Cle ani ng le ver gr oun d co ffee 1. S elec t th e de sire d g rind . 2. L ift t he l id a nd pou r co ffee bea ns in to t he h opp er. 3. S lip b ag u nde r th e ch ute. Re st t he b ag o n th e tr ay. 4. P ress the sta rt s witc h. 5. F lip t he c lean ing leve r a few tim es a s dis pen sing slo...

2 10191 070306 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compresso...

3 special r eg ul ar el ec p er c automat ic drip fine es pr es so turkish turkish co ar se r eg ul ar e lec per k drip auto-drip f ine es pr es so 20545-0000d 01/04 © 1990 bunn-o-matic corporation read the entire operating manual including the limit of warranty and liability before buying or using ...

4 electrical requirements the 120 volt and 240 volt grinders have an attached cordset and requires 2-wire, grounded service rated 120 volts ac and 240 volts ac, 15 amp, single phase, 60 hz. The 230 volt grinders have a power connector and requires 2-wire, grounded service rated 230 volts ac, 15 amp,...

5 coffee grinding 1. Turn the selector knob to align the red arrow with the desired grind. 2. Raise the top lid and add the whole bean coffee. Close the top lid. 3. Locate the back of a bag behind the dispense chute. (the grinder will not operate unless the bag is behind the chute.) 4. Allow the bag...

6 a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of electrical equipment ...

7 probable cause 3. Bag sensor. (cont.) 4. Motor overload protector. 1. Off/on/start switch 2. Bag sensor 3. Relay troubleshooting (cont.) problem grinder will not start. (cont.) grinder will not shut off. Remedy (b) refer to service - bag sensor switch for testing and adjustment procedures. See pag...

8 troubleshooting (cont.) probable cause 1. Hopper 2. Entrance to grind chamber 3.Shear plate problem grinder starts, but will not dis- pense. Remedy coffee must be poured into hopper before grinding. Foreign materials must not block the opening at the bottom of the hopper. Remove both black fillist...

9 contents bag sensor switch ..............................................9 motor and grind chamber (ac) ........................10 motor and grind chamber (dc) ........................13 off/on/start switch ...........................................16 rectifier ......................................

10 4. Disconnect the grinder from the power source. If voltage is present as described, proceed to #5. If voltage is not present as described, refer to the wiring diagrams and check the grinder wiring harness. 5. Check for continuity across the terminals on the bag sensor switch. If continuity is pr...

11 service (cont,) ac motor and grind chamber (cont.) whi/blu to relay n.O.(k4) whi to cordset (120v) red/blk to cordset (230v) grn to ground (120v) grn/yel to ground (230v) p1310 removal and replacement - grind chamber - refer to fig. 6: 1. Loosen the two set screws (16) securing the grind selector...

12 service (cont.) 3. Remove the two .250”-20 screws (1) securing the grind selector dial plate (18) to the grind housing. 4. Slide burr auger rotor/spring assembly (3) off of the grinder motor shaft with burr rotor cup (5), shear plate (4) and burr (7) as an assembly. 5. Remove burr rotor cup (5) a...

13 17. Install grind selector dial plate (18) with adjusting screw w/bearing (19) onto the grind chamber and secure with two .250”-20 screws (1). 18. Install grind selector knob (17) onto the grind selector dial plate (18). Note: refer to adjustments and reset the burrs. Service (cont.) dc motor and...

14 service (cont,) dc motor and grind chamber - g1md only (cont.) blu to blu from rectifier blu to whi/blu from relay (3) red to rectifier (-) blk to rectifier (+) fig. 8 dc motor terminals p1710 10. Remove motor and bracket out the rear of the grinder housing. 11. Remove the two .250”-20 screws sec...

15 service (cont,) dc motor and grind chamber - g1md only (cont.) fig. 9 motor and grind chamber removal p1711 5 7 6 16 18 1 19 17 9 8 11 10 3 4 2 1 7 13 12 14 15 22 21 20 23 11. Install burr (7) on burr auger rotor/spring as- sembly (6) securing with two .250”-20 screws (5). 12. Slide burr auger ro...

16 location: the off/on/start switch is located in the up- per front wrapper above and to the right of the grind selector knob (left side when viewed from rear). Test procedure: 1. Disconnect the grinder from the power source. 2. Check the voltage across the black wire on the off/on/start switch and...

17 + a c a c service (cont.) removal and replacement: 1. Disconnect the wires from the rectifier. 2. Remove the #10-32 screw securing the rectifier to the motor mounting bracket. 3. Remove the rectifier and discard. 4. Install new rectifier on the rear of the motor mounting bracket and secure with a...

18 location: the relay is located on the grinder base inside the lower housing. Test procedure: 1. Disconnect the grinder from the power source and place a coffee bag behind the dispense chute. 2. Check the voltage across the white/orange and white or red/black wires on terminals a & b of the relay ...

19 whi/blu from motor to relay k-4 whi/orn from bag sensor switch (a) fig. 15 relay terminals p1707 service (cont,) relay (cont.) whi to main harness 120v (b) red/blk to main harness 240v (b) whi/vio from switch to relay k-6 whi/red from switch to relay k-7 & k-9 removal and replacement (120 volt an...

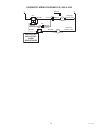

20 whi/vio whi/vio whi/blu whi/ora 1 or a grn l1 n sw1 blk whi/red sw2 k 0 or b m l1 l2 120 volt ac 2 wire single phase 60 hz whi whi k-2 or k-7 k-8 or k-9 k-6 k-4 schematic wiring diagram g1, g2 & g3 10190.0000g 07/05 © 1985 bunn-o-matic corporation 10191 070306.

21 whi/vio whi/vio whi/blu whi/ora schematic wiring diagram g1a, g2a & g3a grn/yel l1 l2 sw1 blk whi/red whi/red sw2 n.O. N.O. M l1 l2 red (230v) red/blk (240v) red (230v) red/blk (240v) 10754.0000e 07/05 © 1993 bunn-o-matic corporation k-4 k-6 230 volts ac 240 volts ac 2 wire single phase k 1 or a ...