- DL manuals

- Jacobsen

- Lawn Mower

- HR-9016 Turbo

- Safety, Operation And Maintenance Manual

Jacobsen HR-9016 Turbo Safety, Operation And Maintenance Manual

When Performance Matters.

™

HR 9016 Turbo

™

Rotary Mower

70538 – Kubota V3800DICR-T-E3B, 4WD

H

70539 – Kubota V3800DICR-T-E3B, 4WD with ROPS

70540 – Kubota V3800DICR-T-E3B, 4WD EC with ROPS

70541 – Kubota V3800DICR-T-E3B, 4WD EC

H

WARNING

WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

4228361-GB-Rev A

Safety, Operation and Maintenance Manual

RJL 100 August 2014

GB

United

Kingdom

Summary of HR-9016 Turbo

Page 1

When performance matters. ™ hr 9016 turbo ™ rotary mower 70538 – kubota v3800dicr-t-e3b, 4wd h 70539 – kubota v3800dicr-t-e3b, 4wd with rops 70540 – kubota v3800dicr-t-e3b, 4wd ec with rops 70541 – kubota v3800dicr-t-e3b, 4wd ec h warning warning: if incorrectly used this machine can cause severe in...

Page 2

1 this manual contains safety and operating instructions for your new jacobsen machine. This manual should be stored with the equipment for reference during operation. Before you operate your machine, you and each operator you employ should read the manual carefully in its entirety. By following the...

Page 3

2 contents safety 1.1 how to operate safely. . . . . . . . . . . . . . . . . . 3 1.2 important safety notes . . . . . . . . . . . . . . . . . 6 specifications 2.1 product identification . . . . . . . . . . . . . . . . . . 7 2.2 cutting units . . . . . . . . . . . . . . . . . . . . . . . . . 7 2.3 mo...

Page 4: Warning

1 safety 3 1 safety 1.1 how to operate safely _____________________________________________________ 1.1.1 safe operation a read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operato...

Page 5

Safety 1 4 d keep your legs, arms and body inside the operator compartment while the mower is in operation. Keep your hands and feet away from the cutting units. E do not use on the slopes greater than the safe slope limit for the equipment. F to guard against over turning or loss of control: – oper...

Page 6

1 safety 5 e refuel the mower before you start the engine. When the engine is in operation or while the engine is hot, never remove the fuel cap or add fuel to the mower. F refuel outdoors only and do not smoke when you add fuel. Extinguish all types of ignition. G the fuel nozzle must touch the rim...

Page 7: Warning

Safety 1 6 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 8

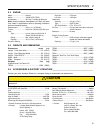

2 specifications 7 2 specifications 2.1 product identification _________________________________________________ 70538 h ........................... Hr 9016 turbo, 4 wheel drive 70539 .............................. Hr 9016 turbo, 4 wheel drive with rops 70540 .............................. Hr 9016 t...

Page 9: Caution

Specifications 2 8 2.4 engine __________________________________________________________________ make ............................... Kubota model .............................. V3800 dicr-t-e3b horsepower..................... 96.4 hp (71.9 kw) @ 2600 rpm note: actual sustained horsepower will likel...

Page 10

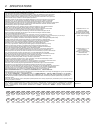

2 specifications 9 2.7 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de con...

Page 11

Specifications 2 10 conformity assessment procedure (noise) ▪ Оценка за съответствие на процедурата (Шум) ▪ postup hodnocení plnění podmínek (hluk) ▪ procedure for overensstemmelsesvurdering (støj) ▪ procedure van de conformiteitsbeoordeling (geluid) ▪ vastavushindamismenetlus (müra) ▪ vaatimustenmu...

Page 12

2 specifications 11 signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to compile the technical file, and who is established in the community. Подпис на човека, упълномощен да състави декларацията от името н...

Page 13

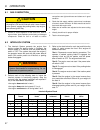

Specifications 2 12 2.8 vibration level_________________________________________________________ the mower was tested for hand and arm vibration levels. The operator was in the normal position to drive the vehicle, with two hands on the steering mechanism. The engine was in operation and the cutting...

Page 14

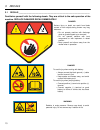

3 decals 13 3 decals 3.1 decals _________________________________________________________________ familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4164381 4181864 4181862 danger serious injury or death can res...

