- DL manuals

- IAI

- Controller

- X-SEL

- Operation Manual

IAI X-SEL Operation Manual

Summary of X-SEL

Page 1

Operation manual fourth edition x-sel controller p/q type.

Page 2: Caution

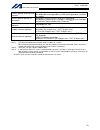

Caution operator alarm on low battery voltage this controller is equipped with the following backup batteries for retention of data in the event of power failure: [1] system-memory backup battery for retention of position data, global variables/flags, error list, strings, etc. [2] absolute-encoder b...

Page 3: Caution

Caution drive-source cutoff relay error (detection of fused relay: e6d) as a condition limited to x-sel-p type controllers of standard single-phase specification, a “drive-source cutoff relay error (e6d)” may generate if the power is turned off and then turned on again (reconnected) too quickly. Thi...

Page 4: Safety Precautions

Intelligent actuator safety precautions please read the information in “safety precautions” carefully before selecting a model and using the product. The precautions described below are designed to help you use the product safely and avoid bodily injury and/or property damage. Directions are classif...

Page 5

Intelligent actuator [installation] z do not use this product in a place exposed to ignitable, inflammable or explosive substances. The product may ignite, burn or explode. Z avoid using the product in a place where the main unit or controller may come in contact with water or oil droplets. Z never ...

Page 6

Intelligent actuator z if the product is generating heat, smoke or a strange smell, turn off the power immediately. Continuing to use the product may result in product damage or fire. Z if any of the internal protective devices (alarms) of the product has actuated, turn off the power immediately. Co...

Page 7

Intelligent actuator z before installing or adjusting the product or performing other operations on the product, display a sign that reads, “work in progress. Do not turn on power.” if the power is turned on inadvertently, injury may result due to electric shock or sudden activation of an actuator. ...

Page 8: Ce Mark

Intelligent actuator ce mark 1. Ec directives the ec directives are a new set of directives issued by the european commission that are intended to protect the health and safety of users and consumers of products distributed within the eu (european union) zone, while ensuring free movements of these ...

Page 9

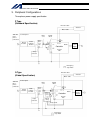

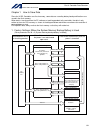

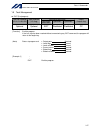

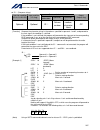

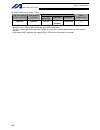

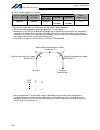

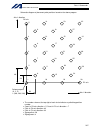

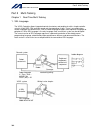

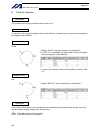

Intelligent actuator 3. Peripheral configurations three-phase power supply specification p type (standard specification) q type (global specification) 200-vac three- phase power bus control panel circuit breaker earth leakage breaker surge protector three- phase noise filter ring core clamp filters ...

Page 10

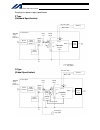

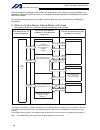

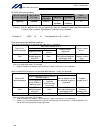

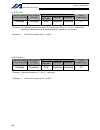

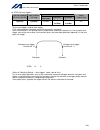

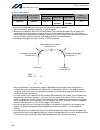

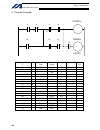

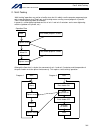

Intelligent actuator single-phase power supply specification p type (standard specification) q type (global specification) 200-vac single- phase power bus control panel circuit breaker earth leakage breaker surge protector single- phase noise filter ring core clamp filters encoder cable motor cable ...

Page 11

Intelligent actuator (1) environment use your x-sel-p/q controller in an environment conforming to pollution degree 2 or 1 as specified in iec 60664-1. Example) install the controller in a control panel having a structure resistant to intrusion of water, oil, carbon, dust, etc (ip54). (2) power sour...

Page 12

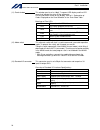

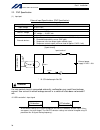

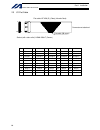

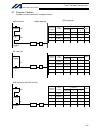

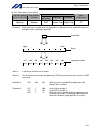

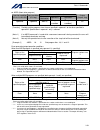

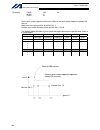

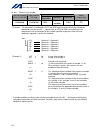

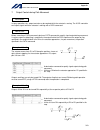

Intelligent actuator (5) three-phase noise filter install a noise filter in the three-phase ac power line. Supplier: densei-lambda model: mc1320 [fig. 1] external view of noise filter (three-phase specification) (6) single-phase noise filter install a noise filter in the single-phase ac power supply...

Page 13

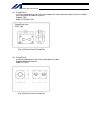

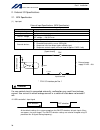

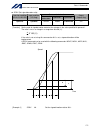

Intelligent actuator (7) ring core install a ring core on the secondary side of the noise filter. Supplier: nec tokin model: esd-r-25 [fig. 3] external view of ring core shape/dimensions esd-r series.

Page 14

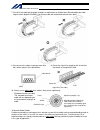

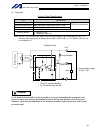

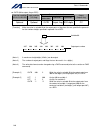

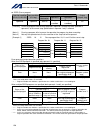

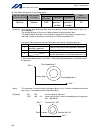

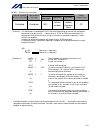

Intelligent actuator (8) clamp filter a install the following noise filter to the control power ac cable and motor cable (if there are multiple axes, connect to the cables of all axes). Supplier: tdk model: zcat3035-1330 [fig. 4] external view of clamp filter (9) clamp filter b install the following...

Page 15

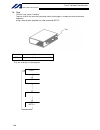

Intelligent actuator (10) surge protector install a surge protector on the primary side of the noise filter. Supplier: okaya electric industries model: r xaxv-781bxz-4 (three-phase) r xaxv-781bwz-4 (single-phase) external dimensions [fig. 6] external view of surge protector resin case lead wire.

Page 16

Intelligent actuator (11) cables the restrictions and cautions regarding the cables are summarized below. A) all cables connected to the x-sel-p/q controller, such as the motor cable, encoder cable and various network cables, must be kept to a length below 30 m. B) for the brake power cable, use a s...

Page 17

Intelligent actuator prohibited handling of cables caution when designing an application system using actuators and controllers, incorrect wiring or connection of each cable may cause unexpected problems such as a disconnected cable or poor contact, or even a runaway system. This section explains pr...

Page 18

Intelligent actuator 7. Do not let the cable get tangled or kinked in a cable bearer or flexible tube. When bundling the cable, keep a certain degree of flexibility (so that the cable will not become too taut when bent). 8. Do not cause the cables to occupy more than 60% of the space in the cable be...

Page 19: Before Use

Intelligent actuator before use caution caution 1. Be sure to read this operation manual to ensure the proper use of this product. 2. Unauthorized use or reproduction of a part or all of this operation manual is prohibited. 3. Always handle or operate the product in manners specified in this operati...

Page 20: Table of Contents

Intelligent actuator table of contents table of contents introduction................................................................................................... 1 part 1 installation ....................................................................................... 3 chapter 1 safety pr...

Page 21

Intelligent actuator table of contents part 2 operation....................................................................................... 83 chapter 1 operation .......................................................................................................................... 83 1. Start...

Page 22

Intelligent actuator table of contents 1.14 structural do .............................................................................................................. 209 1.15 multi-branching..............................................................................................................

Page 23

Intelligent actuator table of contents appendix .................................................................................................. 311 actuator specification list....................................................................................................................311 ho...

