- DL manuals

- CAB

- Printer

- MACH4

- Operator's Manual

CAB MACH4 Operator's Manual

Summary of MACH4

Page 1

Product marking and barcode identification operator’s manual edition 7/06 barcode/label printer mach4 up to serial no. 9999.

Page 2

Copyright by cab/9008531/q34/1 all specifications about delivery, design, performance and weight are given to the best of our current knowledge and are subject to change without prior notice. All rights reserved, including those of the translations. No part of this manual nor any translation may be ...

Page 3: Table of Contents

Edition 7/06 operator’s manual 3 mach4 table of contents table of contents 1 a general guide to the documentation ............................................................................. 5 1.1 structure of the documentation and navigation ...........................................................

Page 4

4 operator’s manual edition 7/06 table of contents mach4 5 device types ....................................................................................................................... 14 5.1 device with peel-off function...........................................................................

Page 5: 1.1

Mach4 a general guide to the documentation edition 7/06 operator’s manual 5 1 a general guide to the documentation 1.1 structure of the documentation and navigation the documentation for the barcode/label printer mach4 consists of the following parts: • operator’s manual this is intended for trained...

Page 6: 1.3

6 operator’s manual edition 7/06 safety and the environment mach4 1.2.2 notes 1.2.3 display text on the printer screen all texts appearing on the printer screen are displayed in a suitably abbreviated manner: e.G.: time zone > utc+1 . This abbreviated text prompts the user to select the time zone me...

Page 7: 2.1

Mach4 safety and the environment edition 7/06 operator’s manual 7 2.1 intended use of the printer • the label printer is built in accordance with the current technological status and the recognized safety rules. However, danger to the life and limb of the user or third parties and/or damage to the l...

Page 8: Installation

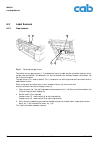

8 operator’s manual edition 7/06 installation mach4 3 installation 3.1 device overview fig. 1: overview b a pause menu cancel feed bereit 6 pause menu cancel feed 19 17 18 9 1 2 3 4 5 6 7 8 10 12 13 14 15 16 10 11 view a view b 1 rs-232 serial interface 2 usb 2.0 high speed slave interface 3 two usb...

Page 9: 3.2

Mach4 installation edition 7/06 operator’s manual 9 3.2 unpacking the label printer ⇒ lift the label printer out of the carton by the straps. ⇒ check the label printer for any possible transportation damage. ⇒ check that the delivery is complete. Delivery scope: • label printer • power cable • quick...

Page 10: 3.5

10 operator’s manual edition 7/06 installation mach4 3.4.2 connection to a computer or computer network ⇒ connect the label printer to a computer or network by a suitable cable. Please refer to the "configuration manual" for details of the configuration of the individual interfaces. 3.5 switching th...

Page 11: Control Panel

Mach4 control panel edition 7/06 operator’s manual 11 4 control panel the user can control the operation of the printer with the control panel, for example: • issuing, interrupting, continuing and cancelling print jobs, • setting printing parameters, e.G. Heat level of the printhead, print speed, in...

Page 12: 4.2

12 operator’s manual edition 7/06 control panel mach4 4.2 functions in print mode 4.2.1 symbol displays the symbols shown in the following table may appear in the status line of the display, depending on the printer configuration. They enable the current printer status to be seen quickly. Please ref...

Page 13

Mach4 control panel edition 7/06 operator’s manual 13 ’correctable error’ state an error has occurred that can be rectified by the operator without interrupting the print job. The print job can be continued after the error has been rectified. The display shows the symbol , the type of error and the ...

Page 14: Device Types

14 operator’s manual edition 7/06 device types mach4 5 device types two versions of the label printer mach4 are supplied, one with a peel-off function and the other with a cutting function. Both versions are offered with 203 dpi, 300 dpi or 600 dpi printheads. Both types of device are used to print ...

Page 15

Mach4 loading material edition 7/06 operator’s manual 15 6.1.2 fitting label rolls the method of fitting label rolls applies to both thermal paper labels and labels that are printed by means of a transfer ribbon. . Fig. 4: roll holder and path of the label stock 1. Open the cover, fig. 1 (9) and hin...

Page 16

16 operator’s manual edition 7/06 loading material mach4 6.1.3 loading fanfold labels the method of loading fanfold labels applies to both thermal paper labels and labels that are printed by means of a transfer ribbon. Fig. 5: loading fanfold labels 1. Stack the fan-folded labels (1) behind the prin...

Page 17

Mach4 loading material edition 7/06 operator’s manual 17 6.1.4 setting up the peel-off function the label stock is loaded as described in section 6.1.2, work steps 1 to 10. Fig. 6: setting up the peel-off function 1. In the control panel, release the pressure roller (3) from the parking position (2)...

