- DL manuals

- Eaton

- UPS

- 93PM

- User And Installation Manual

Eaton 93PM User And Installation Manual

Summary of 93PM

Page 1

User's and installation guide eaton 93pm ups 30–200 kva p-164000249.

Page 2

Copyright © 2017 eaton corporation plc. All rights reserved. This manual contains important instructions that you should follow during installation and maintenance of the ups and batteries. Please read all instructions before operating the equipment and save this manual for future reference. This is...

Page 3

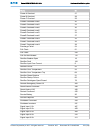

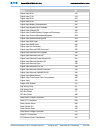

Contents 1 how to read this manual.......................................................................... 7 1.1 safety-related signs.................................................................... 7 1.2 safety symbols...............................................................................

Page 4

3.6.1 ups battery switchgear.............................................. 31 3.7 basic system configurations..................................................... 32 4 ups installation plan and unpacking......................................................35 4.1 creating an installation plan..........

Page 5

7 ups operating instructions.....................................................................88 7.1 ups controls and indicators......................................................88 7.1.1 control panel............................................................... 88 7.1.2 status indicators......

Page 6

9 technical data......................................................................................111 9.1 directives and standards........................................................ 111 9.2 ups system input................................................................... 112 9.3 ups syste...

Page 7

1 how to read this manual 1.1 safety-related signs the following table explains the safety-related signs used in this document. Danger danger indicates a hazard with a high level of risk which, if not avoided, will result in serious injury or death. Warning warning indicates a hazard with a medium l...

Page 8

General symbol for pro- hibited action no smoking limited or restricted ac- cess 1.2.3 mandatory action symbols these symbols are used to indicate an action that must be taken. General symbol for man- datory action disconnect from power source read the manual or in- structions 1.3 conventions used i...

Page 9

Epo emergency power-off ess energy saver system f-upm field installed upm ipm intelligent power manager ipp intelligent power protector mbp maintenance bypass mbs maintenance bypass switch mcb miniature circuit breaker mis maintenance isolation switch mob module output breaker repo remote emergency ...

Page 10

2 safety instructions danger important safety instructions! Keep these instructions! This document contains important instructions that must be obeyed during the installation, operation and maintenance of the ups and the batteries. Read all instructions before operating the equipment. Keep this manu...

Page 11

Warning batteries present a risk of electric shock or burn from high short-circuit current. Observe proper precautions. Electric energy hazard. Do not attempt to alter any battery wiring or connectors. Attempting to alter wiring can cause injury. Do not open or mutilate batteries. Released electroly...

Page 12

Caution keep the surroundings of the ups uncluttered, clean, and free from excess moisture. Obey all danger, caution, and warning notices on the equipment. 2.1 audience this document is intended for: • people who plan and perform the installation of the ups • people who use the ups this document pro...

Page 13

Danger do not open any other screws in the unit than those holding the cover plates of the minislots and the mbs locking plate. Failure to recognize the electrical hazards can prove fatal. Caution the 30–50 kw models are available as a c2 category ups as an option, which can be placed both in reside...

Page 14

Caution: refer to operator's manual refer to your operator's manual for additional information, such as important operating and maintenance instructions. This symbol indicates that you may not discard the ups or the ups batteries in the trash. This product involves sealed, lead-acid batter- ies and ...

Page 15

3 introduction to eaton ups figure 1. Eaton 93pm ups the eaton ® 93pm uninterruptible power supply (ups) is a true online, continuous-duty, transformerless, double-conversion, solid-state, three-phase system that supplies conditioned and uninterruptible ac power to critical load and protects it from...

Page 16

A centralized system static bypass. The available static bypass ratings are 50 kw, 60 kva, 100 kw, 150 kw and 200 kw. The static bypass size is chosen according to ups system power. Eaton 93pm output power ratings are based on 50 kw rated uninterruptible power modules (upms). A single ups cabinet ca...

Page 17

Eaton 93pm ups 30–200 kva user's and installation guide © eaton corporation plc 2017. All rights reserved. Revision: 005 document id: p-164000249 17 (126).

Page 18

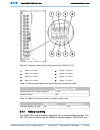

1 control panel 8 rectifier input switch (optional) 2 door latch 9 battery breaker (optional) 3 communications area 10 mbs (optional) 4 upm 1 11 area for internal batteries 5 upm 2 12 communication cable conduit 6 upm 3 13 static bypass section 7 upm 4 14 power cable connections 3.2 ups operating mo...

