- DL manuals

- Echo

- Trimmer

- Power Pruner PPT-2100

- Operator's Manual

Echo Power Pruner PPT-2100 Operator's Manual

P

OWER

P

RUNER

O

PERATOR

'

S

M

ANUAL

1

Power Pruner

Operator's Manual

MODELS:

PPT-2100 TYPE 1/1E

Serial Number 503550 - 506999

PPT-2400 TYPE 1/1E

Serial Number 505900 - 518599

WARNING DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Operator's Manual, which must

be read and understood for proper and safe operation. Failure to do so could result in serous injury.

WARNING

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

89865024661

07/98

X7502301401

Summary of Power Pruner PPT-2100

Page 1

P ower p runer o perator ' s m anual 1 power pruner operator's manual models: ppt-2100 type 1/1e serial number 503550 - 506999 ppt-2400 type 1/1e serial number 505900 - 518599 warning danger read rules for safe operation and instructions carefully. Echo provides an operator's manual, which must be r...

Page 2: –

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the- job-dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operating tips and s...

Page 3: & I

P ower p runer o perator ' s m anual 3 this symbol accompanied by the words warning and danger calls attention to an act or condition that can lead to serious personal injury to operator and bystanders. The circle with the slash symbol means whatever is shown within the circle is prohibited. M anual...

Page 4

4 decals locate this safety decal on your unit. The complete unit illustration found in the "description" section, will help you locate them. Make sure the decals are legible and that you understand and follow the instructions on them. If a decal cannot be read, a new one can be ordered from your ec...

Page 5

P ower p runer o perator ' s m anual 5 guide bar and saw chain warning danger • serious injury may result from the use of non approved guide bar and saw chain combinations. Read and comply with all safety instructions listed in this manual. • echo, inc. Will not be responsible for the failure of cut...

Page 6

6 personal condition & safety equipment warning danger power pruner users risk injury to themselves and others if the power pruner is used improperly and or safety precautions are not followed. Proper clothing and safety gear must be worn when operating a power pruner. Physical condition -- your jud...

Page 7

P ower p runer o perator ' s m anual 7 safe operation warning danger all over head electrical conductors and communications wires can have electricity flow with high voltages. Never touch wires directly or indirectly when pruning, otherwise serious injury or death may result. Hot humid weather -- he...

Page 8

8 keep a firm grip • grip power pruner with both hands with thumbs and fingers tightly encircling the handle, and lower shaft tube. Keep a solid stance • maintain footing and balance at all times. Do not stand on slippery, uneven or unstable surfaces. Do not work in odd positions or on ladders. Do n...

Page 9

P ower p runer o perator ' s m anual 9 extended operation / extreme conditions vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold may c...

Page 10

10 d escription due to packaging restriction the echo product you have purchased requires some assembly. After opening the carton, check for damage. Immediately notify your retailer or echo dealer of damaged or missing parts. Use the contents list to check for missing parts. Contents list __ power h...

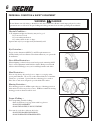

Page 11

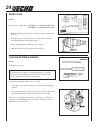

P ower p runer o perator ' s m anual 11 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22.

Page 12

12 1. Power head - includes the engine, clutch, fuel system, ignition system and starter. 2. Rear handle assembly - sturdy handle for right hand placement. Includes stop switch and throttle trigger. 3. Throttle trigger lockout - this lever must be depressed before throttle trigger can be operated. 4...

Page 13

P ower p runer o perator ' s m anual 13 model ppt-2100 ppt-2400 length (standard) 2286 mm (90.0 in.) 2743 mm (108.0 in.) length (extended) 3410 mm (134.25 in.) 3886 mm (153.0 in.) width 222 mm (8.75 in.) 222 mm (8.75 in.) height 229 mm (9.0 in.) 229 mm (9.0 in.) weight (dry) 7.4 kg (16.3 lb.) 7.7 kg...

Page 14

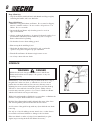

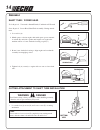

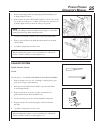

14 1. Loosen bolt (a). 2. Match square socket in engine shaft with square power transmis- sion shaft (b) and slide together until engine rests against the machine surface of lower shaft tube housing coupler (c). 3. Rotate lower shaft tube housing to align engine and rear handle assembly in an uprigh...

