cont.) auger drive components (cont.) 14. Install hopper assy (21) in the dispenser by sliding hopper assy in the guides on the hopper support plate (20) until the slot in the bottom rear the hopper seats against the shoulder screw (19) in the hopper support plate. Auger drive motor (ref...

Page 15

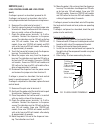

15 blk to blu from door interconnect harness service (cont.) ballast fig. 4 ballast location the front door lamp ballast is located behind the front access panel on the left side of the compo- nent bracket. Test procedure 1. Disconnect the dispenser from the power source. 2. Disconnect the two termi...

Page 16

16 service (cont.) control thermostat fig. 6 control thermostat location the control thermostat (mechanical or elec- tronic) is located inside the dispenser on the upper left side of the housing. Test procedure mechanical thermostat 1. Disconnect the dispenser from the power source. 2. Disconnect th...

Page 17

17 fig. 7 thermostat terminals p1448 blk from limit thermostat blk from tank heater switch 10. Carefully bend the capillary tube so that the tube and bulb inside the tank are in the vertical position and away from any electrical connections. Service (cont.) control thermostat (cont.) 11. Refer to fi...

Page 18

18 fan fig. 10 fan p1436 location: the fan is located inside the dispenser hous- ing on the right rear of the dispenser base plate. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the black and white wires from the fan terminals. 3. Check the voltage across the blac...

Page 19

19 service (cont.) 3. Press and hold the appropriate dispense switch and check the voltage across the disconnected harness wires with a voltmeter. Connect the dis- penser to the power source. The reading must be: a) 120 volts ac for two wire 120 volt models. B) 120 volts ac for three wire 120/208 vo...

Page 20

20 service (cont.) frother and whipper motor (cont.) removal, cleaning and replacement (refer to fig. 12): 1. Open the dispenser door and raise the top front cover. 2. Lift the front edge of the each hopper assembly over the tab on the hopper support panel and slide each hopper assembly out the fron...

Page 21

21 service (cont.) hopper delay board fig. 14 hopper delay board p1445.40 location the hopper delay board is located behind the lower front access panel mounted in the center of the component bracket. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the eight pin plu...

Page 22

22 service (cont.) fig. 15 hot/cold switch p1452.40 hot/cold switch (optional) location: the hot/cold switch is located on the left side of the whipper motor mounting panel. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the four pin plug from the hot/cold switch an...

Page 23

23 service (cont.) lamp holder fig. 17 lamp holders p1454.70 location: the lamp holders are located on the front of the upper panel behind the display panel. Test procedure: 1. Disconnect the dispenser from the power source. 2. Remove upper door panel (4) and disconnect the door wiring harness from ...

Page 24

24 level control board and level probe fig. 18 level control board and probe location: the level control board is located behind the lower access panel mounted on the right side of the component bracket. The level probe is located on the left center of the tank lid just in front of the overflow tube...

Page 25

25 service (cont.) if voltage is present as described, proceed to #5. If voltage is not present as described, refer to the wiring diagram and check the dispenser wiring haness. 5. Reconnect the violet wire to terminal 1. 6. Carefully connect a piece of insulated jumper wire to terminal 4. Keep the o...

Page 26

26 service (cont.) limit thermostat fig. 20 limit thermostat p1445 location: the limit thermostat is located in the center of the tank lid. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect both black wires from the limit ther- mostat. 3. Check for continuity across t...

Page 27

27 service (cont.) overflow protection switch fig. 22 overflow protection switch p1199 location: the overflow protection switch is located in- side the copper overflow cup on the left side of the tank. Test procedures: 1. Disconnect the dispenser from the power source. 2. Remove the wire nuts connec...

Page 28

28 service (cont.) rinse /run switch fig. 24 rinse/run switch p1452.40 location: the rinse/run switch is located on the right side of the whipper motor mounting panel. Test procedures: 1. Disconnect the dispenser from the power source. 2. Check for continuity between center terminal and the upper te...

Page 29

29 service (cont.) solenoid valve (cold water - optional) fig. 26 cold water solenoid valve p1445.40 location: the cold water solenoid valve is located on the left side of the dispenser base just behind the com- ponent bracket. Test procedures: 1. Disconnect the dispenser from the power source. 2. D...

Page 30

30 service (cont.) solenoid valve (cold water - optional) (cont.) fig. 27 cold water solenoid terminals p1215 solenoid valves (dispense) fig. 28 dispense solenoid valves p1445.40 location: the dispense solenoids are located on the upper left side of the tank. Test procedures: 1. Disconnect the dispe...

Page 31

31 service (cont.) solenoid valves (dispense) (cont.) 3. Drain enough water from the tank (approximately 1.0 gallon) so the water level is below the dispense valve mounting hole. Note: bunn-o-matic has a syphon assembly, #12440.0000. Available for this purpose. 4. Disconnect the water line from the ...

Page 32

32 service (cont.) solenoid valve (inlet) (cont.) 7. Disconnect the dispenser from the power source. If the sound is heard as described and water will not pass through the solenoid valve, there may be a block- age in the water line before the solenoid valve or, the solenoid valve may require inspect...

Page 33

33 p1452.40 service (cont.) tank heater (cont.) 5. Check for continuity across the tank heater termi- nals. If continuity is present as described, reconnect the wires, the tank heater is operating properly. If continuity is not present as described, replace the tank heater. Note - if the tank heater...

Page 34

34 test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the black wire from the power supply and the black wire from the control thermostat. 3. With the switch in the “on” lower position check for continuity between the center and the upper terminal. With the switch in th...

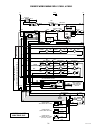

Page 35

35 red/whi fluorescent lamp ballast sol dispense m whipper m hopper run/rinse switch whi whi whi red whi/red whi whi/red sol left dispense m right whipper m right hopper sol right dispense m left whipper m left hopper m center hopper m center whipper sol center dispense whi whi/vio whi/vio whi/vio w...

Page 36

36 red/whi fluorescent lamp ballast sol dispense m whipper m hopper run/rinse switch whi whi whi red whi/red whi whi/red sol left dispense m right whipper m right hopper sol right dispense m left whipper m left hopper m center hopper m center whipper sol center dispense whi whi/vio whi/vio whi/vio w...