- DL manuals

- Fervi

- Grinder

- 0554

- User And Maintenance Manual

Fervi 0554 User And Maintenance Manual

Summary of 0554

Page 1

User and maintenance manual professional combined grinding machine art. 0554 original instructions fervi.Com.

Page 2: Preface

Machines and accessories page 2 of 31 preface read this manual before operating any machinery original instructions reading this instruction manual is required before operating any of the machinery. The guarantee that the machine will function and perform properly is strictly dependent upon the appl...

Page 3: Contents

Machines and accessories page 3 di 31 contents 1 introduction ........................................................................................ 4 1.1 p reface .......................................................................................................................5 2 safety warn...

Page 4: 1 Introduction

Machines and accessories page 4 of 31 1 introduction the purpose of this manual is to provide the knowledge necessary for the use and maintenance of the bench grinding machine in question, and create a sense of responsibility and an understanding of the capabilities and limitations of the means entr...

Page 5: 1.1 Preface

Machines and accessories page 5 di 31 1.1 preface for safe and easy operation of the grinder, this manual must be read carefully in order to acquire the necessary knowledge. In other words, durability and performance are strictly dependent on how it is used. Even experienced bench grinding machine o...

Page 6: 2 Safety Warnings

Machines and accessories page 6 of 31 2 safety warnings 2.1 general safety rules for machine equipment risks associated with using the machine do not underestimate the risks associated with using the machine and concentrate on the work in progress. Risks associated with using the machine despite the...

Page 7: Fervi.Com

Machines and accessories page 7 di 31 13.Wear appropriate clothing. Loose clothing, dangling jewellery, long hair, etc.., can get caught in the moving parts, causing irreparable injury. 14.Do not pick up moving equipment (wheels, brushes, etc.) do not lift the machine by the equipment parts. 15.To s...

Page 8: 2.3 Technical Support

Machines and accessories page 8 of 31 2.2 safety regulations for electrical machine equipment changes in the electrical system do not modify the electrical system in any way. Any attempt in this regard may jeopardize the operation of electrical devices, thus causing malfunction or accident. work...

Page 9: 3 Technical Specifications

Machines and accessories page 9 di 31 3 technical specifications model art. 0554 p la te d a ta weight (kg) 28/30. Voltage (v) 230 power (w) 900 frequency (80 - 16000 hz) 50 size (mm) 520 x 225 x 300 1 st t o o l type of tool dry grinding wheel size (mm) 200 x 25 x 20 speed (r/min) 2950 2 n d t o o ...

Page 10: 4 Installing The Machine

Machines and accessories page 10 of 31 4 installing the machine to install the bench grinding machine, proceed as follows: clean the machine before starting assembly, clean the protective product from the machine's components. 4.1 positioning and fixing on the bench loss of stability mount the bench...

Page 11: Fervi.Com

Machines and accessories page 11 di 31 4.2 installation of screens and clamping brackets 1. Mount the transparent protective screen of the dry grinding wheel using the fixing screws provided (see figure 2). Place the protective screen so that it does not touch the wheel and there is a maximum gap (l...

Page 12: Impact Of Thrown Parts

Machines and accessories page 12 of 31 4.3 connecting the power plug and start-up test 1. Insert the power plug into a power outlet with a grounding wire. 2. Start the machine by pressing the green switch i (see figure 7) and make sure that the rotating direction of the equipment is consistent with ...

Page 13: Fervi.Com

Machines and accessories page 13 di 31 5 description of the machine figure 4 - main parts 1 machine body / motor; 2 start and stop buttons; 3 dry grinding wheel; 4 dry grinding wheel protective screen; 5 protective wheel casing; 6 brush 7 bracket for supporting pieces; 8 fastening holes on the bench...

Page 14: 5.1 Nameplate

Machines and accessories page 14 of 31 5.1 nameplate the following nameplate is attached to the machine: figure 5 – nameplate fervi.Com.

Page 15: 5.2 Pictograms

Machines and accessories page 15 di 31 5.2 pictograms the machine has the following warning and attention pictograms (figure 6): figure 6 – caution and warning pictograms. Fervi.Com.

Page 16: Attenzione

Machines and accessories page 16 of 31 legend plate in italian plate in english errore. Non si possono creare oggetti dalla modifica di codici di campo. Non rimuovere i dispositivi di sicurezza È severamente vietata la rimozione e la omissione dolora d.Lgs. 81/08 don’t remove safety devices and guar...