Page 15

P ower p runer o perator ' s m anual 15 2. Loosen center clamp knob (f) turning counter clockwise. 3. Pull upper shaft tube (g) out of fiberglass lower shaft tube 127-152 mm (5-6 in.), then slide (g) back into fiberglass lower shaft tube exposing inner power transmission shaft (h). Align and join st...

Page 16

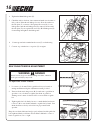

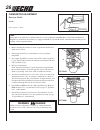

16 b a 4. Tighten the 10mm linkage nuts (e). 5. Check throttle for freedom of movement and make sure it returns to idle position. If the throttle linkage does not allow the carburetor throttle plate (c) to return to idle against idle screw (d), loosen linkage nuts; turn throttle linkage nut (e) coun...

Page 17

P ower p runer o perator ' s m anual 17 p re -o peration fuel fuel requirements gasoline - use 89 octane [ ] gasoline or gasohol known to be good quality. Gasohol may contain up to 10% ethyl (grain) alcohol or 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methanol (wood alcohol) is not ...

Page 18

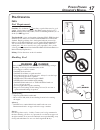

18 s m t w t f s 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 important stored fuel ages. Do not mix more fuel than you expect to use in thirty (30) days, ninety (90) days when a fuel stabilizer is added. Important stored two-stroke fuel may separate. Always sh...

Page 19

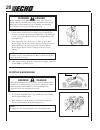

P ower p runer o perator ' s m anual 19 determine operation area • before starting the unit, equip yourself and fellow workers in the 15 m (50 ft.) safety zone with the required protective equipment and clothing. • review the area to be trimmed. Look for hazards that could contribute to unsafe condi...

Page 20

20 warning danger inspect starting area for hazards such as rocks, glass, debris etc. Which could be contacted by the cutting attachment when starting. Keep helpers and bystanders at least 15 m (50 ft.) from starting area, otherwise serious personal injury may result. 4. Lay the pruner on a flat cle...

Page 21

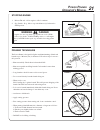

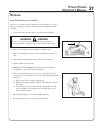

P ower p runer o perator ' s m anual 21 stopping engine 1. Release throttle. Allow engine to idle for a minute. 2. Stop switch - stop. Move stop switch button (a) backward to stop position. Warning danger if engine does not stop when stop switch is moved to stop position, close choke - cold start po...

Page 22

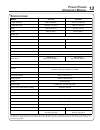

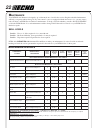

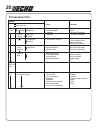

2 2 maintenance intervals / t n e n o p m o c m e t s y s e c n a n e t n i a m e r u d e c o r p d ' q e r l l i k s l e v e l r o y l i a d e r o f e b e s u y r e v e l e u f e r 3 s h t n o m 0 9 r o s r u o h 6 s h t n o m 0 7 2 r o s r u o h y l r a e y 0 0 6 s r u o h s e r u d e c o r p e c ...

Page 23

P ower p runer o perator ' s m anual 23 air filter level 1. Parts required: 90008 repower filter kit 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumu- lated dirt from the air cleaner area. 2. Remove the air clea...

Page 24

24 spark plug level 2. Parts required: spark plug, ngk bpm-7a (15901010630 - ppt-2100) ngk bpm-7y (15901019630 - ppt-2400) 1. Remove spark plug and check for fouling, worn and rounded center electrode. 2. Clean the plug or replace with a new one. Do not sand blast to clean. Remaining sand will damag...

Page 25

P ower p runer o perator ' s m anual 25 1. Remove spark plug lead from spark plug and throttle linkage end from the carburetor swivel. 2. Remove the four screws that retain the engine cover (a). Two at the top of the recoil starter, two on either side of the front. Lift the cover from the engine and...

