- DL manuals

- Gaggia

- Coffee Maker

- Deco

- Tecnichal Service Manual

Gaggia Deco Tecnichal Service Manual

U

S

O

E

M

A

N

U

T

E

N

Z

IO

N

E

IN

S

T

R

U

CT

IO

N

A

N

D

M

A

IN

T

EN

A

N

CE

M

O

D

E

D

’E

M

P

L

O

I

E

T

D

’E

N

T

R

E

T

IE

N

B

ET

R

IEB

U

N

D

W

A

R

T

U

N

G

U

S

O

Y

M

A

N

T

EN

IMI

EN

T

O

MANUALE DI MANUTENZIONE PER L’ASSISTENZA TECNICA

TECNICHAL SERVICE MANUAL

SERVICE - UND REPARATURANLEITUNG

MANUEL D’ASSISTANCE TECHNIQUE

MANUAL DE ASISTENCIA TÉCNICA

Summary of Deco

Page 1

U s o e m a n u t e n z io n e in s t r u ct io n a n d m a in t en a n ce m o d e d ’e m p l o i e t d ’e n t r e t ie n b et r ieb u n d w a r t u n g u s o y m a n t en imi en t o manuale di manutenzione per l’assistenza tecnica tecnichal service manual service - und reparaturanleitung manuel d’a...

Page 2

Dichiarazione di conformita' ce / ec declaration of conformity noi / we gaggia robecco s/naviglio milano dichiariamo sotto la nostra responsabilità che i prodotti / declare under our responsibility that the products : macchina per caffe' professionale / professional coffee machine type : lc/e lc/d –...

Page 3: Importante

5 only for italy importante egregio cliente, la informiamo che tutte le nostre macchine prodotte sono commercializzate in conformità alla direttiva 97/23/ce, recepita con decreto legislativo n. 93 del 25 febbraio 2000. Le disposizioni del decreto sopra menzionato si applicano alla progettazione, all...

Page 4

Gentile cliente, la ringraziamo per la fiducia accordataci con l’acquisto di un nostro prodotto. Se lei avrà la costanza di seguire attentamente le indicazioni contenute nel presente manuale, siamo certi che potrà apprezzare nel tempo e con soddisfazione la qualità della nostra macchina. La preghiam...

Page 5

Prima della messa in funzione, leggere attentamente il manuale di istruzioni carefully read the following instruction booklet before starting up the machine. Lesen sie vor der inbetriebnahme aufmerksam die bedienungsanleitung. Avant la mise en service, lire attentivement le manuel dÊinstructions. An...

Page 6

36 english italiano 8 - 35 english 36 - 63 deutsch 64 - 91 franÇais 92 - 119 espaÑol 120 - 147.

Page 7

37 english table of contents table of contents . ......................................................................... 37 1- use and preservation of the instruction manual . ..................................................... 38 2- how to use the machine ........................38 3 - safety w...

Page 8

38 english 1 - use and preservation of the manual this manual is intended for in-house use only and/or the authorized service centres for gaggia professional ma- chines. The manual is addressed to the maintenance and installation operators of the machine the instruction manual aims to describe how t...

Page 9

39 english 3 - safety warnings only adults who have carefully read and fully understood this manual and all the safety information contained in the manual are permitted to use the machine. The appliance is not to be used by persons (including chil- dren) with reduced physical, mental or sensory abil...

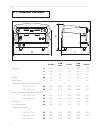

Page 10

40 english b l h 4 - technical features fig. 1 2 units 2 ga units 3 units 3 ga units 4 units dimensions b 765 765 985 985 1205 h 535 620 535 620 535 l 570 570 570 570 570 weight kg 60 67 80 86 100 boiler capacity l 13 13 21 21 28 power absorbed by boiler heating resistor 240 / 415 v 3 n ~ w 4760 476...

Page 11

41 english 5 - installation a - water mains b - discharge line c - water softener d - protection disconnecting switch e - power cable f - discharge tray g - discharge pipe h - supply pipe i - boiler feed valve d c a b e f i h g g h fig. 2 5.2 electrical connection warning! It is important to ensure ...

Page 12

42 english 6 - components description 1 boiler filling valve 2 discharge pipe 3 machine on warning indicator 4 cup warming switch 5 main disconnecting switch 6 adjustable support 7 boiler level indicator 8 left steamer valve 9 left steamer pipe 10 pump pressure gauge 11 boiler pressure gauge 12 hot ...

Page 13

43 english proceed with the initial start up operation of the machine after the water and electrical connections have been completed. Open the water mains valve (a) (fig. 2). Switch on the protection disconnecting switch (d) (fig. 2). Switch the machine’s main power switch (5) to the position marked...

Page 14

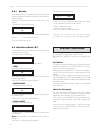

44 english 7.1 pressure switch setting the pressure switch indicated in the figure is designed to main- tain the boiler pressure constant by energising or de-energising the electric heating resistor. This pressure switch is already set to 1.1÷1.3 bar during the machine testing stage, but the pressur...

