- DL manuals

- IBC

- Boiler

- VFC 15-150

- Manual

IBC VFC 15-150 Manual

INST

ALLA

TION AND OPERA

TING INSTR

UCTIONS

www.ibcboiler.com

VFC 15-150 - VFC 45-225

Modulating gas Boilers

(Natural Gas or Propane)

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

this Manual is also available in French - contact iBC or visit our web site www.ibcboiler.com

Summary of VFC 15-150

Page 1

Inst alla tion and opera ting instr uctions www.Ibcboiler.Com vfc 15-150 - vfc 45-225 modulating gas boilers (natural gas or propane) warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Do not s...

Page 2: Safety Considerations

Installation and operation instructions vfc 15-150 - vfc 45-225 modulating gas boilers safety considerations specifications warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Installation, start...

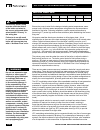

Page 3: Contents

Installation and operation instructions vfc 15-150 - vfc 45-225 modulating gas boilers 1.0 installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Installation and operation instructions vfc 15-150 - vfc 45-225 modulating gas boilers the installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel and termination, gas supply, condensat...

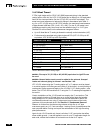

Page 5: Installation

1-1 installation vfc 15-150 - vfc 45-225 modulating gas boilers installation 1.0 general vfcgas-firedmodulatingboilersarelowpressure,fullycondensingunitshaving variable input ranges (a) 15 mbh (15,000 btu/hr) to 150 mbh (15-150 model, 0 to 8,000’) and (b) 45 mbh to 225 mbh (45-225 model, 0 to 8,000’...

Page 6

Installation and operation instructions 1-2 vfc 15-150 - vfc 45-225 modulating gas boilers code requirements thevfc15-150modelwastestedtoandcertifiedundercsa4.9-2000/ansi z21.13-2000. The larger vfc 45-225 unit was approved under csa 4.9a-2005 / anzi z21.13a-2005. Installation must conform to local ...

Page 7

1-3 installation vfc 15-150 - vfc 45-225 modulating gas boilers contaminants; combustion air should be drawn from a clean source (e.G. Outdoors) and the boiler should be isolated from interior dust sources. Do not seal boiler case openings directly when firing - allow for air circulation and ventila...

Page 8

Installation and operation instructions 1-4 vfc 15-150 - vfc 45-225 modulating gas boilers • seal any unused opening in the common venting system. • visually inspect the venting system for proper size and horizontal pitch and determine there is no blockage or restriction, leakage, corrosion and othe...

Page 9

1-5 installation vfc 15-150 - vfc 45-225 modulating gas boilers for long vent runs with higher initial exhaust temperature, some jurisdictions may allow the use of mixed materials for economy: ulc-s636 approved cpvc for the initial run followed by ulc-s636 approved pvc to the termination (it is the ...

Page 10

Installation and operation instructions 1-6 vfc 15-150 - vfc 45-225 modulating gas boilers 1.4.3 vent travel 3" pps (rigid single wall) or cpvc ulc-s636 approved piping is the standard venting option; with this, the vfc 15-150 boiler can be sited up to 120 equivalent feet from the vent termination (...

Page 11

1-7 installation vfc 15-150 - vfc 45-225 modulating gas boilers if the site requires a horizontal exit immediately below the boiler – bush out to 2-1/2" or 3" pipe in the downward vertical run immediately below the 2" threadedadaptor,andelbowtohorizontalbeforesplicinginafieldsourced 2-1/2" or 3" red...

Page 12

Installation and operation instructions 1-8 vfc 15-150 - vfc 45-225 modulating gas boilers figure 3: rooftop vent terminal configurations 1.4.6 sidewall vent termination sidewall direct vent applications shall be vented as follows: • both the inlet and exhaust terminations should normally be located...

