- DL manuals

- CAB

- Label Maker

- SQUIX

- Operator's Manual

CAB SQUIX Operator's Manual

Summary of SQUIX

Page 1

Made in germany operator's manual squix label printer.

Page 2

2 2 family type squix squix 4 squix 4.3 squix 4p squix 4.3p squix 4m squix 4.3m squix 4mp squix 4.3mp squix 4mt squix 4.3mt edition: 01/2017 - part no. 9009902 copyright this documentation as well as translation hereof are property of cab produkttechnik gmbh & co. Kg. The replication, conversion, du...

Page 3

3 1 introduction ............................................................................................................................................ 4 1.1 instructions ..............................................................................................................................

Page 4

4 4 1 introduction 1.1 instructions important information and instructions in this documentation are designated as follows: danger! Draws attention to an exceptionally great, imminent danger to your health or life due to hazardous voltages. ! Danger! Draws attention to a danger with high risk which,...

Page 5

5 1 introduction 1.3 safety instructions • thedeviceisconfiguredforvoltages of 100 to 240 v ac. It only has to be plugged into a grounded socket. • only connect the device to other devices which have a protective low voltage. • switch off all affected devices (computer, printer, accessories) before ...

Page 6

6 6 2 installation 2.1 device overview 3 5 6 7 8 4 1 9 10 2 11 1 cover 2 margin stop (only "m" devices) 3 margin stop 4 roll retainer 5 ribbon supply hub 6 ribbon take-up hub 7 internal rewinder (only "p" devices) 8 print unit 9 cover (not at squix 4p/4.3p/4mt/4.3mt) 10 touchscreen display 11 led "p...

Page 7

7 23 24 25 26 23 antistatic brush 24 pressing roller system 25 detent pin 26 pinch roller figure 3 separator on squix 4mt 27 28 31 29 30 33 32 34 35 27 power switch 28 power connection jack 29 slot for sd card 30 2 usb master ports for keyboard, scanner, usb memory stick, bluetooth adapter or servic...

Page 8

8 8 2 installation 2.2 unpacking and setting-up the printer lift the label printer out of the box. check label printer for damage which may have occurred during transport. set up printer on a level surface. remove foam transportation safeguards near the printhead. check delivery for comple...

Page 9

9 2 installation 2.4 connecting the device the standard available interfaces and connectors are shown in figure 4. 2.4.1 connecting to the power supply the printer is equipped with a wide area power unit. The device can be operated with a supply voltage of 230 v~/50 hz or 115 v~/60 hz without adjust...

Page 10

10 10 3 touchscreen display the user can control the operation of the printer with the control panel, for example: • issuing, interrupting, continuing and canceling print jobs, • settingprintingparameters,e.G.Heatleveloftheprinthead,printspeed,interfaceconfiguration,languageand time of day ( configu...

Page 11

11 withspecialsoftwareorhardwareconfigurationsadditionalsymbolsappearonthestartscreen: printing on demand without print job printing on demand within print job direct cut with cu, pcu or st cutter installed figure 7 optional symbols on the start screen release printing of a single label within a pri...

Page 12

12 12 3.2 navigation in the menu start level selection level parameter/function level figure 9 menu levels to open the menu select on the start screen. select a theme in the selection level. Several themes have substructures again with selection levels. To return from the current level to the up...

Page 13

13 4 loading material i notice! For adjustments and simple installation work, use the accompanying allen key located in the top section of the print unit. No other tools are required for the work described here. 4.1 loading media from roll 4.1.1 positioning the media roll on the roll retainer 4 3 8 ...

Page 14

14 14 4.1.2 inserting the media strip into the printhead 4 1 5 3 2 7 6 4 1 5 3 2 7 6 9 10 8 figure 12 inserting the media strip into the printhead 1. Turn lever (2) counterclockwise to lift the printhead. 2. squix 4mt: pull the detent pin (8). The pressing roller system (10) will swing upwards. 3....

Page 15

15 4 loading material 4.1.4 winding up the media strip in rewind mode 5 6 4 2 3 1 7 figure 13 guiding the media strip in rewind mode in rewind mode, the labels are wound up internally after printing for later use. 1. Install rewind guide plate ( 4.4 on page 20). 2. Lift the pinch roller (3) off th...

Page 16

16 16 4 loading material 4.1.5 removing the wound roll 2 3 1 4 figure 14 removing the wound roll 1. Turn lever (1) counterclockwise to lift the printhead. 2. Cut label strip and wind it fully around the rewinder (3). 3. Holdrewinder(3)firmlyandturnknob(2)clockwise. The rewinder spindle relaxes and t...

Page 17

17 4.1.6 winding up the liner in peel-off mode 6 7 5 2 3 4 1 8 figure 15 guidance of the material in peel-off mode in peel-off mode, the labels are removed after printing, and only the liner is wound up internally. 1. Lift the pinch roller (4) off the rewind assist roller (3). 2. Removelabelsfromthe...

Page 18

18 18 4.2 loading fanfold media 6 1 2 3 4 5 figure 16 feed path of fanfold media 1. Turn ring (2) counterclockwise, so that the arrow points to the symbol , and thus release the margin stop (1). 2. Move the margin stop(s) (1) in such a position that squix 4/4p the media can pass between the margin...