Page 24

Intelligent actuator table of contents absolute reset of a synchro controller.............................................................................................. 352 1. Synchro axes ...............................................................................................................

Page 25

1 intelligent actuator introuduction introduction thank you for purchasing the x-sel controller. Inappropriate use or handling will prevent this product from demonstrating its full function and may even cause unexpected failure or result in a shortened service life. Please read this manual carefully...

Page 26

2 intelligent actuator introduction this controller receives two types of power from external power sources: one for driving the motor (three- phase or single-phase, 200 to 220 v) and the other for control (single-phase, 200 to 220 v). * a single-phase power source is required only for controllers o...

Page 27

3 intelligent actuator part 1 installation part 1 installation caution chapter 1 safety precautions the x-sel controller can be combined with a maximum of six actuators of different types, and is able to provide integrated control over the entire system including peripherals. In other words, the x-s...

Page 28

4 intelligent actuator part 1 installation chapter 2 warranty period and scope of warranty the x-sel controller you have purchased passed our strict outgoing inspection. This unit is covered by the following warranty: 1. Warranty period the warranty period shall be either of the following periods, w...

Page 29

5 intelligent actuator part 1 installation chapter 3 installation environment and selection of auxiliary power devices 1. Installation environment (1) when installing and wiring the controller, do not block the ventilation holes provided for cooling. (insufficient ventilation will not only prevent t...

Page 30

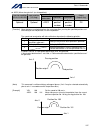

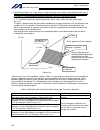

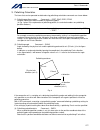

6 intelligent actuator part 1 installation 2. Heat radiation and installation design the control panel size, controller layout and cooling method so that the ambient temperature around the controller will be kept at or below 40°c. Install the controller vertically on a wall, as illustrated below. Th...

Page 31

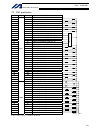

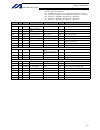

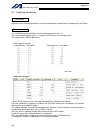

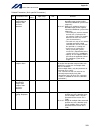

7 intelligent actuator part 1 installation 3. Selection of auxiliary power devices this section provides selection guidelines for breakers, earth leakage breakers, contactors, surge absorbers and noise filters that can be used with the ac power-supply line of the x-sel controller. These devices must...

Page 32

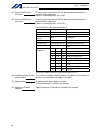

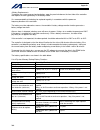

8 intelligent actuator part 1 installation (4) auxiliary power devices [1] breaker or electromagnetic contactor install a circuit breaker or earth leakage breaker in the ac power-supply line (primary side) of the controller in order to prevent damage due to power switching and short current. One cir...

Page 33

9 intelligent actuator part 1 installation [3] surge absorber with both the global specification and standard specification, the motor drive part of the x-sel controller has no built-in surge absorber to protect the equipment against surge noises that may generate in the controller due to lightning,...

Page 34

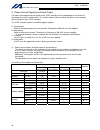

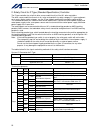

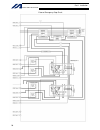

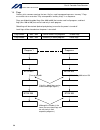

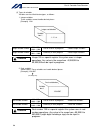

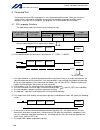

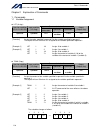

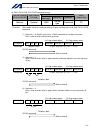

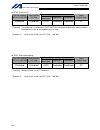

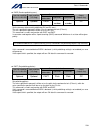

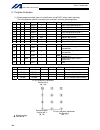

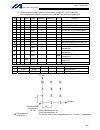

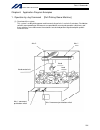

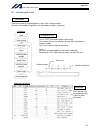

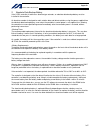

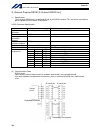

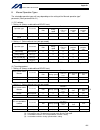

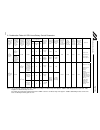

10 intelligent actuator part 1 installation peripheral configurations three-phase power supply specification p type (standard specification) q type (global specification) 200-vac three- phase power bus control panel circuit breaker earth leakage breaker surge protector three- phase noise filter ring...

Page 35

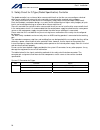

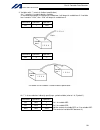

11 intelligent actuator part 1 installation peripheral configurations single-phase power supply specification p type (standard specification) q type (global specification) 200-vac single- phase power bus control panel circuit breaker earth leakage breaker surge protector single- phase noise filter r...

Page 36

12 intelligent actuator part 1 installation 4. Noise control measures and grounding (1) wiring and power source pe on the power terminal block is used for protective grounding. Provide class d grounding from this terminal. Use a grounding cable with a wire size of 1.0 mm 2 (#awg17) or more, which sh...

Page 37

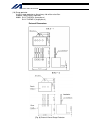

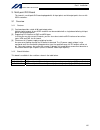

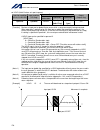

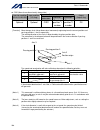

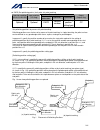

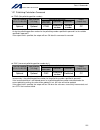

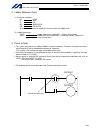

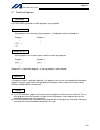

13 intelligent actuator part 1 installation (3) noise sources and noise elimination there are many noise sources, but solenoid valves, magnet switches and relays are of particular concern when building a system. Noise from these parts can be eliminated using the measures specified below: a. Ac solen...

Page 38

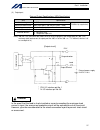

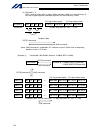

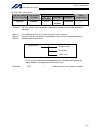

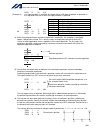

14 intelligent actuator part 1 installation reference circuit diagram controller surge absorber solenoid valve out com cr +24 v 0 v 100 vac cr 0 v.

Page 39

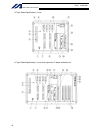

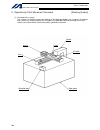

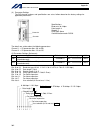

15 intelligent actuator part 1 installation chapter 4 name and function of each part 1. Front view of controller p type (standard specification), 4 axes p type (standard specification), 4 axes with expansion i/o board and brake unit.

Page 40

16 intelligent actuator part 1 installation q type (global specification), 4 axes q type (global specification), 4 axes with expansion i/o board and brake unit.

Page 41

17 intelligent actuator part 1 installation (1) fg terminal this terminal is used to ground fg on the enclosure. The enclosure is connected to pe in the ac input part inside the controller. Fg terminal specifications item description m4 3-point sems screw, 5 mm name fg cable size 2.0 ~ 5.5 mm 2 min....

Page 42

18 intelligent actuator part 1 installation (3) ac-power input connector a 200-vac, single-phase or three-phase input connector consisting of six terminals including motor power terminals, control power terminals and a pe terminal. Note) take note that the single-phase input specification and three-...

Page 43

19 intelligent actuator part 1 installation (6) encoder/axis-sensor connector this connector is used to connect the actuator encoder and axis sensors such as ls, creep and ot. * ls, creep and ot sensors are optional. Encoder/axis-sensor connector specifications item description details connector hal...

Page 44

20 intelligent actuator part 1 installation (7) motor connector this connector is used to drive the motor inside the actuator. Motor connector specifications item description details connector gic2.5/4-stf-7.62 4-pin, 2-piece connector by phoenix contact connector name m1 ~ 6 motor connector cable s...

Page 45

21 intelligent actuator part 1 installation (9) teaching connector the teaching interface connects iai’s teaching pendant or a pc (pc software) to enable operation and setting of your equipment from the teaching pendant/pc. The physical interface consists of a rs232c system based on a 25-pin, d-sub ...

Page 46

22 intelligent actuator part 1 installation interface specifications of teaching serial interface item no. Direction signal name details 1 fg frame ground 2 out txd transmitted data 3 in rxd received data 4 out rts request to send 5 in cts clear to send 6 out dsr equipment ready 7 sg signal ground 8...

Page 47

23 intelligent actuator part 1 installation (10) system i/o connector this i/o connector is used to control the safety actions of the controller. With the global specification, a safety circuit conforming to a desired safety category of up to level 4 can be configured using this connector and an ext...

Page 48

24 intelligent actuator part 1 installation (11) panel window this window consists of a 4-digit, 7-segment led display and five led lamps that indicate the status of the equipment. For the information shown on the display, refer to 2, “explanation of codes displayed on the panel window” or the “erro...

Page 49

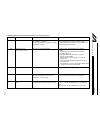

25 intelligent actuator part 1 installation the functions are at the time of shipment. The functions assigned to port nos. 000 to 015, 300 to 310, 313 and 314 can be changed via i/o parameters. (refer to nos. 30 to 56, no. 59 and 60 in 1, “i/o parameters,” of appendix, “list of parameters.”) i/o int...

Page 50

26 intelligent actuator part 1 installation (14) general rs232c port connector 1 channel 1 of the two-channel rs232c port provided for connection of general rs232c equipment. (refer to i/o parameter nos. 201 to 203.) (15) general rs232c port connector 2 channel 2 of the two-channel rs232c port provi...

Page 51

27 intelligent actuator part 1 installation (19) brake-power input connector this connector is used to input the drive power for the actuator brake. 24 vdc must be supplied externally. If the specified brake power is not supplied, the actuator brake cannot be released. Be sure to supply the brake po...

Page 52

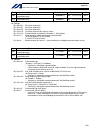

28 intelligent actuator part 1 installation 2. Explanation of codes displayed on the panel window 2.1 application display priority (*1) description 1 ac power is cut off (including momentary power failure or drop in power- source voltage). 1 system-down level error 2 writing data to the flash rom. 3...

Page 53

29 intelligent actuator part 1 installation 2.2 core display priority (*1) description 1 ac power is cut off (including momentary power failure or drop in power- source voltage). 1 cold-start level error 1 cold-start level error 1 operation-cancellation level error 1 operation-cancellation level err...

Page 54

30 intelligent actuator part 1 installation 2.3 current monitor and variable monitor other parameter nos. 49 and 50 can be set up to monitor currents or variables on the panel window (main application version 0.09 or later). (1) current monitor currents of up to four axes having continuous axis numb...

Page 55

31 intelligent actuator part 1 installation (2) variable monitor the contents of global integer variables can be displayed on the panel window. Positive integers of 1 to 999 can be displayed. Parameter settings other parameter no. 49 = 2 other parameter no. 50 = variable number of the global integer...

Page 56

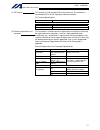

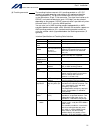

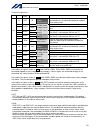

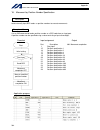

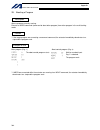

32 intelligent actuator part 1 installation chapter 5 specifications 1. Controller specifications 1.1. P type (standard specification) controller with 1 to 6 axes total output when maximum number of axes are connected single-phase specification: 1600w three-phase specification: 2400w control power i...

Page 57

33 intelligent actuator part 1 installation rs232c port for teaching serial interface enabled only in the manual operation mode. Iai’s dedicated teaching pendant or ansi teaching pendant (selected by a switch) rs232c port for general pc connection dedicated 2-channel rs232c, 9-pin dte specification ...

Page 58

34 intelligent actuator part 1 installation 1.2 q type (global specification) controller with 1 to 6 axes total output when maximum number of axes are connected single-phase specification: 1600w three-phase specification: 2400w control power input single-phase, 200 ~ 230 vac ± 10% motor power input ...

Page 59

35 intelligent actuator part 1 installation rs232c port for teaching serial interface enabled only in the manual operation mode. Iai’s dedicated teaching pendant or ansi teaching pendant (selected by a switch) rs232c port for general pc connection dedicated 2-channel rs232c, 9-pin dte specification ...

Page 60

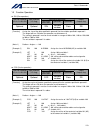

36 intelligent actuator part 1 installation 2. External i/o specifications 2.1. Npn specification (1) input part external input specifications (npn specification) item specification input voltage 24 vdc ±10% input current 7 ma per circuit on/off voltage on voltage --- 16.0 vdc min. Off voltage --- 5...

Page 61

37 intelligent actuator part 1 installation (2) output part external output specifications (npn specification) item specification load voltage 24 vdc maximum load current 100 ma per point, 400 ma per 8 ports note) leakage current 0.1 ma max. Per point td62084 (or equivalent) insulation method photoc...

Page 62

38 intelligent actuator part 1 installation 2.2. Pnp specification (1) input part external input specifications (pnp specification) item specification input voltage 24 vdc ±10% input current 7 ma per circuit on/off voltage on voltage --- 8 vdc max. Off voltage --- 19 vdc min. Insulation method photo...

Page 63

39 intelligent actuator part 1 installation (2) output part external output specifications item specification load voltage 24 vdc maximum load current 100 ma per point, 400 ma per 8 ports note) leakage current 0.1 ma max. Per point td62784 (or equivalent) insulation method photocoupler insulation ex...

Page 64

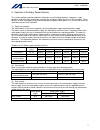

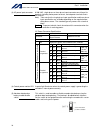

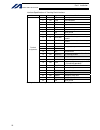

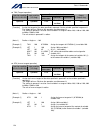

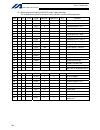

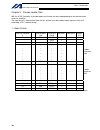

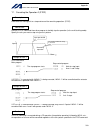

40 intelligent actuator part 1 installation 3. Power-source capacity and heat output the power consumption and heat output of the x-sel controller will vary depending on the number of connected axes and i/o configuration. This section explains how to estimate the power-source capacity and heat outpu...

Page 65

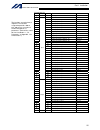

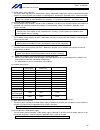

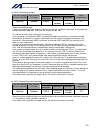

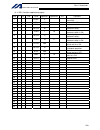

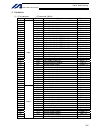

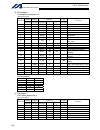

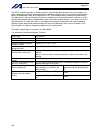

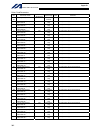

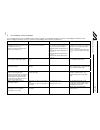

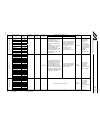

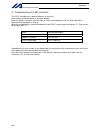

41 intelligent actuator part 1 installation [1] control power-source capacity the power-source capacity of the control power supply is obtained by applying the efficiency coefficient and power factor to the sum of all power consumptions of controlled units, based on the applicable values shown in th...

Page 66

42 intelligent actuator part 1 installation (3) calculation example obtain the power-source capacities and heat outputs when a controller of the following specifications is used. Actuator for axis 1: 200 w actuator for axis 2: 200 w actuator for axis 3: 100 w with brake actuator for axis 4: 60 w sta...

Page 67

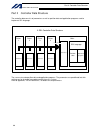

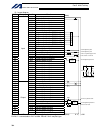

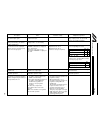

43 intelligent actuator part 1 installation 4. External dimensions 4.1 p/q type (three-phase standard specification, single-phase global specification, single-phase standard specification) 4-axis controller external views of enclosures for various 4-axis controllers are shown below (the external enc...

