- DL manuals

- IBM

- Printer

- 6400 Series

- Maintenance Information Manual

IBM 6400 Series Maintenance Information Manual - Hanzi Printers

14

Chapter

1

The IBM 6400 Series Printer Family

Hanzi Printers

IBM 6400-C05 and 6400-C5P printers have shuttle assemblies, hammer

springs, and software specially designed to print the GB character set and

Song typeface used in the People’s Republic of China. These printers can mix

ASCII and Hanzi characters on the same line, with ASCII characters

occupying half the width of Hanzi character cells. Because of the density and

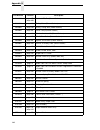

Table 1. The IBM 6400 Series Printer Family

Model

Number

Speed

Enclosure

Hammer

Bank

Data

Controller

Clock

1

6400-004

475 lpm

Cabinet

28 Hammers

25 MHz

6400-04P

475 lpm

Pedestal

28 Hammers

25 MHz

6400-005

500 lpm

Cabinet

28 Hammers

25 MHz

6400-05P

500 lpm

Pedestal

28 Hammers

25 MHz

6400-050

500 lpm

Cabinet

28 Hammers

40 MHz

6400-P50

500 lpm

Pedestal

28 Hammers

40 MHz

6400-008

800 lpm

Cabinet

49 Hammers

25 MHz

6400-08P

800 lpm

Pedestal

49 Hammers

25 MHz

6400-009

900 lpm

Cabinet

49 Hammers

25 MHz

6400-09P

900 lpm

Pedestal

49 Hammers

25 MHz

6400-010

1000 lpm

Cabinet

60 Hammers

40 MHz

6400-P10

1000 lpm

Pedestal

60 Hammers

40 MHz

6400-012

1200 lpm

Cabinet

91 Hammers

25 MHz

6400-014

1400 lpm

Cabinet

91 Hammers

40 MHz

6400-015

1500 lpm

Cabinet

102 Hammers

40 MHz

6400-C05

585 lpm

Cabinet

91 Hammers

40 MHz

6400-C5P

585 lpm

Pedestal

91 Hammers

40 MHz

1

The microprocessor of the Data Controller unit on the CMX controller

board runs at 25 MHz or 40 MHz, depending on printer model. This means

there are two kinds of CMX controller board for IBM 6400 printers, used as

shown in this table. The 40 MHz controller board, however, is backwards

compatible in all models that use the 25 MHz board.

Summary of 6400 Series

Page 1

6400 line matrix printers maintenance information manual cabinet and pedestal models form number s246-0117-08 © copyright ibm corp. 1995, 2000

Page 3: Cabinet And Pedestal Models

Maintenance information manual cabinet and pedestal models 6400 line matrix printers s246-0117-08.

Page 4: Nergy

Energy star note: before using the information and the product it works with, make sure that you read the general information under “notices” below. Ninth edition (august 2000) this edition applies to the ibm 6400 line matrix printer. The following paragraph does not apply to any other country where...

Page 5: Notices

Notices note: the e nergy s tar emblem does not represent epa endorsement of any product or service. Notices references in this publication to ibm products, programs, or services do not imply that ibm intends to make these available in all countries in which ibm operates. Any reference to an ibm lic...

Page 6

Trademarks and service marks trademarks and service marks the following terms, denoted by an asterisk (*) in this publication, are trademarks of ibm corporation in the united states or other countries or both: as/400 ibm pc-dos risc system/6000 scs token-ring the following terms, denoted by a double...

Page 7

Table of contents energy star ................................................................................4 notices ..............................................................................................5 electrical safety .....................................................................

Page 8

Table of contents printing mechanism ...............................................................................38 shuttle frame assembly .................................................................39 paper transport system .................................................................41...

Page 9

Table of contents 6 adjustment procedures ..................................... 151 introduction ..........................................................................................151 list of adjustments .......................................................................151 preparing the ...

Page 10

Table of contents fan assembly, hammer bank ......................................................210 hammer spring assembly ............................................................211 ibm coax/twinax expansion board..............................................215 magnetic pick-up (mpu) assembl...

Page 11

Table of contents mass and density..........................................................................338 temperature..................................................................................338 power ........................................................................................

Page 12

Table of contents.

Page 13: About The Printer

13 1 maintenance overview about the printer the entire system architecture of an ibm* 6400 line matrix printer is contained on one circuit board. The use of dram and flash memory on this board permits rapid access to stored printer emulations and fast processing of print data. A variable-speed shutt...

Page 14: Hanzi Printers

14 chapter 1 the ibm 6400 series printer family hanzi printers ibm 6400-c05 and 6400-c5p printers have shuttle assemblies, hammer springs, and software specially designed to print the gb character set and song typeface used in the people’s republic of china. These printers can mix ascii and hanzi ch...

Page 15: Printer Evolution

Printer evolution 15 complexity of hanzi characters, the highest rated speed for these models is 585 lpm. Printer evolution ibm 6400-050, -p50, -010, -p10, and -015 printers use a redesigned shuttle frame assembly, hammer bank, and ribbon guides. These models use the cmx 040 controller board, which ...

Page 16: About This Manual

16 chapter 1 about this manual important maintenance notes to ensure the best performance of the printer, remember these important maintenance concepts when you service the printer. Attention failure to observe the guidelines below can result in damage to the equipment. • do not adjust the platen ga...

Page 17: Notes and Notices

Notes and notices 17 notes and notices for your safety and to protect valuable equipment, it is very important that you read and comply with all information highlighted under notes and notices: attention the word attention indicates the possibility of damage to a program, device, system, or data. Th...

Page 18: Related Documents

18 chapter 1 about this manual important the word important indicates information vital to proper operation of the printer. Note: a note gives you helpful tips about printer operation and maintenance. Printing conventions in this manual operator panel keys and lcd messages are set off from regular t...

Page 19

Related documents 19 • ibm 6400 code v user’s manual: form no. S544-5638 provides information used with the optional code v printronix emulation enhancement feature. The code v printronix emulation allows the user to create and store forms, generate logos, bar codes, and expanded characters, create ...

Page 20: Controls And Indicators

20 chapter 1 controls and indicators controls and indicators electrical controls, cabinet models key or indicator function power indicator lit when the printer is on. Ready indicator lit when the printer is in ready mode (on-line), no errors are pending, and the printer is ready to process data. Off...

Page 21

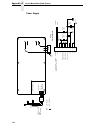

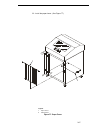

Electrical controls, cabinet models 21 figure 2. Electrical controls, cabinet models ready power cancel processing start stop form feed set top of form line feed enter return scroll menu view attention scroll micro micro printer con- figuration eject/ restore lcd power switch (off) (on).

Page 22

22 chapter 1 controls and indicators electrical controls, pedestal models key or indicator function power indicator lit when the printer is on. Ready indicator lit when the printer is in ready mode (on-line), no errors are pending, and the printer is ready to process data. Off when the printer is in...

Page 23

Electrical controls, pedestal models 23 figure 3. Electrical controls, pedestal models ready power cancel processing start stop form feed set top of form line feed enter return scroll menu view attention scroll micro micro printer con- figuration eject/ restore lcd power switch (off) (on).

Page 24

24 chapter 1 controls and indicators mechanical controls, all models control or indicator function forms thickness lever sets the platen for paper and forms of different thicknesses. Lever must be fully opened (raised) to load or unload paper. Paper supports help prevent paper jams by supporting inn...

Page 25

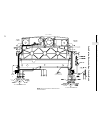

Mechanical controls, all models 25 figure 4. Mechanical controls, all models horizontal adjustment knob tractor lock left tractor right tractor vertical position knob forms thickness lever and scale forms thickness pointer tractor lock paper supports ribbon loading path diagrams.

Page 26

26 chapter 1 tools, test equipment, and supplies tools, test equipment, and supplies the tools and equipment required for field level maintenance of the printer are listed below. Item part no. 6400 line matrix printer configuration utility disk 63h7379 1-30 inch-pound torque screwdriver 16f1661 esd ...

Page 27

27 2 installation installing and configuring the ibm 6400 printer installation and configuration of the printer are covered in the 6400 line matrix printer set-up guide, form no. S544-5640 installation, operation, and replacement parts for the optional coax/twinax interface are covered in the coax/t...

