Summary of KMS 400 AS

Page 1

Operating manual • english en fastmig™ kms 400 as.

Page 3: Operating Manual

Operating manual english fastm ig kms 400 as / © kemppi o y / 1021.

Page 4: Contents

En contents 1. Preface ...................................................................................... 3 1.1 general ................................................................................................................................................................. 3 1.2 about fa...

Page 5: Preface

En preface 1. General 1.1 congratulations on choosing the fastmig welding equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and ...

Page 6

En in environments classified as dangerous, only use s-marked welding equipments with • a safe idle voltage level. These work environments include, for example, humid, hot or small spaces, where the user may be directly exposed to the surrounding conductive materials. Do not use arc welding equipmen...

Page 7

En do not exceed the maximum allowable load of suspension beams or the transportation • trolley of welding equipment. It is recommended that the wire coil be removed during lifting or transportation. Environment welding equipment is not recommended for use in rain or snow - see manual. Protect • the...

Page 8: Installation

En installation 3. Before use 3.1 the product is packed in specially designed transport cartons. However, before use always make sure the products have not been damaged during transportation. Check also that you have received the components you ordered and the instruction manuals needed, as describe...

Page 9

En positioning and location of the machine 3.3 place the machine on a firm, dry and level surface. Where possible, do not allow dust or other impurities to enter the machines cooling air flow. Preferably site the machine above floor level; for example on a suitable carriage unit. Notes for positioni...

Page 10

En fastmig kms as + arcfeed 3.4.2 gnd arcfeed connection to the mains supply 3.5 fastmig power sources are delivered as standard with 5 meters of mains power cable. No mains plug is fitted at the kemppi factory. Note! If local country based regulations state an alternative power cable is required, t...

Page 11

En welding and earth cables 3.6 recommended copper cables with cross-sectional area are as follows: fastmig kms 400 as 70 ... 90 mm² in enclosed table are shown typical load capacities of rubber insulated copper cables, when ambient temperature is 25 ºc and lead temperature is 85 ºc. Cable duty cycl...

Page 12

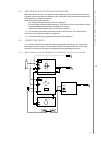

En mig/mag welding fastmig kms as is designed for mig/mag welding with either the kemppi arcfeed voltage sensing wire feed unit, or fastmig series msf and mxf wire feeding units. When using msf or mxf wire feed units, connect the unit as described in picture on page 7, and select the kms function fr...

Page 13: Basic Troubleshooting

En operation of cooling fan 4.3 in fastmig kms 400 as power source there is two simultaneously operating fans. The fan is started for a moment when main switch is placed into position i. • the fan will start during welding as the machine heats up and it will run for 1 to 10 • minutes after the weldi...

Page 14: Maintenance

En maintenance 6. When considering and planning routine maintenance, please consider the frequency of machine use and the working environment. Correct operation of the machine and regular maintenance will help you avoid unnecessary downtime and equipment failure. Note! Disconnect the machine from th...

Page 15: Operation Disturbances

En operation disturbances 7. Should you experience a malfunction from your machine, please consult the basic troubleshooting text above first, and complete some basic checks. If the machine malfunction cannot be corrected with these measures, contact your kemppi maintenance service workshop. Operati...

Page 16: Disposal Of The Machine

En disposal of the machine 8. Do not dispose of electrical equipment with normal waste! In observance of european directive 2002/96/ec on waste electrical and electronic equipment, and its implementation in accordance with national law, electrical equipment that has reached the end of its life must ...

Page 17: Technical Data

En technical data 10. Fastmig kms 400 as connection voltage 3~, 50/60 hz 400 v -15 %...+20 % rated power 60 ed - 80 % ed 19.5 kva 100 % ed 18.5 kva connection cable/fuse delayed h07rn-f 4g6 (5 m) fuse (delayed) 35 a load capacity 40 °c 60 % ed - 80 % ed 400 a 100 % ed 380 a welding current and volta...

Page 18: Warranty Policy

En warranty policy 11. Kemppi oy provides a warranty for products manufactured and sold by the company if defects in materials or workmanship occur. Warranty repairs are to be carried out only by an authorised kemppi service agent. Packing, shipping, and insurance are at the orderer’s expense. The w...

Page 20

Www.Kemppi.Com 1905320 1021 kemppi oy pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 www.Kemppi.Com kemppikoneet oy pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 734 8398 e-mail: myynti.Fi @kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige ...