- DL manuals

- Karcher

- Pressure Washer

- HD 3.0/30 Pb

- Operator's Manual

Karcher HD 3.0/30 Pb Operator's Manual

Summary of HD 3.0/30 Pb

Page 1

9.807-623.0 model order # hd 3.0/30 pb 1.575-152.0 hd 3.7/35 pb 1.575-154.0 hd 3.0/40 pb 1.575-155.0 operator’s man u al to locate your local kärcher commercial pressure washer dealer nearest you, visit www.Karchercommercial.Com.

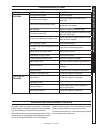

Page 2: Contents

Contents 2 model number ______________________________ serial number ______________________________ date of purchase ____________________________ the model and serial numbers will be found on a decal attached to the pressure washer. You should record both serial number and date of purchase and keep ...

Page 3: Important Safety

9.807-623.0 • rev. 10/15 3 pressure w asher opera t or’s manu al introduction & important safety information thank you for purchasing this pressure washer. We reserve the right to make changes at any time without incurring any obligation. Owner/user responsibility: the owner and/or user must have an...

Page 4: Important Safety Information

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 4 important safety information warning keep water spray away from electrical wiring. Warning: keep wand, hose, and water spray away from electric wiring or fatal electric shock may result. 9. Do not spray water on or near electrical comp...

Page 5: Component Identification

9.807-623.0 • rev. 10/15 5 pressure w asher opera t or’s manu al component identification pump — develops high pressure. Starter grip— used for starting the engine manu- ally. Spray gun — controls the application of water and detergent onto cleaning surface with trigger device. Includes safety latch...

Page 6: Assembly Instructions

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 6 step 1: attach the handle to the frame of the pressure washer. Note: it may be necessary to move the handle supports from side to side in order to align the handle so it will slide over the frame supports. Step 2: insert the carriage b...

Page 7: Operating Instructions

9.807-623.0 • rev. 10/15 7 pressure w asher opera t or’s manu al step 1: check engine oil level. Oil level should be level with the bottom of the oil fi ller neck. Be sure the machine is level when checking the oil level. (refer to the engine's operating manual included with machine.) we recommend t...

Page 8

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 8 step 7: turn the engine switch to "on" position. On briggs engines, move the throttle lever to "fast" position, shown on engine as a rabbit. Step 8: pull the starter grip. If the engine fails to start after 2 pulls, squeeze the trigger...

Page 9: Thermal Pump Protection

9.807-623.0 • rev. 10/15 9 pressure w asher opera t or’s manu al warning: some detergents may be harmful if inhaled or ingested, causing severe nau- sea, fainting or poisoning. The harmful elements may cause property damage or severe injury. Step 1: connect detergent injector to discharge nipple on ...

Page 10: Shutting Down and Clean-Up

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 10 shutting down and clean-up step 1: remove detergent suc- tion tube from container and insert into one gallon of fresh water. Slide nozzle forward for low pressure or to connect black detergent nozzle into wand quick coupler. Pull trig...

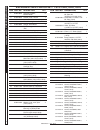

Page 11: Troubleshooting

9.807-623.0 • rev. 10/15 11 pressure w asher t roub leshooting guide problem possible cause solution low operating pressure faulty pressure gauge install new gauge. Insuffi cient water supply use larger supply hose; clean fi lter at water inlet. Old, worn or incorrect spray nozzle match nozzle numbe...

Page 12: Preventative Maintenance

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 12 preventative maintenance this pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regula...

Page 13

9.807-623.0 • rev. 10/15 13 pressure w asher opera t or’s manu al “th is pr oduct conta ins chemicals kno wn to the sta te of calif orn ia to cause cancer and bi rth defects or other repr odu cti ve har m. Operation of this equipment ma y creat e s parks that can star t fires ar oun d dry veg eta ti...

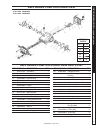

Page 14

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 14 exploded view parts list - 1.575-152.0,154.0,155.0 item part no. Description qty 1 9.802-064.0 grommet, rubber, 5 nozzle holder 2 8.920-262.0 handle, grab, chrome 1 3 9.800-723.0 label, cold water handle 1 4 9.803-126.0 plate, warning...

Page 15

9.807-623.0 • rev. 10/15 15 pressure w asher opera t or’s manu al exploded view parts list - 1.575-152.0,154.0,155.0 item part no. Description qty 58 9.802-802.0 washer, 1/4" flat 10 59 9.802-773.0 nut, 1/4" esna 8 60 8.718-980.0 washer, 5/16" flat 4 61 9.802-776.0 nut, 5/16" esna 4 62 9.802-802.0 w...

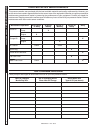

Page 16: Specifications

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 16 model gpm pressure (psi) nozzle size pump pump part no. Unloader part no. Engine engine part no. Pump pulley pump pulley part no. 1.575-152.0 3.0 3000 3.5 kd3030 9.804-006.0 9.175-018.0 gx270 (270cc) 8.750-680.0 2bk80 9.802-389.0 1.57...

Page 17: Specifications

9.807-623.0 • rev. 10/15 17 pressure w asher specifi cations model pump bushing bushing part no. Engine pulley pulley part no. Engine bushing bushing part no. Belt size belt part no. 1.575-152.0 24mm 9.802-402.0 2bk40h 9.802-384.0 hx1" 9.802-398.0 bx38 (2) 9.802-417.0 1.575-154.0 24mm 9.802-402.0 2b...

Page 18: Hose & Spray Gun Assembly

9.807-623.0 • rev. 10/15 pressure w asher specifi cations 18 hose & spray gun assembly parts list hose & spray gun assembly item part no. Description qty 1 9.802-219.0 wand assy., side grip w/1/4" coupler, 35-1/2" 1 2 8.710-384.0 gun, st-1500, 5000 psi, 10.4 gpm 1 3 9.802-164.0 coupler, 1/4” female,...

Page 19

9.807-623.0 • rev. 10/15 19 pressure w asher opera t or’s manu al 8.750-300.0, 8 gpm, 4500 psi ez start vtr3 unloader exploded view and parts list unloader adjustment procedures 1. Remove lock nut (item 19). 2. Remove adjustment knob (item 24). 3. Loosen the two (2) nuts (item 20), move them upward ...

Page 20

9.807-623.0 • rev. 10/15 21 pressure w asher opera t or’s manu al item part no. Description qty 1 8.751-216.0 crankcase 1 2* see kits below plunger oil seal 3 3* see kits below o-ring Ø1.78 x 31.47 3 4* see kits below pressure ring 3 5* see kits below u-seal 3 6* see kits below intermediate ring 3 7...

Page 21

9.807-623.0 • rev. 10/15 opera t or’s manu al pressure w asher 22 item part no. Description qty 40 9.803-158.0 connecting rod 3 41 8.751-228.0 connecting rod pin 3 42 9.803-218.0 spring washer 6 43 9.803-238.0 connecting rod screw 6 44 70-060009 o-ring, Ø2.62 x 126.67 1 45 8.751-229.0 crankcase cove...

Page 22

Www.Karchercommercial.Com form # 9.807-623.0 • revised 10/15 • printed in u.S.A. Or mexico.