Page 68

44 intelligent actuator part 1 installation fig. 4-3 p/q type 4-axis controller with expansion i/o board (three-phase standard specification, single-phase global specification, single-phase standard specification) fig. 4-4 p/q type 4-axis controller with expansion i/o board + absolute brake unit (th...

Page 69

45 intelligent actuator part 1 installation 4.2 p/q type (standard specification) 6-axis controller (three-phase standard specification, single-phase global specification, single-phase standard specification) external views of enclosures for various 6-axis controllers are shown below (the external e...

Page 70

46 intelligent actuator part 1 installation fig. 4-7 p/q type 6-axis controller (three-phase standard specification, single-phase global specification, single-phase standard specification) fig. 4-8 p/q type 6-axis controller with expansion i/o board + absolute brake unit (three-phase standard specif...

Page 71

47 intelligent actuator part 1 installation 4.3 q type (three-phase global specification) 4-axis controller external views of enclosures for various 4-axis controllers are shown below (the external enclosure dimensions are the same for 1-axis to 4-axis controllers). Fig. 4-9 q type 4-axis controller...

Page 72

48 intelligent actuator part 1 installation fig. 4-11 q type 4-axis controller with expansion i/o board fig. 4-12 q type 4-axis controller with expansion i/o board + absolute brake unit.

Page 73

49 intelligent actuator part 1 installation 4.4 q type (three-phase global specification) 6-axis controller external views of enclosures for various 6-axis controllers are shown below (the external enclosure dimensions are the same for 5-axis and 6-axis controllers). Fig. 4-13 q type 6-axis controll...

Page 74

50 intelligent actuator part 1 installation fig. 4-15 q type 6-axis controller with expansion i/o board (three-phase global specification) fig. 4-16 q type 6-axis controller with expansion i/o board + absolute brake unit (three-phase global specification).

Page 75

51 intelligent actuator part 1 installation chapter 6 safety circuit the circuit configuration for embodying safety actions such as emergency stop is different between the standard specification and global specification of the x-sel controller. The standard controller has a built-in drive-source cut...

Page 76

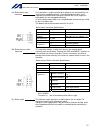

52 intelligent actuator part 1 installation 2. Safety circuit for p type (standard specification) controller the p type controller has a built-in drive-source cutoff circuit just like iai’s other controllers. The drive-source cutoff circuit consists of a relay and conforms to safety category b. If y...

Page 77

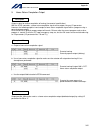

53 intelligent actuator part 1 installation with the p type, use only the signals shown in the shaded fields of the table for connection with the safety switches. Exercise caution that opening the specified pins or wiring them differently may compromise the safety actions of the controller. The rdyo...

Page 78

54 intelligent actuator part 1 installation 3. Safety circuit for q type (global specification) controller the global controller has no internal drive-source cutoff circuit so that the user can configure a desired drive-source cutoff circuit externally to the controller to conform to the required sa...

Page 79

55 intelligent actuator part 1 installation terminal assignments pin no. Signal name overview details 9 det in to fused- contact detection circuit external contact error input (paired with no. 18) connected to the fused-contact detection contacts of the safety circuit. 8 in emergency-stop detection ...

Page 80

56 intelligent actuator part 1 installation • em1/emg2, enb1/enb2 emg1 (line+)/(line-) and emg2 (line+)/(line-) are redundant emergency-stop control lines. Enb1 (line+)/(line-) and enb2 (line+)/(line-) are redundant enabling control lines. Use these lines to cut off the external drive source. Since ...

Page 81

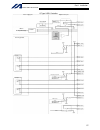

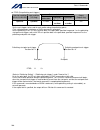

57 intelligent actuator part 1 installation q type x-sel controller power supply part digital control part not installed ac cutoff relay rectifier dc bus to power stage external emergency-stop reset contact output teaching pendant power-on reset mpsdwn bit power error mushroom emergency- stop swit c...

Page 82

58 intelligent actuator part 1 installation external emergency-stop circuit contactor (neo sc) relay contactor (neo sc) 200-vac, three- phase reset switch external emergency-stop switch external emg switch contact 1 external emg switch contact 2 safety relay unit (g9sa-301 by omron) safety gate swit...

Page 83

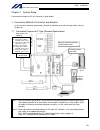

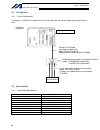

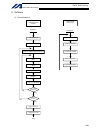

59 intelligent actuator part 1 installation chapter 7 system setup a connection example of a 2-axis controller is given below: 1. Connection method of controller and actuator in the case of an absolute specification, perform an absolute reset after the connection (refer to chapter 8). 1.1 connection...

Page 84

60 intelligent actuator part 1 installation 1.2 connection diagram for q type (global specification) note 1: with the absolute specification, set the absolute-data backup battery enable/disable switch to the bottom position for all axes before connecting the encoder/axis-sensor cables. (after the ca...

Page 85

61 intelligent actuator part 1 installation 1.3 startup procedure note: when installing multiple axes to the controller, be sure to connect the actuator cables to the right connectors. Check the type of the actuator connected to each connector. If the cables and connectors are not connected properly...

Page 86

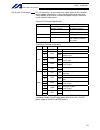

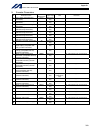

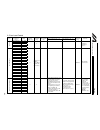

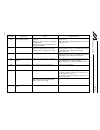

62 intelligent actuator part 1 installation 2. I/o connection diagram 2.1 npn specification pin no. Category port no. Function 1 - +24-v input 2 000 program start 3 001 general-purpose input 4 002 general-purpose input 5 003 general-purpose input 6 004 general-purpose input 7 005 general-purpose inp...

Page 87

63 intelligent actuator part 1 installation 2.2 pnp specification pin no. Category port no. Function 1 - +24-v input 2 000 program start 3 001 general-purpose input 4 002 general-purpose input 5 003 general-purpose input 6 004 general-purpose input 7 005 general-purpose input 8 006 general-purpose i...

Page 88

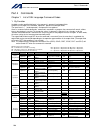

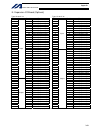

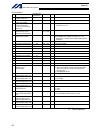

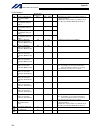

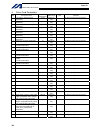

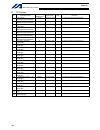

64 intelligent actuator part 1 installation 2.3 i/o flat cable flat cable: kfx-50 (s) (color) (kaneko cord) no. Color no. Color no. Color no. Color no. Color 1 brown-1 11 brown-2 21 brown-3 31 brown-4 41 brown-5 2 red-1 12 red-2 22 red-3 32 red-4 42 red-5 3 orange-1 13 orange-2 23 orange-3 33 orange...

Page 89

65 intelligent actuator part 1 installation 3. Multi-point dio board this board is a multi-point dio board equipped with 48 input points and 48 output points for use with xsel controllers. 3.1 overview 3.1.1 features [1] one board provides a total of 96 input/output points. Multiple inputs/outputs o...

Page 90

66 intelligent actuator part 1 installation 3.2 configuration 3.2.1 system configuration this board is installed in the standard i/o slot or any expansion slot and exchanges signals with external dios. 3.3 specifications 3.3.1 input/output specifications item specification numbers of input/output po...

