- DL manuals

- Canon

- Software

- FAXPHONE L100

- Service Manual

Canon FAXPHONE L100 Service Manual

Summary of FAXPHONE L100

Page 1

8 7 6 5 4 3 2 1 service manual rev.0 l100 / l150 / 154 / l170 / l174 series.

Page 2

Application this manual has been issued by canon inc. For qualified persons to learn technical theory, installation, maintenance, and repair of products. This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does not apply to you...

Page 3

Explanation of symbols the following symbols are used throughout this service manual. Symbols explanation symbols explanation check. Remove the claw. Check visually. Insert the claw. Check the noise. Use the bundled part. Disconnect the connector. Push the part. Connect the connector. Plug the power...

Page 4

Contents 0 safety precautions cdrh provisions -------------------------------------------------------------0-6 laser safety --------------------------------------------------------------------0-6 about laser beams --------------------------------------------------------------- 0-6 handling laser sca...

Page 5

Laser on/off control -------------------------------------------------------------------2-11 horizontal sync control ------------------------------------------------------------------2-11 laser control -----------------------------------------------------------------------2-12 auto power control (ap...

Page 6

Rear side (l100/l170/l174/l250/l150 chn/l150 kor/l154) ---------------- 4-4 front side (l150 eur/l150 aus)------------------------------------------------------ 4-4 rear side (l150 eur/l150 aus) ------------------------------------------------------ 4-5 front side (l150 chn/l150 kor/l154) ----------...

Page 7

Preparation ----------------------------------------------------------------------------------4-44 procedure ------------------------------------------------------------------------------------4-44 removing the ncu pcb --------------------------------------------------------4-45 preparation --------...

Page 8

Removing the pickup unit ------------------------------------------------------4-86 preparation ----------------------------------------------------------------------------------4-86 procedure ------------------------------------------------------------------------------------4-86 removing the picku...

Page 9

Pick-up -------------------------------------------------------------------------------------- 8-6 feeder -------------------------------------------------------------------------------------- 8-7 jam -------------------------------------------------------------------------------------------- 8-7 fe...

Page 10

■cdrh provisions ■laser safety ■toner safety ■notes on handling lithium battery ■notes on assembly/ disassembly safety precautions l100/l150/l154/l170/l174 series.

Page 11

0-11 0-11 cdrh provisions food and drug cdrh (center for devices and radiological health) under fda (food and drug administration) enforced provisions of the section for laser and laser products on august 2, 1976. These provisions are applicable to all laser products manufactured or assembled after ...

Page 12

0-12 0-12 toner safety about toner toner is a non-toxic material composed of plastic, iron, small amount of pigment, etc. Never throw toner in flames to avoid explosion. Handling adhered toner • use dry tissue paper to wipe off toner adhered to skin or clothes and wash in water. • never use warm wat...

Page 13

1 1 product overview product overview ■product lineup ■product features ■specifications ■parts name.

Page 14

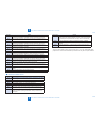

1 1 1-2 1-2 product overview > product features > product features product overview > product features > product features product lineup host machine model name l100 / l170 / l174 l150 l150 chn / l150 kor / l154 configuration 3in1 single-sided adf 3in1 single-sided adf 3in1 single-sided adf design s...

Page 15

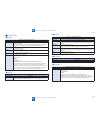

1 1 1-3 1-3 product overview > specifications > adf specifications product overview > specifications > adf specifications specifications product specifications copyboard stream reading machine installation method desktop light source led image reading method cis photosensitive medium opc drum (φ24 m...

Page 16

1 1 1-4 1-4 product overview > parts name > external view > front side of the machine (l100 / l170 / l174) product overview > parts name > external view > front side of the machine (l100 / l170 / l174) fax specifications suitable line public switched telephone network (pstn)*1 communication protocol...

Page 17

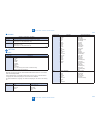

1 1 1-5 1-5 product overview > parts name > external view > rear side of the machine (l100 / l170 / l174) product overview > parts name > external view > rear side of the machine (l100 / l170 / l174) no. Name no. Name [1] document pickup tray [13] handset [2] document feed tray [14] onetouch cover [...

Page 18

1 1 1-6 1-6 product overview > parts name > external view > front side of the machine (l150) product overview > parts name > external view > front side of the machine (l150) ■ front side of the machine (l150) [7] [9] [8] [12] [13] [15] [16] [17] [18] [19] [20] [21] [22] [6] [4] [5] [3] [2] [1] [14] ...

Page 19

1 1 1-7 1-7 product overview > parts name > external view > front side of the machine (l150 chn / l150 kor / l154) product overview > parts name > external view > front side of the machine (l150 chn / l150 kor / l154) ■ rear side of the machine (l150) [1] [2] [3] [4] [5] [7] [6] [8] [9] no. Name no....

Page 20

1 1 1-8 1-8 product overview > parts name > external view > rear side of the machine (l150 chn / l150 kor / l154) product overview > parts name > external view > rear side of the machine (l150 chn / l150 kor / l154) no. Name no. Name [1] document pickup tray [13] handset [2] document feed tray [14] ...

Page 21

1 1 1-9 1-9 product overview > parts name > operation panel (l100 / l170 / l174) product overview > parts name > operation panel (l100 / l170 / l174) cross sectional view [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] no. Name no. Name [1] adf pickup roller [9] feed roller [2] adf...

Page 22

1 1 1-10 1-10 product overview > parts name > operation panel (l150 / l150 chn / l150 kor / l154) product overview > parts name > operation panel (l150 / l150 chn / l150 kor / l154) no. Name function [7] [status monitor/cancel] key confirms and cancels a job. Also allows monitoring of this product's...

Page 23

1 1 1-11 1-11 product overview > parts name > operation panel (l150 / l150 chn / l150 kor / l154) product overview > parts name > operation panel (l150 / l150 chn / l150 kor / l154) no. Name function [7] [status monitor/cancel] key confirms and cancels a job. Also allows monitoring of this product's...

Page 24

2 2 technical overview technical overview ■basic configuration ■controller system ■original exposure system ■laser exposure system ■image formation system ■fixing system ■pickup feed system.

Page 25

2 2 2-2 2-2 technical overview > basic configuration > basic sequence > basic sequence of operation technical overview > basic configuration > basic sequence > basic sequence of operation basic configuration configuration function the machine may be broadly divided into the following 6 functional bl...