Page 28

28 chapter 2 installing and configuring the ibm 6400 printer.

Page 29: Cleaning The Printer

29 3 preventive maintenance cleaning the printer aside from normal replenishment of paper and ribbons, the only preventive maintenance required for the printer is periodic cleaning. Because operating conditions vary widely, the user must determine how often to clean the printer. There is no guarante...

Page 30: Cleaning The Interior

30 chapter 3 cleaning the printer cleaning the interior 1. Power off the printer. 2. Disconnect the ac power cord from the power source. 3. Open the printer cover. 4. Remove paper from the printer. 5. Remove the ribbon. 6. Using a soft-bristled, non-metallic brush, wipe paper dust and ribbon lint of...

Page 31

Cleaning the shuttle frame assembly 31 cleaning the shuttle frame assembly 1. Remove the shuttle cover assembly (page 203). 2. Remove the shuttle frame assembly (page 242). 3. Remove the paper ironer (page 230). 4. Wipe the paper ironer with a soft cloth to remove lint, ink, and paper residue. 5. In...

Page 32

32 chapter 3 cleaning the printer figure 6. Cleaning the hammer tips attention the hammer bank contains a strong magnet. To prevent damage to the hammer tips, do not let the hammer bank cover assembly snap into place as the hammer bank magnet attracts it. Any impact of the cover against the hammer b...

Page 33

Cleaning the card cage fan assembly 33 cleaning the card cage fan assembly 1. Cabinet models: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). 2. Vacuum the card cage fan assembly and surrounding areas to remove paper particles, dust, and lint. (s...

Page 34

34 chapter 3 cleaning the printer.

Page 35: Line Matrix Printing

35 4 principles of operation line matrix printing the printer creates characters and graphics by printing patterns of ink dots on paper, an entire line at a time. This technique is called line matrix printing. Every text character is stored in printer memory as a pattern of dots on a logical grid ca...

Page 36

36 chapter 4 line matrix printing when the shuttle reaches the end of a sweep, it reverses direction, the paper is advanced one dot row, and the hammers print the next row of dots as the shuttle sweeps in the opposite direction. After a line of characters is printed, hammer action stops and the pape...

Page 37

37 figure 10. Action of one hammer spring in text printing = hammer released and dot printed * * * * * * 1 1 3 1 3 5 1 3 5 7 1 3 5 7 9 1 2 3 4 5 6 7 1 2 3 4 5 6 1 2 3 4 5 1 2 3 4 1 2 1 7 6 5 3 4 2 1 1 2 3 * note: even column dot centers within the printed character area and character space hammer po...

Page 38: Printing Rates

38 chapter 4 printing rates printing rates because a line matrix printer prints entire lines sequentially, it is faster than a moving-printhead printer, which prints single characters sequentially. The printing speed of text is measured in lines per minute (lpm) rather than characters per minute (cp...

Page 39: Shuttle Frame Assembly

Shuttle frame assembly 39 shuttle frame assembly the central element of the printing mechanism is the shuttle frame assembly, which houses the hammer bank assembly and the shuttle drive motor. (see figure 11.) figure 11. Shuttle frame assembly hammer bank assembly the hammer springs are grouped in c...

Page 40

40 chapter 4 printing mechanism connecting rod attaches to a counterweight frame surrounding the hammer bank. (the hammer bank and the counterweight constitute the shuttle assembly.) the rotary motion of the shuttle drive motor converts to linear and opposing motion of the hammer bank assembly and t...

Page 41: Paper Transport System

Paper transport system 41 paper transport system figure 13. Paper transport system a two-phase dc stepper motor, directed by the ec on the controller board, drives two tractor sprockets by means of a toothed belt and splined shaft pulley arrangement. The stepper motor permits extremely accurate incr...

Page 42: Ribbon Transport System

42 chapter 4 printing mechanism ribbon transport system figure 14. Ribbon transport system an inked ribbon winds and unwinds continuously on a pair of spools latched to hubs that are driven by the ribbon motors. The hubs and spools are offset vertically to equalize ribbon wear and prolong ribbon lif...

Page 43: Printer Electronics

Printer electronics 43 logical control of the printer the printer is divided into four functional elements: the operator panel, the cmx controller board, the power supply, and the print mechanism. Printer electronics the functional elements of the printer are diagrammed in figure 15. Figure 15. Func...

Page 44: Operator Panel

44 chapter 4 operator panel operator panel the operator communicates with the printer by pressing keys on the operator panel. The keys are momentary contact switches. The operator panel processes and sends key closure information to the controller board and displays information from the controller o...

Page 45: Cmx Controller Board

Printer electronics 45 cmx controller board the heart of the printer is the cmx controller board, which monitors and directs all printer functions. The controller board receives and processes all data from the host computer, builds the printable images, controls all motors, and drives the hammer spr...

Page 46

46 chapter 4 cmx controller board figure 17. Cmx controller board block diagram expansion port rs-232/422 ieee-1284 (parallel) fault sensors paper feed ribbon shuttle platen hammer drive ttl diagnostic port control panel rs-232 diagnostic port 25 or 40 mhz.

Page 47: Data Controller

Data controller 47 data controller the data controller (dc) consists of the following elements: • 68ec030 microprocessor • two flash simm sockets, used for up to 30mb of program memory • two dram simm sockets, used for up to 32mb of data memory • 8k x 8 non-volatile battery-backed static ram (nvram)...

Page 48

48 chapter 4 cmx controller board nvram a 8k x 8 bit non-volatile battery-backed static ram (nvram) device provides for the storage of configuration and system statistical data. Vx asic the vx is a multifunction custom gate array asic containing all the logic for the dc that is not contained in the ...

Page 49: Engine Controller

Engine controller 49 “cajun” bus interface the “cajun” bus interfaces the dc, the ec, and the expansion port. The ec uses this bus to access dc resources, including the semaphore registers. (the semaphore registers are the primary communications path between the ec and dc.) ports the vx asic control...

Page 50

50 chapter 4 cmx controller board controller and the meca asic provide the functionality of three separate processors used in earlier controller board architectures. In this manual, the 80c166 is referred to as either the ec or the 166. The 166 used on the cmx board runs at 20mhz and is housed in a ...

Page 51: Printer Interface

Engine controller 51 the paper feed, ribbon drive, and shuttle motors are driven in control loops containing power mosfets, voltage and current sensors, the meca asic, and the ec processor. The platen open motor is driven by a stepping motor controller ic and the ec processor. Control of the hammer ...

Page 52

52 chapter 4 printer interface 10base2 and 10base-t leds and dip switches 10base2 and 10base-t printnet ethernet interfaces have three leds and three dip switches, as shown below. The indicators and switches are adjacent to the data line connectors. Led patterns are defined in the table below the il...

Page 53

10base2 and 10base-t leds and dip switches 53 run mode and auto reset mode: run mode is the normal operating state of the ethernet interface. Auto reset mode is entered when the watchdog timer is triggered and the print server resets itself. In either mode, the stat led flashes differently, dependin...

Page 54

54 chapter 4 printer interface 10/100base-t leds and dip switches the 10/100base-t ethernet interface has two indicator lights and two dip switches, as shown below. Inspect the two leds on the 10/100base-t ethernet interface: 1. When an ip address is configured into the printer via the control panel...

Page 55

10/100base-t leds and dip switches 55 stat (status) indicator in run and auto reset modes run mode is the normal operating state of this interface. Auto reset mode is entered when the watchdog timer is triggered and the print server resets itself. In either mode, the stat led flashes at a varying ra...

Page 56

56 chapter 4 printer interface for more information . . . For more information about the 10/100base-t ethernet interface, refer to ethernet interface user’s manual, form no.S246-0154. Table 3. 10/100base-t dip switch settings dip switch description 1 2 off off normal operation. With both dip switche...

Page 57: Power Supply Board

Ac power 57 power supply board the printer power supply is contained on a printed circuit board mounted in the card cage. The power supply automatically senses and adjusts to any commercial electrical system that provides ac mains potential in 50 or 60 hertz systems. In other words, the printer is f...

Page 58: Graphics

58 chapter 4 graphics graphics the code v programming language (a qms** graphics emulation) and the igp programming language (a printronix igp emulation) are options that install in flash memory on the cmx controller board. These programming languages simplify the job of creating forms, bar codes, l...

Page 59: Introduction

59 5 troubleshooting introduction this chapter lists fault messages and symptoms, and provides procedures for troubleshooting printer malfunctions. Always have the operator’s guide and the setup guide handy when you troubleshoot because this manual does not cover printer operation or configuration. ...

Page 60: Start Of Call

60 chapter 5 start of call start of call are you here because of an error message? Yes no go to troubleshooting display messages, page 61. Power on the printer and observe the operator panel for the following sequence of events (retry as required): 1. All leds on and black squares on the display. 2....

Page 61

61 troubleshooting display messages if a fault condition occurs in the printer, four things happen: • the attention indicator on the operator panel flashes on and off. • if enabled, the audible alarm sounds. (press stop to silence the alarm.) • a message describing the fault condition appears on the...

Page 62: Message List

62 chapter 5 troubleshooting display messages the printer be powered off and the condition corrected before powering the printer back on. Message list find the message in the message list below and follow the suggested procedure. After correcting an error, press the start key to clear the message. I...

Page 63

Message list 63 002 forms jammed clear jam and reload forms attention message: the printer cannot detect paper motion. Inspect the paper path for jams. 1. Clear jams. Load paper. 2. Press form feed several times and check that forms feed without erratic motion, noise, or pin-hole damage. If forms do...

Page 64

64 chapter 5 troubleshooting display messages 002 forms jammed clear jam and reload forms (continued) 11. Check and adjust the platen gap. 12. Clean the paper motion detector with a cotton swab and alcohol. At the control panel, set the paper motion detector (pmd) fault setting to disable. Load pape...

Page 65

Message list 65 010 parameter error the printer received an illegal parameter value in the command code. 1. Press stop to clear fault. Press start to go on-line. 2. Run the print job that generated the error message. If the message appears, check the host data for invalid characters. 3. Ask the syst...

Page 66

66 chapter 5 troubleshooting display messages 013 activate lost the printer detects a twinax protocol communication error and reports the error. 1. Power off the printer. Disconnect the ac power cord from the printer. Check the twinax host data cable and twinax i/o cable connection at the ct board. ...

Page 67

Message list 67 015 communications check check cable the line is not active on a twinax interface. 1. Power off the printer. Disconnect the ac power cord from the printer. Check the twinax host data cable connection and twinax i/o cable connection at the ct board. Reseat the twinax host data cable c...

Page 68

68 chapter 5 troubleshooting display messages 017 stacker jam check stacker this message is triggered if there is paper inside the throat of the stacker elevator, but the elevator is not moving. 1. Open the cabinet rear door and check for obstructions preventing elevator movement. Remove any obstruc...

Page 69

Message list 69 018 stacker full check stacker status message: the power paper stacker is full. 1. Unload the stacker. 2. Check the stacker limit switches. (see page 119.) if the limit switches are ok, go to the next step. 3. Power off the printer. Remove the paper guide assembly. Disconnect stacker...

Page 70

70 chapter 5 troubleshooting display messages 019 stacker fault check stacker two situations can trigger this message: 1. The stacker elevator is obstructed while attempting to move up or down. The message will always occur if the user presses the elevator up key on the stacker control panel to move...

Page 71

Message list 71 021 receive buffer overrun verify configuration the print buffer has overflowed on a serial interface. The printed output may contain random * (asterisk) characters. 1. Make a configuration printout. Verify that the printer matches the host serial interface configuration settings for...

Page 72

72 chapter 5 troubleshooting display messages 025 serial framing error verify configuration the printed output may contain random ! (exclamation point) characters. 1. Make a configuration printout. Verify that the printer matches host configuration settings for data protocol, baud rate, data bits, s...

Page 73

Message list 73 031 end of forms timeout load forms on a coax interface, a timeout message is sent to the host if paper is not loaded within 10 minutes after stop was pressed to clear an end of forms fault. 1. Load paper. Press stop. If message does not clear, go to the next step. 2. Power off the p...

Page 74

74 chapter 5 troubleshooting display messages 032 forms jammed timeout clear jam and reload forms on a coax interface, a timeout message is sent to the host if paper motion has not occurred for 10 minutes after stop was pressed to clear a paper jam fault. 1. Clear the paper jam. Press stop. 2. Press...

Page 75

Message list 75 032 forms jammed timeout clear jam and reload forms (continued) 11. Check and adjust the platen gap. 12. Clean the paper motion detector with a cotton swab and alcohol. At the control panel, set the paper motion detector (pmd) fault setting to disable. Load paper. Run a print test an...

Page 76

76 chapter 5 troubleshooting display messages 044 ec firmware/ hardware error application software tried to perform an illegal printer function or damaged memory is detected on the cmx controller board. (if the message appears at power-up, replace the cmx controller board. Record the message and ret...

Page 77

Message list 77 057 close platen the forms thickness lever is open. 1. Load paper. Close the forms thickness lever. If message does not clear, go to the next step. 2. Power off the printer. Remove the paper guide assembly or pedestal top cover. Disconnect connector p107 from the cmx controller board...

Page 78

78 chapter 5 troubleshooting display messages 058 shuttle jam see user’s guide the shuttle is not moving or is moving at the wrong speed. 1. Check the forms thickness lever: if it is set too tightly, it can slow the shuttle enough to trigger the fault message. Set the forms thickness lever to match ...

Page 79

Message list 79 058 shuttle jam see user’s guide (continued) 10. Run a print test. If the message appears, replace the shuttle frame assembly. 059 cancel print active non-error status message. No action required. Table 4. Message list operator panel message explanation corrective action.

Page 80

80 chapter 5 troubleshooting display messages 060 printer hot cmx controller board sensors report high temperatures on the board. This message indicates internal temperatures over 60 ° celsius (140 ° fahrenheit). Print jobs do not create such temperatures, so immediately determine that the fans are ...

Page 81

Message list 81 062 exhaust fan fault sensors cannot detect current in the fan circuit. 1. Cycle power. If the message appears, press stop. 2. If the message occurs on a pedestal model, check that the correct operator panel is installed. The operator panel for a pedestal model has resistors r18 and ...

Page 82

82 chapter 5 troubleshooting display messages 065 hammer bank fan fault hammer bank fan fault. Sensors cannot detect current in the fan circuit. 1. Cycle power. If the message appears, press stop. 2. Power off the printer. Remove the paper guide assembly or pedestal top cover. Disconnect connector p...

Page 83

Message list 83 080 power supply hot the printer has sensor circuits that sample the operating temperature of key components of the power supply. When higher than normal temperatures are sensed, print speed is automatically reduced. If the printer runs at reduced speed for an extended period of time...

Page 84

84 chapter 5 troubleshooting display messages 081 power supply voltage failure the power supply has failed. 1. Replace the power supply board. 2. Power on the printer. If the message appears, replace the cmx controller board. 082 power supply 8.5v failed 8.5 volt power failed. Internal power failure...

Page 85

Message list 85 084 power supply 48v failed 48 volt power failed. Internal power failure. 1. Power off the printer. Remove the paper guide assembly or pedestal top cover. Check that power supply connector p101 is fully seated in connector j101 on the cmx controller board. 2. If the printer has the c...

Page 86

86 chapter 5 troubleshooting display messages 086 controller 15v controller voltage failure. 1. Cycle power. Run the print job again. If the message appears, remove the hammer bank logic cable, inspect it for damage, and test it for continuity. (see appendix a.) replace the hammer bank logic cable i...

Page 87

Message list 87 087 platen open timeout close platen on a coax interface, the forms thickness lever has been open for at least one minute. Load paper. 1. Close the forms thickness lever. Press stop. 2. Run a print test. If a platen open or close platen message appears, power off the printer. Remove ...

Page 88

88 chapter 5 troubleshooting display messages 088 controller 23.5v controller voltage failure. 1. Cycle power. Run the print job again. If the message appears, download the emulation software again. 2. Cycle power. Run the print job again. If the message appears, replace the flash memory with pre-wr...

Page 89

Message list 89 089 ribbon stall this message occurs when the ribbon fails to move while printing. 1. Check the forms thickness lever: if it is set too tightly it can inhibit ribbon movement. Set the forms thickness lever to match the thickness of the paper being used, but not too tightly. 2. Inspec...