Page 19

Operating mode description stored energy mode energy is drawn from a dc backup power source and converted to ac power by the ups inverter. Most commonly vrla bat- teries are introduced to the system for this purpose, and the mode of operation is called the battery mode bypass mode critical load is s...

Page 20

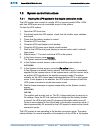

Figure 2. Path of current through the ups in the double conversion mode a static switch 1 bypass in- put main power flow b rectifier 2 rectifier in- put energized c inverter 3 output de-energized d battery con- verter 4 battery breaker trickle current e battery closed open three-phase ac input power...

Page 21

If the ups becomes overloaded or unavailable, the ups seamlessly switches to the bypass mode and continues supplying the load through the static bypass. The ups automatically returns to the double conversion mode when the abnormal condition, such as an extended time overload, is cleared and the syst...

Page 22

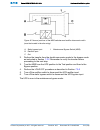

Figure 3. Path of current through the ups in the energy saver system mode a static switch 1 bypass in- put main power flow b rectifier 2 rectifier in- put energized c inverter 3 output de-energized d battery con- verter 4 battery breaker trickle current e battery closed open in the ess mode, the ups...

Page 23

When the power conditions are within acceptable limits, the ups operates as a high efficiency, energy-saving system, providing surge protection for it equipment and making sure that clean power is delivered to the facility. The energy saver system increases system efficiency up to 99% when supplying...

Page 24

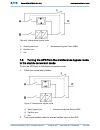

Figure 4. Path of current through the ups in the battery mode a static switch 1 bypass in- put main power flow b rectifier 2 rectifier in- put energized c inverter 3 output de-energized d battery con- verter 4 battery breaker trickle current e battery closed open during a utility power failure, the ...

Page 25

Maximum of 2 minutes before the output of the system shuts down. If the bypass source is available, the ups transfers to the bypass mode instead of shutting down. If the input power becomes available again at any time during the battery discharge, k1 and k5 close and the ups returns to normal operat...

Page 26

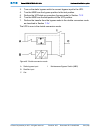

Figure 5. Path of current through the ups in the bypass mode a static switch 1 bypass in- put main power flow b rectifier 2 rectifier in- put energized c inverter 3 output de-energized d battery con- verter 4 battery breaker trickle current e battery closed open in the bypass mode, the output of the...

Page 27

3.3 ups features the eaton ups has many features that provide cost-effective and consistently reliable power protection. The feature descriptions provide a brief overview of the ups standard features. 3.3.1 advanced battery management the advanced battery management technology uses sophisticated sen...

Page 28

3.3.3 power conditioner the power conditioner mode is characterized by the ups running in the double conversion mode without batteries connected. In the power conditioner mode, the ups provides conditioned output voltage and frequency. The ups can also support high nonlinear loads without ithd on th...

Page 29

Separate generator sets, or situation where the bypass sources for the two systems are lost. 3.4 software and connectivity features 3.4.1 user interface minislot communication bays — there are 3 communication bays for minislot connectivity cards. Minislot cards are quickly installed and hot-pluggabl...

Page 30

3.5.2 93pm 200 kw siac-mbs the side integrated accessory cabinet (siac-mbs) for 160-200 kw 93pm includes a mechanical maintenance bypass switch and 1 or 2 input breakers for dual or single feed installation. 3.5.3 top air exhaust kit the top air exhaust kit is used to direct the ups cooling air fron...

Page 31

In order to install an f-upm, the ups cabinet needs to have upgradeability, which is determined by the power rating of the static bypass. For example, if the static bypass is rated for 150 kw, the fourth upm cannot be installed into the frame. For a listing of the upgradeable configurations, see tab...

Page 32

Figure 6. Ups battery switchgear cabling diagram 1 external battery switchgear 5 string breaker n 2 breaker 6 battery cabinet 1 3 ups 7 battery cabinet n 4 string breaker 1 3.7 basic system configurations ups power rating the maximum attainable ups system power rating is determined by the size of th...

Page 33

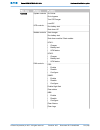

Description system power [kw] power modules [kw] static switch [kw] internal battery 93pm 40(100) 40 1x40 100 no 93pm 40(150) 40 1x40 150 no 93pm 40(200) 40 1x40 200 no 93pm 40+40(100) 40 2x40 100 no 93pm-50(100) 50 1x50 100 no 93pm 50(150) 50 1x50 150 no 93pm 50(200) 50 1x50 200 no 93pm 50+50(100) ...

