- DL manuals

- Dimplex

- Heat Pump

- LA 10MR

- Installation And Operating Instructions Manual

Dimplex LA 10MR Installation And Operating Instructions Manual

Summary of LA 10MR

Page 1

Order no.: 452159.67.07 fd 8602 ce installation and operating instructions air-to-water heat pump for outdoor installation la 6mr la 12tr la 8mr la 16tr la 10mr.

Page 2

2 1 read immediately 3 1.1 important information 1.2 legal provisions and guidelines 1.3 energy-efficient use of the heat pump 2 purpose of heat pump 4 2.1 field of application 2.2 principle of operation 3 scope of delivery 4 3.1 baseline unit 3.2 control box 4 transport 5 5 installation 5 5.1 gener...

Page 3: Caution!

3 read immediately 1.1 important information do not open the unit unless all electrical circuits have been disconnected from the power supply. During transport, the heat pump must not be tilted more than 45 ° (in either direction). Heat pump and transport pallet are only connected by the packaging f...

Page 4: Caution!

4 purpose of heat pump scope of delivery purpose of heat pump 2.1 field of application the air-to-water heat pump is intended for use in existing or newly built heating systems. The heat pump is designed for the cooling or heating of water for heating purposes and the supply of domestic hot water! T...

Page 5: Caution!

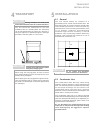

5 transport installation 4 caution! Transport during transport, the heat pump must not be tilted more than 45 ° (in either direction). T h e u n i t s h o u l d b e t r a n s p o r t e d t o t h e f i n a l installation site on a wooden pallet. The heat pump can be transported either by means of a l...

Page 6: Caution!

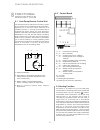

6 mounting 6 mounting 6.1 general the following connections need to be established on the heat pump: - supply/return lines of the heating system - condensate drain - control lead to the remote control - power supply 6.2 heating-side connection the connections on the heating side of the heat pump are...

Page 7

7 commissioning 7 commissioning 7.1 general to ensure proper commissioning it should be carried out by an after-sales service authorized by the manufacturer. Only then can an extended warranty period of 3 years in total be granted (cf. Warranty service). 7.2 preparatory steps prior to commissioning,...

Page 8

8 functional description 8 functional description 8.1 heat pump remote control unit the heat pump can be switched on and off by means of the remote control positioned inside the building. Switching off in this case means switching to a "standby" function, i.E. As long as the heat pump is supplied wi...

Page 9: Caution!

9 cleaning / care 9.1 care to protect the paint finish, avoid placing objects against or on the unit. The external parts of the heat p u m p c a n b e w i p e d w i t h a d a m p c l o t h a n d commercially available cleaning agents. Do not use any cleaning agents containing sand, soda, acid or chl...

Page 10: Caution!

10 cleaning / care malfunctions / troubleshooting decommissioning caution - heating contractors depending on the water quality and quantity, in particular in the case of mixed installations and plastic pipes, mineral deposits (rust sludge, lime) may form impairing the proper functioning of the heati...

Page 11

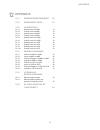

11 appendix 12.1 dimensioned drawing 12 12.2 equipment data 13 12.3 schematics 12.3.1 heating mode la 6mr 14 12.3.2 cooling mode la 6mr 15 12.3.3 heating mode la 8mr 16 12.3.4 cooling mode la 8mr 17 12.3.5 heating mode la 10mr 18 12.3.6 cooling mode la 10mr 19 12.3.7 heating mode la 12tr 20 12.3.8 c...

Page 12

12 dimensioned drawing appendix: 12.1 dimensioned drawing 35 (circumferential) electr . Connection box (inspection side) air discharge end condensate drain condensate drain condensate pan condensate tube (plastic) soil to sewer ( base frame ) feed-through electric lines heating water return g 1” ext...

Page 13

13 equipment data for air-to-water heat pumps for heating 1 type and commercial description la06mrn la08mrn la10mrn la12trn la16trn 2 model 2.1 type reversible reversible reversible reversible reversible 2.2 enclosure type acc. To en 60 529 for compact unit and/or heating element ip 24 ip 24 ip 24 i...

Page 14

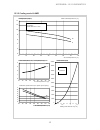

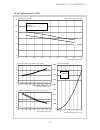

14 0 1 2 3 4 5 6 7 8 9 10 11 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] heizleistung in [kw] 35 50 wasseraustrittstemperatur in [°c] 0 1 2 3 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] leistungsaufnahme (incl. Pumpenleistungsanteil) 50 35 40 0 1 2 3 4 5 6 -20 -10 0 10 20 30 40 l...

Page 15

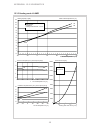

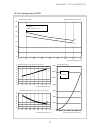

15 12.3.2 cooling mode la 6mr appendix: 12.3 schematics 0 2 4 6 8 10 12 14 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] kühlleistung in [kw] 18 8 wasseraustrittstemperatur in [°c] 0 1 2 3 4 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] leistungsaufnahme (incl. Pumpenleistu...

Page 16

16 0 1 2 3 4 5 6 7 8 9 10 11 12 13 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] heizleistung in [kw] 35 50 wasseraustrittstemperatur in [°c] 0 1 2 3 4 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] leistungsaufnahme (incl. Pumpenleistungsanteil) 50 35 40 0 1 2 3 4 5 6 -20 -10 0 10 20...

Page 17

17 12.3.4 cooling mode la 8mr appendix: 12.3 schematics 0 2 4 6 8 10 12 14 16 18 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] kühlleistung in [kw] 18 8 wasseraustrittstemperatur in [°c] 0 1 2 3 4 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] leistungsaufnahme (incl. Pumpen...