Page 26

2 2 2-3 2-3 technical overview > basic configuration > basic sequence > print sequence technical overview > basic configuration > basic sequence > print sequence ■ print sequence fixing heater cis unit document feed motor (m3) sequence wait power-on start key 0.9 0.1 0.3 0.1 max.1.5 2.4 0.5 0.5 0.06...

Page 27

2 2 2-4 2-4 technical overview > basic configuration > basic sequence > power-on sequence technical overview > basic configuration > basic sequence > power-on sequence ■ power-on sequence the sequences from the power-on to the stby period are described below. 1) power-on. 2) cpu initialization. 3) v...

Page 28

2 2 2-5 2-5 technical overview > controller system > engine controller > general description technical overview > controller system > engine controller > general description controller system main controller ■ overview the main controller receives print information from the reader and external equip...

Page 29

2 2 2-6 2-6 technical overview > controller system > power supply > protective functions technical overview > controller system > power supply > protective functions power supply ■ power supply 5.5v 3.3v 24v 3.3v 5.5v 5.5v 3.3v main controller pcb cis unit control panel unit 5.5v 3.3v 1.0v 24v dc/dc...

Page 30

2 2 2-7 2-7 technical overview > controller system > service tasks > notes on service tasks technical overview > controller system > service tasks > notes on service tasks service tasks ■ at parts replacement ● when replacing the main controller pcb the main controller pcb stores data shown in the b...

Page 31

2 2 2-8 2-8 technical overview > original exposure system > major components > various control technical overview > original exposure system > major components > various control original exposure system overview item function / method document exposure led document scan document stream reading by fi...

Page 32

2 2 2-9 2-9 technical overview > original exposure system > service tasks > notes on service tasks technical overview > original exposure system > service tasks > notes on service tasks j2 1 2 3 4 b0/ b0 a0/ a0 main controller pcb m3 detecting jam ■ jam detection outline ● outline the following case...

Page 33

2 2 2-10 2-10 technical overview > laser exposure system > overview > overview technical overview > laser exposure system > overview > overview laser exposure system overview ■ overview the laser exposure system forms static latent images on the photosensitive drum according to the video signals sen...

Page 34

2 2 2-11 2-11 technical overview > laser exposure system > controlling the laser activation timing > horizontal sync control technical overview > laser exposure system > controlling the laser activation timing > horizontal sync control controlling the laser activation timing ■ laser on/off control i...

Page 35

2 2 2-12 2-12 technical overview > laser exposure system > laser scanner motor control > overview technical overview > laser exposure system > laser scanner motor control > overview laser control ■ auto power control (apc) this is the control to emit a constant level of laser diode. There are two ty...

Page 36

2 2 2-13 2-13 technical overview > laser exposure system > service tasks > notes on service tasks technical overview > laser exposure system > service tasks > notes on service tasks ■ scanner motor fault detection this is the detection of faults in the laser scanner unit. When the laser scanner unit...

Page 37

2 2 2-14 2-14 technical overview > image formation system > overview/configuration > print process technical overview > image formation system > overview/configuration > print process image formation system overview/configuration ■ overview the image formation system is the core of this equipment; i...

Page 38

2 2 2-15 2-15 technical overview > image formation system > overview/configuration > development block technical overview > image formation system > overview/configuration > development block ■ static latent image formation block this block is comprised of two steps and forms static latent images on...

Page 39

2 2 2-16 2-16 technical overview > image formation system > overview/configuration > drum cleaning block technical overview > image formation system > overview/configuration > drum cleaning block ■ transfer block this block is comprised of two steps; it transfers toner images on the surface of the p...

Page 40

2 2 2-17 2-17 technical overview > image formation system > high-voltage control > generating transfer bias technical overview > image formation system > high-voltage control > generating transfer bias high-voltage control ■ overview this circuit is comprised of the circuits that apply biases to the...

Page 41

2 2 2-18 2-18 technical overview > image formation system > toner cartridge > operation when toner level is low/nearly out technical overview > image formation system > toner cartridge > operation when toner level is low/nearly out toner cartridge ■ toner level detection toner level is detected by t...

Page 42

2 2 2-19 2-19 technical overview > image formation system > service tasks > notes on service tasks technical overview > image formation system > service tasks > notes on service tasks ■ toner cartridge absence/presence detection the engine controller detects the position of the toner cartridge detec...

Page 43

2 2 2-20 2-20 technical overview > fixing system > overview/configuration > main parts of fixing assembly technical overview > fixing system > overview/configuration > main parts of fixing assembly fixing system overview/configuration ■ overview fixing/delivery system consists of the fixing film uni...

Page 44

2 2 2-21 2-21 technical overview > fixing system > various control mechanisms > protective functions technical overview > fixing system > various control mechanisms > protective functions various control mechanisms ■ fixing temperature control ● heater temperature control the heater temperature cont...

Page 45

2 2 2-22 2-22 technical overview > fixing system > various control mechanisms > protective functions technical overview > fixing system > various control mechanisms > protective functions off relays to shut the power supply to fixing heater (h1). 2) protection function by fixing heater safety circui...

Page 46

2 2 2-23 2-23 technical overview > fixing system > other functions > throughput down control technical overview > fixing system > other functions > throughput down control ● processing after failure detection if the main motor is in driving state when fixing assembly failure is detected, rotation of...

Page 47

2 2 2-24 2-24 technical overview > fixing system > service tasks > notes on service tasks technical overview > fixing system > service tasks > notes on service tasks ● throughput down between sheets throughput down control is performed according to fixing mode, special mode, resolution, and actual f...

Page 48

2 2 2-25 2-25 technical overview > pickup feed system > overview > overview technical overview > pickup feed system > overview > overview pickup feed system overview ■ overview main controller engine controller pickup tray delivery roller transfer roller photosensitive drum separation pad fixing pre...

Page 49

2 2 2-26 2-26 technical overview > pickup feed system > detecting jams > delay jam technical overview > pickup feed system > detecting jams > delay jam detecting jams ■ jam detection outline ● overview the following sensors are installed to detect absence/presence of papers and whether papers are co...

Page 50

2 2 2-27 2-27 technical overview > pickup feed system > detecting jams > delay jam technical overview > pickup feed system > detecting jams > delay jam b. Preceding sheet exists 1 off on off on 1490(2235)msec 70 msec jam paper leading edge sensor (ps751) fixing delivery sensor (ps701) when the paper...

Page 51

2 2 2-28 2-28 technical overview > pickup feed system > detecting jams > other jams technical overview > pickup feed system > detecting jams > other jams ■ stationary jam ● pickup stationary jam when the paper leading edge sensor (ps751) cannot detect the trailing edge of paper within 5325 (7990) ms...