Page 34

The following table shows different standard and optional ups features and the models where they apply. Table 3: standard and optional ups features feature 30–50 kw, 60 kva 80–100 kw 120–150 kw 160–200 kw smart touch screen display for system control and monitoring standard standard standard standar...

Page 35

4 ups installation plan and unpacking use the following basic sequence of steps to install the ups: 1. Create an installation plan for the ups system. 2. Prepare your site for the ups system. 3. Inspect and unpack the ups cabinet. 4. Unload and install the ups cabinet and wire the system. 5. Complet...

Page 36

4.2 installation checklist action yes / no all packing materials and restraints are removed from each cabinet. Each cabinet in the ups system is placed in its installed location. A cabinet grounding kit / mounting kit is installed between any cabinets that are bolted together. All conduits and cable...

Page 37

Operating environment must meet the height, clearance, and environmental requirements specified. 4.3.1 environmental and installation considerations the ups system can be installed where there is tn, tt, or it power distribution system. • install the system indoors on a level floor suitable for comp...

Page 38

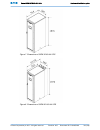

Figure 7. Dimensions of 93pm 30-50 kw ups figure 8. Dimensions of 93pm 80-150 kw ups eaton 93pm ups 30–200 kva user's and installation guide © eaton corporation plc 2017. All rights reserved. Revision: 005 document id: p-164000249 38 (126).

Page 39

Figure 9. Dimensions of 93pm 160-200 kw ups the ups cabinets use forced air cooling to regulate internal component temperature. By standard, air inlets are in the front of the cabinet and outlets are in the back. You must allow clearance in front of and behind each cabinet for proper air circulation...

Page 40

Figure 10. 93pm air outlets the clearances required around the ups cabinet in both of these situations are shown in table 6 . Table 6: ups cabinet clearances 30–50 kw, 60 kva [mm] 80–100 kw [mm] 120–200 kw [mm] 80–200 kw with top air exhaust kit [mm] from the top of the cabinet 500 500 500 500 from ...

Page 41

• temperature rise of max. +5 °c requires the airflow of 600 m 3 /h per 1 kw of losses • temperature rise of max. +10 °c requires the airflow of 300 m 3 /h per 1 kw of losses an ambient temperature from +20 to +25 °c is recommended to achieve a long life of the ups and batteries. The cooling air ent...

Page 42

• refer to national and local electrical codes for acceptable external wiring practices. • to allow for future kva upgrades (software and/or hardware), consider using conductors sized for full bypass rating of the ups. • material and labor for external wiring requirements must be provided by designa...

Page 43

Caution make sure that prospective short-circuit current resulting at the input terminals of the ups is equal or less than conditional short-circuit current declared on the type plate of the ups. Table 9: minimum recommended multi-core cable and fuse sizes for battery connection ups rating [kw] batt...

Page 44

Rated power [kw] rated voltage [v] rectifier input ups output / bypass rated current [a] maximum current [a] rated current [a] maximum current [a] 50 380 80 95 77 91 400 76 90 74 87 415 73 86 71 83 60 kva 380 80 90 77 91 400 76 86 74 87 415 73 150 71 83 80 380 127 164 122 145 400 121 156 116 138 415...

Page 45

Rated power [kw] battery rated current [a] maximum current* [a] 60 kva 132 158 80 195 233 100 244 292 120 292 350 150 365 438 160 390 467 200 487 584 *maximum battery current calculated at rated load and 1.67 v cell voltage for 36 block string length. Table 12: ups power cable terminations terminal ...

Page 46

Caution to reduce the risk of a fire, connect only to a circuit that is provided with maximum input circuit breaker current ratings from table 10 and table 11 in accordance with the national and local installation rules. The line-to-line unbalanced output capability of the ups is limited only by the...

Page 47

2. Make a visual inspection to make sure that there are no signs of shipping damages. Examine the indicators. See the instructions next to the indicators on the package. 3. Open the ups package and remove the ramp attached to the side of the package by forcing the locking pieces to open. There are l...

Page 48

5. If the leveling feet are not fully retracted, turn them until they are retracted. 6. Open the cabinet door. 7. Remove the bolts that fasten the shipping brackets to the cabinet and to the pallet. 8. Remove the shipping brackets. Note: after you have removed the shipping brackets, move the unit im...

