- DL manuals

- Icematic

- Ice Maker

- N 132M

- Service Manual

Icematic N 132M Service Manual

Summary of N 132M

Page 1

Service manual cod. 71503769/0 - rev.01 - gb - 03/2010 our systems comply with eec directive 2006/95/eec - 2004/108/eec service manual e l e c t r o n i c m o d u l a r c u b e s n n 132m n n 192m n n 202m n n 302m n n 402m n n 502m.

Page 3

Gb 3 index table of contents .......................................................................................... 3 specifications ................................................................ 4-5-6-7-8-9-10-11-12 for the installer introduction .................................................

Page 4

Gb 4 d201 d310 n202m/n302m n202m/n302m n202m/n302m n202m/n302m kn311 ks201/301 11 mm 23 mm 2 6 m m 2 6 m m 2 3 m m 2 3 m m standard half dice specifications modular cuber n 132m model cond. Unit finish comp. Hp water req. Lt/24 hr n132m - a n132m - w air water stainless steel 7/8 168** 2568** note. ...

Page 5

Gb 5 model basic electr. Amps start amps watts electric power cons. Kwhx24 hr. N. Of wires amps fuse n192m - a n192m - w 220-240/50/1 7,5 4,9 32 1050 850 23,50** 19,50** 3x1,5 mm 2 16 d201 d310 n202m/n302m n202m/n302m n202m/n302m n202m/n302m kn311 ks201/301 11 mm 23 mm 2 6 m m 2 6 m m 2 3 m m 2 3 m ...

Page 6

Gb 6 d201 d310 n202m/n302m n202m/n302m n202m/n302m n202m/n302m kn311 ks201/301 13 mm 26.5 mm 2 6 m m 2 6 m m 2 6 .5 m m 2 6 .5 m m standard half dice specifications modular cuber n 202m model cond. Unit finish comp. Hp water req. Lt/24 hr n202m - a n202m - w air water stainless steel 7/8 410 2400* n...

Page 7

Gb 7 d201 d310 n202m/n302m n202m/n302m n202m/n302m n202m/n302m kn311 ks201/301 13 mm 26.5 mm 2 6 m m 2 6 m m 2 6 .5 m m 2 6 .5 m m standard half dice specifications modular cuber n 302m model cond. Unit finish comp. Hp water req. Lt/24 hr n302m - a n302m - w air water stainless steel 1 3/8 440 2750*...

Page 8

Gb 8 d201 d310 n402m n402m n402m n402m kn311 ks401 13 mm 26.5 mm 2 6 m m 2 6 m m 2 6 .5 m m 2 6 .5 m m standard half dice specifications modular cuber n 402m model cond. Unit finish comp. Hp water req. Lt/24 hr n402m - a n402m - w air water stainless steel 1 5/8 580 3900* note. To keep your modular ...

Page 9

Gb 9 d201 d310 n502m n502m n502m n502m kn311 ks501 13 mm 26.5 mm 2 6 m m 2 6 m m 2 6 .5 m m 2 6 .5 m m standard half dice specifications modular cuber n 502m model cond. Unit finish comp. Hp water req. Lt/24 hr n502m - a n502m - w air water stainless steel 2 600 3800* note. To keep your modular cube...

Page 10

Gb 10 for the installer introduction these instructions provide the specifications and the step-by-step procedures for the installation, start up and operation for the model n 202-302-402-502 modular cubers. The modular cubers are quality designed, engineering and constructed, and are thor- oughly t...

Page 11

Gb 11 ice machine the use of a mechanical lift is recommended for lifting the uncrated icemaker onto the bin. Remove front, top and sides panels. Place the unit directly onto the bin, align it with the back of the bin. Locate the hardware package, take out two mounting screws, and use them to secure...

Page 12

Gb 12 when choosing the water supply for the n cuber, con- sideration should be given to: a. Length of run. B. Water clarity and purity. C. Adequate water supply pressures. Since water is the most important single ingredient in producing ice you cannot over emphasize the three items listed above. Lo...

Page 13

Gb 13 start-up start-up cycle 1. Open the water tap/valve and switch on the power on the electrical supply line. 2. The models n 202-302-402-502 enter in the start up mode with the pc board energized as well as the green led of the machine under power while the models n 402-502 enter in 90 minutes d...