Page 52

2 2 2-29 2-29 technical overview > pickup feed system > service tasks > notes on service tasks technical overview > pickup feed system > service tasks > notes on service tasks note: the leading-edge detection margin is 8 mm, and the trailing-edge detection margin is 20 mm. The above 910 (1360) msec....

Page 53

3 3 periodical services periodical services ■periodically replaced parts ■consumables ■periodical service ■cleaning.

Page 54

3 3 3-2 3-2 periodical services > cleaning periodical services > cleaning periodically replaced parts periodically replaced parts there is no periodically replaced part with this machine. Consumables consumables there is no consumable with this machine. Periodical service scheduled servicing there i...

Page 55

4 4 disassembly/assembly disassembly/assembly ■list of parts ■list of connectors ■external cover ■controller system ■original exposure system ■laser exposure system ■image formation system ■fixing system ■pickup feed system.

Page 56

4 4 4-2 4-2 disassembly/assembly > preface > outline disassembly/assembly > preface > outline preface outline this chapter describes disassembling/assembling procedure of this equipment. The service technician is to identify the cause of the failures according to "chapter 6 troubleshooting" and to r...

Page 57

4 4 4-3 4-3 disassembly/assembly > list of parts > external view > front side (l100/l170/l174/l250/l150 chn/l150 kor/l154) disassembly/assembly > list of parts > external view > front side (l100/l170/l174/l250/l150 chn/l150 kor/l154) list of parts external view ■ front side (l100/l170/l174/l250/l150...

Page 58

4 4 4-4 4-4 disassembly/assembly > list of parts > external view > front side (l150 eur/l150 aus) disassembly/assembly > list of parts > external view > front side (l150 eur/l150 aus) ■ rear side (l100/l170/l174/l250/l150 chn/l150 kor/l154) [1] [2] [5] [6] [7] [8] [9] [3] [4] no. Name reference [1] ...

Page 59

4 4 4-5 4-5 disassembly/assembly > list of parts > external view > rear side (l150 eur/l150 aus) disassembly/assembly > list of parts > external view > rear side (l150 eur/l150 aus) no. Name reference [1] document pickup tray - [2] document feed tray (refer to page 4-61) [3] adf right cover (refer t...

Page 60

4 4 4-6 4-6 disassembly/assembly > list of parts > external view > front side (l150 chn/l150 kor/l154) disassembly/assembly > list of parts > external view > front side (l150 chn/l150 kor/l154) ■ front side (l150 chn/l150 kor/l154) [7] [9] [8] [12] [11] [10] [13] [14] [16] [17] [18] [19] [20] [21] [...

Page 61

4 4 4-7 4-7 disassembly/assembly > list of parts > list of main unit > adf unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) disassembly/assembly > list of parts > list of main unit > adf unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) ■ rear side (l150 chn/l150 kor/l154) [1] [2] [5] [6] [7] [8] [...

Page 62

4 4 4-8 4-8 disassembly/assembly > list of parts > list of main unit > adf unit (l150 chn/l150 kor/l154) disassembly/assembly > list of parts > list of main unit > adf unit (l150 chn/l150 kor/l154) ■ adf unit (l150 eur/l150 aus) [2] [1] no. Name reference [1] adf unit (refer to page 4-54) [2] operat...

Page 63

4 4 4-9 4-9 disassembly/assembly > list of parts > electrical components > adf unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) disassembly/assembly > list of parts > electrical components > adf unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) ■ printer unit [1] [2] [3] [4] [5] no. Name reference ...

Page 64

4 4 4-10 4-10 disassembly/assembly > list of parts > electrical components > motor disassembly/assembly > list of parts > electrical components > motor ■ adf unit (l150 eur/l150 aus) [1] [2] [3] [4] no. Name main unit reference adjastment during parts replacement [1] ds sensor adf unit - - [2] des s...

Page 65

4 4 4-11 4-11 disassembly/assembly > list of parts > electrical components > sensor disassembly/assembly > list of parts > electrical components > sensor ■ solenoid [1] no. Name main unit reference adjastment during parts replacement [1] pickup solenoid pickup unit (refer to page 4-91) - f-4-8 t-4-1...

Page 66

4 4 4-12 4-12 disassembly/assembly > list of parts > electrical components > heater/thermistor/thermoswitch/ disassembly/assembly > list of parts > electrical components > heater/thermistor/thermoswitch/ ■ switch/speaker [1] [2] [3] no. Name main unit reference adjastment during parts replacement [1...

Page 67

4 4 4-13 4-13 disassembly/assembly > list of parts > electrical components > pcb disassembly/assembly > list of parts > electrical components > pcb ■ pcb [8] [2] [4] [3] [5] [6] [7] [1] no. Name main unit reference adjastment during parts replacement [1] operation panel pcb operation panel unit (ref...

Page 68

4 4 4-14 4-14 disassembly/assembly > list of connectors > adf unit > (l100/l170/l174/l250/l150 chn/l150 kor/l154) disassembly/assembly > list of connectors > adf unit > (l100/l170/l174/l250/l150 chn/l150 kor/l154) list of connectors adf unit ■ (l100/l170/l174/l250/l150 chn/l150 kor/l154) [10] [11] [...

Page 69

4 4 4-15 4-15 disassembly/assembly > list of connectors > adf unit > (l150 eur/l150 aus) disassembly/assembly > list of connectors > adf unit > (l150 eur/l150 aus) ■ (l150 eur/l150 aus) [1] [2] [3] [4] [6] [7] [5] key no. Jack no. Name relay connector key no. Jack no. Name [1] j2 main controller pcb...

Page 70

4 4 4-16 4-16 disassembly/assembly > list of connectors > printer unit disassembly/assembly > list of connectors > printer unit printer unit [2] [15] [17] [19] [12] [13] [11] [14] [10] [20] [16] [18] [4] [1] [5] [3] [6] [7] [9] [8] key no. Jack no. Name relay connector key no. Jack no. Name [1] j101...

Page 71

4 4 4-17 4-17 disassembly/assembly > list of connectors > printer unit disassembly/assembly > list of connectors > printer unit [10] [1] [11] [2] [12] [3] [13] [4] [14] [5] [6] [7] [8] [9] key no. Jack no. Name relay connector key no. Jack no. Name [1] j4 main controller pcb [8] j1201 ncu pcb [2] j5...

Page 72

4 4 4-18 4-18 disassembly/assembly > external cover > layout drawing > front side (l100/l170/l174/l250/l150 chn/l150 kor/l154) disassembly/assembly > external cover > layout drawing > front side (l100/l170/l174/l250/l150 chn/l150 kor/l154) external cover layout drawing ■ front side (l100/l170/l174/l...

Page 73

4 4 4-19 4-19 disassembly/assembly > external cover > layout drawing > front side (l150 eur/l150 aus) disassembly/assembly > external cover > layout drawing > front side (l150 eur/l150 aus) ■ rear side (l100/l170/l174/l250/l150 chn/l150 kor/l154) [1] [2] [5] [6] [7] [8] [9] [3] [4] no. Name referenc...

Page 74

4 4 4-20 4-20 disassembly/assembly > external cover > layout drawing > rear side (l150 eur/l150 aus) disassembly/assembly > external cover > layout drawing > rear side (l150 eur/l150 aus) no. Name reference [1] document pickup tray - [2] document feed tray (refer to page 4-61) [3] adf right cover (r...

Page 75

4 4 4-21 4-21 disassembly/assembly > external cover > layout drawing > front side (l150 chn/l150 kor/l154) disassembly/assembly > external cover > layout drawing > front side (l150 chn/l150 kor/l154) ■ front side (l150 chn/l150 kor/l154) [7] [9] [8] [12] [11] [10] [13] [14] [16] [17] [18] [19] [20] ...

Page 76

4 4 4-22 4-22 disassembly/assembly > external cover > layout drawing > rear side (l150 chn/l150 kor/l154) disassembly/assembly > external cover > layout drawing > rear side (l150 chn/l150 kor/l154) ■ rear side (l150 chn/l150 kor/l154) [1] [2] [5] [6] [7] [8] [9] [3] [4] no. Name reference [1] docume...

Page 77

4 4 4-23 4-23 disassembly/assembly > external cover > removing the adf right cover > procedure disassembly/assembly > external cover > removing the adf right cover > procedure removing the adf left cover ■ procedure 1) release the claw [1]. [1] 2) open the adf unit, and remove the adf left cover [1]...

Page 78

4 4 4-24 4-24 disassembly/assembly > external cover > removing the handset base unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure disassembly/assembly > external cover > removing the handset base unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure removing the handset base unit...

Page 79

4 4 4-25 4-25 disassembly/assembly > external cover > removing the handset base unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure disassembly/assembly > external cover > removing the handset base unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure 2) insert the arm shaft [1] in...

Page 80

4 4 4-26 4-26 disassembly/assembly > external cover > removing the adf left upper cover (l150 eur/l150 aus) > procedure disassembly/assembly > external cover > removing the adf left upper cover (l150 eur/l150 aus) > procedure note: when replacing the handset base unit, execute steps 6 and 7. 5) free...

Page 81

4 4 4-27 4-27 disassembly/assembly > external cover > removing the left cover > procedure disassembly/assembly > external cover > removing the left cover > procedure removing the left cover ■ procedure note: the following shows the 5 claws [1] and 3 hooks [2] of the left cover. [1] [1] [1] [2] f-4-2...

Page 82

4 4 4-28 4-28 disassembly/assembly > external cover > removing the right cover > procedure disassembly/assembly > external cover > removing the right cover > procedure removing the right cover ■ procedure note: the following shows the 5 claws [1] and 3 hooks [2] of the right cover. [1] [1] [1] [2] f...

Page 83

4 4 4-29 4-29 disassembly/assembly > external cover > removing the rear cover > procedure disassembly/assembly > external cover > removing the rear cover > procedure removing the front cover unit ■ preparation 1) remove the left cover (refer to page 4-27). 2) remove the right cover (refer to page 4-...

Page 84

4 4 4-30 4-30 disassembly/assembly > external cover > removing the upper cover > procedure disassembly/assembly > external cover > removing the upper cover > procedure 2) remove the rear cover [1]. • 2 claws [2] • 1 hook [3] [2] [3] [1] x2 f-4-38 removing the upper cover ■ preparation 1) remove the ...

Page 85

4 4 4-31 4-31 disassembly/assembly > external cover > removing the upper cover > procedure disassembly/assembly > external cover > removing the upper cover > procedure 4) remove the delivery tray [1]. [1] 5) remove the arm shaft rail holder [1] of the adf unit. • 2 hooks [2] [2] [1] [2] f-4-40 f-4-4...

Page 86

4 4 4-32 4-32 disassembly/assembly > external cover > removing the upper cover > procedure disassembly/assembly > external cover > removing the upper cover > procedure caution: be sure to install the 2 fixing pressure arms [2] and the cartridge arm [3] to the delivery tray [1] when assembling. [1] [...

Page 87

4 4 4-33 4-33 disassembly/assembly > controller system > layout drawing disassembly/assembly > controller system > layout drawing controller system layout drawing [4] [9] [5] [6] [3] [1] [2] [7] [8] [10] [11] [12] [15] [16] [17] [18] [13] [14] f-4-44 no. Name main unit reference adjastment during pa...

Page 88

4 4 4-34 4-34 disassembly/assembly > controller system > removing the drive belt > procedure disassembly/assembly > controller system > removing the drive belt > procedure removing the operation panel unit ■ procedure 1) open the adf upper unit. 2) remove the control panel unit [1]. • 3 claws [2] • ...

Page 89

4 4 4-35 4-35 disassembly/assembly > controller system > removing the drive belt > procedure disassembly/assembly > controller system > removing the drive belt > procedure 3) remove the drive cover [1]. • 4 screws [2] caution: be sure to slowly remove the drive cover [1] directly upward so as not to...

Page 90

4 4 4-36 4-36 disassembly/assembly > controller system > removing the main motor > procedure disassembly/assembly > controller system > removing the main motor > procedure caution: be sure to align the shafts with the 7 shaft holes [1] to install the drive cover [2] when assembling. [2] [1] [1] f-4-...

Page 91

4 4 4-37 4-37 disassembly/assembly > controller system > removing the main motor > procedure disassembly/assembly > controller system > removing the main motor > procedure 2) remove the motor driver pcb [1]. • 2 connectors [2] • 2 claws [3] • 1 guide [4] x2 x2 [2] [3] [4] [1] 3) free the motor harne...

Page 92

4 4 4-38 4-38 disassembly/assembly > controller system > removing the main motor > procedure disassembly/assembly > controller system > removing the main motor > procedure caution: be sure to install the main motor with the harness [1] side up when assembling. [1] [1] f-4-58 caution: • be sure to pa...