Page 49

9. Slowly roll the cabinet toward the ramp edge. Do not to push the cabinet too much or too fast because the cabinet can tip over. Note that the cabinet is heavy. Make sure that you have enough manpower to handle and support the unit while rolling it off the pallet. 10. Roll the cabinet to its final...

Page 50

5 ups system installation the operator has to supply the wiring to connect the ups to the local power source. The installation of the ups must be made by a locally qualified electrician. The electrical installation procedure is described in the following section. The installation inspection and the ...

Page 51

3. For 30-50 kw frame: remove the screw securing the mbs protection cover on bottom left of the front panel. 4. Loosen the screw in the middle of the know and pull the knob off the shaft. 5. Remove the screws and pull out the safety shield panel in front of the connectors. 6. For 80-150 kw frame: re...

Page 52

7. For 160-200 kw frame: remove the cover panel (1) by removing the screw and lifting the cover panel. Remove the screws and pull out the safety shield panel (2) in front of the connectors. 8. For 30-50 kw frame: locate and remove the screws from the relevant cable gland plates for installing the po...

Page 53

9. For 80-150 kw frame: locate and remove the screws from the relevant cable gland plates for installing the power cables. 10. For 160-200 kw frame: locate and remove the screws from the relevant cable gland plates for installing the power cables. Eaton 93pm ups 30–200 kva user's and installation gu...

Page 54

11. Drill or punch holes for the cable glands on the plate used for cable entry. Do the work while the plate is outside the ups cabinet to prevent metal shavings or chips from entering into electronics. 12. Install suitable cable glands on the plate. 13. Route all cables through the wire way to the ...

Page 55

5.2 connector and power cable terminal locations the list of connectors and power cable terminal locations is applicable to all 93pm 30-200 kva ups models. Eaton 93pm ups 30–200 kva user's and installation guide © eaton corporation plc 2017. All rights reserved. Revision: 005 document id: p-16400024...

Page 56

Figure 11. 93pm 30–50 kw connectors and power cable terminals figure 12. 93pm 80-150 kw connectors and power cable terminals eaton 93pm ups 30–200 kva user's and installation guide © eaton corporation plc 2017. All rights reserved. Revision: 005 document id: p-164000249 56 (126).

Page 57

Figure 13. 93pm 160–200 kw ups connectors and power cable terminals 1 x1: rectifier input l1-l3 9 x5:1 2 x1: neutral for rectifier input 10 x5:2 3 x2: bypass input l1-l3 11 x5:3 4 x3: ups output l1-l3 12 x5:4 5 x2, x3: neutral for ups output and bypass input 13 x6:1 6 external battery batt+ and batt...

Page 58

Figure 14. 93pm 30–150 kw top cable access kit a view from the top 2 top panel (removable) b view from the right 3 cable binding profile 1 top cable access gland plate 5.3 installing 93pm 160-200kw with side integrated accessory cabinet mbs side integrated accessory cabinet for 160-200 kw 93pm inclu...

Page 59

These instructions guide the installation of the device with siac-mbs. 1. Remove the front plate of the integrated accessory cabinet (finger screw on the top of the plate). 2. Remove dead-front screws and dead-front. 3. Remove the applicable plates for cable installation access. You can install the ...

Page 60

Figure 15. Mbs positions a ups c bypass b test figure 16. 93pm 200 kw siac-mbs connector locations (1 breaker single-feed version) 1 bypass input breaker 8 x3: ups output l3 2 maintenance bypass switch 9 x3: ups output l2 3 x2: neutral for ups input 10 x3: ups output l1 4 x2: ups input l3 11 externa...

Page 61

Figure 17. 200 kw siac-mbs connector locations (2 breaker dual-feed version) 1 bypass input breaker 10 x3: rectifier input l1 2 rectifier input breaker 11 x3: ups output n 3 maintenance bypass switch 12 x3: ups output l3 4 x1: neutral & x2: neutral for rectifier and bypass inputs 13 x3: ups output l...

Page 62

Figure 19. 93pm 200 kw siac-mbs gland plate locations (rear) 1 cable access gland plate 2 communication cable conduit 5.4 installing the battery system danger this ups can have internal batteries. The batteries are designed to deliver a large amount of energy. An incorrect connection can lead to a s...

Page 63

Avoid damages to the equipment or injuries to personnel, let only the commissioning personnel do the connection of these batteries. Note: see section 9.5 for the battery specification. Warning do not connect battery strings with different battery quantity and voltage in parallel. For eaton 93pm prod...

Page 64

5.4.1 installing the battery system for 93pm ups with separate battery option if you choose to order a multi-modular eaton 93pm ups (up to 200 kva) with a separate battery option, the ups external battery connections require installing a separate battery for each upm. Figure 21 and figure 22 show th...

Page 65

Figure 22. Separate battery option battery terminals for 93pm 200 kw 1 battery + for upm 1 5 battery - for upm 1 2 battery + for upm 2 6 battery - for upm 2 3 battery + for upm 3 7 battery - for upm 3 4 battery + for upm 4 8 battery - for upm 4 table 15: recommended battery cable and fuse sizes for ...

Page 66

Cannot have an internal breaker. The external battery breaker is a crucial part of the external battery cabinet or rack and must be placed in it. Both internal and external battery breakers can be tripped (switched off) by energizing its shunt trip coil. The shunt trip coils are energized (controlle...

Page 67

Figure 23. Battery trip wiring for 50 kw 93pm ups a signal inputs 4 aux contact b external battery breaker 5 shunt trip coil + c external battery breaker 6 shunt trip coil - d internal battery breaker 7 aux contact return 1 signal input 5 return 8 aux contact 2 signal input 5 9 shunt trip coil + 3 a...

Page 68

Figure 24. Battery trip wiring for 100–150 kw 93pm ups a signal inputs 4 aux contact b external battery breaker 5 shunt trip coil - c external battery breaker 6 shunt trip coil + d internal battery breaker 7 aux contact return 1 signal input 5 return 8 aux contact 2 signal input 5 9 shunt trip coil ...

Page 69

Figure 25. Battery trip wiring for 200 kw 93pm ups a signal inputs 5 shunt trip coil - b external battery breaker 6 shunt trip coil + c external battery breaker 7 aux contact return 1 signal input 5 return 8 aux contact 2 signal input 5 9 shunt trip coil - 3 aux contact return 10 shunt trip coil + 4...

Page 70

Figure 26. Connections of the epo switch. Note that in "normally closed" (b) situation a jumper between pins 3 and 4 is needed. Table 17: remote epo wire terminations from remote epo switch to user interface ter- minal block epo in ups cabinet remarks no 3-4 nc 1-2 wire jumper between 3-4 must be in...

Page 71

Higher signaling circuit voltage requirements, please use industrial relay adapter in minislot. 5.6.1 installing customer input signals interface these inputs are located behind the ups door, in the top section of the ups. See figure 29 for the connector locations. Tie points with strain relief for ...

Page 72

1. Make sure that the ancillary equipment system is turned off and all the power sources are removed. Refer to the appropriate operation manual of any ancillary equipment for shutdown instructions. 2. Install wiring from the irc to the monitoring equipment using appropriate conduits through the cabl...

Page 73

8. When all the wiring is completed, close the front door and secure it with the latch. 5.6.6 installing signal interface connections in a parallel system the installation of the signal interface connections in a parallel system is done by following the aforementioned instructions. Signal inputs can...

Page 74

Shortest length of power wire from the source to the ups must be a minimum of 95% of the length of the longest wire. Output the neutrals of all the upss must be connected. The shortest length of wire from the source to the ups must be a minimum of 95% of the length of the longest wire. The measureme...

Page 75

Figure 28. Principle of paralleled ups systems a bypass inputs to upss 1 ups 1 7 battery b outputs from upss 2 ups 2 8 battery c load 3 ups 3 9 mob1 4 ups 4 10 mob2 5 battery 11 mob3 6 battery 12 mob4 the required parallel system wiring length must be equal to ensure approximately equal current shar...

Page 76

Ecan provides a means for communication between the upss in a parallel system. The system will continue to share load and protect the load when this network fails bypass pull-chain bypass pull-chain is an open collector signal that goes low when the bypass static switch of any ups is online. When ex...

Page 77

Figure 30. External parallel connector figure 31. Simplified can and pull-chain wiring for parallel ups system a ups 1 1 can b ups 2 2 pull chain c ups 3 (if installed) d ups 4 (if installed) note: this drawing is for distributed bypass wiring purposes and it is not a floor layout plan. Upss can be ...