Page 18

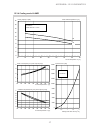

18 12.3.5 heating mode la 10mr appendix: 12.3 schematics 0 2 4 6 8 10 12 14 16 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] heizleistung in [kw] 35 50 wasseraustrittstemperatur in [°c] 0 1 2 3 4 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] leistungsaufnahme (incl. Pumpenleistungsan...

Page 19

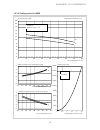

19 12.3.6 cooling mode la 10mr appendix: 12.3 schematics 0 2 4 6 8 10 12 14 16 18 20 22 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] kühlleistung in [kw] 18 8 wasseraustrittstemperatur in [°c] 0 1 2 3 4 5 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] leistungsaufnahme (inc...

Page 20

20 12.3.7 heating mode la 12tr appendix: 12.3 schematics 0 2 4 6 8 10 12 14 16 18 20 22 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] heizleistung in [kw] 35 50 wasseraustrittstemperatur in [°c] 0 1 2 3 4 5 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] leistungsaufnahme (incl. Pumpen...

Page 21

21 appendix: 12.3 schematics 12.3.8 cooling mode la 12tr 0 5 10 15 20 25 30 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] kühlleistung in [kw] 18 8 wasseraustrittstemperatur in [°c] 0 1 2 3 4 5 6 7 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] leistungsaufnahme (incl. Pumpe...

Page 22

22 12.3.9 heating mode la 16tr appendix: 12.3 schematics 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] heizleistung in [kw] 35 50 wasseraustrittstemperatur in [°c] 0 1 2 3 4 5 6 7 -20 -10 0 10 20 30 40 lufteintrittstemperatur in [°c] leistungsaufnahme ...

Page 23

23 appendix: 12.3 schematics 12.3.10 cooling mode la 16tr 0 5 10 15 20 25 30 35 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] kühlleistung in [kw] 18 8 wasseraustrittstemperatur in [°c] 0 1 2 3 4 5 6 7 8 10 15 20 25 30 35 40 45 50 lufteintrittstemperatur in [°c] leistungsaufnahme (incl....

Page 24

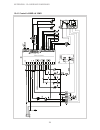

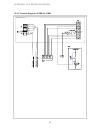

24 12.4.1 control la 6mr-la 10mr appendix: 12.4 wiring diagrams on/off call heating/cooling copressor fan reversing valve heating circulating pump back-up heater attention! Low voltage supply sensor external sensor fsk sensor setpoint coding on/of f cooling setpoint.

Page 25

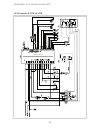

25 12.4.2 load la 6mr-la 10mr appendix: 12.4 wiring diagrams jumper 4kw jumper 6kw mains supply back-up heater mains supply.

Page 26

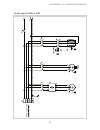

26 appendix: 12.4 wiring diagrams 12.4.3 terminal diagram la 6mr-la 10mr jumper 4kw ye/gn ye/gn jumper 6kw mains supply mains supply for back-up heater switch box la 6-10 connecting lead connecting lead.

Page 27

27 a1 wire jumper: the jumper must be removed for external control (via potential-free contact) or when a dew point monitor (via potential-free contact) is used. B3* thermostat, hot water b5 control thermostat, back-up heater c1 operating capacitor, compressor c3 operating capacitor, fan e3 pressost...

Page 28

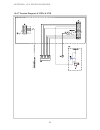

28 appendix: 12.4 wiring diagrams 12.4.5 control la 12tr-la 16tr call heating/cooling copressor fan reversing valve heating circulating pump back-up heater attention! Low voltage supply sensor external sensor fsk sensor setpoint coding cooling setpoint.

Page 29

29 appendix: 12.4 wiring diagrams 12.4.6 load la 12tr-la 16tr mains supply - load.

Page 30

30 appendix: 12.4 wiring diagrams 12.4.7 terminal diagram la 12tr-la 16tr ye/gn mains supply connecting lead switch box la 12-16.

Page 31

31 12.4.8 legend la 12tr-la 16tr a1 wire jumper: for external control (via potential-free contact) or use of a dew point monitor (via potential-free contact) the jumper must be removed. B3* hot water thermostat b5 control thermostat, back-up heater e3 pressostat defrost end e4 nozzle ring heater e10...

Page 32

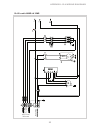

32 12.5.1 mono-energetic system appendix: 12.5 hydraulic block diagrams overflow valve safety assembly circulating pump expansion vessel thermostat/manual valve shut-of f valve with drain heat consumers t emperature sensor flexible connecting hose electric distribution electric heating element heati...

Page 33

33 appendix: 12.5 hydraulic block diagrams 12.5.2 mono-energetic systems and domestic hot water function overflow valve safety assembly circulating pump expansion vessel thermostat/manual valve three-way valve shut-of f valve with drain heat consumers air-to-water heat pump buf fer tank hot water ta...

Page 34

34 ec declaration of conformity appendix: 12.6 ec declaration of conformity declaration of conformity the undersigned glen dimplex deutschland gmbh division dimplex am goldenen feld 18 d-95326 kulmbach hereby confirm that the design and construction of the product(s) listed below, in the version(s) ...

Page 35

Notes 35.

Page 36

Glen dimplex deutschland gmbh subject to technical modifications division dimplex telefax (0 92 21) 709-589 am goldenen feld 18 www.Dimplex.De d-95326 kulmbach.