Page 91

67 intelligent actuator part 1 installation 3.4 external interface specifications 3.4.1 terminal assignment for external dio interface overview of multi-point dio interface specifications item overview remarks applicable connector half-pitch flat connector, 100 pins hif6-100pa-1.27ds (hirose) connec...

Page 92

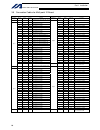

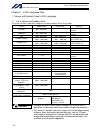

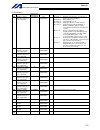

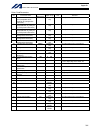

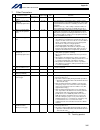

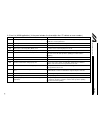

68 intelligent actuator part 1 installation 3.5 connection cables for multi-point io board cable 1 cable 2 category pin no. Color port no. Function category pin no. Color port no. Function - 1 brown-1 - external power supply 24 vdc for pin nos. 2 to 25/51 to 74 51 brown-1 300 alarm output 2 red-1 00...

Page 93

69 intelligent actuator part 1 installation 3.6 connection cables for multi-point io board model: cb-x-pioh020 • cable with connectors on both ends model: cb-x-pioh020-h6 this connector is used to connect the multi-point dio board and an optional terminal block unit. Socket: hif6-100d-1.27r (hirose)...

Page 94

70 intelligent actuator part 1 installation 3.7 input/output circuits 3.7.1 input input specifications item specification (common to pnp/npn specifications) external power-supply voltage dc24v ± 10% input current 7 ma max. Per point leak current 1 ma max. Per point input circuit • npn specification ...

Page 95

71 intelligent actuator part 1 installation 3.7.2 output output specifications item specification output element transistor array npn specification: td62084af by toshiba corporation pnp specification: td62784af by toshiba corporation external power-supply voltage dc24 ± 10% maximum load current 50 m...

Page 96

72 intelligent actuator part 1 installation chapter 8 how to perform an absolute encoder reset (absolute specification) when the absolute-encoder battery voltage of the x-sel controller is abnormal or when the battery or encoder cable is disconnected, an encoder battery error will occur and an absol...

Page 97

73 intelligent actuator part 1 installation (6) the x-sel pc software window will be displayed. Clicking the [ok] button will clear the error message. (7) from the [monitor (m)] menu, select [detailed error information (e)] to check the current error status. In the case of an encoder battery error, ...

Page 98

74 intelligent actuator part 1 installation (8) from the [controller (c)] menu, select [absolute reset (a)]. (9) when a [warning] dialog box is displayed, click the [ok] button. (10) the [abs. Encoder reset] dialog box will be displayed. Click here to select the axis you wish to perform an absolute ...

Page 99

75 intelligent actuator part 1 installation (12) another [warning] dialog box will be displayed. Click the [yes] button. (13) when the processing of “encoder rotation data reset 1” is complete, the red arrow will move to the next item. Press the following processing buttons one by one (the red arrow...

Page 100

76 intelligent actuator part 1 installation (15) when the [confirmation] dialog box is displayed, click the [yes] button and restart the controller. (note) commencing the operation without first executing a software reset or reconnecting the power may generate the following errors: error no. C70: ab...

Page 101

77 intelligent actuator part 1 installation chapter 9 maintenance • routine maintenance and inspection are necessary so that the system will operate properly at all times. Be sure to turn off the power before performing maintenance or inspection. • the standard inspection interval is six months to o...

Page 102

78 intelligent actuator part 1 installation 3. Replacement procedure for system-memory backup battery backing up the system memory if “other parameter no. 20, backup-battery installation function type” is set to “2” (installed), the following sram data in the x-sel controller will be backed up by th...

Page 103

79 intelligent actuator part 1 installation battery replacement procedure 1) remove the 7-segment led panel from the controller. Slide the panel upward and pull it toward you to remove. 2) press the center of the battery using a finger, as shown. The battery will come off from the holder. 3) install...

Page 104

80 intelligent actuator part 1 installation (8) when the replacement of system-memory backup battery is complete, confirm that the battery is installed securely and then turn on the controller power. (9) revert “other parameter no. 20, backup-battery installation function type” to the value recorded...

Page 105

81 intelligent actuator part 1 installation 4. Replacement procedure for absolute-data backup battery the replacement procedure will vary depending on if errors are present at the time of replacement and if so, which errors are present (no.A23, 914, ca2). • if no error is present, perform steps (1) ...

Page 106

82 intelligent actuator part 1 installation (6) turn on the controller power. (7) set the absolute-data backup battery enable/disable switch to the top (enb) position. (note) this operation is not required if no error has generated or when an a23 error has generated. (8) turn off the controller powe...

Page 107

83 intelligent actuator part 2 operation part 2 operation chapter 1 operation how to start a program with the x-sel controller, the stored programs can be started (run) using four methods. Of these methods, two are mainly used to debug programs or perform trial operations, while the remaining two ar...

Page 108

84 intelligent actuator part 2 operation 1. Starting a program by auto-start via parameter setting i/o parameter no. 33 (input function selection 003) = 1 (default factory setting) set the number of the program you wish to start automatically in other parameter no. 1 (auto-start program number). Set...

Page 109

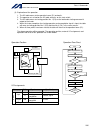

85 intelligent actuator part 2 operation 2. Starting via external signal selection (1) flow chart when the ready signal turns on, the rdy lamp (green) on the controller front panel will illuminate. Input a desired program number as a bcd code from the external device. Input a start signal from the e...

Page 110

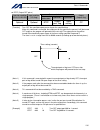

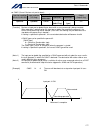

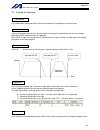

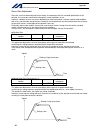

86 intelligent actuator part 2 operation (2) timing chart ready output program number input external start input program 1 program 2 t1: duration after the ready output turns on until input of external start signal is permitted t1 = 10 msec min. T2: duration after the program number is input until i...

Page 111

87 intelligent actuator part 2 operation 3. Drive-source recovery request and operation-pause reset request (1) drive-source recovery request 1. How to request a drive-source recovery a drive-source recovery request can be issued using one of the following methods: • set i/o parameter no. 44 to “1” ...

Page 112

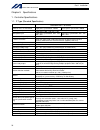

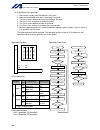

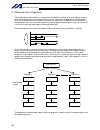

88 intelligent actuator part 3 controller data structure part 3 controller data structure the controller data consists of parameters as well as position data and application programs used to implement sel language. X-sel controller data structure the user must create position data and application pr...

Page 113

89 intelligent actuator part 3 controller data structure chapter 1 how to save data since the x-sel controller uses flash memory, some data are saved by battery backup while others are saved in the flash memory. When data is transferred from the pc software or teaching pendant to the controller, the...

Page 114

90 intelligent actuator part 3 controller data structure since the programs, parameters and symbols are read from the flash memory at restart, the data in the temporary memory will remain the same as the original data before edit unless the edited data are written to the flash memory. The controller...

Page 115

91 intelligent actuator part 3 controller data structure 3. Points to note point to note when transferring data and writing to the flash memory never turn off the main power while data is being transferred or written to the flash memory. The data will be lost and the controller operation may be disa...

Page 116

92 intelligent actuator part 3 controller data structure chapter 2 x-sel language data 1. Values and symbols used in sel language 1.1 list of values and symbols used the various functions required in a program are represented by values and symbols. Function global range local range remarks input por...

Page 117

93 intelligent actuator part 3 controller data structure z the variables and flags in the global range will be retained even after the controller power is turned off. (when other parameter no. 20 is set to “2.” refer to chapter 1, “how to save data,” of part 3.) z the variables and flags in the loca...

