- DL manuals

- FAAC

- Gate Opener

- 455 D

- Instruction Manual

FAAC 455 D Instruction Manual

400

Hydraulic Swing Gate Operator

UL325 Compliant

FAAC International Inc.

Headquarter & East Coast Operations

5151 Sunbeam Road

Suites 9-11

Jacksonville, FL 32257

Tel. 866 925 3222

www.faacusa.com

FAAC International Inc.

West Coast Operations

357 South Acacia Avenue

Unit 357

Fullerton, CA 92831

Tel. 800 221 8278

Summary of 455 D

Page 1

400 hydraulic swing gate operator ul325 compliant faac international inc. Headquarter & east coast operations 5151 sunbeam road suites 9-11 jacksonville, fl 32257 tel. 866 925 3222 www.Faacusa.Com faac international inc. West coast operations 357 south acacia avenue unit 357 fullerton, ca 92831 tel....

Page 3

1 contents faac 400 hydraulic swing gate operator important safety information 4 important safety instructions 4 important installation instructions 4 general safety precautions 5 ul325 gate operator classifications 6 installing the warning signs 6 1. Technical specifications 7 dimensions 7 2. Wirin...

Page 4

2 faac 400 hydraulic swing gate operator 16. Power and accessories connections 29 ac power wiring guidelines 29 ac power connection 29 magnetic lock connection 29 17. Troubleshooting 30 limited warranty 31 read this instruction manual before you begin installing the product. = information regarding ...

Page 5

3 faac 400 hydraulic swing gate operator 1. Install the gate operator only when the following condi- tions have been met: • the operator is appropriate for the type and usage class of the gate. • all openings of a horizontal slide gate have been guarded or screened from the bottom of the gate to a m...

Page 6

4 faac 400 hydraulic swing gate operator gate construction vehicular gates should be constructed and installed in accordance with astm f2200: standard specification for automated vehicular gate construction. For more information, contact astm at: www.Astm.Org installation • if you have any questions...

Page 7

5 faac 400 hydraulic swing gate operator residential vehicular gate operator class i a vehicular gate operator system intended for use in a single family dwelling, garage or associated parking area. Ul325 gate operator classifications commercial / general access vehicular gate operator class ii a ve...

Page 8

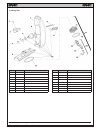

6 15 awg 20 awg 15 awg 15 awg 20 awg 20 awg 15 awg 20 awg faac 400 hydraulic swing gate operator 3 11/32” 3 11/32” 4 3/4” model cbc cbac sb sbs cbacr cbac eg sb eg max traction / thrust force: (dan) 620 620 620 775 465 465 465 effective rod stroke: (inches) 10 1/4 10 1/4 10 1/4 10 1/4 10 1/4 15 15 l...

Page 9

7 lo standard = 37 3/4” , eg = 47 1/4” z min = 2” s s = 0 s > 0 y standard = 3” y eg= 4” faac 400 hydraulic swing gate operator if the dimensions indicated in table a or b cannot be achieved, the following must be considered in order to calculate different measurements: • to obtain 90° opening of th...

Page 10

8 figure 6 figure 7 1/4 inch faac 400 hydraulic swing gate operator figure 8 figure 9 figure 10 2.) secure the operator to the rear attachment with the supplied screws (fig. 6). 3.) screw, halfway down, the front attachment onto the rod (fig. 8, ref.1). Tighten with the supplied nut. 4.) release the...

Page 11

9 faac 400 hydraulic swing gate operator 4. Start-up the model 400 has an anti-crushing safety device which limits the operator’s force when an obstacle is encountered while the gate is moving. To adjust the intervention threshold of the anti-crushing system, temporarily open the release cover. • li...

Page 12

10 faac 400 hydraulic swing gate operator opening angle a (inches) b (inches) s (inches) d(**) (inches) c(*) (inches) 90° 4 3 1/2 0 2 7 1/2 90° 4 5/16 4 0 2 3/8 8 1/4 90° 4 3/4 4 5/16 0 2 3/4 9 90° 5 1/8 4 3/4 0 3 1/8 9 7/8 refer to table 1 for this particular application. Select the operator accord...

Page 13

11 faac 400 hydraulic swing gate operator 10. Positive stop accessory in case the gate doesn’t allow you to have built in mechanical stops, it is possible to install, directly on the operator, an accessory to limit the rod’s travel in both directions. (p/n: 490109 standard, 490043 eg) the accessory ...

Page 14

12 faac 400 hydraulic swing gate operator run a functional check of the system at least twice a year. Pay special attention to the efficiency of safety and release devices (including the thrust force of the operator), and the perfect operation of the gate hinges. Checking oil level: periodically che...

Page 15

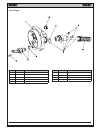

13 faac 400 hydraulic swing gate operator 400 cbac pos. P/n description 01 702202 galvanized nut (8 mm) 02 7220015 rear mounting bracket 03 7284005 rear mounting plate 04 7182075 short pin 05 7228015 die-cast rear fork 06 702302 self-locking nut 08 70991015 gasket diameter 80 09 490325 kit locking c...

Page 16

14 faac 400 hydraulic swing gate operator cylinder pos. P/n description 01 7049135 retaining ring nut 02 7090050015 gasket o-ring 10.82x1.78 03 4404065 inlet valve with spring 04 7049005 retainer 05 4404085 lock valve in zamack 06 4994655 valve body 07 7230295 tie rod cylinder 08 703204 star washer ...