Page 93

4 4 4-39 4-39 disassembly/assembly > controller system > removing the main controller pcb > procedure disassembly/assembly > controller system > removing the main controller pcb > procedure removing the main controller pcb ■ before replacing the main controller pcb • check the version. Service mode ...

Page 94

4 4 4-40 4-40 disassembly/assembly > controller system > removing the engine controller pcb > procedure disassembly/assembly > controller system > removing the engine controller pcb > procedure 2) remove the main controller pcb [1]. • 1 screw (binding) [2] • 5 screws (black tp) [3] x6 [1] [2] [3] [3...

Page 95

4 4 4-41 4-41 disassembly/assembly > controller system > removing the engine controller pcb > procedure disassembly/assembly > controller system > removing the engine controller pcb > procedure 2-1) disconnect the terminal [1] of the grounding wire. • 1 screw (black tp) [2] 3-1) remove the ferrite c...

Page 96

4 4 4-42 4-42 disassembly/assembly > controller system > removing the engine controller pcb > procedure disassembly/assembly > controller system > removing the engine controller pcb > procedure 7) disconnect the 3 flat cables [1] and the 3 connectors [2]. 8) disconnect the 4 connectors [3], and free...

Page 97

4 4 4-43 4-43 disassembly/assembly > controller system > removing the engine controller pcb > procedure disassembly/assembly > controller system > removing the engine controller pcb > procedure caution: be sure to install the switchboard [2] of the engine controller pcb to the lower side of the swit...

Page 98

4 4 4-44 4-44 disassembly/assembly > controller system > removing the communication pcb unit > procedure disassembly/assembly > controller system > removing the communication pcb unit > procedure caution: be sure to keep the transfer high voltage harness [1] from the engine controller pcb when assem...

Page 99

4 4 4-45 4-45 disassembly/assembly > controller system > removing the paper leading edge sensor > procedure disassembly/assembly > controller system > removing the paper leading edge sensor > procedure removing the ncu pcb ■ preparation 1) remove the left cover (refer to page 4-27). 2) remove the ri...

Page 100

4 4 4-46 4-46 disassembly/assembly > controller system > removing the paper leading edge sensor > procedure disassembly/assembly > controller system > removing the paper leading edge sensor > procedure 2) disconnect the terminal [1], and free the transfer high voltage harness [2] from the harness gu...

Page 101

4 4 4-47 4-47 disassembly/assembly > controller system > removing the fixing delivery/paper width sensor pcb > procedure disassembly/assembly > controller system > removing the fixing delivery/paper width sensor pcb > procedure caution: be sure that the terminal [1] is in contact with the contact sp...

Page 102

4 4 4-48 4-48 disassembly/assembly > controller system > removing the fixing delivery/paper width sensor pcb > procedure disassembly/assembly > controller system > removing the fixing delivery/paper width sensor pcb > procedure 2) disconnect the terminal [1], and free the transfer high voltage harne...

Page 103

4 4 4-49 4-49 disassembly/assembly > controller system > removing the toner sensor > procedure disassembly/assembly > controller system > removing the toner sensor > procedure caution: be sure that the terminal [1] is in contact with the contact spring [2] when installing. [1] [2] f-4-92 caution: be...

Page 104

4 4 4-50 4-50 disassembly/assembly > controller system > removing the toner sensor > procedure disassembly/assembly > controller system > removing the toner sensor > procedure 1) remove the scanner cover [1]. • 2 screws (black tp) [2] x2 [2] [1] 2) remove the sensor holder [1]. • 1 claw [2] • 3 hook...

Page 105

4 4 4-51 4-51 disassembly/assembly > controller system > removing the speaker > procedure disassembly/assembly > controller system > removing the speaker > procedure removing the speaker ■ preparation 1) remove the left cover (refer to page 4-27). ■ procedure 1) remove the speaker [1]. • 1 connector...

Page 106

4 4 4-52 4-52 disassembly/assembly > original exposure system > layout drawing > (l100/l170/l174/l250/l150 chn/l150 kor/l154) disassembly/assembly > original exposure system > layout drawing > (l100/l170/l174/l250/l150 chn/l150 kor/l154) original exposure system layout drawing ■ (l100/l170/l174/l250...

Page 107

4 4 4-53 4-53 disassembly/assembly > original exposure system > layout drawing > (l150 eur/l150 aus) disassembly/assembly > original exposure system > layout drawing > (l150 eur/l150 aus) ■ (l150 eur/l150 aus) [2] [1] [4] [3] [5] [6] [8] [7] [14] [10] [11] [12] [13] [15] [9] [16] f-4-101 no. Name ma...

Page 108

4 4 4-54 4-54 disassembly/assembly > original exposure system > removing the adf unit > procedure disassembly/assembly > original exposure system > removing the adf unit > procedure removing the adf unit ■ preparation 1) remove the left cover (refer to page 4-27). ■ procedure note: between l100/l170...

Page 109

4 4 4-55 4-55 disassembly/assembly > original exposure system > removing the adf unit > procedure disassembly/assembly > original exposure system > removing the adf unit > procedure 6) remove the arm shaft [1] of the adf unit, and lift the arm [2]. [1] [2] caution: be careful not to get fingers caug...

Page 110

4 4 4-56 4-56 disassembly/assembly > original exposure system > removing the adf upper unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure disassembly/assembly > original exposure system > removing the adf upper unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure 7) remove the ad...

Page 111

4 4 4-57 4-57 disassembly/assembly > original exposure system > removing the adf upper unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure disassembly/assembly > original exposure system > removing the adf upper unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure 3) free the docu...

Page 112

4 4 4-58 4-58 disassembly/assembly > original exposure system > removing the adf upper unit (l150 eur/l150 aus) > procedure disassembly/assembly > original exposure system > removing the adf upper unit (l150 eur/l150 aus) > procedure 7) free the ferrite core [1] from the wire saddle [2]. [1] [2] 8) ...

Page 113

4 4 4-59 4-59 disassembly/assembly > original exposure system > removing the adf upper unit (l150 eur/l150 aus) > procedure disassembly/assembly > original exposure system > removing the adf upper unit (l150 eur/l150 aus) > procedure [3] [4] [2] [1] 2) insert the arm shaft [1] into the holder groove...

Page 114

4 4 4-60 4-60 disassembly/assembly > original exposure system > removing the adf upper unit (l150 eur/l150 aus) > procedure disassembly/assembly > original exposure system > removing the adf upper unit (l150 eur/l150 aus) > procedure 6) free the document feed motor harness [1] from the adf harness g...

Page 115

4 4 4-61 4-61 disassembly/assembly > original exposure system > removing the document feed tray > procedure disassembly/assembly > original exposure system > removing the document feed tray > procedure 11) disconnect the terminal [1] of the grounding wire. • 1 screw (black tp) [2] 12) disconnect the...

Page 116

4 4 4-62 4-62 disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l100/l170/l174/l250/l150 chn/l150 ...

Page 117

4 4 4-63 4-63 disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l100/l170/l174/l250/l150 chn/l150 ...

Page 118

4 4 4-64 4-64 disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l100/l170/l174/l250/l150 chn/l150 kor/l154) > procedure disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l100/l170/l174/l250/l150 chn/l150 ...

Page 119

4 4 4-65 4-65 disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l150 eur/l150 aus) > procedure disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l150 eur/l150 aus) > procedure removing the adf upper unit ...

Page 120

4 4 4-66 4-66 disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l150 eur/l150 aus) > procedure disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l150 eur/l150 aus) > procedure [3] [4] [2] [1] 4) place the...

Page 121

4 4 4-67 4-67 disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l150 eur/l150 aus) > procedure disassembly/assembly > original exposure system > removing the adf upper unit and adf lower unit (l150 eur/l150 aus) > procedure 5) remove the 3 screws [1] o...

Page 122

4 4 4-68 4-68 disassembly/assembly > original exposure system > removing the cis unit > procedure disassembly/assembly > original exposure system > removing the cis unit > procedure 7) free the ferrite core [1] from the wire saddle [2]. [1] [2] 8) disconnect the terminal [1] of the grounding wire. •...

Page 123

4 4 4-69 4-69 disassembly/assembly > original exposure system > removing the white plate retainer > procedure disassembly/assembly > original exposure system > removing the white plate retainer > procedure 1) remove the 3 screws [1] and the grounding plate [2] securing the cis unit. X3 [1] [2] 2) re...

Page 124

4 4 4-70 4-70 disassembly/assembly > original exposure system > removing the adf pickup roller > procedure disassembly/assembly > original exposure system > removing the adf pickup roller > procedure caution: be sure to pay attention to the direction of the white plate retainer when assembling. F-4-...

Page 125

4 4 4-71 4-71 disassembly/assembly > original exposure system > removing the adf pickup roller > procedure disassembly/assembly > original exposure system > removing the adf pickup roller > procedure 1) release the locks of the adf upper unit [1] and the adf lower unit [2]. • 2 claws [3] note: relea...

Page 126

4 4 4-72 4-72 disassembly/assembly > original exposure system > removing the adf feed roller > procedure disassembly/assembly > original exposure system > removing the adf feed roller > procedure removing the adf feed roller ■ preparation 1) remove the left cover (refer to page 4-27). 2) remove the ...

Page 127

4 4 4-73 4-73 disassembly/assembly > original exposure system > removing the adf feed roller > procedure disassembly/assembly > original exposure system > removing the adf feed roller > procedure 3) remove the e-ring [1] and bushing [2]. [1] [2] 4) move the gear [1] and the 2 bushings [3]. • 1 claw ...

Page 128

4 4 4-74 4-74 disassembly/assembly > original exposure system > removing the adf separation pad > procedure disassembly/assembly > original exposure system > removing the adf separation pad > procedure removing the adf separation pad ■ procedure caution: be sure not to touch the surface of the pad w...

Page 129

4 4 4-75 4-75 disassembly/assembly > original exposure system > removing the adf delivery roller > procedure disassembly/assembly > original exposure system > removing the adf delivery roller > procedure removing the adf delivery roller ■ preparation 1) remove the left cover (refer to page 4-27). 2)...

Page 130

4 4 4-76 4-76 disassembly/assembly > original exposure system > removing the adf delivery roller > procedure disassembly/assembly > original exposure system > removing the adf delivery roller > procedure 4) remove the adf delivery roller [1]. • 2 bushings [2] [1] [2] [2] f-4-167.

Page 131

4 4 4-77 4-77 disassembly/assembly > laser exposure system > removing the laser scanner unit > procedure disassembly/assembly > laser exposure system > removing the laser scanner unit > procedure laser exposure system layout drawing [1] [2] [3] no. Name main unit reference adjastment during parts re...

Page 132

4 4 4-78 4-78 disassembly/assembly > laser exposure system > removing the laser scanner unit > procedure disassembly/assembly > laser exposure system > removing the laser scanner unit > procedure 2) remove the laser scanner unit [1]. • 1 flat cable [2] • 1 connector [3] • 4 screws [4] [1] [2] [3] [4...

Page 133

4 4 4-79 4-79 disassembly/assembly > image formation system > removing the transfer roller > procedure disassembly/assembly > image formation system > removing the transfer roller > procedure image formation system layout drawing [1] no. Name main unit reference adjastment during parts replacement [...

Page 134

4 4 4-80 4-80 disassembly/assembly > image formation system > removing the transfer roller > procedure disassembly/assembly > image formation system > removing the transfer roller > procedure caution: be sure that the bushing [1] is in the correct direction when assembling. [1] [1] f-4-176 caution: ...

Page 135

4 4 4-81 4-81 disassembly/assembly > fixing system > removing the fixing assembly > procedure disassembly/assembly > fixing system > removing the fixing assembly > procedure fixing system layout drawing [2] [3] [4] [1] no. Name main unit reference adjastment during parts replacement [1] fixing assem...

Page 136

4 4 4-82 4-82 disassembly/assembly > fixing system > removing the fixing assembly > procedure disassembly/assembly > fixing system > removing the fixing assembly > procedure 2) disconnect the terminal [1], and free the transfer high voltage harness [2] from the harness guide [a]. 3) remove the harne...

Page 137

4 4 4-83 4-83 disassembly/assembly > fixing system > removing the fixing assembly > procedure disassembly/assembly > fixing system > removing the fixing assembly > procedure 7) free the fixing harness [1] from the harness holder [2]. 8) remove the harness holder [2]. • 1 claw [3] • 2 bosses [4] [1] ...

Page 138

4 4 4-84 4-84 disassembly/assembly > fixing system > removing the fixing assembly > procedure disassembly/assembly > fixing system > removing the fixing assembly > procedure caution: • be sure that the groove [1] of the hook is hooked to the edge of the left side plate. • be sure to fit the 3 bosses...