Page 78

Figure 32. Can and pull-chain wiring for parallel ups with mobs figure 33. Can and pull-chain wiring for parallel ups without mobs a external parallel connector, ups 1 5 gnd (isp) b external parallel connector, ups 2 6 earth c external parallel connector, ups 3 7 canbl 1 external pull chain 8 canb_1...

Page 79

The ups and mob aux contacts. Always confirm contact operation prior to wiring. 5.8 ups system interface wiring preparation control wiring for features and options should be connected at the customer interface terminal blocks located on top front of the ups, behind the door. Note: do not connect rel...

Page 80

6 communication interfaces this section describes the communication features of the eaton 93pm ups. Caution all the communication interfaces are selv circuits. When connecting to other equipment, make sure that you maintain this characteristic. The ups has the following communication interfaces: fig...

Page 81

Provides remote monitoring through a web browser interface, e-mail, and a network management system (nms) using snmp and connects to a twisted- pair ethernet (10/100baset) network. Figure 35. Network card - ms • px gateway card provides remote monitoring through a web browser interface, e-mail, and ...

Page 82

Figure 37. Industrial relay card-ms 6.2 intelligent power software intelligent power software are productivity tools for ups power management. These software solutions enhance the protection provided by a ups by shutting down applications and operating systems, triggering disaster recovery procedure...

Page 83

6.3 signal input monitoring this standard feature lets you connect smoke detectors or over-temperature alarms to your signal inputs. The user interface terminals for external connections are located inside the ups. Use twisted-pair wires for each alarm input and common. The signal inputs can be prog...

Page 84

Figure 38. Output relay configurations: a) normally closed (pins 1 and 3), b) normally open (pins 2 and 3) 6.5 configuring relays 93pm offers one native relay output. Additionally, each of the 3 minislots can be equipped with a 5-relay adapter for additional relay outputs. These instructions guide y...

Page 85

Figure 39. Sign in window with the password field 3. Enter the password 0101 and press . 4. Select continue. 5. Select configuration and then relays outputs. Figure 40. Selecting relay outputs in the configurations screen 6. Select from these options: • native (alarm) relay it is possible to set 8 d...

Page 86

Figure 41. Options for relay outputs configuration 7. Enter the code(s) of the function(s) that you want to trigger the relay when they become active. 8. Press ok and save to save the changes. Figure 42. Entering the codes of the functions that will trigger the relay 9. If you selected one of the mi...

Page 87

10. You can test the relays by selecting any of the options in the test mode (see figure 41 ). Figure 43. Relays 1 cable exit opening for up to 12 mm (½”) conduit 3 k1 thru k5 terminal connections for relay contacts to operator's monitoring equipment 2 signal input connector with voltage supply eato...

Page 88

7 ups operating instructions this section describes how to operate the ups. Caution before you operate the ups, make sure that all the installation tasks are completed and a preliminary startup has been performed by authorized service personnel. The preliminary startup verifies all the electrical in...

Page 89

Figure 44. Parts of the display the display consists of the following parts: 1 status bar the status bar displays the ups name, state, current date and time, meters information, and a sign in/out button. It also shows any active alarms and warn- ings. 2 main navigation select a screen by tapping on ...

Page 90

Indicator status description yellow symbol for bypass mode on the ups is in the bypass mode. The critical load is supported by the bypass source. The green indica- tor for normal operation is not illuminated when the system is in the bypass mode. Red symbol for active alarm on the ups has an active ...

Page 91

Color led indicators (screen and door) ups status alarm 7.1.3 system events when the ups system is running in the double conversion mode, it continually monitors itself and the incoming utility power. In the battery or bypass mode, the ups may issue alarms to let you know exactly what event caused t...

Page 92

Main menu submenu functions meters meters summa- ry a summary of the ups or system meters. Input meters detailed information on ups or system input meters. Bypass meters detailed information on ups or system bypass me- ters. Output meters detailed information on ups or system output me- ters. Upm po...

Page 93

Main menu submenu functions controls system controls go online go to bypass turn off charger load off ups controls run battery test shut down up module controls start charger run battery test shut down module / start module upm 1: • charger • battery test • upm status upm 2: • charger • battery test...

Page 94

Main menu submenu functions mimics ups mimics an overview of the ups operation, including informa- tion on load, efficiency and consumption. If there is an error, an error indicator is displayed next to the af- fected part. Active events log can be opened by tap- ping the error indicator. Ups module...

Page 95

Setting description signal input select signal input name and function or change contact polarity. Relay outputs configure the relay outputs. Battery test change the power level and duration for battery test. Bypass limits change the bypass voltage or bypass frequency. Screen saver time- out change ...

Page 96

7.3 system control instructions 7.3.1 starting the ups system in the double conversion mode the ups system can consist of a single ups or several parallel upss. Upss with their mob open are not considered as part of the system. To start the ups system: 1. Open the ups front door. 2. If included insi...

Page 97

7.3.2 starting the ups system in the bypass mode caution in the bypass mode, the critical load is not protected from mains power interruptions and abnormalities. If the inverter output of the ups is not available and the critical load needs to be energized, perform the following procedure: 1. Open t...

Page 98

The ups system is now operating in the bypass mode and the yellow bypass status indicator is illuminated. The upm status is shown as ready. The system status is shown as on bypass. 7.3.4 transferring from the bypass mode to the double conversion mode to transfer the critical load to the double conve...

Page 99

To transfer the critical load to the double conversion mode: 1. In the home screen, press controls. 2. Select service controls. 3. Select disable ess. The ups system transfers to the battery mode and then to the double conversion mode. If the power module is not available, the system remains in the ...

Page 100

Note: all power to the critical load is lost when load off is selected. Only use this feature when you want to de-energize the critical load. When load off is selected, the input, output, and bypass backfeed contactors open, the battery breaker or disconnect is tripped, and all the upss in the syste...

Page 101

Starting online the rectifier and inverter turn on. The dc voltage continues to ramp up to full voltage. Once the dc link reaches full voltage and the battery breaker is closed, the ups output relay k3 closes. Power is now supplied to the critical load in the double conversion mode. It takes approxi...

Page 102

7. Wait for the ups control panel to become active and indicate logic power. 8. In the home screen, press controls. The system controls screen is displayed. 9. In the system controls screen, check that the ups status is shown as shutdown. 10. Check that there are no active alarms. 11. In the system ...

Page 103

Caution when the epo switch is activated, all power to the critical load is lost. Use this feature only in case of emergency. Note: the following instructions are for the epo switch supplied by eaton corporation. If you are using a customer-supplied epo switch, it may not activate in the same way. F...

Page 104

Figure 45. Normal positions of the mbs switches and rectifier disconnect switch (must be located in the site wiring) a static bypass input 1 maintenance bypass switch (mbs) b rectifier input c out 2. Perform the transfer from the double conversion mode to the bypass mode as instructed in section 7.3...

Page 105

Figure 46. Maintenance bypass mode a static bypass input 1 maintenance bypass switch (mbs) b rectifier input c out 7.8 turning the ups from the maintenance bypass mode to the double conversion mode to turn the ups back to the double conversion mode: 1. Follow the normal start position: figure 47. Ma...

Page 106

3. Turn on the static bypass switch to connect bypass input to the ups. 4. Turn the mbs from the bypass position to the test position. 5. Perform the ups start-up procedure (bypass mode) in section 7.3.2 . 6. Turn the mbs from the test position to the ups position. 7. Perform the transfer from the b...

Page 107

8 ups maintenance the components inside the ups cabinet are secured to a sturdy metal frame. All repairable parts and assemblies are located for easy removal with very little disassembly. This design allows authorized service personnel to perform routine maintenance and servicing quickly. Schedule p...

Page 108

Figure 49. Warning label since each battery string is an energy source in itself, opening the battery circuit breaker does not de-energize the voltage within the battery string. Danger do not attempt to access any internal area of the battery string. Voltages are always present in the battery string...

Page 109

2. If the optional air filters are installed, examine them (located behind the front doors) and wash or replace them, if needed. Contact your service representative for replacement filters. To replace the filters: a. Open the ups front door. B. Replace the filters. C. Close the ups front door. 3. Re...

Page 110

Figure 50. Weee symbol (left) and battery recycling symbol when you handle waste from electrical and electronic equipment, use proper local collecting centers that meet local legislation. Warning hazardous materials. Batteries can contain high voltages and caustic, toxic and flammable substances. If...

Page 111

9 technical data for a complete technical specification, contact your eaton representative. Due to continuous product improvement programs, specifications are subject to change without notice. 9.1 directives and standards safety iec 62040-1: uninterruptible power systems (ups) - part 1: general and ...