Page 15

45 english the following operations can be monitored by using the programming software: - management of 2 – 3 - 4 coffee units - controlling four different coffee doses for each unit (model “d”). - controlling the tea doses (hot water) - simultaneous operation of coffee and tea units - volumetric co...

Page 16

46 english 8.1 programming coffee doses the coffee dose quantities can be changed (using the volumetric control) and the settings can be memorised by proceeding as follows: - press key t5 (on the keyboard referring to unit 1) and continue to press for more than 5 seconds and verify that all the keyb...

Page 17

47 english t1 espresso programming delivery starts after key t1 has been pressed, then press key t1 again after the desired coffee dose has been reached, or any one of the other keys on the keyboard of the unit that is being programmed to interrupt the coffee dose delivery. The new value of the dose...

Page 18

48 english 8.2 programming tea doses (hot water) the timed quantities for the tea doses can be changed by following the sequence described: press key t5 on the coffee 1 unit and continue pressing for more than 5 seconds and verify that all the leds on the keyboard are illuminated. Press key t6 tea 1...

Page 19

49 english 8.3 coffee delivery the corresponding delivery solenoid val- ves are energised for the time necessary to distribute the quantity of product pro- grammed previously (volumetric control) by pressing the corresponding key: t1- t2-t3 or t4. The led corresponding to the dose key of the unit se...

Page 20

50 english 8.6 model “e” distributions press key t8 corresponding to the unit intended to be used or key t9 to obtain the distribution of the coffee or tea dose. The indicator light corresponding to the key will be energised and will remain on for all the duration of the delivery while the other ind...

Page 21

51 english 8.7 clock setting (model “d”) press key t5 on the first unit for more than 5 seconds. Press key t5 a second time after the program- ming procedure has been accessed to proceed to the clock synchronisation function. Press key t3 when “clock” appears on the display to access the setting sub...

Page 22

52 english 8.8.1 rest day the weekly rest day can be defined, and on this day the machine ignores the automatic start setting and can only be started manually. Whereas, the automatic off function remains active on the rest day. The display will show the following: rest xxx 8.9 calculations (model “d...

Page 23

53 english the software can be used to access the “technical programming” environment, which enables special parameters or functions to be programmed. The “technical programming” function can be accessed by setting the machine to off and by pressing key t5 for 10 seconds consecutively. Important : c...

Page 24

54 english 9.6 continuous key this key enables or disables the continuous dose distribution function. The display shows the following: where xxxxxxxx can be enabled or disabled use key t1 and key t2 if the parameter is to be changed. This function is pre-set to enabled mode. Pressing key t5 enables ...

Page 25

55 english the values vary between 0.1÷5 in steps of 0.1 sec. Press key t1 or key t2 to increase or decrease the values if the parameters need to be changed. Use key t5 to review all the values used. 9.9 sensitivity this function enables the sensitivity level to be set. The setting is based on the m...

Page 26

56 english 9.15 pid control this function enables the pid control range to be set compa- red to the set point temperature. This function is not currently operational. A recommendation is made not to change the pre-set parameters. The display shows the following: pressing key t5 enables the next sett...

Page 27

57 english 10.1 language the display shows the following: where xxxxxxxx are the languages which can be selec- ted: italian, french, english, spanish, german, dutch and portuguese. Press keys t8 to select the various options available if the parameter displayed needs to be changed; press key t9 to d...

Page 28

58 english 10.7 units temperatures this function enables the temperatures of each single unit to be set. The display shows the following: where 2 represents the number corresponding to the unit, xxx is a value selectable from 80÷125°c in 1°c steps. Press keys t8 if the parameter needs to be changed....

Page 29

59 english the machine includes a procedure to display the tempera- tures actually measured by the probes for each unit. This menu can be accessed first of all by switching off the ma- chine using the main power switch, keeping key t8 of unit 1 pressed and at the same time switching on the machine u...

Page 30

60 english 12.4 maintenance alarm when the display indicates: where xxxxxxxx is the recommended telephone number setting (refer to paragraph 9.3). When this message is displayed it means that the value set in the “technical programming” phase for the number of cycles to be carried out has been excee...

Page 31

61 english nb. The regenerating operations are applicable only if the water softener is the same type as indicated in the figures. Proceed as indicated in the instructions attached to the water softener if the water softener in question is a different type. 14 water softener regeneration a water inl...

Page 32

62 english 15 - maintenance and useful advice a recommendation is made to use the filter holder (d) with a blind filter (once the machine is hot) before starting work early in the morning and operate the unit several times to ensure the spouts (b) remain clean and free from coffee powder deposits wh...

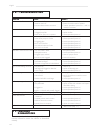

Page 33

63 english 16 - troubleshooting 17- machine dismantling the instructions described on the last pages of the manual must be followed to ensure the machine is dismantled correctly. Problem cause remedy machine switch off 1. Mains switch off 1. Position the machine switch to position on 2. Machine swit...