Page 139

4 4 4-85 4-85 disassembly/assembly > fixing system > removing the fixing assembly > procedure disassembly/assembly > fixing system > removing the fixing assembly > procedure caution: be sure that the terminal [1] is in contact with the contact spring [2] when assembling. [1] [2] f-4-190 caution: be ...

Page 140

4 4 4-86 4-86 disassembly/assembly > pickup feed system > removing the pickup unit > procedure disassembly/assembly > pickup feed system > removing the pickup unit > procedure pickup feed system layout drawing [2] [3] [4] [1] no. Name main unit reference adjastment during parts replacement [1] picku...

Page 141

4 4 4-87 4-87 disassembly/assembly > pickup feed system > removing the pickup unit > procedure disassembly/assembly > pickup feed system > removing the pickup unit > procedure 2) disconnect the terminal [1], and free the transfer high voltage harness [2] from the harness guide [a]. 3) remove the har...

Page 142

4 4 4-88 4-88 disassembly/assembly > pickup feed system > removing the pickup unit > procedure disassembly/assembly > pickup feed system > removing the pickup unit > procedure 7) remove the shaft retainer [1]. • 1 boss [2] [2] [1] 8) turn the machine so that it is placed with its front side down. F-...

Page 143

4 4 4-89 4-89 disassembly/assembly > pickup feed system > removing the pickup unit > procedure disassembly/assembly > pickup feed system > removing the pickup unit > procedure caution: • be sure that the contact spring [2] of the pickup unit [1] is in contact with the area [a] when assembling. Be su...

Page 144

4 4 4-90 4-90 disassembly/assembly > pickup feed system > removing the pickup roller > preparation disassembly/assembly > pickup feed system > removing the pickup roller > preparation removing the pickup roller ■ preparation caution: be sure not to touch the surface [1] of the transfer roller and th...

Page 145

4 4 4-91 4-91 disassembly/assembly > pickup feed system > removing the pickup solenoid > procedure disassembly/assembly > pickup feed system > removing the pickup solenoid > procedure removing the pickup solenoid ■ preparation 1) remove the left cover (refer to page 4-27). 2) remove the adf unit (re...

Page 146

4 4 4-92 4-92 disassembly/assembly > pickup feed system > removing the pickup solenoid > procedure disassembly/assembly > pickup feed system > removing the pickup solenoid > procedure 5) free the pickup solenoid harness [1] from the harness guide [a]. [1] [a] 6) remove the screw [1], move the soleno...

Page 147

4 4 4-93 4-93 disassembly/assembly > pickup feed system > removing the separation pad > preparation disassembly/assembly > pickup feed system > removing the separation pad > preparation caution: be sure to keep the transfer high voltage harness [1] from the engine controller pcb when assembling. [1]...

Page 148

5 5 adjustment adjustment ■electrical adjustment.

Page 149

5 5 5-2 5-2 adjustment > electrical adjustment > electric part-related adjustment > after replacing the main controller pcb adjustment > electrical adjustment > electric part-related adjustment > after replacing the main controller pcb electrical adjustment electric part-related adjustment ■ when re...

Page 150

6 6 trouble shooting trouble shooting ■test print ■trouble shooting items ■version upgrade ■log collector.

Page 151

6 6 6-2 6-2 trouble shooting > test print > test print function trouble shooting > test print > test print function test print test print function this equipment has a test print function to check if the printer engine normally operates. Test patterns (horizontal lines) are output when executing thi...

Page 152

6 6 6-3 6-3 trouble shooting > trouble shooting items > image faults > smudged/streaked trouble shooting > trouble shooting items > image faults > smudged/streaked trouble shooting items image faults ■ smudged/streaked ● bleeding (smear) occurs immediately after the power is turned on for the first ...

Page 153

6 6 6-4 6-4 trouble shooting > mechanical adjustment > confirming nip width trouble shooting > mechanical adjustment > confirming nip width ■ repetitive image defects ruler component distance between defects (mm) image defects dirt dropouts dirt on back loose toner photosensitive drum about 75 ○ ○ t...

Page 154

6 6 6-5 6-5 trouble shooting > version upgrade > preparation > preparation trouble shooting > version upgrade > preparation > preparation version upgrade overview the firmware of this machine is upgraded by downloading the firmware from a personal computer (pc) to this machine using a user support t...

Page 155

6 6 6-6 6-6 trouble shooting > version upgrade > downloading system software trouble shooting > version upgrade > downloading system software downloading system software 1) open the ust. Ustupd.Exe 2) write down the version of the firmware to be updated, and then click the [next] button. F-6-6 f-6-7...

Page 156

6 6 6-7 6-7 trouble shooting > version upgrade > downloading system software trouble shooting > version upgrade > downloading system software 5) click [start] button. 6) a warning screen will appear. Click the [yes] button. Download will start. F-6-10 f-6-11 f-6-12 7) click [ok] button when download...

Page 157

6 6 6-8 6-8 trouble shooting > log collector > overview > operation procedure trouble shooting > log collector > overview > operation procedure log collector overview a method to collect the operational status log of the host machine will be provided as a means to analyze failures occurred in the fi...

Page 158

6 6 6-9 6-9 trouble shooting > log collector > overview > troubleshooting trouble shooting > log collector > overview > troubleshooting naming rule for log file: it is recorded as "usb_yyyymmdd_hhmmss.Log". “yyyymmdd_hhmmss” indicates year, month, date, and time (hour, minute, second) when the log i...

Page 159

7 7 error codes error codes ■overview ■error codes.

Page 160

7 7 7-2 7-2 error codes > overview error codes > overview overview this section describes codes shown in case any problem is occurred. Since this product does not collect logs for jams and alarms, no jam / alarm code is shown. Code type description reference error code shown for any problem occurred...

Page 161

7 7 7-3 7-3 error codes > error codes error codes > error codes error codes code detail code item description e000 0000 detection description startup failure remedy (1) check the connectors of the fixing assembly. (j101, j1011, j552 and j702) (2) replace the fixing assembly. (3) replace the engine c...

Page 162

7 7 7-4 7-4 error codes > fax error code > service error code > error code error codes > fax error code > service error code > error code fax error code error code overview ■ overview a fax error code shows the status of an error which occurred in a fax, and is displayed on the reports. Fax error co...

Page 163

7 7 7-5 7-5 error codes > fax error code > service error code > error code error codes > fax error code > service error code > error code error code details ##763 at time of ecm transmission, the protocol signal has been transmitted more than specified after transmission of pps-eom, or t5 time-out (...

Page 164

8 8 service mode service mode ■overview ■copier ■feeder ■fax ■testmode.

Page 165

8 8 8-2 8-2 service mode > overview > service mode menu > screen flow of service mode service mode > overview > service mode menu > screen flow of service mode overview entering service mode. Contact the sales company for the method to enter service mode. Exiting service mode the service mode change...

Page 166

8 8 8-3 8-3 service mode > copier > adjust > ccd service mode > copier > adjust > ccd copier display ■ version copier > display > version small item description display example -main- 03.03,20110804 9c815fdd,japan -econ- 00.07 main:display the version / date / checksum / country group of bootable ( ...

Page 167

8 8 8-4 8-4 service mode > copier > function > param service mode > copier > function > param function ■ clear copier > function > clear small item description tel-user clear the user data and the registered address data. Sssw is not cleared. When this service mode is executed, a message "rebooting....

Page 168

8 8 8-5 8-5 service mode > copier > option > body service mode > copier > option > body ■ splman copier > function > splman small item description top-cst adjustment of leading edge margin when feeding from cassette. Adjustment in: 0.1mm setting range: 50 ~ 150 (default value: 104) left-cst adjustme...

Page 169

8 8 8-6 8-6 service mode > copier > counter > pick-up service mode > copier > counter > pick-up country group language select ountry/region oceania chinese (simplified) chinese (traditional) english frranch japanese korean portuguese spanish thai vietnamese australia (au) new zealand (nz) other t-8-...

Page 170

8 8 8-7 8-7 service mode > copier > counter > jam service mode > copier > counter > jam ■ feeder copier > counter > feeder display / setting / adjustment range: 0 to 999,999. Returns to 0 when value exceeds 999,999. Small item description feed total counter of document pickup by adf ■ jam copier > c...

Page 171

8 8 8-8 8-8 service mode > feeder > function service mode > feeder > function feeder adjust feeder > adjust small item description docst adjustment of the page front reading position when using duplex adf setting range: -30 ~ 30 (default value: 0) la-spd adjustment of magnification ratio in vertical...

Page 172

8 8 8-9 8-9 service mode > fax > list of sssw service mode > fax > list of sssw fax list of sssw fax > sssw sssw no. Bit no. Function sw 01 ( errors, copy functions) bit 0 output error codes for service technicians bit 1 - 7 not in use sw 02 (setting for network connection criteria) bit 0 do not sta...

Page 173

8 8 8-10 8-10 service mode > fax > list of menu service mode > fax > list of menu fax > sssw sssw no. Bit no. Function sw 25 (setting for report display function) bit 0 prioritize the received telephone number to the dialed number bit 1 not in use bit 2 regard a received blank cis as an unreceived c...

Page 174

8 8 8-11 8-11 service mode > fax > setting of ncu parameters > tone/pulse service mode > fax > setting of ncu parameters > tone/pulse list of num numeric parameter setting mode no. Parameter allowable setting range 001 not in use 002 rtn transmission criteria x 1 to 99 % 003 rtn transmission criteri...

Page 175

8 8 8-12 8-12 service mode > fax > setting of ncu parameters > bustone1 service mode > fax > setting of ncu parameters > bustone1 parameter no. Function setting range 005; t4 timer 0 to 9999 (x 10 msec) 006; signal detection table 0 to 16 007; signal detection level 0 to 7 008; number of signal freq...

Page 176

8 8 8-13 8-13 service mode > fax > setting of ncu parameters > cngdtct service mode > fax > setting of ncu parameters > cngdtct ● numeric value parameter parameter no. Function setting range 001; not in use - 002; t1 timer 0 to 9999 (x 10 msec) 003; t2 timer 0 to 9999 (x 10 msec) 004; t3 timer 0 to ...

Page 177

8 8 8-14 8-14 service mode > fax > setting of ncu parameters > pbxbusyt service mode > fax > setting of ncu parameters > pbxbusyt ■ specialb parameter no. Function setting range sw1 - sw30; not in use - ■ specialn parameter no. Function setting range 001 - 070; not in use - ■ rkey ● numeric value pa...

Page 178

8 8 8-15 8-15 service mode > testmode > scan > adftest service mode > testmode > scan > adftest testmode system ■ dram testmode > system > dram small item description test1 data read/write check for dram (except system work area) ■ speaker testmode > system > speaker small item description on volume...

Page 179

8 8 8-16 8-16 service mode > testmode > panel service mode > testmode > panel fax ■ modem testmode > fax > modem small item description relay-1 cml : test on/off of port sw and relay on ncu setting value: on, off h : test on/off of port sw and relay on ncu setting value: on, off freq transmit select...

Page 180

■service tools ■solvent/oil list ■general circuit diagram ■signal input/output list ■general timing chart ■backup data appendix.

Page 181

9-2 9-2 appendix > service tools appendix > service tools service tools the followings are the required tools to perform the service operation. No. Tool name tool number usage/remarks 1 tool case tkn-0001 2 jumper wire tkn-0069 with clip 3 gap gauge ck-0057 0.02 to 0.03mm 4 spring scale ck-0058 to c...

Page 182

9-3 9-3 appendix > solvent/oil list appendix > solvent/oil list solvent/oil list name usage remarks ethyl alcohol cleaning e.G.) metal parts grease toner contamination • local procurement • keep fire away lubricant • apply it on gears etc. • apply it on shafts and shaft supports etc. • tool number: ...

Page 183

Iv iv appendix > general circuit diagram > general circuit diagram appendix > general circuit diagram > general circuit diagram general circuit diagram general circuit diagram 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 f e d c b a f e d c b a p.1 engine controller pcb main controller pcb ncu pcb cis ...

Page 184

9 9 9-5 9-5 appendix > signal input/output list appendix > signal input/output list signal input/output list connector pin abbreviation i/o signal name j103 1 ac_n 2 3 ac_h j542 1 /bdir i bd input signal 2 +3.3u 3 gnd 4 cnt1 o laser control signal 5 cnt0 o laser control signal 6 gnd(v) 7 vdo o video...

Page 185

9-6 9-6 appendix > general timing chart appendix > general timing chart general timing chart fixing heater cis unit document feed motor (m3) sequence wait power-on start key 0.9 0.1 0.3 0.1 max.1.5 2.4 0.5 0.5 0.06 0.06 0.9 2.0 2.0 forcible emission forcible emission masking emission masking emissio...

Page 186

9-7 9-7 appendix > backup data appendix > backup data backup data data to be stored data location replacement delete user backup service backup service function when replacing main pcb dc controller pcb clear > tel- user clear > srvc-dat clear > hist*2 clear > pwd- clear clear > all can data be back...