Page 112

9.2 ups system input rated input voltage 220/380 v; 230/400 v; 240/415 v voltage tolerance (rectifier input) 230 v -20% / +20% voltage tolerance (bypass input) 230 v -15% / +10% rated input frequency 50 or 60 hz, user configurable frequency tolerance 40 to 72 hz number of input phases (rectifier & b...

Page 113

Overload capability at ambient 40 °c (in the stored energy mode) 10 min 102–110% load 60 s 111–125% load 300 ms > 126% load overload capability at ambient 40 °c (in the bypass mode) continuous ≤ 125% load 10 ms 1,000% load note! Bypass fuses may limit the overload capability. Load power factor (rate...

Page 114

Ambient operating temperature range, 60 kva model from +5 °c ... +30 °c relative humidity range 5 to 95%, no condensation allowed maximum service altitude 1,000 m (3,300 ft) above sea level at +40 °c maximum 2,000 m (6,600 ft) with 1% derat- ing per each additional 100 m above 1,000 m. Maximum stora...

Page 115

10 warranty 10.1 general the product is warranted against defects in materials and workmanship for a period of twelve (12) months from its original date of purchase. The local office or distributor may grant a warranty period different to the above. Please refer to local terms of liability as define...

Page 116

10.2 whom to contact in case of warranty in case of warranty, or while unsure if the unit in question is covered by warranty, contact the respective sales organization where the unit was purchased. Have the following information available: • purchase order number and purchase order date • installati...

Page 117

Appendix a: relay alarms name id 24v power supply failed 73 5v power supply failed 72 abm active 232 abm enable 231 abm installed 230 abm state reset 91 abm state charging 88 abm state floating 89 abm state resting 90 adaptive overload capacity off 116 adaptive overload capacity off 326 alternate sy...

Page 118

Name id battery test in progress 60 battery test cancel command 439 battery test command 438 boost charging active 327 boost charging available 328 boost charging installed 330 bypass ac over voltage 192 bypass ac under voltage 193 bypass breaker active 278 bypass breaker installed 277 bypass comman...

Page 119

Name id command received 294 configuration error 53 csb control power 425 csb eeprom version downgrade 464 csb software incompatible 426 dc link over voltage 10 dc link under voltage 11 disable abm command 447 disable ess command 444 disable hrs command 456 disable service mode command 441 disable v...

Page 120

Name id horn is buzzing 418 hrs active 283 hrs enabled 282 hrs installed 281 i2c bus failed 115 input ac over voltage 2 input ac under voltage 3 input sync out of range 75 input sync out of range 269 input under/ over frequency 4 internal can bus failed 109 internal can bus failed 310 internal commu...

Page 121

Name id mcu control power 289 mcu eeprom checksum failed 240 mcu software incompatible 210 mis installed 291 mis open/closed 292 mob open 279 not enough bypass capacity 272 not enough redundant upms 323 not enough upms 271 on alarm led is lit 416 on battery led is lit 260 on bypass led is lit 261 on...

Page 122

Name id phase a overload 27 phase b overload 28 phase c overload 29 phasea overload level2 30 phasea overload level3 33 phasea overload level4 36 phaseb overload level2 31 phaseb overload level3 34 phaseb overload level4 37 phasec overload level2 32 phasec overload level3 35 phasec overload level4 3...

Page 123

Name id signal input 6 on 412 signal input 7 on 413 signal input 8 on 451 signal input 9 on 452 signal input battery disconnected 402 signal input bypass sync disabled 400 signal input charger off 392 signal input disable battery charge and discharge 401 signal input forced maintenance bypass 404 si...

Page 124

Name id sts fan failed 288 system not redundant 233 system on bypass 312 system on maintenance bypass 270 system overload 311 system test in progress 259 to bypass command 221 too many eep written operation 468 too many inverter transfers 65 too many inverter transfers 285 too many battery transfers...

Page 125

Name id upm unlock 110 upms not redundant 314 ups exit ect process 306 ups normal command 222 ups not redundant 313 ups on battery 215 ups on bypass 211 ups on generator 220 ups phasea output overload 242 ups phasea overload level2 245 ups phasea overload level3 248 ups phasea overload level4 251 up...

Page 126

Copyright © 2017 eaton corporation plc. All rights reserved. Unauthorized copying and lending are prohibited. Eaton power quality oy koskelontie 13 fi-02920 espoo, finland www.Eaton.Eu.