Page 90

90 chapter 5 troubleshooting display messages 090 shuttle cover open close shuttle cover the shuttle cover is missing, damaged, or not correctly installed. 1. Inspect shuttle cover for warping, damage, or missing magnet. (the magnet covers the sensor housing when the cover is installed.) if the shut...

Page 91

Message list 91 101 upper driver short hammer driver circuits on the cmx controller board are shorted to ground. 1. Cycle power. If the message appears, press stop. If the message does not clear, replace the hammer bank logic cable and the hammer bank power cable assemblies. 2. Power on the printer....

Page 92

92 chapter 5 troubleshooting display messages 107 hammer coil hot one or more hammer coils are overheating. The printer has sensor circuits that sample the operating temperature of key components of the print mechanism. When higher than normal temperatures are sensed, print speed is automatically re...

Page 93

Message list 93 110 stack overflow see user’s guide system stack has run out of room and overflowed into other memory. 1. Cycle power. Run the print job again. If the message appears, download the emulation software again. 2. Cycle power. Run the print job again. If the message appears, replace the ...

Page 94

94 chapter 5 troubleshooting display messages 116 illegal external bus access see user’s guide illegal external bus accessed. Firmware error on the cmx controller board. 1. Cycle power. Run the print job again. If the message appears, download the emulation software again. 2. Cycle power. Run the pr...

Page 95

Message list 95 122 paper not scheduled see user’s guide the paper feed process is not scheduling on the cmx controller board, and the printer cannot advance paper. 1. Cycle power. Run the print job again. If the message appears, download the emulation software again. 2. Cycle power. Run the print j...

Page 96

96 chapter 5 troubleshooting display messages 124 paper fifo overflow see user’s guide paper first in first out overflow. Firmware error on the cmx controller board. 1. Cycle power. Run the print job again. If the message appears, download the emulation software again. 2. Cycle power. Run the print ...

Page 97

Message list 97 126 paper feed bad table see user’s guide the paper feed process on the cmx controller board has a corrupted table. If this message appears during a software download, do the download again. If the message appears on the second try, replace the cmx controller board. 1. Cycle power. R...

Page 98

98 chapter 5 troubleshooting display messages 131 paper feed interrupt see user’s guide unexpected interrupt in the paper feed process on the cmx controller board. 1. Cycle power. Run the print job again. If the message appears, download the emulation software again. 2. Cycle power. Run the print jo...

Page 99

Message list 99 137 shuttle invalid command see user’s guide firmware error on the cmx controller board. 1. Cycle power. Run the print job again. If the message appears, download the emulation software again. 2. Cycle power. Run the print job again. If the message appears, replace the cmx controller...

Page 100

100 chapter 5 troubleshooting display messages boot diagnostics non-error status message. No action required. Clearing program from flash status message: emulation software successfully loaded into printer ram and the checksum matched. The old program is now being deleted from flash memory. No actio...

Page 101

Message list 101 error: flash did not program the printer encountered an error trying to program flash memory. 1. Download the program again. 2. If the message occurs again, replace the flash memory with pre-written flash. (see table 8 and table 9 on page 219 and figure 35 on page 220.) error occurr...

Page 102

102 chapter 5 troubleshooting display messages ethernet detected status message that indicates that the internal network interface card has established communication. No action required. Fm header error frame header error. Application software has violated header parameters. Not a printer problem. T...

Page 103

Message list 103 hammer coil bad #, #, #, #, ... Etc. Hammer coil(s) number #, #, etc. Failed the current test at power-up. Check that the hammer bank cables are connected. 1. Cycle power. If the message appears, replace the shuttle frame assembly. Record the message and return it with the defective...

Page 104

104 chapter 5 troubleshooting display messages operator menu unlocked non-error status message. No action required, unless you want to lock the enter key. Pa1 selected attach status message. No action required. Pa2 selected attach status message. No action required. P05 diagnostic test passed non-er...

Page 105

Message list 105 p63 error: program not compatible the printer is not compatible with the downloaded program.(the user may have tried to load a cmx- compatible diskette in a cbo-controlled printer, or vice versa.) use the correct emulation software option(s) for this model printer. If the printer is...

Page 106

106 chapter 5 troubleshooting display messages p68 error: ec program not valid the printer cannot find the engine controller program or the validation checksum is corrupt. 1. Download the program again. If the message occurs again, replace all flash memory simms with pre-written flash. (see table 8 ...

Page 107

Message list 107 restoring boot code status message when downloading boot code. Code is checked then saved in flash memory. No action required. Ribbon out of ink change ribbon ribbonminder** software has determined that the ribbon is out of ink. Install a new ribbon and set ribbon life to 100%. Send...

Page 108

108 chapter 5 troubleshooting display messages waiting for ethernet adapter status message that appears when printer is first powered on if the internal network interface card is installed. An ethernet adapter must be detected early in the power up sequence so the printer can tell the adapter it has...

Page 109

Message list 109 troubleshooting other symptoms use standard fault isolation techniques to troubleshoot malfunctions that are not indicated by display messages. These techniques are summarized below: 1. Ask the operator to describe the problem. 2. Verify the fault by running a diagnostic printer tes...

Page 110: General Symptom List

110 chapter 5 troubleshooting other symptoms 8. Stop troubleshooting and return the printer to normal operation when the reported symptoms disappear. General symptom list table 5 is a list of possible printer problems that are not indicated by messages on the lcd. Troubleshooting procedures are incl...

Page 111

General symptom list 111 clear jam message will not clear and paper does not move 1. Remove the paper guide assembly or pedestal top cover. Make sure connector p107/papr m is fully seated in connector j107 on the cmx controller board. 2. Check the paper feed motor pulley for looseness. Hold the coll...

Page 112

112 chapter 5 troubleshooting other symptoms operator panel black squares on operator panel display 1. Power off the printer. Remove the paper guide assembly or pedestal top cover. Disconnect the operator panel cable from the panel and from j110 on the cmx controller board. Check continuity of the c...

Page 113

General symptom list 113 operator panel keys do not work 1. Power on the printer. Check the operation of the operator panel keys. Replace the operator panel if keys do not work. 2. Power on the printer. Check the operation of the operator panel keys. Replace the operator panel cable assembly if keys...

Page 114

114 chapter 5 troubleshooting other symptoms power / iml failures no power, and the operator panel is blank, and the card cage fan is not running 1. Check that the ac power outlet has power. Restore ac power as required. 2. Unplug the printer ac power cord from the printer (leave it plugged into the...

Page 115

General symptom list 115 printer does not complete iml note: power-on initialization is explained on page 146. 1. Power off the printer. Remove the paper guide or pedestal top cover. Check that all cables are connected to the cmx controller board. Reseat all cable connectors on the cmx controller bo...

Page 116

116 chapter 5 troubleshooting other symptoms power stacker printer does not detect presence of power stacker -or- stacker not working 1. Check that the power stacker is enabled under the printer control menu. (refer to the setup guide.) if the power stacker enable/disable option does not appear in t...

Page 117

General symptom list 117 stacker chatters at upper or lower limit 1. Check for and remove obstructions preventing elevator movement. 2. Check for misaligned stacker rails adjust the stacker rails if they are not vertical and parallel. 3. Move the elevator up and down by hand. Check that the limit sw...

Page 118

118 chapter 5 troubleshooting other symptoms stacker does not stack properly -or- stacker elevator does not move 1. Check for and remove obstructions preventing elevator movement. 2. Check for misaligned stacker rails adjust the stacker rails if they are not vertical and parallel. 3. Power on the pr...

Page 119

General symptom list 119 stacker limit switch check note: this procedure tests the motion limit switches at the top and bottom of the vertical rails. You will usually be referred to this procedure from other troubleshooting procedures. When you have completed this procedure, return to the procedure ...

Page 120

120 chapter 5 troubleshooting other symptoms stacker motor check note: this procedure tests the four stacker motors and their cables. You will usually be referred to this procedure from other troubleshooting procedures. When you have completed this procedure, return to the procedure that sent you he...

Page 121

General symptom list 121 print quality characters or dots are missing, smeared, too light, or too dark 1. Check the forms thickness lever: if it is set too loose or too tightly print quality can be affected. Set the forms thickness lever to match the thickness of the paper being used. 2. Check the p...

Page 122

122 chapter 5 troubleshooting other symptoms characters or dots are missing, smeared, too light, or too dark (continued) 13. Power on the printer. If the problem still occurs, replace the power supply board. 14. Power on the printer. If the problem still occurs, replace the cmx controller board. Hor...

Page 123

General symptom list 123 randomly misplaced dots 1. Power off the printer. Check and adjust the platen gap. 2. Remove the paper guide assembly or pedestal top cover. On the left rear wall of the card cage, make sure the nut which secures the line filter ground line and the ac-in power supply cable l...

Page 124

124 chapter 5 troubleshooting other symptoms printer operation downloads consistently fail note: most download problems are detected by software during the procedure and communicated by lcd messages. If downloads fail consistently with no messages or with erratic messages, suspect a hardware failure...

Page 125

General symptom list 125 paper feeds poorly 1. Check the forms thickness lever: if it is set too tightly paper feeding can be affected. Set the forms thickness lever to match the thickness of the paper being used. 2. Power off the printer. Remove paper. Inspect the paper feed path for obstructions t...

Page 126

126 chapter 5 troubleshooting other symptoms reverse paper feed: platen does not open 1. Raise the forms thickness lever and check that the platen opens. If the platen opens with difficulty, inspect for and remove jams or obstructions. 2. Check the platen open pulley and the platen pulley for loosen...

Page 127

General symptom list 127 tof is lost repeatedly 1. Check that the customer is setting the forms length to match the size paper used. Set the forms length to match the length of paper being used. 2. If the customer is using multi-part forms, check that the forms thickness lever is not being set too t...

Page 128

128 chapter 5 troubleshooting other symptoms ribbon ribbon folding or feed problems 1. Check that both ribbon spools are fully seated on the ribbon hubs and the ribbon runs between the ribbon mask and hammer bank cover. Install the ribbon correctly. 2. Check that the ribbon spools are not rubbing ag...

Page 129

General symptom list 129 shuttle shuttle does not move 1. Power down the printer. Remove the shuttle cover. Adjust the gap between the mpu assembly and the flywheel to 0.010 ± .001 inch (0.254 ± 0.025 mm). Torque the 7/16 inch mpu clamp screw to 18 ± 1 inch-pounds (2.03 ± 0.11 n•m). 2. Check that th...

Page 130

130 chapter 5 troubleshooting other symptoms shuttle is noisy 1. Check the bolts securing the mechanism base to the base pan. Tighten the mechanism base mounting bolts if they are loose enough to permit movement of the mechanism base. 2. Remove the shuttle cover. Check the shuttle frame assembly mou...

Page 131: Communications Failures

General symptom list 131 communications failures many host-printer communications problems are complex. With the exception of a defective interface cable, most communications problems are not a result of a hardware failure. They usually result from an incompatible configuration of the host computer ...

Page 132: Operator Print Tests

132 chapter 5 operator print tests operator print tests a set of print tests is included in the configuration menu structure for use as diagnostic tools. These are called the “operator print tests” because they are available to the user. You can use these print tests to check the print quality and b...

Page 133: Selecting and Running Tests

Selecting and running tests 133 splined shaft bearings tractors or tractor belts • underlines an underline pattern useful for identifying hammer bank misalignment. Hammer bank cover hammer tips paper feed belt or motor splined shaft bearings tractor bearings or belts selecting and running tests to r...

Page 134

134 chapter 5 customer engineer (ce) tests customer engineer (ce) tests a set of printer tests is included in the configuration menu structure for use as maintenance tools. These are called “customer engineer tests” (ce tests) because they are for your use; they are not available to the user through...

Page 135

Selecting and running tests 135 hammer springs hammer coils (the shuttle frame assembly) • shuttle only this test runs only the shuttle. • shuttle slow verifies proper operation by exercising the shuttle and ribbon mechanisms at low speed. You can also use this test to check ribbon tracking and reve...

Page 136

136 chapter 5 customer engineer (ce) tests top exit tear distance: this parameter allows adjustment in 0.01 inch increments of the final location of page perforations when top paper exit is used. Shuttle speed: sets shuttle speed in 6400-004, -04p, -005, and -05p printers. See page 182. Set coil tem...

Page 137: Boot Diagnostics Menu

Boot diagnostics menu 137 boot diagnostics menu printer boot-up software contains a menu structure that you can access by holding down the eject/restore and stop keys while powering up the printer. These menus are not intended for the end user, but provide useful information for manufacturing and ma...

Page 138

138 chapter 5 customer engineer (ce) tests figure 19. Boot diagnostics menu boot diagnostics press enter boot diagnostics version check version check boot version version check software version version check ec version version check asic versions enter > > > > boot/cmx v10b 12sep95 #158945 09/08/95 ...

Page 139

Boot diagnostics menu 139 figure 19. Boot diagnostics menu (continued) a from previous page boot diagnostics misc utilities misc utilities display memory misc utilities reset printer misc utilities copy flash simms misc utilities copy boot simms > > > > flash = 2 mbytes dram = 2 mbytes resetting... ...

Page 140: Hex Code Printout

140 chapter 5 hex code printout hex code printout a hex code printout (“hex dump”) prints every ascii character received from the host computer with its corresponding two-digit hexadecimal code. Hex dumps can be used to troubleshoot printer data reception problems by comparing the printed hex data t...

Page 141

Boot diagnostics menu 141 11. Operator menu unlocked relocks the enter key. 12. Ready puts printer in ready mode. 13. Send a file from the host computer. The printer outputs a hex dump. Refer to the ascii chart on page 142. 14. When the hex dump is complete, take the printer offline and change the h...

Page 142: Ascii Character Set

142 chapter 5 ascii character set ascii character set the ascii character set is shown below in chart form. Key ascii character name esc 33 27 1b octal equivalent decimal equivalent hex equivalent b7 0 0 0 0 1 1 1 1 b6 0 b5 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 column 0 1 2 3 4 5 6 7 bits row b4 b2 b3 b1 0 ...

Page 143: Printer Information Menu

Boot diagnostics menu 143 printer information menu you can view various printer statistics, such as hours of usage, and refer to these figures for preventive maintenance purposes. Printer statistics accumulate continuously; they do not reset when you power off the printer. All of the printer statist...

Page 144

144 chapter 5 printer information menu displaying printer information you obtain printer information by using the configuration menus, as follows: step press displayed result notes 1. Install the ribbon, load paper, and power on the printer. 2. Not ready puts printer in not ready mode. 3. Operator m...

Page 145: Soft Vs. Hard Reset

Soft reset 145 soft vs. Hard reset resetting the printer returns it to a previous configuration. There are two kinds of reset. Soft reset a soft(ware) reset clears printer memory then loads the power-up configuration into memory. (the procedure for saving configurations is described in the setup gui...

Page 146: The Power On Sequence

146 chapter 5 the power on sequence the power on sequence this section describes the normal sequence of events from the time the power switch is set to 1 until ready (or not ready, if so configured by the user) appears on the lcd. Use this sequence as a reference baseline to help you isolate problem...

Page 147

Cmx controller board handshake sequences 147 with the i/o clock, the error blink code 4-3-4 is sent to the diagnostic led on the cmx board. • read operator panel keys — the operator panel keys are read to determine if the user is requesting that the printer be placed in download mode, diagnostic mod...

Page 148

148 chapter 5 the power on sequence • display vx registers — the boot code displays the values of the vx registers out of the debug serial port. • check for pedestal — boot code uses the operator panel to determine if the printer is a pedestal or floor cabinet model. Boot code needs to know the diff...

Page 149

Cmx controller board handshake sequences 149 • check security pal and nvram — the chip select for nvram comes from the security pal. If the pal is not installed, nvram cannot be accessed, so the pal is tested before nvram. If the security pal is not detected, boot codes displays “error: security pal...

Page 150

150 chapter 5 the power on sequence • jump back into flash and clear dram — boot code jumps back into flash memory, then clears the dram that held the boot code. • jump to mtos — jump to start initialization of the mtos (multi-tasking operating system). Dc software initialization and power up the fi...

Page 151: Introduction

151 6 adjustment procedures introduction the ibm 6400 series printer is a durable, low-maintenance machine, but some components and systems require occasional adjustment. Usually, you will be referred to this chapter by a troubleshooting procedure, or as part of a removal/installation procedure. Lis...

Page 152

152 chapter 6 preparing the printer for maintenance preparing the printer for maintenance to prepare the printer for maintenance, always do the following steps before you do any maintenance procedure: 1. Power off the printer. 2. Unplug the printer power cord from the ac power source. 3. Disconnect ...