Page 14

Gb 14 harvest cycle 1. During the harvest cycle the components in opera- tion are: • hot gas valve • harvest assist solenoid (pusher) • water drain/purge valve • water pump for the first 40" • compressor and both • machine under power • machine in operation 2. 30 seconds after the beginning of the h...

Page 15

Gb 15 refrigeration during freeze: this ice machine employes either air or water as a condensing media, the refrigeration system for either one is a follows: at the hermetic compressor, refrigerant is com- pressed into a high temperature, high pressure gas. The gas moves through the discharge line i...

Page 16

Gb 16 water system a combination of a solenoid water inlet valve with a water level sensor is used to control the level of the water into the reservoir/sump. A pump, running continuously, after the first 30" of freezing cycle, forces the water to the top of the evap- orator, where it is distributed ...

Page 17

Gb 17 refrigeration system during harvest the refrigeration system performs the harvest of ice by use of a hot gas bypass valve. When the time comes to de-ice the evaporators, the hot gas valve is ener- gized, and the high temperature, high pressure gas bypasses the condenser, and is allowed directl...

Page 18

Water - for more than 10 seconds, a small relay of the electronic board, get energized, controlling - simulta- neously the hot gas valve, the water drain valve and the harvest assist solenoid. At this point, the unit initiates the defrost cycle. The hot gas circulating into the evaporator serpentine...

Page 19

Pc board set up the pc board can be set up for: • water fills up only at beginning of freezing cycle (standard) - jump in • continuous water fills up during the freezing cycle (option for n usph version for installation on board) - jump out gb 19.

Page 20

Gb 20 service specification in servicing a machine, it is often, useful to compare that individual units operating characteristics to those of a normally operating machine. The data that follows gives those characteristics; however, be aware that these values are for new, clean machine operating at ...

Page 21

21 component description 1. Front console panel equipped with five led plus a push button that when glow or blink are monitoring: led nr. 1 electrical power supply. Led nr. 2 operation. Led nr. 3 bin full./washing. Led nr. 4 alarm. Led nr. 5 alarm high pressure. Button b reset/washing. 2. P.C. Board...

Page 22

Gb 22 4. Ice thickness sensor located in the front upper right side off the evaporator, the sensor is made with two metal reeds in which passes power at low voltage. The two metal reeds, which are individually insulated, are set, through a set- ting screw, to maintain a minimum clearence from the ev...

Page 23

Gb 23 to shut off electrical power to icemaker, should a loss of water occur to the water cooled condenser or a burnt out of the fan motor on air cooled versions. The high pressure control is manual reset with reset but- ton located on the rear side of the machine and a mon- itoring light on the fro...

Page 24

Gb 24 13. Water pump the water pump primes the water from the sump to the water distributor tube and through the distributing holes it cascades down onto the evaporator cells by gravity so to be frozen into clear ice cubes. The water pump remains off during the first 30" seconds of the freezing cycl...

Page 25

Gb 25 a - input terminal board b - compressor remote control switch c - compressor d - ice sensor e - end defrosting switch f - water level sensor g - condenser temperature probe h - led card i - electronic card j - max pressure switch k - automatic reset switch l - water pump m - water inlet valve ...

Page 26

Gb 26 a - input terminal board b - compressor remote control switch c - compressor d - ice sensor e - end defrosting switch f - water level sensor g - condenser temperature probe h - led card i - electronic card j - max pressure switch k - automatic reset switch l - water pump m - water inlet valve ...

Page 27

Gb 27.

Page 28

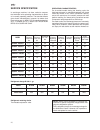

Gb 28 service diagnosis the table below is intended as a quick reference to aid the service agent in determining the cause of a partic- ular type of malfunction, as well as the recommended repair. It is not intended to be an exclusive list. Reference to other portions of this manual, inclusing wirin...

Page 29

Gb 29 maintenance & cleaning & sanitation instructions a icematic ice system represent a sizable investment of time and money in any company’s business. In order to receive the best return for that investment, in must receive periodic maintenance. It is the user’s responsibility to see that prefer- ...

Page 30

Via del lavoro, 9 c.P. 172 i - 31033 castelfranco veneto (tv) italy tel. +39 0423 738452 - fax +39 0423 722811 e-mail: service@castelmac.It web-site: www.Castelmac.It cod. 71503769/0 - rev.01 - gb - 03/2010 iso 9001 cert. N° 0412.