Page 18: 6.2

18 operator’s manual edition 7/06 loading material mach4 6.2 loading the transfer ribbon fig. 7: loading the transfer ribbon do not insert a transfer ribbon for direct thermal printing. Caution! When inserting the transfer ribbon ensure that the coated side faces the labels, as otherwise the printhe...

Page 19

Mach4 loading material edition 7/06 operator’s manual 19 1. Open the cover, fig. 1 (9) and hinge down the control panel, fig. 1 (16). 2. Press the release button, fig.1 (14) and hinge the print module up. 3. Press the transfer ribbon unwinding unit (2) to the right until there is perceptible resista...

Page 20: 6.3

20 operator’s manual edition 7/06 loading material mach4 6.3 label sensors 6.3.1 gap sensors fig. 8: selecting the gap sensor the printer has two gap sensors (1, 2) to detect the start of a label and the end of the material, which can be used alternatively. The detectors (1a, 2a) are located in the ...

Page 21

Mach4 loading material edition 7/06 operator’s manual 21 6.3.2 reflex sensor the reflective sensor (1) can detect marks on the back of the label stock. Move the sensor transversely to the transport direction with the slide (2) to adapt to the position of the reflective marks: ⇒ determine the distanc...

Page 22: Printing Operation

22 operator’s manual edition 7/06 printing operation mach4 7 printing operation the printer is ready for operation when all connections have been made and labels and, if applicable, the transfer ribbon have been loaded. 7.1 synchronization of the paper feed after the label stock has been inserted, f...

Page 23: Cleaning and Maintenance

Mach4 cleaning and maintenance edition 7/06 operator’s manual 23 8 cleaning and maintenance the label printer mach4 requires very little maintenance. It is important to clean the thermal printhead regularly. This guarantees a consistently good printed image and plays a major part in preventing pre- ...

Page 24: 8.4

24 operator’s manual edition 7/06 cleaning and maintenance mach4 8.4 cleaning label sensors the label sensors can be soiled by paper dust. This can impair the detection of the start of the label or the print marks (see section 6.3 on page 20). ⇒ clean the label sensors with a brush, or with a cotton...

Page 25: 8.6

Mach4 cleaning and maintenance edition 7/06 operator’s manual 25 8. Insert the printhead holder (5) into the guide (8), and press upwards against the springs (10), whereby the springs (10) must contact the hickeys (9). In so doing, pass the holding lug (1) up through the slit (3), and slide the prin...

Page 26: Fault Correction

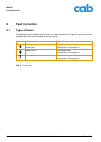

26 operator’s manual edition 7/06 fault correction mach4 9 fault correction 9.1 types of errors the diagnostic system indicates on the screen if an error has occurred. The printer is set into one of the three possible error states according to the type of error. Tab. 3: error states symbol navigator...

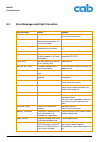

Page 27: 9.2

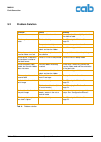

Mach4 fault correction edition 7/06 operator’s manual 27 9.2 problem solution tab. 4: problem solution problem cause remedy transfer ribbon creases transfer ribbon too wide use a transfer ribbon slightly wider than the width of label. Print image has smears or voids printhead is dirty see "cleaning ...

Page 28: 9.3

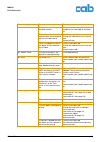

28 operator’s manual edition 7/06 fault correction mach4 9.3 error messages and fault correction error messages cause remedy adc malfunction hardware error switch the printer off and then on. If error recurs call service. Barcode error invalid barcode content, e.G. Alphanumeric characters in a numer...

Page 29

Mach4 fault correction edition 7/06 operator’s manual 29 no label found there are labels missing on the label material press pause key repeatedly until printer recognizes the next label on the mate- rial. The label format as set in the software does not correspond with the real label format cancel c...

Page 30

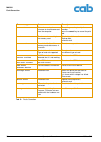

30 operator’s manual edition 7/06 fault correction mach4 tab. 5: faults correction protocol error printer has received an unknown or invalid command from the computer. Press the pause key to skip the com- mand or press the cancel key to cancel the print job. Read error read error when reading from t...

Page 31: Eu Declaration of Conformity

Mach4 eu declaration of conformity edition 7/06 operator’s manual 31 10 eu declaration of conformity gesellschaft für computer- und automations- bausteine mbh & co kg wilhelm-schickard-str. 14 d-76131 karlsruhe, germany eu declaration of conformity we declare herewith that as a result of the manner ...

Page 32

32 operator’s manual edition 7/06 mach4 index a adapting the roll holders .................................14 c changing the media feed roller ........................25 changing the printhead ...................................24 cleaning ........................................................23 c...