- DL manuals

- Karcher

- Pressure Washer

- HD 1050 B

- Service Handbook

Karcher HD 1050 B Service Handbook

Summary of HD 1050 B

Page 1

Service handbook hd 1050 5.905-032 07/97.

Page 2

Foreword hd 1050 foreword indispensable prerequisites for the competent execution of service procedures are comprehensive, real-life training workshops for technical personnel, supported by clearly designed documentation. To meet these requirements, we provide all service technicians with regular co...

Page 3

Hd 1050 contents 3 contents a. Unit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1. Operation with mains water feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2. Operation with...

Page 4

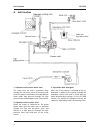

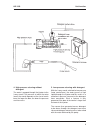

Unit function hd 1050 4 1. Operation with mains water feed the water from the mains connection flows through the non-return valve to the pump and, when the motor is switched on, the pump delivers water under high pressure through the high pressure hose and hand gun to the 3-way nozzle. 2. Operation ...

Page 5

Hd 1050 unit function 5 4. High-pressure cleaning without detergent the water is pumped through the injector to the 3-way nozzle. The pressure at which the water leaves the nozzle depends on the size of nozzle bore, the larger the bore, the lower the pressure and vice-versa. 5. Low-pressure cleaning...

Page 6

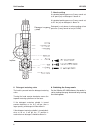

Unit function hd 1050 6 6. Detergent metering valve the knob is pressed onto the detergent metering valve. Turning the knob counter-clockwise moves the tapered metering spindle out of the bore. If the detergent metering spindle is turned counter-clockwise as far as it will go, then a lager quantity ...

Page 7

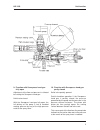

Hd 1050 unit function 7 9. Function with servopress hand gun fully open adjustment of the flow and pressure is effected bei setting the servopress hand gun. Relief valve closed with the servopress hand gun fully open, the full delivery of the pump is fed at standard working pressure by way of the hi...

Page 8

Unit function hd 1050 8 11. Function with servopress hand gun fully closed relief valve fully opened. Complete circulation pressure. When the servopress hand gun is fully closed, the pressure generated by the pump increases to such an extent that the piston with piston pin opens the ball from valve ...

Page 9

Hd 1050 basic settings 9 b. Basic settings 1. Checking the pump delivery fit the shut off valve (special tool) to the high pressure outlet, connect the high pressure hose (without hand gun and spray lance). Start the cleaner. Close the shutoff valve as far as necessary to bring the cleaner up to wor...

Page 10

Basic settings hd 1050 10 4. Checking the detergent feed start the cleaner and switch over to “operation with detergent” by turning the 3-way nozzle to low-pressure chem. Turn the detergent-feed knob to “o”. When the metering valve is set to position “o”, no detergent must be drawn into the cleaner....

Page 11

Hd 1050 trouble shooting 11 c. Trouble shooting 1. Cleaner does not run 1.1 motor does not run check main fuse or circuit braker (16 amp delayed action). Check voltage at power socket and compare the voltage on the nameplate. Check the motor protective switch on the cleaner. 1.2 circuit breaker trip...

Page 12

Trouble shooting hd 1050 12 2.6 functional faults in relief valve safety valve pulsating (repeatedly opens and closes with the hand gun closed). Remove the pressure gauge and valve screw. Pull out the pressure holding valve with pliers (special tool). Check the valve seat and valve plate for wear, i...

Page 13

Hd 1050 trouble shooting 13 2.7 no detergent is drawn in detergent check valve sticking. Pull suction hose from the hose nipple. Unscrew the hose nipple using a 19 mm wrench. Caution: the non-return valve could fall out. Remove the spring, ball and o-ring and clean them. Replace the o-ring (without ...

Page 14

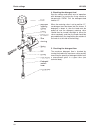

Trouble shooting hd 1050 14 3. Internal water leakage measuring the pump delivery, indicates a loss of some water. Possible cause: the suction valves, pressure valves or relief valve are defective or incorrectly mounted. 3.1 checking the suction valves remove the housing cover. Pull out the valves u...

Page 15

Hd 1050 trouble shooting 15 caution: it is important for o-rings and support rings to be greased with silicon grease before mounting and that they be inserted correctly. Press the valve into the cylinder head, screw in the valve screw and tighten with a torque of 65 nm. 3.3 checking the relief valve...

Page 16

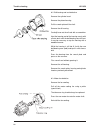

Trouble shooting hd 1050 16 replace the o-ring set of the piston and the o-ring set of the bushing, greasing the new parts with silicon grease before fitting. Caution: be sure to insert the parts in the correct order. Secure the new piston to the rod with loctite (no. 6.869-028). 3.4 checking the va...

Page 17

Hd 1050 trouble shooting 17 4. Visible water leakage 4.1 relief valve unscrew the nuts, pull off the springs and un- screw the screw plug. Pull the rod together with the piston out of the housing. Heat the rod and screw out the piston. Replace the o-ring and o-ring sets. For fitting instructions, se...

Page 18

Trouble shooting hd 1050 18 4.3 leakage between the cylinder head and the pump housing a leakages of 1 drop per minute is acceptable. Unscrew the cylinder-head screws and remove the cylinder head. Pull out the high pressure seal ring by hand. If this is difficult, use a puller. Grease a new high pre...

Page 19

Hd 1050 trouble shooting 19 5. Oil leakage from housing 5.1 oil drain plug leaking unscrew the oil drain plug and drain the oil into a suitable container. Replace the seal ring. Screw in the oil drain plug and tighten with a torque of 45 nm. Caution: fill with correct oil (see technical data). 5.2 p...

Page 20

Trouble shooting hd 1050 20 remove the housing together with the pistons. Pass a suitable screwdriver through the leakage bores and lever out the oil seal rings. Caution: take care not to damage the sealing surface of the housing. Remove the o-ring. Clean the housing of grease and oil. Note: the new...

Page 21

Hd 1050 trouble shooting 21 6. Pumps drive defective 6.1 piston jammed, swash plate worn remove the cylinder head. Use the mounting screws (special tool) to pull off the housing. Check the pistons for wear and, if necessary, replace the pistons and springs. Carefully lever out the oil seal rings wit...

Page 22

Trouble shooting hd 1050 22 6.2 ball bearing and seal defective remove the cylinder head. Remove the piston housing. Pull the swash plate off the shaft. Remove the oil housing. Carefully lever out the oil seal with a screwdriver. Heat the bearing end of the housing evenly with a flame torch until th...

Page 23

Hd 1050 special tools 23 d. Special tools 2.901-015 mounting mandrel 2.901-030 shutoff valve 4.901-038 swash plate puller 4.901-062 pliers for valve removal 5.901-069 servopress hand gun, mounting mandril 5.901-070 servopress hand gun, mounting tool 6.815-029 valve seat internal puller 6.816-069 pul...

Page 24

Technical date hd 1050 24 e. Technical date cleaner type hd 1050 part. No. For cleaner 1.720-111 circuit diagram no. 0.087-027 voltage volt 380 type of current ph/hz 3 ~ 50 hz full-load power consumption amp 13,0 setting of motor overload trip amp 14,5 - 15,0 high pressure nozzle 055 working pressur...

Page 25

Hd 1050 circuit diagram 25 phases l1, l2 and l3 are connected to the motor by way of the cleaner’s motor protective switch q1 (with integral thermal overload protection). M 1 motor q1 motor protective switch with thermal overload trips.

Page 26

Notes hd 1050 26.

Page 27

Hd 1050 notes 27.