Page 118

94 intelligent actuator part 3 controller data structure 1.3 virtual i/o ports (1) virtual input ports port no. Function 7000 always off 7001 always on 7002 voltage low warning for system-memory backup battery 7003 abnormal voltage of system-memory backup battery 7004 (for future expansion = use str...

Page 119

95 intelligent actuator part 3 controller data structure (2) virtual output ports port no. Function 7300 latch cancellation output for a latch signal indicating that all-operation-cancellation factor is present (7011) (latch is cancelled only when operation-cancellation factor is no longer present) ...

Page 120

96 intelligent actuator part 3 controller data structure 1.4 flags contrary to its common meaning, the term “flag” as used in programming means “memory.” flags are used to set or reset data. They correspond to “auxiliary relays” in a sequencer. Flags are divided into global flags (nos. 600 to 899) t...

Page 121

97 intelligent actuator part 3 controller data structure 1.5 variables (1) meaning of variable “variable” is a technical term used in software programming. Simply put, it means “a box in which a value is put.” variables can be used in many ways, such as putting in or taking out a value and performin...

Page 122

98 intelligent actuator part 3 controller data structure (2) types of variables variables are classified into two types, as follows: 1. Integer variables these variables cannot handle decimal places. [example] 1234 integer variable number 200 ~ 299 1200 ~ 1299 can be used in all programs “global int...

Page 123

99 intelligent actuator part 3 controller data structure 3. Variables with “*” (asterisk) (indirect specification) an “*” (asterisk) is used to specify a variable. In the following example, the content of variable box 1 will be put in variable box 2. If variable box 1 contains “1234,” then “1234” wi...

Page 124

100 intelligent actuator part 3 controller data structure 1.6 tags the term “tag” means “heading.” tags are used in the same way you attach labels to the pages in a book you want to reference frequently. A tag is a destination specified in a jump command “goto.” command operand 1 tag tag number (int...

Page 125

101 intelligent actuator part 3 controller data structure 1.7 subroutines by taking out the parts of a program that are used repeatedly and registering them as “subroutines,” the same processing can be performed with fewer steps. (a maximum of 15 nests are accommodated.) they are used only in each p...

Page 126

102 intelligent actuator part 3 controller data structure 1.8 symbols in the x-sel controller, values such as variable numbers and flag numbers can be handled as symbols. For the method to edit symbols, refer to “editing symbols” in the operation manual for x- sel teaching pendant or “symbol edit wi...

Page 127

103 intelligent actuator part 3 controller data structure 1.10 axis specification axes can be specified based on axis number or axis pattern. (1) axis numbers and how axes are stated each of multiple axes is stated as follows: axis number how axis is stated 1 axis 1 2 axis 2 3 axis 3 4 axis 4 5 axis...

Page 128

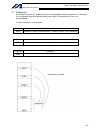

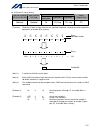

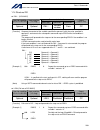

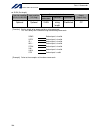

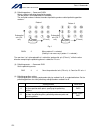

104 intelligent actuator part 3 controller data structure (2) axis pattern whether or not each axis will be used is indicated by “1” or “0.” (upper) (lower) axis number axis 6 axis 5 axis 4 axis 3 axis 2 axis 1 used 1 1 1 1 1 1 not used 0 0 0 0 0 0 [example] when axes 1 and 2 are used axis 2 000011 ...

Page 129

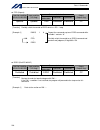

105 intelligent actuator part 3 controller data structure x-sel language consists of a position part (position data = coordinates, etc.) and a command part (application program). 2. Position part as position data, coordinates, speeds, accelerations and decelerations are set and stored. Position no. ...

Page 130

106 intelligent actuator part 3 controller data structure 3. Command part the primary feature of sel language is its very simple command structure. Since the structure is simple, there is no need for a compiler (to translate into computer language) and high-speed operation is possible via an interpr...

Page 131

107 intelligent actuator part 3 controller data structure 3.2 extension condition conditions can be combined in a complex manner. (sel language) command extension condition input condition command operand 1 operand 2 output condition 1 a condition 2 a condition 3 command operand 1 operand 2 command ...

Page 132

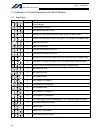

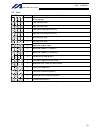

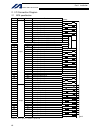

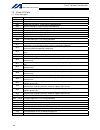

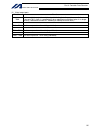

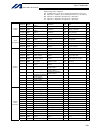

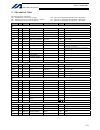

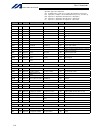

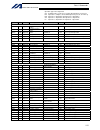

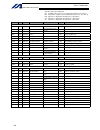

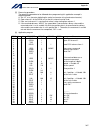

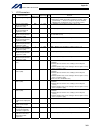

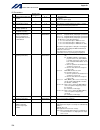

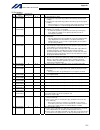

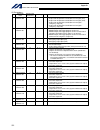

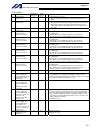

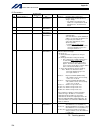

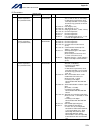

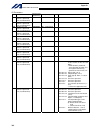

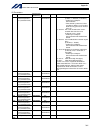

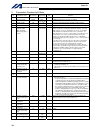

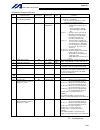

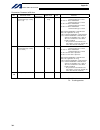

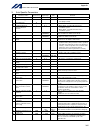

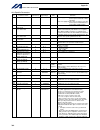

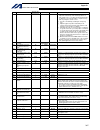

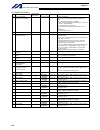

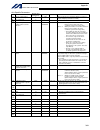

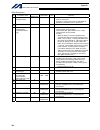

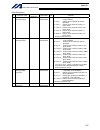

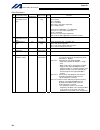

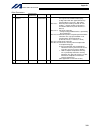

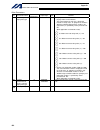

108 intelligent actuator part 4 commands part 4 commands chapter 1 list of sel language command codes 1. By function variables can be specified indirectly in the operand 1, operand 2 and output fields. Symbols can be input in the condition, operand 1, operand 2 and output fields. The input items in ...

Page 133

109 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 134

110 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 135

111 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 136

112 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 137

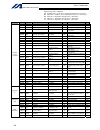

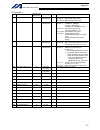

113 intelligent actuator part 4 commands 2. Alphabetical order operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand...

Page 138

114 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 139

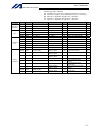

115 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 140

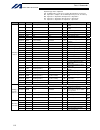

116 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 141

117 intelligent actuator part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 ≠ operand 2, gt: operand 1 > operand 2, ge: op...

Page 142

118 intelligent actuator part 4 commands chapter 2 explanation of commands 1. Commands 1.1 variable assignment z let (assign) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional let v...

Page 143

119 intelligent actuator part 4 commands z clr (clear variable) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional clr variable number variable number zr [function] clear the variabl...

Page 144

120 intelligent actuator part 4 commands 1.2 arithmetic operation z add (add) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional add variable number data zr [function] add the conten...

Page 145

121 intelligent actuator part 4 commands z mult (multiply) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional mult variable number data zr [function] multiply the content of the vari...

Page 146

122 intelligent actuator part 4 commands z mod (remainder of division) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional mod variable number data zr [function] assign, to the variab...