Page 26

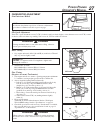

26 carburetor adjustment emission models level 2. Parts required: none. 1. Before adjusting the carburetor, clean or replace the air filter and spark arrester screen. 2. Start engine and run for several minutes to reach operating temperature. 3. Stop engine. Turn hi (a) speed needle ccw (counter clo...

Page 27

P ower p runer o perator ' s m anual 27 warning danger when carburetor adjustment is completed, cutting attachment should not move at idle, otherwise serious personal injury may result. Carburetor adjustment non emissions models note if carburetor has limiter caps follow "carburetor adjustment" proc...

Page 28

28 guide bar and saw chain replacement warning danger never try to replace or adjust guide bar and saw chain with engine running. This saw chain is very sharp, wear heavy gloves to protect your hands when handling it. Wear eye protection meeting ce or ansi z87.1 specification. Guide bar replacement ...

Page 29

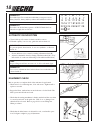

P ower p runer o perator ' s m anual 29 filing saw chain level 3. Important dull or damaged cutters will result in poor cutting performance, increased vibration and premature saw chain failure. Warning danger always stop engine and wear gloves when filing saw chain, otherwise serious personal injury...

Page 30

30 t roubleshooting remedy muffler wet with fuel engine does not crank no fuel at cylinder spark at end of plug wire no spark at end of plug wire spark at plug no spark at plug engine cranks fuel at carburetor no fuel at carburetor open choke clean/replace air filter adjust carburetor see your echo ...

Page 31

P ower p runer o perator ' s m anual 31 s torage long term storage (over 30 days) do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following: 1. Store unit in a dry, dust free place, out of the reach of chi...

Page 32: Dealer?

32 echo, incorporated 400 o akwood r oad l ake z urich , il 60047 dealer? Call 1-800-432-echo echo incorporated 400 oakwood road lake zurich, il 60047 technical publications orders service service of this product during the warranty period must be performed by an authorized echo service dealer. For ...

Page 33

Supplement to operator's manual part number 89865024661 (x7502301401) for models: ppt-2100 s/n 507000 & up ppt-2400 s/n 518000 & up cutting attachment installation instructions the enclosed pages include important assembly and adjustment procedures for your new power pruner. Please replace original ...

Page 34: 10A

10a d escription due to packaging restriction the echo product you have purchased requires some assembly. After opening the carton, check for damage. Immediately notify your retailer or echo dealer of damaged or missing parts. Use the contents list to check for missing parts. Contents list __ power ...

Page 35: 13A

P ower p runer o perator ' s m anual 13a s pecifications specifications, descriptions and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without notice. Illustrations may include optional equipment and accessories, and may not ...

Page 36: 14A

14a 1. Loosen bolt (a). 2. Match square socket in engine shaft with square power transmis- sion shaft (b) and slide together until engine rests against the machine surface of lower shaft tube housing coupler (c). 3. Rotate lower shaft tube housing to align engine and rear handle assembly in an uprig...

Page 37: 15A

P ower p runer o perator ' s m anual 15a 2. Loosen center clamp knob (f) turning counter clockwise. 3. Pull upper shaft tube (g) out of fiberglass lower shaft tube 127-152 mm (5-6 in.), then slide (g) back into fiberglass lower shaft tube exposing inner power transmission shaft (h). Align and join s...

Page 38: 16A

16a 4. Tighten the 10mm linkage nuts (e). 5. Check throttle for freedom of movement and make sure it returns to idle position. If the throttle linkage does not allow the carburetor throttle plate (c) to return to idle against idle screw (d), loosen linkage nuts; turn throttle linkage nut (e) counter...

Page 39: 18A

18a automatic oiling system 1. Wipe debris from around oil fill cap. 2. Remove oil fill cap and fill reservoir with a quality, low viscosity guide bar and saw chain oil. Note the discharge volume of the automatic oiler is preset to deliver 3 to 4 cc/min. At normal operating rpm. During heavy or dry ...

Page 40: 29A

P ower p runer o perator ' s m anual 29a a b guide bar and saw chain replacement warning danger never try to replace or adjust guide bar and saw chain with engine running. This saw chain is very sharp, wear heavy gloves to protect your hands when handling it. Wear eye protection meeting ce or ansi z...