Bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com operating & service manual bunn ® caution caution discard decanter discard decanter if: if: . C ra ck ed . Cracked . S cr at ch ed . Scratched . B oil ed d ry ....

Page 2 warranty bunn-o-matic corp. (“bunn”) warrants the equipment manufactured by it to be commercially free from defects in material and workmanship existing at the time of manufacture and appearing within one year from the date of installation. In addition: 1.) bunn warrants electronic circuit an...

Page 3 00656.0000 ! Warning hot water 00831.0000 00658.0000 20201.5600 user notices the notices on this brewer should be kept in good condition. Replace unreadable or damaged labels. 32248 100500 introduction this brewer utilizes bunn® dbc™ technology to control most of its functions. The controller...

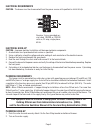

Page 4 32248 100500 plumbing hook-up 1. Flush the water line and securely attach it to the flare fitting located on bottom of brewer. 2. Turn on the water supply. Plumbing requirements this brewer must be connected to a cold water system with operating pressure between 20 and 90 psi (138 and 620 kpa...

Page 5 initial set-up caution – the brewer must be disconnected from the power source throughout the initial set-up, except when specified in the instructions. 1. Insert an empty funnel into the funnel rails of one of the brew stations. 2. Place an empty server under the funnel. 3. Connect the brewe...

Page 6 32248 100500 dbc controller general this brewer utilizes bunn® dbc™ technology to control most of its functions. The controller is factory set to brew in accordance with accepted coffee industry standards, yet may be customized by the owner to achieve a variety of coffee flavor profiles. All ...

Page 7 32248 100500 setting or adjusting the brewer’s controls refer to the function list for the accessible screen numbers and their values. Scroll to the desired function screen and change the value by pressing either the “+” or “–“ keys. The change will not be entered into the programming until y...

Page 8 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 9 brew cycle will not start (cont.) automatic refill will not operate beverage level will not adjust (selector switch in any position) remedy 4. Start switch 5. Dispense valve 6. Brew selector switch 7. Defective dbc 1. No water 2. Water strainer 3. Solenoid valve 4. Overflow protection switch ...

Page 10 water flows into tank continuously . Water from tank is not hot 1. Solenoid valve 2. Defective dbc 3. Overflow protection switch 1. Limit thermostat caution - do not eliminate or by- pass limit thermostat. Use only b.O.M. Part #23717.0001 2. Defective dbc 3. Tank heaters 4. Tank not filled w...

Page 11 troubleshooting (cont.) spitting or unusual steaming from sprayhead or airvents. Inconsistent beverage level in server. Consistently high or low beverage level in server. Dripping from sprayhead. Water overflows server. 1. Lime build-up caution - tank and tank compo- nents should be delimed ...

Page 12 troubleshooting (cont.) water overflows filter (cont.) beverage overflows server. Weak beverage 2. Type of paper filters 3. No sprayhead 1. Beverage left in server 2. Volume adjustment needed 3. Dispense valve 1. Type of paper filters 2. Coffee 3. Sprayhead 4. Funnel loading 5. Water tempera...

Page 13 troubleshooting (cont.) brewer is making unusual noises. Server will not heat 1. Solenoid valve 2. Plumbing lines 3. Water supply 4. Tank heaters 1. Circuit breaker 2. Receptacle contacts 3. Transformer 4. Rectifier remedy probable cause problem the nut on back of the solenoid must be tight ...

Page 14 ca ut io n caution di sc ar d de ca nt er discard decanter if: if: . C ra ck ed . Cracked . S cr at ch ed . Scratched . B oi le d d ry . Boiled dry . H ea te d w he n e mp ty . Heated when empty . U se d on h ig h f la me . Used on high flame . O r ex po se d el ec tr ic . Or exposed electri...

Page 15 service (cont.) location: the bypass valves are located inside the right front and the center front of the hood. Test procedures: 1. Disconnect the brewer from the power source and place 1.5 or 1.75 gallon server under the funnel. 2. Check the water level in the tank to confirm that it is wi...

Page 16 service (cont.) brew selector switch location: the brew selector switches are located in the front left and right side of the hood. Test procedure: timer: left or right 1. Disconnect the brewer from the power supply. 2. Separate the connector on the selector switch harness from the brew time...

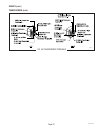

Page 17 p2233 fig. 5 brew selector switch terminals brew selector switch (cont.) service (cont.) removal and replacement: 1. Disconnect the connector on the selector switch harness from the dbc controller. 2. Disconnect wires from the selector switch, inter- face socket and dispense valve. 3. Loosen...