Page 153

List of adjustments 153 returning the printer to normal operation when you are finished servicing the printer, restore it to operation by following these steps: 1. Connect the host data cable to the printer interface. 2. Install the ribbon. 3. Load paper. 4. Plug the ac power cord into the power sou...

Page 154

154 chapter 6 belt, paper feed timing, adjustment belt, paper feed timing, adjustment to make this adjustment, follow these steps: 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204)...

Page 155

List of adjustments 155 legend: 1) timing belt shield 2) motor mount bolt (2) 3) paper feed drive motor 4) splined shaft figure 21. Paper feed timing belt adjustment direction of force 1 2 3 4 2 $ $.

Page 156

156 chapter 6 belt, platen open, adjustment belt, platen open, adjustment to make this adjustment, follow these steps: 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). 3. Remove ...

Page 157

List of adjustments 157 legend: 1) belt cover 2) motor mount screw (2) 3) platen open motor shaft figure 22. Platen open belt adjustment $ direction of force 1 $ 2 3 2.

Page 158

158 chapter 6 paper drive motor pulley alignment paper drive motor pulley alignment to make this adjustment, follow these steps: 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). ...

Page 159

List of adjustments 159 legend: 1) belt shield 2) cap screw 3) motor pulley collar 4) motor pulley 5) splined shaft pulley figure 23. Paper drive motor pulley alignment $ $ 1 2 3 5 4.

Page 160: Paper Scale Alignment

160 chapter 6 paper scale alignment paper scale alignment to make this adjustment, follow these steps: 1. Open the printer cover. 2. Load paper and ribbon. 3. Connect the power cord to the ac power source. 4. Set the printer power switch to 1 (on). 5. Verify that the shuttle cover (1) is properly in...

Page 161

List of adjustments 161 legend: 1) shuttle cover 2) screw, button-head, 5/64 inch hex (3) 3) paper scale figure 24. Paper scale alignment 1 2 2 2 3.

Page 162: Platen Gap Adjustment

162 chapter 6 platen gap adjustment platen gap adjustment to make this adjustment, follow these steps: important only do this procedure if the original equipment shuttle frame assembly or platen has been replaced by a new or refurbished unit. 1. Prepare the printer for maintenance (page 152). 2. Rem...

Page 163

List of adjustments 163 legend: 1) forms thickness lever 2) feeler gauge (0.011 inch or 0.28 mm) 3) hammer bank cover 4) ribbon mask 5) set screw, 3/32 inch hex (2) figure 25. Platen gap adjustment orf 0d\ $ $ note: left side adjustment shown. Right side is the same. 1 2 3 4 5.

Page 164

164 chapter 6 platen open motor pulley alignment platen open motor pulley alignment to make this adjustment, follow these steps: 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: go to step 3. Pedestal model: remove the top cover assembly (page 204). 3. Remove the platen open belt...

Page 165

List of adjustments 165 legend: 1) belt cover 2) set screw 3) platen open motor pulley 4) platen shaft pulley figure 26. Platen open motor pulley alignment $ $ 1 4 3 2.

Page 166: Ribbon Guide Alignment

166 chapter 6 ribbon guide alignment ribbon guide alignment to make this adjustment, follow these steps: 1. Open the printer cover. 2. Load paper and install the ribbon. To align a ribbon guide, wind the ribbon fully onto the ribbon spool on the opposite side. For example, to align the left ribbon g...

Page 167

List of adjustments 167 legend: 1) screw, skid (2) 2) ribbon 3) white nylon washer 4) screw, retaining (2) figure 27. Ribbon guide alignment $ $ % left ribbon guide right ribbon guide % 2 3 2 4 4 early models later models 1 3 1.

Page 168

168 chapter 6 splined shaft skew adjustment splined shaft skew adjustment if lines of print are not parallel with the edge perforations on the paper, perform the following adjustment. 1. Open the printer cover. 2. Loosen the screw (1) securing the adjusting link (2). 3. Adjust the link (2) by raisin...

Page 169

List of adjustments 169 adjusting the end of forms distance this procedure tests and sets the distance from the page perforation at which an end of forms fault message is triggered. This adjustment prevents printing on the platen when the printer runs out of paper. The measurement units are dot rows...

Page 170

170 chapter 6 adjusting the end of forms distance figure 29. Paper preparation for paper out adjustment test page perforation page perforation page perforation cut out here 4 in. 4 in..

Page 171

List of adjustments 171 8. The display will show “service / printer mechanism tests”, the first menu item. Press enter to enter the mechanism tests menu. 9. Press scroll ↑ or scroll ↓ until “printer mechanism tests / end of forms adjust” is on the display. This test will print a vertical “comb” patt...

Page 172

172 chapter 6 adjusting the end of forms distance 17. Press enter. The number of dots will move up to the top line of the display. 18. Using the scroll ↑ or scroll ↓ key, adjust the xx dots value up or down by the number of dots you counted in step 12. (if the comb pattern stopped short of the perfo...

Page 173: Hammer Phasing Adjustment

List of adjustments 173 hammer phasing adjustment you must check and adjust hammer phasing if the cmx controller board is replaced, the shuttle frame assembly is removed, or if the mpu is replaced. The hammer phase value is a timing parameter that permits you to adjust the horizontal alignment of do...

Page 174

174 chapter 6 hammer phasing adjustment 13. Press enter. The phasing index (followed by an asterisk) will move up to the top line of the display. 14. Press scroll ↑ or scroll ↓ to increase or decrease the phasing index, then press enter to activate the value as it prints. Continue to increase or dec...

Page 175

List of adjustments 175 downloading 6400 microcode from the world wide web this section describes the procedure for obtaining microcode for all models of the 6400 printer. This process is done through lotus notes ibm first service system. Note: it is helpful to create a directory named 6400 on the l...

Page 176: Loading Flash Memory

176 chapter 6 loading flash memory loading flash memory emulation and operating system software are loaded into flash memory at the factory, but you will install software in the following situations: • the customer needs to upgrade printer software • the customer needs different emulation software •...

Page 177

List of adjustments 177 9. Connect the parallel data cable to the parallel port of the printer. 10. Plug the ac power cord into the printer. 11. Power on the computer. 12. On the printer control panel, press and hold down the start + cancel keys. Without releasing the keys, power the printer on. Con...

Page 178

178 chapter 6 loading flash memory 22. If you had to install a parallel data cable to the computer and printer in step 8, disconnect it from the computer and printer. 23. Reconnect the customer’s data input cable(s) to the printer, if required. 24. Return the printer to normal operation (page 153). ...

Page 179

List of adjustments 179 error: flash not detected the printer could not find any flash memory. Install flash memory before attempting to download this program. Error: no dram detected the printer could not find any dram. Check dram on cmx. If present, reseat dram, if missing, install dram. Error: nv...

Page 180

180 chapter 6 loading flash memory error: writing to flash hardware or software fault in flash memory. Download the program again: power off the printer and start over at step 12. If the message occurs again, replace the flash memory. Error: wrong checksum the printer received the complete program b...

Page 181: Coil Temperature Adjustment

List of adjustments 181 coil temperature adjustment this procedure applies only to models 6400-014 and 6400-015. Do this procedure only when the original cmx controller board or shuttle frame assembly have been replaced. Do not do this procedure if the original cmx board or shuttle frame assembly we...

Page 182: Set Shuttle Speed

182 chapter 6 set shuttle speed set shuttle speed this procedure applies only to models 6400-004, -04p, -005, and -05p. Do this procedure only when the original cmx controller board or shuttle frame assembly have been replaced. Do not do this procedure if the original cmx board or shuttle frame asse...

Page 183: Ethernet Initialization

List of adjustments 183 ethernet initialization to initialize the ethernet interface, do the following steps: 1. Power on the printer. 2. Wait for “ready / ethernet adapter is ready” to display on the lcd. 3. If the ready indicator is on, press the stop key. The printer must be in the not ready stat...

Page 184

184 chapter 6 ethernet initialization.

Page 185

185 7 replacement procedures and illustrated parts lists organization of this chapter this chapter is divided into two sections. • section i: replacement procedures this section contains written procedures for removing and installing components that are replaceable at the field service level of main...