Page 15

Decals 3 14 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4199140 4181863 warning read manuals before operating mower. Engage lockup pins with wing arms in raised position for transport, storage, or mainten...

Page 16: Warning

3 decals 15 3008521 4257090 warning the front deck is heavy and could cause serious injury or damage if dropped. Always use proper lifting techniques when lifting or lowering the front deck to the service position. Warning to prevent injury or risk of being thrown from mower, always wear seat belt w...

Page 17

Decals 3 16 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4231860 warning 1. Read operator’s manual. Do not allow untrained operators to use this machine. 2. Keep shields in place and hardware securely fast...

Page 18

3 decals 17 !.

Page 19

Decals 3 18 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. Cut height 1 1-1/2 2 2-1/2 3 3-1/2 4 2-1/2 4 4-1/2 5 5-1/2 mount location lower lower lower lower lower middle middle middle middle middle upper upp...

Page 20: Caution

4 initial inspection 19 4 initial inspection 4.1 general ________________________________________________________________ the inspection and testing of the unit should always be performed by a trained technician, familiar with the operation of this equipment. Read each instruction completely and mak...

Page 21: Warning

Controls 5 20 5 controls 5.1 icons ___________________________________________________________________ warning never attempt to drive the mower unless you have read the safety and operation manual and know how to operate all controls correctly. Familiarize yourself with the icons shown above and wha...

Page 22

5 controls 21 4231860 ! K l m o p q r a b b c d d 1 2 1 2 e f g h i j s t u v w x y z solid st a t e hours 0 0 0 0 0 n aa a tilt steering b1 turn assist - left b2 turn assist - right c speed limiter d1 traction pedal -forward d2 traction pedal - reverse e alarm f hydraulic oil cap/dipstick g fuel ca...

Page 23: Caution

Controls 5 22 5.2 controls _______________________________________________________________ a. Tilt steering pull lever up to release steering column. Tilt column up or down to position desired. Release lever to lock steering column in place. B. Turn assist reduces the turning radius of the machine f...

Page 24

5 controls 23 5.3 instrument panel ______________________________________________________ figure 5c k. Alarm system test switch used to test the alarm system. To test, turn ignition key to run and press switch. An audible alarm will sound and warning lights will come on. L. 2wd / 4 wd switch - forwa...

Page 25: Notice

Controls 5 24 v. Ignition switch the ignition switch has three positions. Off-run (on)-start. In the run position the electrical system is active. Turn to start to crank engine. Always turn switch to off and remove key when leaving machine. W. Hydraulic oil level light alerts the operator of a low f...

Page 26

5 controls 25 5.4 operator alerts_______________________________________________________ the electrical system monitors vital machine systems. It uses an audible alarm and warning lights to alert the operator of conditions requiring immediate action. When an alert occurs follow the general guideline...

Page 27

Controls 5 26 7. Check engine light - light comes on when fault detected. Return mower to service area as soon as possible. Check engine error codes using obdii reader. Alert action.

Page 28: Caution

6 operation 27 6 operation 6.1 daily inspection________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and hoses ...

Page 29: Warning

Operation 6 28 6.3 operating procedures _________________________________________________ 1. Under no circumstances should the engine be started without the operator seated on the mower. Never start the engine with operator or bystanders standing behind a discharge chute. 2. Never run the engine in ...

Page 30: Notice

6 operation 29 6.4 starting _______________________________________________________________ the engine is equipped with an air intake heating system. This system does not require glow plugs to start the engine. 1. Sit in operator’s seat, make sure the power take-off switch (y) is off and the parking...

Page 31: Notice

Operation 6 30 6.5 stopping / parking ______________________________________________________ to stop: remove your foot from traction pedal. The mower will automatically brake when the traction pedal returns to neutral. To park the mower under normal conditions: 1. Disengage the power take-off switch...

Page 32: Warning

6 operation 31 6.7 hillside operation _____________________________________________________ the mower has been designed for good traction and stability under normal mowing conditions; however, use caution when operating on slopes, especially over rough terrain, or when the grass is wet. Wet grass re...