Page 18 circuit breakers ca ution caution di sc ar d de ca nt er discard decanter if: if: . C ra ck ed . Crack ed . S cr at ch ed . Scratched . B oi le d dr y . Boiled dry . H ea te d w he n em pt y . Heated when empty . U se d on h ig h fl am e . Used on high fla me . O r ex po se d el ec tr ic . O...

Page 19 service (cont.) dbc display 32248 100500 caution dis ca rd d ec an te r discard decanter if: if: . Cr ack ed . Cracked . Sc ra tc hed . Scratched . Bo iled dr y . Boiled dry . H ea ted whe n em pty . Heated when empty . Used on h ig h fla me . Used on hig h flame . O r expo sed el ect ri c ....

Page 20 if continuity is present as described, reconnect the wires to the dispense valve(s) and proceed to #7 if continuity is not present as described, replace the dispense valve. 7. Check the dispense valve for coil action. Connect the brewer to power source. Place the on/off" switch in the "on" p...

Page 21 service (cont.) funnel sensor switch 32248 100500 fig. 12 funnel sensor switch p2232 location: the funnel sensor switches are located inside the hood and to the right of each dispense valve. Test procedures: 1. Disconnect the dispenser from the power source. 2. Verify the funnel is activatin...

Page 22 service (cont.) funnel lock solenoid 32248 100500 fig. 14 funnel lock solenoid p2232 location: the funnel lock solenoids are located inside the hood and to the front right of each dispense valve. Test procedures: 1. Disconnect the dispenser from the power source. Removal and replacement:.

Page 23 service (cont.) grinder interface circuit board 32248 100500 fig. 16 grinder interface circuit board p2232 location: the grinder interface circuit board is located inside the trunk housing on a bracket just below the tank assy. Test procedures: 1. Disconnect the dispenser from the power sour...

Page 24 grinder selector switch fig. 18 grinder selector switch ca ut io n caution di sc ar d de ca nt er discard decanter if: if: ra ck ed . Cracked ch ed . Scratched y . Boiled dry mp ty . Heated whe n empty . Used on hi gh flame . Or exposed electric elements failure to comply risks injury pn: 6 ...

Page 25 location: the limit thermostat is located inside the hood on the tank lid just to the left of the right tank heater. Test procedure: 1. Disconnect the brewer from the power supply. 2. Disconnect the black wires from the limit thermo- stat. 3. Check continuity across the limit thermostat ter-...

Page 26 location: the overflow protection switch is located inside the hood on the left side of the tank inside the copper overflow cup. Test procedure: 1. Disconnect the brewer from the power source. 2. Remove the wire nuts connecting the red wires from the overflow protection switch to the wires t...

Page 27 service (cont.) receptacle assemblies cautio n caution dis ca rd d ec an te r discard decanter if: if: . Cracked . Cracked . Scratched . Scratched . Bo iled d ry . Boiled dry . Heat ed when empty . Heated when empty . Used on high flame . Used on high flame . O r exposed elect ric . Or expos...

Page 28 service (cont.) test procedures: 1. Disconnect the brewer from the power source; 2. Remove the wires from the (+) and (-) terminals on the rectifier to be tested. 3. With a voltmeter check the voltage across the (+) and (-) terminals on the rectifier. Connect the brewer to the power source. ...

Page 29 service (cont.) location: the solenoid valve is located inside the lower right front of the brewer. Test procedure: 1. Disconnect the brewer from the power source and draw 1/4 gallon of water from faucet. 2. Remove both wires from the solenoid valve coil terminals. 3. With a voltmeter check ...

Page 30 service (cont.) start/stop switches location: the momentary start/stop switches are lo- cated in front of hood just left and right of center. Test procedure: 1. Disconnect the brewer from the power source. P2235 caution discard decanter discard decanter if: if: . C ra ck ed . Cracked . S cr ...

Page 31 if continuity is present as described, reconnect the wires, the tank heaters are operating properly. If continuity is not present as described, replace the tank heater(s). Note - if the tank heater remains unable to heat, remove and inspect the heater for cracks in the sheath. Removal and re...

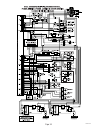

Page 32 service (cont.) location: the transformers are located in the brewer base on the right center of the base plate. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the black wire from terminal #1 (from the start switch) and the white or red wire from terminal # 6....

Page 33 fig. 36 transformer terminals service (cont.) transformers (cont.) p1383 32248 100500

Page 34 32248 100500