Page 186: List Of Procedures

186 chapter 7 section i: replacement procedures section i: replacement procedures this section contains removal/installation procedures for components that are replaceable at the field service maintenance level. These procedures are listed below. Important do not attempt field repairs of electronic ...

Page 187

List of procedures 187 motor assembly, ribbon drive........................................................ Page 225 network print server ....................................................................... Page 226 operator panel assembly, cabinet model ...................................... Pag...

Page 188: Belt, Paper Feed Timing

188 chapter 7 section i: replacement procedures belt, paper feed timing removal 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). 3. Cabinet model: loosen four screws and remove t...

Page 189: Belt, Platen Open

Belt, platen open 189 belt, platen open removal 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). 3. Remove the platen open belt cover by squeezing the top and bottom to release t...

Page 190: Circuit Board: Controller

190 chapter 7 section i: replacement procedures circuit board: controller note: 6400-050, -p50, -010, -p10, -014, -015, -c05, and c5p printers must use the 40 mhz cmx controller board. Attention to prevent electrostatic damage to electronic components, wear a properly grounded static wrist strap whe...

Page 191

Circuit board: controller 191 installation attention to prevent electrostatic damage to electronic components, wear a properly grounded static wrist strap when handling circuit boards, the shuttle frame assembly, and any other electronic component. 1. Install the dram simm, flash memory, and securit...

Page 192

192 chapter 7 section i: replacement procedures circuit board: power supply attention do not touch components or flex the board during removal/installation. Handle the board by the ejection levers and the sides. Wear a properly grounded static wrist strap when handling the power supply board. Remova...

Page 193: Circuit Breaker

Circuit breaker 193 circuit breaker removal 1. Prepare the printer for maintenance (page 152). 2. Open the printer cover. 3. Remove the card cage fan (page 209). 4. Disconnect the four circuit breaker electrical leads. (cabinet model: see figure 53, page 280. Pedestal model: see figure 46, page 262....

Page 194

194 chapter 7 section i: replacement procedures coax/twinax multi-platform interface note: installation, operation, and replacement parts for this optional feature are covered in detail in the coax/twinax multi-platform interface feature installation and operation guide, form number s246-0149. Remov...

Page 195: Connector Shells

Connector shells 195 connector shells some of the printer cable connectors are grouped inside connector shells. The procedure below explains how to remove and install cable assemblies from any connector shell in the printer. Note: there is also a diagram of the p106 / p107 connector shells on the pl...

Page 196

196 chapter 7 section i: replacement procedures installation 1. Position the cable connector in the connector shell. Two-wire connectors are always grouped across from two-wire connectors in a connector shell. Four-wire connectors are always grouped across from four-wire connectors in a connector sh...

Page 197

Connector shells 197 figure 30. Cable connector shell, disassembly/assembly ccf = card cage fan lrib m = left ribbon motor lrp = left ribbon guide plat m = platen open motor pmd = paper motion detector (switch) pod = paper out detect (switch) cvo = cover open (switch) ehf* = exhaust fan hbf = hammer...

Page 198: Connector Stiffening Clips

198 chapter 7 section i: replacement procedures connector stiffening clips later model printers have connector stiffening clips on cmx board connectors p106 and p107. For earlier models, the clips are available in a field kit. The clips stiffen connectors p106 and p107 and help prevent accidental re...

Page 199

Connector stiffening clips 199 figure 31. Connector stiffening clips p107 p106 stiffening clip $ $ $ connector shell.

Page 200

200 chapter 7 section i: replacement procedures cover assembly, hammer bank / ribbon mask removal 1. Prepare the printer for maintenance (page 152). 2. Remove the shuttle frame assembly (page 242). 3. Early models: lift the thick plate of the hammer bank cover assembly at one end, and peel the cover...

Page 201

Cover assembly, hammer bank / ribbon mask 201 installation attention the hammer bank contains a strong magnet. To prevent damage to the hammer tips, do not let the hammer bank cover assembly snap into place as the hammer bank magnet attracts it. Any impact of the cover against the hammer bank can br...

Page 202

202 chapter 7 section i: replacement procedures figure 32. Hammer bank cover assembly / ribbon mask 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 5 4 6 early models later models hammer bank cover (thick plate) ribbon mask torque sequence hammer bank cover torque sequence ribbon mask (thin plate) hammer bank cove...

Page 203: Cover Assembly, Shuttle

Cover assembly, shuttle 203 cover assembly, shuttle removal 1. Prepare the printer for maintenance (page 152). 2. Loosen the shuttle cover screws (page 258, figure 44, item 2). 3. Grasping the edges of the shuttle cover assembly, tilt up the rear edge and lift the shuttle cover assembly out of the p...

Page 204

204 chapter 7 section i: replacement procedures cover assembly, top, pedestal model removal 1. Prepare the printer for maintenance (page 152). 2. Remove the operator panel (page 228). 3. Remove five screws and the control panel bracket. (see figure 43, page 256, items 3 and 4.) 4. Loosen the two cap...

Page 205: Dashpot

Dashpot 205 dashpot this procedure applies only to cabinet models. Removal 1. Prepare the printer for maintenance (page 152). 2. Open the printer cover. 3. Open the floor cabinet rear door. 4. Pry back the spring retaining clips (page 254, figure 42). 5. Remove the dashpot from the ball studs. Insta...

Page 206: Doors, Cabinet, Reversing

206 chapter 7 section i: replacement procedures doors, cabinet, reversing note: floor cabinet printers are assembled with the front door hinged on the left side so that it opens at the right side. The rear door is hinged on the right side so that it opens on the left side. This procedure enables you...

Page 207

Ethernet interface assemblies 207 ethernet interface assemblies note: the ethernet lan option is available in one of three configurations: 10base-t, 10base2, or 10/100base-t. These options are available factory installed or as field kits. Removal and installation is the same for all versions. The fu...

Page 208

208 chapter 7 section i: replacement procedures fan assembly, cabinet exhaust removal 1. Prepare the printer for maintenance (page 152). 2. Open the floor cabinet doors and the printer cover. 3. Remove the paper stacker. (see figure 41, page 252.) 4. Remove the three screws securing the air exhaust ...

Page 209: Fan Assembly, Card Cage

Fan assembly, card cage 209 fan assembly, card cage removal 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). 3. Disconnect the fan cable connector: cabinet model, figure 52, page...

Page 210: Fan Assembly, Hammer Bank

210 chapter 7 section i: replacement procedures fan assembly, hammer bank removal 1. Prepare the printer for maintenance (page 152). 2. Remove the shuttle cover assembly (page 203). 3. Pedestal model: remove the top cover assembly (page 204). 4. Trace the hammer bank fan cable assembly back to the c...

Page 211: Hammer Spring Assembly

Hammer spring assembly 211 hammer spring assembly removal 1. Prepare the printer for maintenance (page 152). 2. Remove the shuttle frame assembly (page 242). 3. Carefully vacuum the shuttle frame assembly. 4. Remove the hammer bank cover assembly (page 200). Attention hammer springs and hammer tips ...

Page 212

212 chapter 7 section i: replacement procedures figure 33. Hammer spring assembly, removal hammer spring assembly 7 hammer spring assembly 1 note: the hammer spring assemblies shown here are for 6400-004/-04p/-005/-05p printers. The number of hammer springs and mounting screws varies among printer m...

Page 213

Hammer spring assembly 213 installation note: 6400-050, -p50, -010, -p10, -014, -015, -c05, and -c5p printers must use the cmx 040 controller board. 1. Using a clean dry cloth, wipe the hammer spring mounting surface on the hammer bank. Make sure the cloth does not leave lint on the hammer bank. Att...

Page 214

214 chapter 7 section i: replacement procedures figure 34. Hammer spring assembly, installation use new screws from the kit. Torque the screws to 14 inch-pounds (1.58 newton-meters). New hammer spring assembly note: the hammer spring assemblies shown here are for 6400-004/-04p/-005/-05p printers. Th...

Page 215

Ibm coax/twinax expansion board 215 ibm coax/twinax expansion board removal attention to prevent electrostatic damage to electronic components, wear a properly grounded static wrist strap when handling circuit boards, the shuttle frame assembly, and any other electronic component. 1. Prepare the pri...