Page 17: Fervi.Com

Machines and accessories page 17 di 31 attenzione!! leggere le istruzioni prima di utilizzare la macchina non avvicinare le mani all’utensile in movimento non afferrare il pezzo con le mani per arrestarlo non regolare la macchina mentre È in funzione indossare sempre idonee protezioni qual...

Page 18: 6 Control Switches

Machines and accessories page 18 of 31 6 control switches they are located on the base of the machine body. They are used to turn the bench grinding machine on and off. 6.1 on switch (start) the green button (i), is used for starting (turning on) the bench grinding machine (figure 7). With this butt...

Page 19: 6.3 Emergency Button

Machines and accessories page 19 di 31 6.3 emergency button on the control buttons panel there is an emergency stop button. To stop the machine in case of emergency, press the red button. When it is pushed, the motion of the electric motor and the grinding wheels is interrupted. To restore power to ...

Page 20: 7 Operation

Machines and accessories page 20 of 31 7 operation 7.1 instructions for use bench grinding machines are very easy to use. The dry grinding wheel is used for grinding, sanding and/or smoothing solid and massive material (especially metal and metal alloys) by abrasion. The metallic brush is used to cl...

Page 21: 7.3 Metal Brush Operation

Machines and accessories page 21 di 31 7.2 using the dry grinding wheel 1. Press the green start button (start, see figure 9) figure 9 – starting the grinding wheel. 2. Place the piece to be ground on the support bracket and push it towards the grinding wheel without pressing excessively; 3. To avoi...

Page 22: 8 Machine Safety

Machines and accessories page 22 of 31 8 machine safety 8.1 electrical safety the control device inserted in the electrical circuit of the bench grinding machine is a magnetic switch with two buttons (see section 6 of this manual). This prevents the danger of unwanted and/or accidental starts of the...

Page 23: Use Of Ppe

Machines and accessories page 23 di 31 8.2 "mechanical" safety devices protective casing and transparent screens this prevents the hot splinters, dust or wheel fragments that eventually get separated from being thrown into the operator's face. Checking the safety devices each time the grinding whe...

Page 24: 9 Maintenance

Machines and accessories page 24 of 31 9 maintenance 9.1 routine maintenance electric shock before maintenance or checks, turn off the machine and always unplug the plug from the power outlet. This is so that there is no risk of electric shock. Regularly clean and take care of the machine to guarant...

Page 25: 9.2 Replacing Tools

Machines and accessories page 25 di 31 9.2 replacing tools electric shock before replacing tools, turn off the machine and always unplug the plug from the power outlet. This is so that there is no risk of electric shock. Characteristics of the wheels do not use grinding wheels with a cavity. onl...

Page 26: Fervi.Com

Machines and accessories page 26 of 31 9.2.1 dry grinding wheel 1. Unscrew the three fastening screws and remove the protective casing. 2. For this purpose use a screwdriver. Figure 12 – protective casing. 3. Unscrew the fastening nut (ref. 17 in figure 13) using a spanner for hexagonal nuts, turnin...

Page 27: Fervi.Com

Machines and accessories page 27 di 31 9.2.2 metal brush 1. Insert the steel pin in the hole which is located on the brush shaft, between the brush itself and the protective casing. Figure 14 – hole on the shaft. Unscrew the fastening nut (ref. 19 in figure 15) using a spanner for hexagonal nuts, tu...

Page 28: 10 Fault Finding

Machines and accessories page 28 of 31 10 fault finding problem probable cause solution noisy operation. A) damaged bearings. B) bearings not lubricated. C) rubbing of a tool. D) loose tool. A) contact the service department. B) lubricate. C) remove / replace the tools and check they are balanced. D...

Page 29: Respect The Environment!

Machines and accessories page 29 di 31 11 disposal of parts and materials if the machine is to be scrapped, its parts must be disposed of separately. Respect the environment! Contact a specialist centre for the collection of metallic materials. The structure of the grinding wheels is made of steel, ...

Page 30: 12 Electrical Circuit

Machines and accessories page 30 of 31 12 electrical circuit figure 16 – wiring diagram. Fervi.Com.

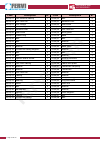

Page 31: 12.1Parts Of The Machine

Machines and accessories page 31 di 31 12.1parts of the machine figure 17 – set of parts. Fervi.Com.

Page 32: Fervi.Com

Machines and accessories page 32 of 32 code description n° code description n° 0554/01 left external casing 1 0554/30 bolt 4 0554/02 disc lock nut 1 0554/31 abrasive disc 1 0554/03 disc flange 2 0554/32 short axis 1 0554/04 disc nameplate 2 0554/33 disc flange 1 0554/05 abrasive disc 1 0554/34 disc ...