Page 19

19 4.3 setting the head locking system squix 4/4p the printhead is pushed on via two plungers. The location of the outer plunger must be set to the width of the label medium used so as to • achieve even print quality across the entire label width • prevent wrinkles in the feed path of the transfer r...

Page 20

20 20 4.4 removing and installing the rewind guide plate, dispense plate or tear-off plate to convert the printer for use in another operating mode, a rewind guide plate (2a), a dispense plate (2b) or a tear-off plate (2c) may need to be installed. 1 1 3 2 2a 2b 2c figure 19 removing and installing ...

Page 21

21 4.5 loading transfer ribbon i notice! With direct thermal printing, do not load a transfer ribbon; if one has already been loaded, remove it. 6 1 2 3 4 5 6 1 2 3 4 5 squix 4/4p squix 4m/4mp/4mt figure 20 loading transfer ribbon 1. Clean printhead before loading the transfer ribbon ( 6.3 on page...

Page 22

22 22 4.6 setting the feed path of the transfer ribbon transferribbonwrinklingcanleadtoprintimageerrors.Thetransferribbondeflection(3)canbeadjustedsoasto prevent wrinkles. I notice! A maladjustment of the head locking system may also cause ribbon wrinkling ( 4.3 on page 19). 1 2 3 figure 22 settin...

Page 23

23 5 printing operation ! Attention! Printhead damage caused by improper handling! Do not touch the underside of the printhead with the fingers or sharp objects. ensure that the labels are clean. ensure that the label surfaces are smooth. Rough labels act like emery paper and reduce the service ...

Page 24

24 24 5 printing operation 5.5 suppressing backfeed (squix 4mt only) i notice! Feeding back the material to the printhead in the cut mode or between print jobs is not allowed for squix 4mt. To avoid the backfeed : in the printer driver menu general > print settings > advanced setup > options • act...

Page 25

25 6 cleaning 6.1 cleaning information danger! Risk of death via electric shock! disconnect the printer from the power supply before performing any maintenance work. The label printer requires very little maintenance. It is important to clean the thermal printhead regularly. This guarantees a cons...

Page 26

26 26 6 cleaning 6.4 cleaning the label sensor ! Attention! Label sensor can be damaged! Do not use sharp or hard objects or solvents to clean the label sensor. The label sensor can become dirtied with paper dust. This can adversely affect label detection. 1 2 3 4 figure 23 cleaning the label sensor...

Page 27

27 7 fault correction 7.1 error display the appearance of an error will be shown on the display: figure 24 error display the error treatment is pending on the error type 7.2 on page 27. The display offers the following possibilities to continue after an error occurred: repeat the print job will be...

Page 28

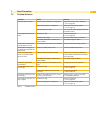

28 28 7 fault correction error message cause remedy no label found there are labels missing on the label material press repeat repeatedly until printer recognizes the next label on the material. The label format as set in the software does not correspond with the real label format cancel current pri...

Page 29

29 7.3 problem solution problem cause remedy transfer ribbon creases transferribbondeflectionnotadjusted adjustthetransferribbondeflection. 4.6 on page 22 head locking system not adjusted adjust the head locking system. 4.3 on page 19 transfer ribbon too wide use a transfer ribbon slightly wider...

Page 30

30 30 8 media 8.1 media dimensions labels endless material / shrink tubes feed direction figure 25 media dimensions dim. Designation dim. In mm 4/4p 4.3/4.3p 4m/4mp/4mt 4.3m/4.3mp/4.4mt b label width 20 - 116 4 -110 h label height in peel-off mode 6 - 2000 12 - 200 4 - 2000 12 - 200 - tear-off lengt...

Page 31

31 8.2 device dimensions squix 4/4p squix 4m/4mp/4mt gap sensor & reflective sensor printhead peel-off edge tear-off edge cut edge feed direction figure 27 device dimensions dim. Designation dim. In mm 4 4p 4.3 4.3p 4m 4mp 4.3m 4.3mp 4mt 4.3mt ip distance printhead - peel-off edge 13,5 - it distance...

Page 32

32 32 8.3 reflex mark dimensions feed direction virtual label front edge reflex mark labelswithreflexmarks endlessmaterialwithreflexmarks virtual label front edge reflex mark squix 4/4p squix 4m/4mp/4mt figure 28 reflexmarkdimensions dim. Designation dim. In mm a label distance > 2 az distance betwe...

Page 33

33 8.4 cut-out mark dimensions feed direction labels with cut-out marks endless material with cut-out marks squix 4/4p squix 4m/4mp/4mt for marginal cut-out marks minimum liner thickness 0,06 mm figure 29 cut-out mark dimensions dim. Designation dim. In mm a label distance > 2 az distance between pr...

Page 34

34 34 9 licenses 9.1 reference to the eu declaration of conformity the printers of the squix seriescomply with the relevant fundamental regulations of the eu rules for safety and health: • directive 2014/35/eu relating to electrical equipment designed for use within certain voltage limits • directiv...

Page 35

35 10 index b backfeed...........................................24 c cleaning information .................................. 25 printhead ..................................... 25 print roller .................................... 25 cleaning information.........................25 connecting ...........

Page 36

36 36 this page was left blank intentionally..