Page 33

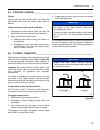

Operation 6 32 how to calculate a slope: tools required: level (a), either 1 yard, or 1 meter long. Tape measure (b). With the level (a) positioned horizontally, measure the distance (c) with tape measure (b). Use the chart to calculate either the slope angle or the % grade of the slope (d). Figure ...

Page 34: Warning

6 operation 33 6.8 mowing_________________________________________________________________ to mow: 1. If side deck transport locks are engaged, release them. See section 6.6. 2. Set mower to 4wd (l). Cutting units will not operate in 2wd. 3. Press deck levers (o) forward to lower decks. Engage power...

Page 35

Operation 6 34 6.11 towing / trailering _____________________________________________________ if the mower experiences problems and must be shut down and removed from the area, it should be loaded onto a trailer for transport. If a trailer is not available, the unit can be towed slowly short distanc...

Page 36: Notice

6 operation 35 6.12 daily maintenance _____________________________________________________ 1. Park the mower on a flat and level surface. Fully lower the cutting units to the ground, engage parking brake, stop the engine, and remove the key from ignition switch. 2. Grease and lubricate all points i...

Page 37: Warning

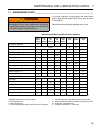

Maintenance and lubrication charts 7 36 7 maintenance and lubrication charts 7.1 maintenance chart _____________________________________________________ for smooth operation of pivot points and other friction points, apply several drops of sae 30 oil every 50 hours or as required. Remove wheels and ...

Page 38

7 maintenance and lubrication charts 37 7.2 lubrication chart _____________________________________________________ 1 2 2 4 3 4 4 6 13 14 7 7 1 grease fitting locations f1 - 50 hours (every week) qty 1 caster spindles (10) 2 caster wheel axles (10) 3 gauge wheel axles (2) 4 lift cylinder - front dec...

Page 39: Warning

Maintenance 8 38 8 maintenance 8.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 40: Warning

8 maintenance 39 8.3 sharpening blades_____________________________________________________ 1. Place a wooden block between the blade and mower housing to stop the blade from moving. To remove blade, turn screw holding blade counterclockwise . 2. When dressing or sharpening the blade, do not follow ...

Page 41: Warning

Maintenance 8 40 8.4 engine _________________________________________________________________ important: a separate engine manual, prepared by the engine manufacturer, is supplied with this mower. Read the engine manual carefully until you are familiar with the operation and maintenance of the engin...

Page 42: Warning

8 maintenance 41 8.7 air filter_______________________________________________________________ check the service indicator daily. Replace air cleaner element immediately when red band becomes visible (a) do not remove the element for inspection or cleaning. Unnecessary removal of the filter increase...

Page 43: Caution

Maintenance 8 42 8.9 fuel system ____________________________________________________________ refer to section 7 for specific maintenance intervals. See engine manual for detailed procedures. Before replacing any filter, thoroughly clean the filter housing and the area around the filter. Dirt must n...

Page 44: Warning

8 maintenance 43 8.12 charging battery _____________________________________________________ 1. Refer to section 8.10. Read the battery and charger’s manual for specific instructions. 2. Whenever possible, remove the battery from the mower before charging. If battery is not sealed, check that the el...

Page 45

Maintenance 8 44 8.14 hydraulic oil___________________________________________________________ refer to section 7.2 for specific maintenance intervals. Drain and replace the hydraulic oil if you notice the presence of water or foam in the oil, a rancid odor (indicating excessive heat), or after a ma...

Page 46: Warning

8 maintenance 45 8.16 radiator & oil cooler _________________________________________________ check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. If you have to add coolant more than once a month, or add more than one quart at a time, have a jacobsen...

Page 47: Caution

Maintenance 8 46 8.18 care and cleaning _____________________________________________________ clean the mower and implements after each use. Keep the equipment clean. Note: shut off engine prior to cleaning. Do not wash any portion of the equipment while it is hot. Do not use high pressure spray or ...

Page 48

8 maintenance 47 always check interlock system after servicing the electrical system! Relay description function kya / k2 key switch “a” provide power to alternator ig circuit when ignition switch is in the run position and operator is seated. Kyi / k1 key switch “i” provides power to kys/k3 relay w...