Page 13

1-9 installation vfc 15-150 - vfc 45-225 modulating gas boilers • use a 45° elbow on the exhaust termination to launch the plume up and off the sidewall, for protection of wall. • bird screen of 1/4" stainless steel or plastic mesh is useful to guard against foreign objects. To promote the projectio...

Page 14

Installation and operation instructions 1-10 vfc 15-150 - vfc 45-225 modulating gas boilers vent terminal clearance minimums are as follows: • clearance above grade, veranda, porch, deck or balcony – 12" (0.3m), but check local code also (anticipated snow levels may supersede). • clearance to openab...

Page 15

1-11 installation vfc 15-150 - vfc 45-225 modulating gas boilers 1.4.7 “direct vent” combustion air intake piping there are two basic methods of supplying combustion air to an ibc boiler. The direct vent option uses piping from the outside to supply combustion air directly to the boiler’s combustion...

Page 16

Installation and operation instructions 1-12 vfc 15-150 - vfc 45-225 modulating gas boilers combustion air piping is connected at the base of the boiler using a standard 2” pvc (abs) coupler or elbow and run horizontally or vertically to the outdoors. Screen material can be placed at the inlet as ap...

Page 17

1-13 installation vfc 15-150 - vfc 45-225 modulating gas boilers air intake filter ibc part # 103 1.4.9 combustion air filtration if combustion air contamination from ingested particulate matter may be a concerninanyinstallation,anoptionalairintakefiltermaybeinstalled.Ibc suppliedairintakefiltershav...

Page 18

Installation and operation instructions 1-14 vfc 15-150 - vfc 45-225 modulating gas boilers condensate removal ibc’sspecifiedventconfigurationpromotesthesafedrainageofmoisturefromthe boilerandexhaustventingwithoutflowingliquidsbackthroughtheheatexchanger (as done by other condensing boilers). Reliab...

Page 19

1-15 installation vfc 15-150 - vfc 45-225 modulating gas boilers 1.5.1.1 with schedule 40 plastic venting systems (e.G. Ulc-s636 cpvc) a condensate trap must be installed near the base of the boiler as shown in figures 14 or 15.Thetrapisformedusingpvcpipe,elbowsandthreadedunionfittings. Note: for cp...

Page 20

Installation and operation instructions 1-16 vfc 15-150 - vfc 45-225 modulating gas boilers 1.5.1.2 with pps venting systems a condensate trap must be installed on the drain connection at the base of the boiler as shown in figure 17. Please follow the installation instructions below: 1. Undo drain s...

Page 21

1-17 installation vfc 15-150 - vfc 45-225 modulating gas boilers 1.5.3 condensate trap assembly - cleaning procedure 1. Turn off the power to the boiler and allow it to cool down. 2. Remove the trap from the boiler (reverse the installation procedure above). 3. Remove the trap cleanout assembly (h),...

Page 22

Installation and operation instructions 1-18 vfc 15-150 - vfc 45-225 modulating gas boilers figure 19: condensate trap drainage figure 20: condensate neutralization tank warning if condensates are to be discharged into building drain piping materials that are subject to corrosion, a neutralization p...

Page 23

1-19 installation vfc 15-150 - vfc 45-225 modulating gas boilers water piping 1.6.1 general piping issues the vfc modulating series boilers are designed for use within a closed loop, forced circulation, low pressure system. A 30 psi pressure relief valve (3/4" npt) issuppliedforfieldinstallationinth...

Page 24

Installation and operation instructions 1-20 vfc 15-150 - vfc 45-225 modulating gas boilers do not place any water connections overhead the boiler; leaks can damage the fan & controls. If needed, create a shield over the louvered top of the cover, butallowclearanceforairflowandserviceaccess. For bes...

Page 25

1-21 installation vfc 15-150 - vfc 45-225 modulating gas boilers the vfc modulating series boilers are designed to supply three different heating loads with temperatures within the range 34°f to 185°f - to meet three separately piped loads. Use closely spaced tees to connect each pumped “load” (e.G....

Page 26

Installation and operation instructions 1-22 vfc 15-150 - vfc 45-225 modulating gas boilers pressure vessel head flow rate (gpm) 4 8 12 16 20 head@flow(ftwc) 0.7 2.5 5.0 8.3 12.3 table 6: pressure vessel head ensure the pump is rated for the design circulating water temperatures; some pumps have a m...

Page 27

1-23 installation vfc 15-150 - vfc 45-225 modulating gas boilers shallbecarriedoutaftertheretrofit,withfilterclearingafterthe1stday,1stweek, monthandannuallythereafter.Careistobetakentoavoiduseofferrousfittings and pumps on pb tube systems. 1.6.2 installation rules note: the boiler trim element – co...

Page 28

Installation and operation instructions 1-24 vfc 15-150 - vfc 45-225 modulating gas boilers new load is not exceeded. In the case of the typical maximum limit for a radiant floor(mostwouldenter140°f);thefloorpumpwouldremainoff,theboilershut down, leaving primary circulation on until the primary loop...

Page 29

1-25 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers for further information and details, consult our application notes – which provide detailonspecificsingleandmultipleboilerapplications“piping”, “wiring” and “settings”. (available at www.Ibcboiler.Com or from your ibc r...

Page 30

Installation and operation instructions 1-26 vfc 15-150 - vfc 45-225 modulating gas boilers removing wiring box cover line voltage leads for power supply, primary pump and variable speed output line voltage load pump terminal strip electrical connections all electrical wiring to the boiler (includin...

Page 31

1-27 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers 1.8.2 power quality and electrical protection thecontrolboard(forallmodels)isprotectedusingin-linefieldreplaceable fuses of 5 amp (slow-blow). The control circuit board is further protected using on-board factory repair...

Page 32

Installation and operation instructions 1-28 vfc 15-150 - vfc 45-225 modulating gas boilers note: sensors connected to any sensor input contacts must be of ntc thermister-typewitharesistanceof10,000ohmsat25°candβ=3892.Wedo not recommend using 3rd party supplied sensors. Compatible water temperature ...

Page 33: Boiler Systems and Operation

2-1 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers boiler systems and operation 2.0 2.1 general vfc modulating series boilers are designed to service three separate, directly piped heating loads using different pre-selected water temperatures and heat regulation routines...

Page 34

Installation and operation instructions 2-2 vfc 15-150 - vfc 45-225 modulating gas boilers 2.3.2 lcd display uponpower-up,thelcdscreeninitiallyflashesasoftwarereleasenumber then switches to a standby- display mode, showing real time data plus key temperature target settings. Whenthereisacallforheatf...

Page 35

2-3 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers 2.4.1 user setup the occupant has access to a number of practical settings. The most meaningful include adjustment of the indoor temperature target plus the temperature setback and occupied / unoccupied modes. The user m...

Page 36

Installation and operation instructions 2-4 vfc 15-150 - vfc 45-225 modulating gas boilers sequence of operation the control module has 5 cycles during normal operation, as well as an error mode for problem detection: 1. Standby cycle 2. Purging 3. Ignition cycle 4. Heating cycle 5. Circulating cycl...

Page 37

2-5 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers the pump remains on for 5 minutes (adjustable) after the heating cycle ends. If the heating cycle ends as a result of water temperature exceeding the load specificbandlimit,the postpurge will continue as normal, but the ...

Page 38

Installation and operation instructions 2-6 vfc 15-150 - vfc 45-225 modulating gas boilers temperatureload(e.G.Dhwat180°f)toacooltarget(e.G.Radiantflooron outdoor reset, at perhaps 90°f). In the case in which the temperature is outside the applicable differentials, the burner will shut off while the...

Page 39

2-7 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers theapproachoptimizesthelowtemperaturecombustionbenefitsofdirectcool runningofaradiantfloor.Thelargethrottleturndownrangecoupledwithoutdoor reset means that several loads can receive heat in-turn, with less on/off duty cy...

Page 40

Installation and operation instructions 2-8 vfc 15-150 - vfc 45-225 modulating gas boilers in an “open loop” reset system, a room or zone thermostat is used to send a call for heat over a 24vac lead; this opens the respective zone valve, and signals the boilertofireusingonwardleadstotheboiler’sdryco...

Page 41

2-9 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers 2.6.4 variable speed pumping this section reserved. 2.6.5 temperature setback for heating loads declared as space heating (e.G. With outdoor reset) and/ or dhw (where a thermistor probe is used), there are provisions for...

Page 42

Installation and operation instructions 2-10 vfc 15-150 - vfc 45-225 modulating gas boilers outdoor reset enabled load once the outdoor temperature reaches a threshold level e.G. 60°f. The load will be automatically reactivated once the weather returns to levels below the selected threshold. Use of ...

Page 43

2-11 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers 5. Eachoftheboiler’s3loadpositionscanbeconfiguredforanytypeof heating. Vfc boilers are factory shipped with default settings as follows: load 1 set as space heating or reset heating, with high mass radiant floor set as ...

Page 44

Installation and operation instructions 2-12 vfc 15-150 - vfc 45-225 modulating gas boilers 10. For all loads, select and enter a maximum allowable temperature and on/ off supply differential temp. Note these values must be input; they are not automatically assigned as done within some boiler contro...

Page 45

2-13 boiler systems and operation vfc 15-150 - vfc 45-225 modulating gas boilers 18. Upon completion of the input of load parameters, use the left button to step back through the menu system to return to the operating status screen. 19. To enact the control arrangements as input, it is necessary tha...

Page 46

Installation and operation instructions 2-14 vfc 15-150 - vfc 45-225 modulating gas boilers this page intentionally left blank.

Page 47: Startup and Commissioning

3-1 startup and commissioning vfc 15-150 - vfc 45-225 modulating gas boilers startup and commissioning 3.0 3.1 lighting and shutting down the boiler.

Page 48

Installation and operation instructions 3-2 vfc 15-150 - vfc 45-225 modulating gas boilers 3.2 prior to start-up 3.2.1 pre-ignition checks 1. Ensureventingsystemiscompleteandsealtested.Confirmanycommon venting system at the installation site is isolated and independent of the vfc boiler, that any ho...

Page 49

3-3 startup and commissioning vfc 15-150 - vfc 45-225 modulating gas boilers 4. Withacombustionanalyzerprobeinthefluegastestport,turnthegas:air ratio adjustment screw (see figure 31, “b”) to achieve 28% excess air (corresponding co2 values are 9.2% for natural gas and 10.4% for propane). Thisscrewof...

Page 50

Installation and operation instructions 3-4 vfc 15-150 - vfc 45-225 modulating gas boilers this page intentionally left blank.

Page 51: Maintenance

4-1 maintenance vfc 15-150 - vfc 45-225 modulating gas boilers maintenance 4.0 boiler maintenance 4.1.1 general care • keepcombustiblematerialsandflammableliquidsandvapoursawayfromthe boiler. • keep vent terminals clear of obstructions (snow, dirt, etc.). 4.1.2 inspection inspection of the boiler is...

Page 52

Installation and operation instructions 4-2 vfc 15-150 - vfc 45-225 modulating gas boilers 4.1.6 heat exchanger during burner inspection (with the burner removed), examine the heat exchanger tubes adjacent to the burner’s normal position. In areas of poor gas quality, there may be a buildup of black...

Page 53

4-3 maintenance vfc 15-150 - vfc 45-225 modulating gas boilers • the second screen (below) shows another boiler (a 45-225) has operated for 26% of the total load 2 on-time at the bottom 30% of the throttle range and virtually no time below that. Interpretation of this type of operation must be done ...

Page 54

Installation and operation instructions 4-4 vfc 15-150 - vfc 45-225 modulating gas boilers component description a diagram of components and their placement can be found at the end of this manual. To obtain service parts, contact your installer, telephone ibc technologies or visit our website at www...

Page 55

4-5 maintenance vfc 15-150 - vfc 45-225 modulating gas boilers 4.2.5 water pressure sensor type: water pressure (ibc # 240-006) function: waterpressureandflowsensing. Installation: (see diagram 6.1-1, and diagram 6.1-2, 31 for correct position). 4.2.6 high limit part#/type: ibc # 240-032 high limit ...

Page 56

Installation and operation instructions 4-6 vfc 15-150 - vfc 45-225 modulating gas boilers this page intentionally left blank.

Page 57: 5.0 Troubleshooting

5-1 troubleshooting vfc 15-150 - vfc 45-225 modulating gas boilers 5.0 troubleshooting the troubleshooting section is divided into 3 sections: 5.1 preliminary checks 5.2 electronic components 5.3 troubleshooting guide often,aproblemcanbeidentifiedandsolvedthroughsimplechecksofthe basics:confirmingth...

Page 58

Installation and operation instructions 5-2 vfc 15-150 - vfc 45-225 modulating gas boilers electronic components this section details the method for troubleshooting the non-standard electronic components on the boiler including the electronic differential air pressure sensor and the temperature sens...

Page 59

5-3 troubleshooting vfc 15-150 - vfc 45-225 modulating gas boilers 5.2.2 fan/blower operating power is provided by means of a separate 120 vac connector at the back of the fan (white/black/green). Control of the fan is provided via a four lead connector at the front of the fan. This connector feeds ...

Page 60

Installation and operation instructions 5-4 vfc 15-150 - vfc 45-225 modulating gas boilers next,confirmthatthecircuitisproperlypowered.Thesupplyvoltagetothe sensor should be 13.8 vdc; to check, the simplest technique is to measure the circuit on the face of the controller circuit board (vs. An attem...

Page 61

5-5 troubleshooting vfc 15-150 - vfc 45-225 modulating gas boilers 2-7 microamps should be measured by your meter. The control will lock out if the reading drops below 0.7 microamps. (see section 5.3.1 - “control module - maximum ignition trials error”, and section 5.3.2 - “ignition problems”). For ...

Page 62

Installation and operation instructions 5-6 vfc 15-150 - vfc 45-225 modulating gas boilers 5.3 troubleshooting guide symptom diagnosis remedy airflow error lcd screen message: error – insufficient air flow - check venting insufficient combustion airflow; soft error; will retry in 5 minutes check fan...

Page 63

5-7 troubleshooting vfc 15-150 - vfc 45-225 modulating gas boilers symptom diagnosis remedy maximum ignition trials error lcd screen message: error – ignition failure after 3 tries boiler has failed to ignite on 3 successive attempts. Boiler in lockout for 1 hour, then repeats 3-try seq. Consult ser...

Page 64

Installation and operation instructions 5-8 vfc 15-150 - vfc 45-225 modulating gas boilers 5.3.2 ignition problems symptom diagnosis remedy noisy spark when igniting ignition lead is not firmly connected. Reconnect ignition lead. Contaminants/ moisture on igniter probe/flame sensor. Ensure probe is ...

Page 65

5-9 troubleshooting vfc 15-150 - vfc 45-225 modulating gas boilers 5.3.3 cycling problems symptom diagnosis remedy rapid cycling improper values entered via keypad. Check load maximum temps are above target temps, by 1/2 of the selected boiler differential. Ensure boiler differential is ok (16-30°f ...

Page 66

Installation and operation instructions 5-10 vfc 15-150 - vfc 45-225 modulating gas boilers 5.3.4 temperature problems symptom diagnosis remedy insufficient heat operating temperature too low. Increase temperature target. See section 2.7 priority parameters or load configuration improperly set up. R...

Page 67

5-11 troubleshooting vfc 15-150 - vfc 45-225 modulating gas boilers 5.3.5 miscellaneous symptom diagnosis remedy fumes and high humidity improperly installed condensate trap refer to installation/operation instructions leak in vent piping inspect using soap solution flue gas leak within boiler visua...

Page 68

Installation and operation instructions 5-12 vfc 15-150 - vfc 45-225 modulating gas boilers this page intentionally left blank.

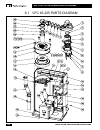

Page 69: 6.0 Diagrams

6-1 diagrams vfc 15-150 - vfc 45-225 modulating gas boilers 6.0 diagrams 6.1 - vfc 45-225 parts diagrams 6.2 - vfc 15-150 parts diagrams 6.3 - additional parts diagrams 6.4 - wiring diagrams 6.5 - sequence of operation.

Page 70

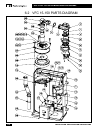

Installation and operation instructions 6-2 vfc 15-150 - vfc 45-225 modulating gas boilers 6.1 vfc 45-225 parts diagram.

Page 71

6-3 diagrams vfc 15-150 - vfc 45-225 modulating gas boilers item # description part # qty 5 fan nrg 137 240-048 1 10 o-ring 150-073 1 15 fan adapter plate 180-023 1 20 screw, m4x10 tapping, flat head, equipped w/fan 3 25 air intake base 180-017 1 30 swirl plate 180-020 1 35 air intake cover 180-018 ...

Page 72

Installation and operation instructions 6-4 vfc 15-150 - vfc 45-225 modulating gas boilers 6.2 vfc 15-150 parts diagram.

Page 73

6-5 diagrams vfc 15-150 - vfc 45-225 modulating gas boilers item # description part # qty 6 fan rg 130 240-040 1 11 gasket fan-fan adapter 250-310 1 15 fan adapter plate 180-023 1 20 screw, m4 x 10, flat head equipped w/240-040 4 25 air intake, base 180-017 1 30 swirl plate 180-020 1 35 air intake, ...

Page 74

Installation and operation instructions 6-6 vfc 15-150 - vfc 45-225 modulating gas boilers diagram 6.1-2: water pressure sensor group diagram 6.1-3: vent high limit diagram 6.1-4: accessory parts kit (shipped with boiler) 51 trap/exhaust kit diagram 6.1-5: intake air filter (order separately) item #...

Page 75

6-7 diagrams vfc 15-150 - vfc 45-225 modulating gas boilers 6.4 wiring diagrams diagram 6.2-1: pictorial wiring diagram electrical notes and specifications.

Page 76

Installation and operation instructions 6-8 vfc 15-150 - vfc 45-225 modulating gas boilers diagram 6.2-2: ladder wiring diagram.

Page 77

6-9 diagrams vfc 15-150 - vfc 45-225 modulating gas boilers diagram 6.2-3: internal wiring diagram.

Page 78

Installation and operation instructions 6-10 vfc 15-150 - vfc 45-225 modulating gas boilers 6.5 sequence of operation diagram 6.3: sequence of operation diagram.

Page 79

Installation & commissioning report boiler details: model number _____________________ serial number ______________________________________________ date of installation ______________ address of installation __________________________________________ _________________________________________________...

Page 80

Service record date licensed contractor description of work done installer set-up load definition - load #1 _______________________________________________________________________ load configuration - load #1 ___________________________________________________________________________________________...

Page 81

Notes.

Page 82

Notes.

Page 83: Important

Revision history r1 (sept 2005) initial release r2 (july 2007) venting requirements (canada) to ulc-s636; internal wiring diagram and warranty details added r3 (mar 2010) vfc 45-225-sl variant added (with new nrg-137 fan); warranty removed to separate document r4 (sept 2012) polypropylene venting, d...

Page 84

Ibc technologies inc. 1445 charles street, vancouver, bc canada v5l 2s7 tel: 604.877.0277 fax: 604.877.0295 www.Ibcboiler.Com 120-100e-a-r4 september 2012.