Page 216

216 chapter 7 section i: replacement procedures magnetic pick-up (mpu) assembly removal 1. Prepare the printer for maintenance (page 152). 2. Remove the shuttle cover (page 203). 3. Disconnect the shuttle cable assembly connector (page 272, figure 49). 4. Disconnect the magnetic pick-up (mpu) cable ...

Page 217

Memory and security modules 217 memory and security modules removal 1. Make a configuration printout of all configurations. (refer to the setup guide.) 2. Prepare the printer for maintenance (page 152). 3. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cove...

Page 218

218 chapter 7 section i: replacement procedures installation attention to prevent electrostatic damage to electronic components, wear a properly grounded static wrist strap when handling circuit boards, the shuttle frame assembly, and any other electronic component. Note: flash simms from one cmx co...

Page 219

Memory and security modules 219 table 8. Pre-written flash simms and security modules: early models code load description pre-written flash for models 004, 04p, 005, 05p, 008, 08p, 009, 09p, 012, 014, c05, c5p security module ibm p/n (vendor p/n) base ascii 24h9315 14h5509 (154143-002) ascii with ig...

Page 220

220 chapter 7 section i: replacement procedures figure 35. Memory and security modules 2 1 3 bank 0 bank 1 bank 0 bank 1 80-pin simm j11 = bank 0 (must always be filled) j10 = bank 1 reserved for upgrades if 1 flash simm, use bank 0 if 2 flash simms, use both banks but put pre-programmed simms in j1...

Page 221: Motor Assembly, Paper Feed

Motor assembly, paper feed 221 motor assembly, paper feed removal 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). 3. Cabinet model: loosen four screws and remove the barrier shi...

Page 222

222 chapter 7 section i: replacement procedures installation 1. Position the paper feed motor assembly on the right side plate and install the motor mount bolts and nuts finger tight (page 278, figure 52). 2. Connect the paper feed motor cable connector to connector p107, then connect p107 to j107 o...

Page 223: Motor Assembly, Platen Open

Motor assembly, platen open 223 motor assembly, platen open removal 1. Prepare the printer for maintenance (page 152). 2. Cabinet model: remove the paper guide assembly (page 229). Pedestal model: remove the top cover assembly (page 204). 3. Cabinet model: remove the card cage fan (page 209). 4. Rem...

Page 224

224 chapter 7 section i: replacement procedures installation 1. Position the platen open motor assembly with the wires toward the rear (page 278, figure 52). 2. Install the two 5/16 inch motor mount screws (and nuts, if present) finger tight. 3. Install the platen open belt and motor pulley. Bottom ...

Page 225

Motor assembly, ribbon drive 225 motor assembly, ribbon drive removal 1. Prepare the printer for maintenance (page 152). 2. Remove the ribbon hub (page 238). 3. Remove two screws and washers securing the ribbon drive motor to the base casting (page 278, figure 52). 4. Lift and rotate the ribbon driv...

Page 226: Network Print Server

226 chapter 7 section i: replacement procedures network print server installation and operation of this optional feature are described in the print server user’s guide, p/n 30h4056. This guide describes error messages and troubleshooting information. Also provided is a section that describes ibm ser...

Page 227

Operator panel assembly, cabinet model 227 operator panel assembly, cabinet model removal 1. Prepare the printer for maintenance (page 152). 2. Open the printer cover. 3. Remove the four screws securing the operator panel plate to the panel bracket. (see figure 42, page 254.) 4. Press down on the pl...

Page 228

228 chapter 7 section i: replacement procedures operator panel assembly, pedestal model removal 1. Prepare the printer for maintenance (page 152). 2. Open the printer cover. 3. Tilt the operator panel toward the front of the printer. 4. Disconnect the phone-style cable connector at the rear of the o...

Page 229: Paper Guide Assembly

Paper guide assembly 229 paper guide assembly this procedure applies only to cabinet models. Removal 1. Prepare the printer for maintenance (page 152). 2. Open the printer cover. 3. Loosen the three paper guide assembly hold-down screws (page 258, figure 44, item 6). 4. Slide the paper guide assembl...

Page 230: Paper Ironer

230 chapter 7 section i: replacement procedures paper ironer removal 1. Remove the shuttle frame assembly (page 242). 2. Move the forms thickness lever to the open position. 3. Push the ends of the paper ironer toward the rear of the printer, disengage the tabs, then lift it up and out (page 276, fi...

Page 231: Platen

Platen 231 platen removal 1. Prepare the printer for maintenance (page 152). 2. Remove the shuttle frame assembly (page 242). 3. Remove the paper ironer (page 230). 4. Remove the three 1/4 inch screws securing the paper ironer bracket assembly and remove the assembly. (see figure 51, page 276, items...

Page 232

232 chapter 7 section i: replacement procedures installation important the dowel pins protruding from the ends of the platen are the platen shafts, and are not equal in length. The platen must be installed with the longer shaft on the right side. 1. Wipe the platen shafts clean of grease and debris....

Page 233

Platen 233 figure 37. Positioning the platen adjust brackets 9. Slide the right ribbon guide assembly into the side plate and install the two 7/32 inch screws and washers. (see figure 52, page 278, items 11, 13 and 14.) 10. Install the forms thickness indicator plate: a. Slide the indicator plate, w...

Page 234

234 chapter 7 section i: replacement procedures for the right side of the platen, a washer goes on both sides of the paper ironer hook and the hook goes to the left of the right platen adjustment bracket. (see figure 36, page 232.) b. Install and torque three screws to 20 ± 2 inch-pounds (2.26 ± 0.2...

Page 235: Resistors, Terminating

Resistors, terminating 235 resistors, terminating for parallel interface configurations, the printer is equipped with 470 ohm pull- up terminating resistors and 1k ohm pull-down terminating resistors on the controller board. These are suitable for most applications. (see figure 38, page 236.) if the...

Page 236

236 chapter 7 section i: replacement procedures figure 38. Terminating resistors, removal/installation default: 470 ohm alt 1: 220 ohm alt 2: 1k ohm default: 1k ohm alt 1: 330 ohm alt 2: none rp1 rp2 cmx controller board resistor kit: 14h5525.

Page 237: Ribbon Guide Assembly (L/r)

Ribbon guide assembly (l/r) 237 ribbon guide assembly (l/r) removal 1. Prepare the printer for maintenance (page 152). Note: the right ribbon guide is shown in figure 52. The removal procedure is the same for the left ribbon guide. 2. Cut and remove the tie wrap from the tie wrap hole to free the ri...

Page 238: Ribbon Hub

238 chapter 7 section i: replacement procedures ribbon hub removal 1. Prepare the printer for maintenance (page 152). 2. Loosen the torx t-10 screw in the ribbon spool hub (page 278, figure 52). 3. Remove the hub from the shaft of the ribbon drive motor. Installation 1. Install the ribbon spool hub ...

Page 239: Shaft, Splined

Shaft, splined 239 shaft, splined removal 1. Prepare the printer for maintenance (page 152). 2. Open the printer cover. 3. Remove the paper supports from the splined shaft and support shaft. (see figure 50, page 274, item 21.) 4. Remove the paper feed timing belt (page 188). 5. Remove the ground cli...

Page 240

240 chapter 7 section i: replacement procedures installation 1. Open the doors on the left and right tractors. Position the tractor belts so the alignment marks are at the top on both tractors. (see figure 39.) 2. Grasp the vertical adjustment knob and slide the splined shaft through the right side ...

Page 241: Shaft, Support

Shaft, support 241 shaft, support removal 1. Prepare the printer for maintenance (page 152). 2. Open the printer cover. 3. Unlock the tractors and slide them to the far right. 4. Remove the paper supports from the splined shaft and support shaft. (see figure 50, page 274, item 21.) 5. Remove the e-r...

Page 242: Shuttle Frame Assembly

242 chapter 7 section i: replacement procedures shuttle frame assembly removal 1. Prepare the printer for maintenance (page 152). 2. Remove the shuttle cover assembly (page 203). 3. Disconnect the mpu cable connector (page 272, figure 49). Attention to prevent electrostatic damage to electronic comp...

Page 243

Shuttle frame assembly 243 installation 1. Install the hammer bank / ribbon mask cover assembly (page 200), if it was removed. Attention to prevent electrostatic damage to electronic components, wear a properly grounded static wrist strap when handling circuit boards, the shuttle frame assembly, and...

Page 244: Spring, Extension