Page 147

123 intelligent actuator part 4 commands 1.3 function operation z sin (sine operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional sin variable number data zr [function] assig...

Page 148

124 intelligent actuator part 4 commands z tan (tangent operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional tan variable number data zr [function] assign the tangent of the...

Page 149

125 intelligent actuator part 4 commands z sqr (root operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional sqr variable number data zr [function] assign the root of the data ...

Page 150

126 intelligent actuator part 4 commands 1.4 logical operation z and (logical and) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional and variable number data zr [function] assign th...

Page 151

127 intelligent actuator part 4 commands z or (logical or) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional or variable number data zr [function] assign the logical or operation re...

Page 152

128 intelligent actuator part 4 commands z eor (logical exclusive-or) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional eor variable number data zr [function] assign the logical exc...

Page 153

129 intelligent actuator part 4 commands 1.5 comparison operation z cp (compare) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) eq ne gt ge optional optional cp variable number data lt le [functio...

Page 154

130 intelligent actuator part 4 commands 1.6 timer z timw (timer) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional timw time prohibited tu [function] stop the program and wait for ...

Page 155

131 intelligent actuator part 4 commands z timc (cancel timer) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional timc program number prohibited cp [function] cancel a timer in other...

Page 156

132 intelligent actuator part 4 commands z gttm (get time) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gttm variable number prohibited cp [function] read system time to the va...

Page 157

133 intelligent actuator part 4 commands 1.7 i/o, flag operation z bt (output port, flag operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional bt output, flag (output, flag) ...

Page 158

134 intelligent actuator part 4 commands z btpn (output on pulse) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional btpn output port, flag timer setting cp [function] turn on the sp...

Page 159

135 intelligent actuator part 4 commands z btpf (output off pulse) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional btpf output port, flag timer setting cp [function] turn off the ...

Page 160

136 intelligent actuator part 4 commands z wt (wait for i/o port, flag) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional wt i/o, flag (time) tu [function] wait for the i/o port or ...

Page 161

137 intelligent actuator part 4 commands z in (read i/o, flag as binary) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional in i/o, flag i/o, flag cc [function] read the i/o ports or...

Page 162

138 intelligent actuator part 4 commands z inb (read i/o, flag as bcd) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional inb i/o, flag bcd digits cc [function] read the i/o ports or...

Page 163

139 intelligent actuator part 4 commands z out (write output, flag as binary) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional out output, flag output, flag cc [function] write the...

Page 164

140 intelligent actuator part 4 commands z outb (write output, flag as bcd) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional outb output, flag bcd digits cc [function] write the va...

Page 165

141 intelligent actuator part 4 commands z fmio (set in, inb, out, outb command format) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional fmio format type prohibited cp [function] s...

Page 166

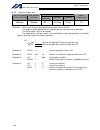

142 intelligent actuator part 4 commands (4) operand 1 = 3 data is read or written after its upper 16 bits and lower 16 bits are reversed every 32 bits and its upper eight bits and lower eight bits are reversed every 16 bits. (i/o, flag number upper) (i/o, flag number lower) 01234567h ⇔ 67h 45h 23h ...

Page 167

143 intelligent actuator part 4 commands [example 2] variable 99 = 00001234h (decimal: 4660, bcd: 1234) 00001234h variable 99 4660 (in/out command) 1234 (inb/outb command) (i/o, flag number upper) (i/o, flag number lower) fmio = 0 00h 00h 12h 34h ⇔ 0000 0000 0000 0000 0001 0010 0011 0100 fmio = 1 00...

Page 168

144 intelligent actuator part 4 commands 1.8 program control z goto (jump) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional goto tag number prohibited cp [function] jump to the pos...

Page 169

145 intelligent actuator part 4 commands z exsr (execute subroutine) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional exsr subroutine number prohibited cp [function] execute the su...

Page 170

146 intelligent actuator part 4 commands z edsr (end subroutine) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) prohibited prohibited edsr prohibited prohibited cp [function] declare the end of a ...

Page 171

147 intelligent actuator part 4 commands 1.9 task management z exit (end program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional exit prohibited prohibited cp [function] end the ...

Page 172

148 intelligent actuator part 4 commands z expg (start other program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional expg program number (program number) cc [function] start the ...

Page 173

149 intelligent actuator part 4 commands z abpg (abort other program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional abpg program number (program number) cc [function] forcibly e...

Page 174

150 intelligent actuator part 4 commands z sspg (pause program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional sspg program number (program number) cc [function] pause the progra...

Page 175

151 intelligent actuator part 4 commands z rspg (resume program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional rspg program number (program number) cc [function] resume the prog...

Page 176

152 intelligent actuator part 4 commands 1.10 position operation z pget (read position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pget axis number position number cc [f...

Page 177

153 intelligent actuator part 4 commands z pput (write position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pput axis number position number cp [function] write the valu...

Page 178

154 intelligent actuator part 4 commands z pclr (clear position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pclr position number position number cp [function] clear the ...

Page 179

155 intelligent actuator part 4 commands z pcpy (copy position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pcpy position number position number cp [function] copy the po...

Page 180

156 intelligent actuator part 4 commands z pred (read current position) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pred axis pattern position number cp [function] read the cu...

Page 181

157 intelligent actuator part 4 commands z prdq (read current axis position (1 axis direct)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional prdq axis number variable number cp th...

Page 182

158 intelligent actuator part 4 commands z ptst (check position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional ptst axis pattern position number cc [function] check if vali...

Page 183

159 intelligent actuator part 4 commands z pvel (assign speed data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pvel speed position number cp [function] write the speed specif...

Page 184

160 intelligent actuator part 4 commands z pacc (assign acceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pacc acceleration position number cp [function] write th...

Page 185

161 intelligent actuator part 4 commands z pdcl (assign deceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pdcl deceleration position number cp [function] assign t...

Page 186

162 intelligent actuator part 4 commands z paxs (read axis pattern) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional paxs variable number position number cp [function] store the ax...

Page 187

163 intelligent actuator part 4 commands z psiz (check position data size) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional psiz variable number prohibited cp [function] set an app...

Page 188

164 intelligent actuator part 4 commands z gvel (get speed data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gvel variable number position number cp [function] obtain speed da...

Page 189

165 intelligent actuator part 4 commands z gacc (get acceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gacc variable number position number cp [function] obtain a...

Page 190

166 intelligent actuator part 4 commands z gdcl (get deceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gdcl variable number position number cp [function] obtain d...

Page 191

167 intelligent actuator part 4 commands 1.11 actuator control declaration z vel (set speed) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional vel speed prohibited cp [function] set...

Page 192

168 intelligent actuator part 4 commands z ovrd (override) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional ovrd speed ratio prohibited cp [function] reduce the speed in accordance...

Page 193

169 intelligent actuator part 4 commands z acc (set acceleration) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional acc acceleration prohibited cp [function] set the travel accelera...

Page 194

170 intelligent actuator part 4 commands z dcl (set deceleration) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dcl deceleration prohibited cp [function] set the travel decelera...

Page 195

171 intelligent actuator part 4 commands z scrv (set sigmoid motion ratio) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional scrv ratio prohibited cp [function] set the ratio of sig...

Page 196

172 intelligent actuator part 4 commands z ofst (set offset) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional ofst axis pattern offset value cp [function] reset the target value by...

Page 197

173 intelligent actuator part 4 commands z deg (set arc angle) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional deg angle prohibited cp [function] set a division angle for the inte...

Page 198

174 intelligent actuator part 4 commands z base (specify axis base) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional base axis number prohibited cp [function] count the axes sequen...

Page 199

175 intelligent actuator part 4 commands z grp (set group axes) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional grp axis pattern prohibited cp [function] allow only the position d...

Page 200

176 intelligent actuator part 4 commands z hold (hold: declare axis port to pause) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional hold (input port, global flag) (hold type) cp [f...

Page 201

177 intelligent actuator part 4 commands z canc (cancel: declare axis port to abort) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional canc (input port, global flag) (canc type) cp ...

Page 202

178 intelligent actuator part 4 commands z vlmx (specify vlmx speed) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional vlmx prohibited prohibited cp [function] set the actuator trav...

Page 203

179 intelligent actuator part 4 commands z dis (set division distance at spline movement) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dis distance prohibited cp [function] set...

Page 204

180 intelligent actuator part 4 commands z potp (set path output type) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional potp 0 or 1 prohibited cp [function] set the output type in ...

Page 205

181 intelligent actuator part 4 commands z papr (set push-motion approach distance, speed) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional papr distance speed cp [function] set th...

Page 206

182 intelligent actuator part 4 commands z qrtn (set quick-return mode) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional qrtn 0 or 1 prohibited cp [function] set and cancel the qui...

Page 207

183 intelligent actuator part 4 commands 1.12 actuator control command z sv (turn on/off servo) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional sv axis pattern prohibited pe [func...

Page 208

184 intelligent actuator part 4 commands z home (return to home) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional home axis pattern prohibited pe [function] perform home return of ...

Page 209

185 intelligent actuator part 4 commands z movp (move ptp by specifying position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional movp position number prohibited pe [function...

Page 210

186 intelligent actuator part 4 commands z movl (move by specifying position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional movl position number prohibited pe [function] mo...

Page 211

187 intelligent actuator part 4 commands z mvpi (move via incremental ptp) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional mvpi position number prohibited pe [function] move the a...

Page 212

188 intelligent actuator part 4 commands z mvli (move via incremental interpolation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional mvli position number prohibited pe [function] ...

Page 213

189 intelligent actuator part 4 commands z path (move along path) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional path start position number end position number pe [function] move...

Page 214

190 intelligent actuator part 4 commands z j w (jog) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional j w axis pattern input, output, flag number pe [function] the axes in the axis...

Page 215

191 intelligent actuator part 4 commands z stop (stop movement) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional stop axis pattern prohibited cp [function] decelerate and stop the ...

Page 216

192 intelligent actuator part 4 commands z pspl (move along spline) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pspl start position number end position number pe [function] co...

Page 217

193 intelligent actuator part 4 commands z push (move by push motion) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional push target position number prohibited pe [function] perform ...

Page 218

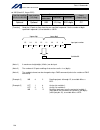

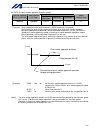

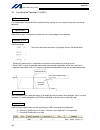

194 intelligent actuator part 4 commands [example] papr 100 20 movp 2 push 10 set the push-motion approach distance to 100 mm and push-motion approach speed to 20 mm/sec. Move from the current position to position no. 2. Perform push-motion movement from position nos. 2 to 10. The diagram below desc...

Page 219

195 intelligent actuator part 4 commands z ptrq (change push torque limit parameter) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional ptrq axis pattern ratio cc [function] change t...

Page 220

196 intelligent actuator part 4 commands z cir2 (move along circle 2 (arc interpolation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional cir2 passing position 1 number passing po...

Page 221

197 intelligent actuator part 4 commands z arc2 (move along circle 2 (arc interpolation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional arc2 passing position number end position...

Page 222

198 intelligent actuator part 4 commands z cirs (move three-dimensionally along circle) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional cirs passing position 1 number passing posi...

Page 223

199 intelligent actuator part 4 commands z arcs (move three-dimensionally along arc) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional arcs passing position number end position numb...

Page 224

200 intelligent actuator part 4 commands z chvl (change speed) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional chvl axis pattern speed cp [function] change the speed of the axes o...

Page 225

201 intelligent actuator part 4 commands z arcd (move along arc via specification of end position and center angle (arc interpolation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional opti...

Page 226

202 intelligent actuator part 4 commands z arcc (move along arc via specification of center position and center angle (arc interpolation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional o...

Page 227

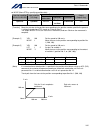

203 intelligent actuator part 4 commands z pbnd (set positioning band) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pbnd axis pattern distance cp [function] set the position co...

Page 228

204 intelligent actuator part 4 commands z cir (move along circle) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional cir passing position 1 number passing position 2 number pe [func...

Page 229

205 intelligent actuator part 4 commands z arc (move along arc) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional arc passing position number end position number pe [function] move ...

Page 230

206 intelligent actuator part 4 commands 1.13 structural if z if (structural if) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional if variable number data cp [function] compare the ...

Page 231

207 intelligent actuator part 4 commands z is (compare strings) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional is column number column number, character literal cp [function] com...

Page 232

208 intelligent actuator part 4 commands z else (else) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) prohibited prohibited else prohibited prohibited cp [function] an else command is used arbitra...

Page 233

209 intelligent actuator part 4 commands 1.14 structural do z dw (do while) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dw variable number data cp [function] compare the conte...

Page 234

210 intelligent actuator part 4 commands z iter (repeat) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional iter prohibited prohibited cp [function] forcibly switch the control to ed...

Page 235

211 intelligent actuator part 4 commands 1.15 multi-branching z slct (start selected group) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional slct prohibited prohibited cp [function...

Page 236

212 intelligent actuator part 4 commands z wh (select if true; variable) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) prohibited prohibited wh variable number data cp [function] this command is ...

Page 237

213 intelligent actuator part 4 commands z ws (select if true; character) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) prohibited prohibited ws column number column number, character literal cp ...

Page 238

214 intelligent actuator part 4 commands z othe (select other) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) prohibited prohibited othe prohibited prohibited cp [function] this command is used be...

Page 239

215 intelligent actuator part 4 commands 1.16 system information acquisition z axst (get axis status) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional axst variable number axis num...

Page 240

216 intelligent actuator part 4 commands z pgst (get program status) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pgst variable number program number cp [function] store in the...

Page 241

217 intelligent actuator part 4 commands z syst (get system status) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional syst variable number prohibited cp [function] store the system ...

Page 242

218 intelligent actuator part 4 commands 1.17 zone z wzna (wait for zone on, with and) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional wzna zone number axis pattern cp [function] ...

Page 243

219 intelligent actuator part 4 commands z wzno (wait for zone on, with or) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional wzno zone number axis pattern cp [function] wait for th...

Page 244

220 intelligent actuator part 4 commands z wzfa (wait for zone off, with and) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional wzfa zone number axis pattern cp [function] wait for ...

Page 245

221 intelligent actuator part 4 commands z wzfo (wait for zone off, with or) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional wzfo zone number axis pattern cp [function] wait for t...

Page 246

222 intelligent actuator part 4 commands 1.18 communication z open (open channel) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional open channel number prohibited cp [function] open...

Page 247

223 intelligent actuator part 4 commands z read (read) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional read channel number column number cc [function] read a character string from...

Page 248

224 intelligent actuator part 4 commands (note1) a read command must be executed before the other side sends the end character. (note2) channel nos. 31 to 34 (available with the ethernet option) cannot be specified for dummy read (operand 2: 0). Scha 10 open 1 read 1 2 other side clos 1 • return cod...

Page 249