Page 49: Warning

Maintenance 8 48 8.20 efi diagnostic check ___________________________________________________ the electrical system is equipped with an obd-ii and diagmaster diagnostic connectors located near the engine controller. Plug an obd-ii reader into the matching connector, turn ignition switch to the on p...

Page 50: Caution

8 maintenance 49 8.22 rollover protection structure (rops) ________________________________ a rollover protection system (rops) designed for this mower is available as an optional accessory. If your mower is equipped with this device, inspect it periodically and follow operating procedures described...

Page 51: Warning

Adjustments 9 50 9 adjustments 9.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Page 52: Warning

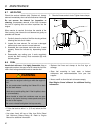

9 adjustments 51 figure 9a 9.3 servicing front deck __________________________________________________ the front deck can be raised and tilted up to improve access to the cutting unit and blades for service and cleaning. Be sure to disengage all drives, engage parking brake, stop engine, and remove ...

Page 53

Adjustments 9 52 figure 9d k j h g g.

Page 54: Warning

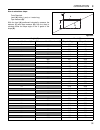

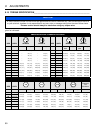

9 adjustments 53 9.5 cutting height _________________________________________________________ cutting height for decks can be adjusted from 1 to 5-1/2 in. (2.5-14 cm) in 1/2 in. (1.3 cm) increments. Actual cutting height may vary somewhat from the heights given depending on turf conditions and other...

Page 55

Adjustments 9 54 9.6 lift limit switches _____________________________________________________ the rotation of the cutting blades is controlled by limit switches positioned on the mower frame near the lift arms for each deck. When a deck is raised the switch opens and automatically disengages the cu...

Page 56

9 adjustments 55 9.7 neutral adjustment ___________________________________________________ important: the neutral adjustment on the drive pump is preset at the factory on all new mowers and replacement pumps. Further adjustment is required only if the pump has been disassembled for service or neutr...

Page 57

Adjustments 9 56 9.9 forward sensing switch _______________________________________________ the forward sensing switch allows the mower to operate in four wheel drive only with the traction pedal in its forward position. When operating in reverse the switch opens and returns the mower to two wheel d...

Page 58: Caution

9 adjustments 57 9.11 parking brake _________________________________________________________ 1. Check linkage and pivots to ensure they are operating smoothly. Inspect parking brake and steering assist cables. 2. Park the mower on a 30% slope (16.7°) near the bottom of the hill, with the front of t...

Page 59

Adjustments 9 58 9.14 steering stop bolts ____________________________________________________ 1. Steering toe-in must be set before adjusting stop bolts. If toe-in is changed, stop bolts must be re- adjusted. 2. Turn stop bolts (p and q) outas far as possible without removing them. 3. Turn steering...

Page 60: Notice

9 adjustments 59 9.15 torque specification___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Notice all torque values included in these charts are approximate and...

Page 61

Troubleshooting 10 60 10 troubleshooting 10.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems conta...

Page 62

11 quality of cut 61 11 quality of cut 11.1 quality of cut troubleshooting _______________________________________ it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area shoul...

Page 63

Quality of cut 11 62 11.3 step cutting____________________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a cutting unit than the other or on one side of mower to the other. This is usually caused by mech...

Page 64

11 quality of cut 63 11.4 scalping _______________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is...

Page 65

Quality of cut 11 64 11.5 stragglers ____________________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy dull cutting blade(s). Sharpen blade(s). Mowing (ground) speed is too fast....

Page 66

11 quality of cut 65 11.6 streaks ________________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a damaged blade. Probable cause remedy damaged blade(s). Replace blade(s). Turning too aggressive...

Page 67

Quality of cut 11 66 11.7 windrowing ____________________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between cutting units, forming line(s) in the direction of travel. Probabl...

Page 68

11 quality of cut 67 11.8 mismatched cutting units ______________________________________________ note: arrow indicates direction of travel. Mismatched cutting units is a pattern of varying cutting heights, resulting in a stepped cut appearance, usually due to mismatched hoc (height-of-cut) adjustme...

Page 69

Notes 12 68 12 notes.

Page 70

Europe & rest of the world except north & south america ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com north & south america jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacob...