- DL manuals

- IBC

- Boiler

- VFC 15-150

- Installation And Operating Instructions Manual

IBC VFC 15-150 Installation And Operating Instructions Manual

INST

ALLA

TION AND OPERA

TING INSTR

UCTIONS

www.ibcboiler.com

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

This Manual is also available in French - contact IBC or visit our web site www.ibcboiler.com

VFC 15-150, VFC 45-225

MODULATING GAS BOILERS

(Natural Gas or Propane)

Summary of VFC 15-150

Page 1

Inst alla tion and opera ting instr uctions www.Ibcboiler.Com warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Do not store or use gasoline or other flammable vapours and liquids or other com...

Page 2: Safety Considerations

Installation and operation instructions vfc 15-150, vfc 45-225 modulating gas boilers 2 safety considerations installation, start-up and servicing of ibc boilers must be done with due care and attention, and should only be performed by competent, qualified, licensed and trained heating technicians. ...

Page 3: Specifications

Installation and operation instructions vfc 15-150, vfc 45-225 modulating gas boilers 3 specifications specification vfc 15-150 vfc 45-225 csa input (natural gas or propane) - mbh csa input (natural gas or propane) - kw csa output - mbh csa output - kw 15 - 150 4.4 - 44 14 - 139 4.1 - 41 45 - 225 13...

Page 4

Installation and operation instructions vfc 15-150, vfc 45-225 modulating gas boilers 4 this page intentionally left blank.

Page 5: Contents

Installation and operation instructions vfc 15-150, vfc 45-225 modulating gas boilers 5 contents 1.0 installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

Installation and operation instructions vfc 15-150, vfc 45-225 modulating gas boilers 6 the installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel and termination, gas supply, condensa...

Page 7: Installation

1-1 installation vfc 15-150, vfc 45-225 modulating gas boilers installation 1.0 general vfc gas-fired modulating boilers are low pressure, fully condensing units having variable input ranges (a) 15 mbh (15,000 btu/hr) to 150 mbh (15-150 model, 0 to 12,000’) and (b) 45 mbh to 225 mbh (45-225 model, 0...

Page 8

Installation and operation instructions 1-2 vfc 15-150, vfc 45-225 modulating gas boilers code requirements the vfc 15-150 and vfc 45-225 boiler models were tested to and certified under csa 4.9-2014 / ansi z21.13-2014. Installation must conform to local codes, or in the absence of these, with the l...

Page 9

1-3 installation vfc 15-150, vfc 45-225 modulating gas boilers sources. Do not seal boiler case openings directly when firing - allow for air circulation and ventilation in the immediate area. Surface distance from combustible surfaces recommended distance for service front 2" 24" rear 0" 0" left si...

Page 10

Installation and operation instructions 1-4 vfc 15-150, vfc 45-225 modulating gas boilers determine there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition. • insofar as is practical, close all building doors and windows and all doors betw...

Page 11

1-5 installation vfc 15-150, vfc 45-225 modulating gas boilers that sufficient temperature loss is allowed for in the cpvc section to fall below the limit for pvc, taking into account the highest possible ambient temperature in the area of vent travel (e.G. Boiler room, attic and/or chase). Exhaust ...

Page 12

Installation and operation instructions 1-6 vfc 15-150, vfc 45-225 modulating gas boilers 1.4.3 vent travel cpvc or pps (rigid single wall) piping is the standard venting option; with this, the vfc 15-150 boiler, for example, can be sited up to 50 equivalent feet from the vent termination using 2” o...

Page 13

1-7 installation vfc 15-150, vfc 45-225 modulating gas boilers exhaust venting must slope down to the trap/drain with a pitch of at least 1/4" per foot (pps vent: follow pps manufacturer requirements for slope) so condensate runs towards the trap. Support should be provided for intake and vent pipin...

Page 14

Installation and operation instructions 1-8 vfc 15-150, vfc 45-225 modulating gas boilers figure 3: rooftop vent terminal configurations 1.4.4 venting passage through ceiling and floor • confirm material meets local codes including fire stopping requirements. • pipe clearances - no ibc requirements,...

Page 15

1-9 installation vfc 15-150, vfc 45-225 modulating gas boilers 1.4.6 sidewall vent termination sidewall direct vent applications shall be vented as follows: • both the inlet and exhaust terminations should normally be located on the same plane (side) of the building. • the exhaust outlet is to be pl...

Page 16

Installation and operation instructions 1-10 vfc 15-150, vfc 45-225 modulating gas boilers for side venting of multiple boiler sets, group all intake terminals together with 4" to 8" lateral spacing, and similarly group the exhaust pipes. Place the 2 groups on the same plane of the building (e.G. No...

Page 17

1-11 installation vfc 15-150, vfc 45-225 modulating gas boilers 1.4.7 “direct vent” combustion air intake piping there are two basic methods of supplying combustion air to an ibc boiler. The direct vent option uses piping from the outside to supply combustion air directly to the boiler’s combustion ...

Page 18

Installation and operation instructions 1-12 vfc 15-150, vfc 45-225 modulating gas boilers combustion air piping is connected at the base of the boiler using a standard 2” pvc (abs) coupler or elbow and run horizontally or vertically to the outdoors. Screen material can be placed at the inlet as app...

Page 19

1-13 installation vfc 15-150, vfc 45-225 modulating gas boilers air intake filter ibc part #sc100a 1.4.9 combustion air filtration if combustion air contamination from ingested particulate matter may be a concern in any installation, an optional air intake filter may be installed. Ibc supplied air i...

Page 20

Installation and operation instructions 1-14 vfc 15-150, vfc 45-225 modulating gas boilers condensate removal ibc’s specified vent configuration promotes the safe drainage of moisture from the boiler and exhaust venting without flowing liquids back through the heat exchanger (as done by other conden...

Page 21

1-15 installation vfc 15-150, vfc 45-225 modulating gas boilers 1.5.1.1 with schedule 40 plastic venting systems (e.G. Ulc-s636 cpvc) a condensate trap must be installed near the base of the boiler as shown in figure 14. The trap is formed using pvc pipe, elbows and threaded union fittings. Note: fo...

Page 22

Installation and operation instructions 1-16 vfc 15-150, vfc 45-225 modulating gas boilers figure 17: condensate trap installation - pps figure 18: ibc kit #p-166a for centrotherm pps (with centrotherm clips – ibc #180-050).

Page 23

1-17 installation vfc 15-150, vfc 45-225 modulating gas boilers each manufacturer of pps venting systems has its own unique design for their metal retaining clips. While they may look very similar, do not mix any such components between suppliers. Ibc supplies these only within the respective parts ...

Page 24

Installation and operation instructions 1-18 vfc 15-150, vfc 45-225 modulating gas boilers 6. Confirm the drain spout compression nut (e) is secure by applying 10 lbs of downward force on the trap body (d). Then apply ibc #152-004 reusable strap as shown in figure 17 to prevent blow-off of the trap ...

Page 25

1-19 installation vfc 15-150, vfc 45-225 modulating gas boilers warning if condensates are to be discharged into building drain piping materials that are subject to corrosion, a neutralization package must be used. Caution when a condensate neutralization package is installed, the ph of the condensa...

Page 26

Installation and operation instructions 1-20 vfc 15-150, vfc 45-225 modulating gas boilers water piping 1.6.1 general piping issues the vfc modulating series boilers are designed for use within a closed loop, forced circulation, low pressure system. A 30 psi pressure relief valve (3/4" npt) is suppl...

Page 27

1-21 installation vfc 15-150, vfc 45-225 modulating gas boilers do not place any water connections overhead the boiler; leaks can damage the fan & controls. If needed, create a shield over the louvered top of the cover, but allow clearance for airflow and service access. For best results, use a prim...

Page 28

Installation and operation instructions 1-22 vfc 15-150, vfc 45-225 modulating gas boilers the vfc modulating series boilers are designed to supply up to four different heating loads with temperatures within the range 34°f to 185°f - to meet three separately piped loads. Use closely spaced tees to c...

Page 29

1-23 installation vfc 15-150, vfc 45-225 modulating gas boilers pressure vessel head flow rate (gpm) 4 8 12 16 20 head @ flow (ft wc) 0.7 2.5 5.0 8.3 12.3 table 6: pressure vessel head ensure the pump is rated for the design circulating water temperatures; some pumps have a minimum water temperature...

Page 30

Installation and operation instructions 1-24 vfc 15-150, vfc 45-225 modulating gas boilers 1.6.2 installation rules note: the boiler trim element – common to each of the following systems - includes the pressure relief, fill, expansion tank and air bleed elements. The primary pump can be located on ...

Page 31

1-25 installation vfc 15-150, vfc 45-225 modulating gas boilers the use of the multi-temperature modulating system is optimized when the need to shutdown the boiler is reduced or eliminated during the transitional period. System design enhancements: (a) keep a relatively low thermal mass in the prim...

Page 32

Installation and operation instructions 1-26 vfc 15-150, vfc 45-225 modulating gas boilers gas piping the boiler requires an inlet gas pressure of at least 3.0" w.C. For natural gas or propane. For either fuel, the inlet pressure shall be no greater than 14.0" w.C. Confirm this pressure range is ava...

Page 33

1-27 installation vfc 15-150, vfc 45-225 modulating gas boilers electrical connections all electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or national electrical code, ans/nfpa no. 70 – latest edition, or the canadian electrical code, c22.1 - part 1. ...

Page 34

Installation and operation instructions 1-28 vfc 15-150, vfc 45-225 modulating gas boilers 1.8.2 power quality and electrical protection in areas of unreliable power, appropriate surge protectors and or power conditioning equipment should be installed in powers supply wiring circuits. 1.8.3 zone val...

Page 35

1-29 installation vfc 15-150, vfc 45-225 modulating gas boilers 1.8.6 thermostat heat anticipator ibc “therm.” contacts draw no power, so an anticipator setting for the thermostat is not applicable with the vfc modulating series boilers. In the case of a single temperature / heat load where zone val...

Page 36

Installation and operation instructions 1-30 vfc 15-150, vfc 45-225 modulating gas boilers this page intentionally left blank.

Page 37: 2.0 Ibc Boiler Controller

2-1 boiler systems and operation vfc 15-150, vfc 45-225 modulating gas boilers 2.0 ibc boiler controller general this boiler is equipped with the v-10 touch screen controller. The controller simplifies the programing of the boiler while providing greater flexibility. For more detailed instructions, ...

Page 38

Installation and operation instructions 2-2 vfc 15-150, vfc 45-225 modulating gas boilers operational and historical data may be accessed at any time using the system status and load profiles sections of the control. Error logs are available in the diagnostics section and the controller is capable o...

Page 39: Startup and Commissioning

3-1 startup and commissioning vfc 15-150, vfc 45-225 modulating gas boilers startup and commissioning 3.0 3.1 lighting and shutting down the boiler.

Page 40

Installation and operation instructions 3-2 vfc 15-150, vfc 45-225 modulating gas boilers 3.2 prior to start-up 3.2.1 pre-ignition checks 1. Ensure venting system is complete and seal tested. Confirm any common venting system at the installation site is isolated and independent of the vfc boiler, th...

Page 41

3-3 startup and commissioning vfc 15-150, vfc 45-225 modulating gas boilers procedure. Pressure may droop up to 1” to 2” w.C. At high fire but under no circumstances should it drop below 3” w.C. At the gas valve inlet test port. 2. Allow the boiler to ignite / run against a large load, to maintain h...

Page 42

Installation and operation instructions 3-4 vfc 15-150, vfc 45-225 modulating gas boilers figure 32: gas valve and pressure reference system.

Page 43

3-5 startup and commissioning vfc 15-150, vfc 45-225 modulating gas boilers fuel conversion the vfc series modulating boiler is factory fire-tested to operate with natural gas, or propane as ordered. The rating plate will be marked to indicate which fuel the particular boiler has been set up with. F...

Page 44

Installation and operation instructions 3-6 vfc 15-150, vfc 45-225 modulating gas boilers this page intentionally left blank.

Page 45: Maintenance

4-1 maintenance vfc 15-150, vfc 45-225 modulating gas boilers maintenance 4.0 boiler maintenance 4.1.1 general care • keep combustible materials and flammable liquids and vapours away from the boiler. • keep vent terminals clear of obstructions (snow, dirt, etc.). 4.1.2 inspection inspection of the ...

Page 46

Installation and operation instructions 4-2 vfc 15-150, vfc 45-225 modulating gas boilers 4.1.6 heat exchanger during burner inspection (with the burner removed), examine the heat exchanger tubes adjacent to the burner’s normal position. In areas of poor gas quality, there may be a buildup of black ...

Page 47

4-3 maintenance vfc 15-150, vfc 45-225 modulating gas boilers 4.1.12 boiler treatment • check consistency of any boiler treatment used (e.G. Furnox™), for appropriate mixture. Chemical inhibitors are consumed over time, lowering their density. • verify proper operation after servicing. 4.1.13 relief...

Page 48

Installation and operation instructions 4-4 vfc 15-150, vfc 45-225 modulating gas boilers component description a diagram of components and their placement can be found at the end of this manual. To obtain service parts, contact your installer, telephone ibc technologies or visit our website at www....

Page 49

4-5 maintenance vfc 15-150, vfc 45-225 modulating gas boilers 4.2.5 water pressure sensor type: water pressure (ibc # 240-006) function: water pressure and flow sensing. Installation: (see diagram 6.1-1, and diagram 6.1-2). 4.2.6 high limit part#/type: ibc # 240-032 high limit calibrated for 200°f, ...

Page 50

Installation and operation instructions 4-6 vfc 15-150, vfc 45-225 modulating gas boilers gaining access to combustion chamber, burner removal instructions; fan and gas valve removal instructions the installer or service technician can select from three separate routes to gain access to the burner a...

Page 51

4-7 maintenance vfc 15-150, vfc 45-225 modulating gas boilers angle-driver to reach past the gas valve, or a stubby phillips screwdriver for enhanced working space. Ii. Three vinyl hoses do not need to be disconnected, but if that is chosen ensure they are marked for reinstallation. Avoid placing pr...

Page 52

Installation and operation instructions 4-8 vfc 15-150, vfc 45-225 modulating gas boilers c. For option 3 – install the 4 small phillips screws through the gas valve support bracket and into the gas valve adjacent to the gas inlet. The screws are to be loosely attached at this stage to allow easier ...

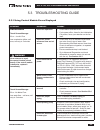

Page 53: 5.0 Troubleshooting

5-1 troubleshooting vfc 15-150, vfc 45-225 modulating gas boilers 5.0 troubleshooting the troubleshooting section is divided into 3 sections: 5.1 preliminary checks 5.2 electronic components 5.3 troubleshooting guide often, a problem can be identified and solved through simple checks of the basics: ...

Page 54

Installation and operation instructions 5-2 vfc 15-150, vfc 45-225 modulating gas boilers electronic components this section details the method for troubleshooting the non-standard electronic components on the boiler including the electronic differential air pressure sensor and the temperature senso...

Page 55

5-3 troubleshooting vfc 15-150, vfc 45-225 modulating gas boilers 5.2.2 fan/blower operating power is provided by means of a separate 120 vac connector at the back of the fan (white/black/green). Control of the fan is provided via a four lead connector at the front of the fan. This connector feeds a...

Page 56

Installation and operation instructions 5-4 vfc 15-150, vfc 45-225 modulating gas boilers 5.2.5 hi-limit switch (water and vent) check resistance between leads. If resistance is very low, temperature should be acceptable. If resistance is very high, temperature should be out of bounds. A simple mean...

Page 57

5-5 troubleshooting vfc 15-150, vfc 45-225 modulating gas boilers 5.3 troubleshooting guide symptom diagnosis remedy airflow error touch screen message: error – low air flow low combustion airflow; soft error; will retry in 5 minutes check fan operation • check lead is attached at fan. • cycle power...

Page 58

Installation and operation instructions 5-6 vfc 15-150, vfc 45-225 modulating gas boilers symptom diagnosis remedy maximum ignition trials error touch screen message: error – ignition failure after 3 tries boiler has failed to ignite on 3 successive attempts. Boiler in lockout for 1 hour, then repea...

Page 59

5-7 troubleshooting vfc 15-150, vfc 45-225 modulating gas boilers 5.3.2 ignition problems symptom diagnosis remedy noisy spark when igniting ignition lead is not firmly connected. Reconnect ignition lead. Contaminants/ moisture on igniter probe/flame sensor. Ensure probe is dry by re-running post-pu...

Page 60

Installation and operation instructions 5-8 vfc 15-150, vfc 45-225 modulating gas boilers 5.3.3 cycling problems symptom diagnosis remedy rapid cycling improper values entered via keypad. Check load maximum temps are above target temps, by 1/2 of the selected boiler differential. Ensure boiler diffe...

Page 61

5-9 troubleshooting vfc 15-150, vfc 45-225 modulating gas boilers 5.3.4 temperature problems symptom diagnosis remedy insufficient heat operating temperature too low. Increase temperature target. Priority parameters or load configuration improperly set up. Review load configuration parameters. Unit ...

Page 62

Installation and operation instructions 5-10 vfc 15-150, vfc 45-225 modulating gas boilers 5.3.5 miscellaneous symptom diagnosis remedy fumes and high humidity improperly installed condensate trap refer to installation/operation instructions leak in vent piping inspect using soap solution flue gas l...

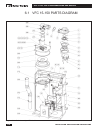

Page 63: 6.0 Diagrams

6-1 diagrams vfc 15-150, vfc 45-225 modulating gas boilers 6.0 diagrams 6.1 - vfc 15-150 parts diagrams 6.2 - vfc 45-225 parts diagrams 6.3 - additional parts diagrams 6.4 - wiring diagrams 6.5 - sequence of operation.

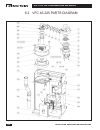

Page 64

Installation and operation instructions 6-2 vfc 15-150, vfc 45-225 modulating gas boilers 6.1 vfc 15-150 parts diagram diagram 6.1-1: boiler assembly – vfc 15-150

Page 65

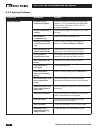

6-3 diagrams vfc 15-150, vfc 45-225 modulating gas boilers item# description part# qty 175 refractory, outer 250-287 1 180 refractory, inner 250-306 1 185 gasket, heat exchanger lid 250-328 1 190 lid, heat exchanger 250-284 1 195 screw, m10 x 55, hex head 150-106 4 200 washer, fender, m10 150-104 4 ...

Page 66

Installation and operation instructions 6-4 vfc 15-150, vfc 45-225 modulating gas boilers 6.2 vfc 45-225 parts diagram diagram 6.2-1: boiler assembly – vfc 45-225.

Page 67

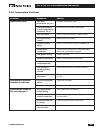

6-5 diagrams vfc 15-150, vfc 45-225 modulating gas boilers item# description part# qty 5 fan, nrg 137 240-048 1 10 o-ring 150-073 1 15 fan adapter plate 180-023 1 20 screw, m4x10 tapping, flat head, equipped w/fan 3 25 air intake, base 180-017 1 30 swirl plate 180-020 1 35 air intake, cover 180-018 ...

Page 68

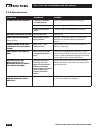

Installation and operation instructions 6-6 vfc 15-150, vfc 45-225 modulating gas boilers diagram 6.3-3: water pressure sensor group diagram 6.3-1: vent high limit diagram 6.3-4: accessory parts kit (shipped with boiler) 51 trap/exhaust kit diagram 6.3-2: intake air filter (order separately) item # ...

Page 69

6-7 diagrams vfc 15-150, vfc 45-225 modulating gas boilers 6.4 wiring diagrams diagram 6.4-1: ladder wiring diagram.

Page 70

Installation and operation instructions 6-8 vfc 15-150, vfc 45-225 modulating gas boilers diagram 6.4-2: internal wiring diagram.

Page 71

6-9 diagrams vfc 15-150, vfc 45-225 modulating gas boilers 6.5 sequence of operation diagram 6.5-1: sequence of operation diagram.

Page 72

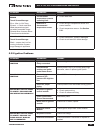

Installation & commissioning report boiler details: model number _____________________ serial number ______________________________________________ date of installation ______________ address of installation __________________________________________ _________________________________________________...

Page 73

Installer set-up load definition - load #1 _______________________________________________________________________ load configuration - load #1 _____________________________________________________________________________________________ load definition - load #2 ____________________________________...

Page 74

Service record date licensed contractor description of work done.

Page 75

Notes.

Page 76

Notes.

Page 77

Notes.

Page 78: Important

Important this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equipped with an override which is provided primarily to permit the use of an external energy management system that serves the same function. Th...

Page 79

Revision history r1 (september 2005) initial release r2 (july 2007) venting requirements (canada) to ulc-s636; internal wiring diagram and warranty details added r3 (march 2010) vfc 45-225-sl variant added (with new nrg-137 fan); warranty removed to separate document r4 (september 2012) polypropylen...

Page 80

Ibc technologies inc. 8015 north fraser way burnaby, bc canada v5j 5m8 tel: 604.877.0277 fax: 604.877.0295 www.Ibcboiler.Com 120-100e-a-r6 may 2015 © ibc technologies inc. 2015.