Page 17

15 faac 400 hydraulic swing gate operator locking cap pos. P/n description 01 701307 screw 4x8 stainless steel 02 7290445 release knob 03 701526 torx 4x10 stainless steel 04 720344 top cover 05 729043 lock lever 06 7090895 21x2 o-ring 07 7275285 top cover 08 7131005 key 09 7275275 cap for lock pos. ...

Page 18

16 faac 400 hydraulic swing gate operator pos. P/n description 01 7171485 back flange 02 417010 wiring harness 03 63001005 moulded cable kit 04 7090895 21x2 o-ring 05 7110015 plug pos. P/n description 06 7109135 strain relief 07 701479 screw 3x12 08 701466 screw m3x8 09 7090725 o-ring 14x1.5 rear fl...

Page 19

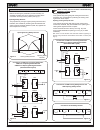

17 faac 400 hydraulic swing gate operator figure b 13.4. 455 d layout and components nb: capacitors are supplied with the operator. Important: before attempting any work on the control board (connections, maintenance), always turn off power. 13. 455 d control board 13.3 electric connections j4 j1 j3...

Page 20

18 faac 400 hydraulic swing gate operator 1 2 5 4 3 1 2 rx cl tx cl 1 2 5 4 3 1 2 rx op/cl tx op/cl 9 10 11 12 13 14 15 16 17 18 19 open a b stp cl op fsw - - - +24v + + -tx fsw 20 21 w.L. Lock - + - + - + - + 1 2 5 4 3 1 2 rx op tx op - + - + - + - + - + + + + -tx fsw -tx fsw -tx fsw 1 2 5 4 3 1 2 ...

Page 21

19 faac 400 hydraulic swing gate operator -tx fsw 1 2 5 4 3 1 2 rx cl1 tx cl1 1 2 5 4 3 1 2 rx cl2 tx cl2 9 10 11 12 13 14 15 16 17 18 19 open a b stp cl op fsw - - - +24v + + -tx fsw 20 21 w.L. Lock - + - + - + - + - + + -tx fsw - + + 9 10 11 12 13 14 15 16 17 18 19 open a b stp cl op fsw - - - +24...

Page 22

20 faac 400 hydraulic swing gate operator 455 d rp 1418 rp 433 rc figure q this is used for rapid connection to rp receivers (see fig. Q). Connect the accessory with the components side facing the inside of the card. Insert and remove with power off. 13.4.4 terminal block j1 - accessories (fig. B) o...

Page 23

21 faac 400 hydraulic swing gate operator = semi-automatic = automatic = “safety” automatic = “stepped” semi-automatic = “stepped” automatic = “safety stepped” automatic = “b” semi-automatic = dead-man fc c 2 red red black black white white leaf 1 force: adjusts thrust of motor 1. = minimum force = ...

Page 24

22 faac 400 hydraulic swing gate operator f + + to access advanced programming, press and hold key f and then press key +: • release key +, the unit displays the name of the first function. • release key f, modify the value of the function with keys + and -. • press and hold key f, the unit displays...

Page 25

23 faac 400 hydraulic swing gate operator figure u the board has a two-digit display. When not in “programming” mode, this display is used to indicate the status of inputs. Fig. U shows how the led segments of the display exactly correspond to the inputs. The table below shows the status of the leds...

Page 26

24 faac 400 hydraulic swing gate operator 1° open - leaf 1 slows down at opening (it stops automatically on reaching the stop limit) 2° open - leaf 2 opening movement begins 3° open - leaf 2 slows down at opening (it stops automatically on reaching the stop limit) 4° open - leaf 2 closing movement b...

Page 27

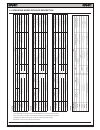

25 faac 400 hydraulic swing gate operator ta b .3 /a ta b .3 /b ta b .3 /c ta b .3 /d " a" ci g ol s e sl u p s ut at s et a g a- n e p o b - n e p o p ot s s e ci v e d yt e f a s g ni n e p o s e ci v e d yt e f a s g ni s ol c e ci v e d yt e f a s l c / p o d e s ol c s es ol c d n a f a el e ht...

Page 28

26 faac 400 hydraulic swing gate operator ta b .3 /e ta b .3 /f ta b .3 /g ta b .3 /h " c" ci g ol n w o d dl e h s y a wl a sl o rt n o c s e sl u p s ut at s et a g ) g ni n e p o( a- n e p o ) g ni s ol c( b- n e p o p ot s s e ci v e d yt e f a s g ni n e p o s e ci v e d yt e f a s g ni s ol c ...

Page 29

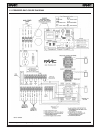

27 faac 400 hydraulic swing gate operator 15. Prewired enclosure diagram.

Page 30

28 faac 400 hydraulic swing gate operator ac power wiring guidelines 1. Check local wiring codes in all cases and follow all local building codes. Wiring and hookup should be performed by qualified electricians/installers only. 2. Ac power should be supplied from a circuit breaker panel and must hav...

Page 31

29 faac 400 hydraulic swing gate operator 17. Troubleshooting the following table may help you identify and resolve some common problems. Condition suggestion a gate does not move. • check that main power is supplied. • ensure that the operator is not unlocked (see section 8). • check the adjustment...

Page 32

30 faac 400 hydraulic swing gate operator to the original purchaser only: faac international, inc., warrants, for twenty- four (24) months from the date of invoice, the gate operator systems and other related sys- tems and equipment manufactured by faac s.P.A. And distributed by faac international, ...