- DL manuals

- Kemppi

- Welding System

- FastMig X 450

- Operating Manual

Kemppi FastMig X 450 Operating Manual

FastMig

X 450

Operating manual

Bruksanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Brugsanvisning

Instrukcja obsługi

Manual de utilização

Инструкции по эксплуатации

Bruksanvisning

操作手册

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

RU

SV

ZH

CHANNEL

MENU

X37

Summary of FastMig X 450

Page 1

Fastmig x 450 operating manual bruksanvisning gebrauchsanweisung manual de instrucciones käyttöohje manuel d’utilisation manuale d’uso gebruiksaanwijzing brugsanvisning instrukcja obsługi manual de utilização Инструкции по эксплуатации bruksanvisning 操作手册 en da de es fi fr it nl no pl pt ru sv zh ch...

Page 3: Operating Manual

Operating manual english.

Page 4

En contents 1. Introduction ....................................................................................................... 3 1.1 general ....................................................................................................................................... 3 1.2 about fastmi...

Page 5

En 1. Introduction 1.1 general congratulations on choosing the fastmig x 450 welding equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maint...

Page 6

En 2. Installation 2.1 before use the product is packed in specially designed transport cartons. However, before use always make sure the products have not been damaged during transportation. Check also that you have received the components you ordered and the corresponding instruction manuals. Prod...

Page 7

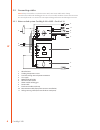

En 2.3 machine introduction channel v 6,3a 1. 2. 3. 4. 8. 10. 5. 7. 9. 6. 11. 1. Control panel x 37 2. Main switch (on/off) 3. Power on pilot lamp 4. Overheating pilot lamp 5. Welding cable connection, negative pole (–) 6. Welding cable connection, positive pole (+) 7. Control cable connection 8. Fu...

Page 8

En 2.5 connecting cables note! Always check before use that the mains cable, earth return cable and its clamp, interconnection cable and shielding gas hose are in a serviceable condition. Ensure that connectors are correctly fastened. Lose connectors can impair welding performance and damage connect...

Page 9

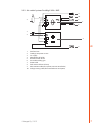

En 2.5.2 air-cooled system: fastmig x 450 + mxp 1. 4. 5. 10. 6. 8. 2. 3. 7. 9. V v 1. Wire feed unit 2. Fastmig x 450 power source 3. Gas supply 4. Mma electrode holder 5. Remote control device 6. Air-cooled welding gun 7. Power cable 8. Earth return cable and clamp 9. Measurement cable (from power ...

Page 10

En 2.5.3 cable positions for multiple machine configurations when using two or more fastmig x 450 units working on the same work piece, the right positioning of voltage sensing cable and the earth return cable is important. In order for the voltage sensing function to work properly, the earth return...

Page 11

En 2.5.5 cables kemppi always recommend the use of high quality copper cables with a suitable cross- sectional area. Cable size should be selected depending on the intended welding application. 50 mm² copper cables may be used for low duty work in basic or synergic 1-mig. However, using pulsed mig/m...

Page 12

En 3. Operation control 3.1 main switch i/o when you turn the on/off switch into position i, the pilot warning lamp is illuminated and the machine is ready for use. Always turn the machine on and off with the power source mains switch. Never use the mains plugs as a switch. 3.2 pilot lamps the pilot...

Page 13

En 4. Control panel x 37 fastmig x 450 power source features x 37 control panel with a clear and logical lcd menu display. The menu allows the operator to refine, adapt and manage the arc process and system function before, during and after welding. The following information details control panel la...

Page 14

En 4. Adjustment knob turn the knob to change the value of the selected parameter 5. Menu browsing buttons use up and down arrows to move the selection up and down in the menu structure. 6. Menu shortcut buttons • f1 displays the channel information • f2 selects the user • f3 selects another wire fe...

Page 15

En 4.2.3 shortcut buttons there are three shortcut buttons on the control panel that you can use to display important information on screen. • f1 (channel info) displays the basic data recorded to the displayed channel. • f2 (user) displays the selected active user and allows a new user profile acti...

Page 16

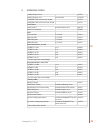

En 4.3 welding parameters mig wfspeed 0.7…25 m/min sets the wire feed speed. Changes by steps of 0.05, when wfspeed and by 0.1, when wfspeed > 5 m/min wfs-max sets the limit for maximum wfspeed wfs-min sets the limit for minimum wfspeed voltage 8…50 v step: 0.1 controls the length of the arc voltage...

Page 17

En double pulse mig wfspeed 0.7…25 m/min * sets the wire feed speed. Changes by steps of 0.05, when wfspeed min, and by 0.1, when wfspeed > 5 m/min wfs-max sets the limit for maximum wfspeed wfs-min sets the limit for minimum wfspeed finetuning -9…+9 factory setting is 0 ( = curve point) adjusts the...

Page 18

En cc process current 10…450 a welding current currentmax 10…450 a set the limit for maximum current value currentmin 10…450 a set the limit for minimum current value dynamics -9…+9 factory setting is 0 controls the short circuit behaviour of the arc. The lower the value the softer the arc is. The h...

Page 19

En creep start 10…99 % step: 1 off, curve (off=100%) factory setting is curve curve means that the creep start value comes from welding program. Startpower -9…+9 factory setting is 0 adjusts arc ignition. Advanced functions wisepenet on, off penetration control selection penet%(123a) -30…+30 % facto...

Page 20

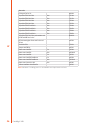

En info shows following information about the selected device. Device name: devsw: unit software version. Syssw: system software version (base software version). Bootsw: boot software version. Sw item: software item number (ifs code). Serial: device serial number. Prog: programmer name date: program...

Page 21

En control * user, panel, remote, gun. Factory settings is user this setting affects the xf 37 control panel remote control unit selection. User: user can select the remote control device at xf 37 panel panel: selection is locked to panel, and user can not select the remote device at xf 37 panel. Re...

Page 22

En administrator menu change pin code factory pin code is 0000 administrator pin code change. Ask pin off, startup, menu factory setting is off pin code inquiry selection off: no pin code inquiry. Startup: control panel x 37 always asks for the pin code when the machine is turned on. Wire feeder pan...

Page 23

En 5. Troubleshooting note! The problems listed and the possible causes are not definitive, but serve to suggest some standard and typical situations that may present during normal environmental use when using the mig/mag process with fastmig x 450. Problem check the following machine won’t work • c...

Page 24

En err 4 power source is overheated • do not shut down, let the fans cool the machine. • check ventilation. • if cooling fans are not running, contact kemppi service representative. Err 5 mains power supply voltage is too low or one of the phases is missing or auxiliary supply is faulty • check the ...

Page 25

En 6. Operation disturbances should you experience a malfunction from your machine, please consult the basic troubleshooting text above first, and complete some basic checks. If the machine malfunction cannot be corrected with these measures, contact your kemppi maintenance service workshop. Operati...

Page 26

En 7.2 periodic maintenance note! Periodic maintenance should only be carried out by a suitably qualified person. Disconnect the plug of the machine from the mains socket and wait about 2 minutes (capacitor charge) before removing the cover plate. Check at least every half year: • electric connector...

Page 27

En 9. Ordering codes fastmig x 450 power source 6103450 fastmig x 450 power source no control panel 610345001 fastmig mxp 37 pipe steel wire feeder, 300 mm 6103700 fastmig mxp 37 pipe stainless wire feeder, 300 mm 6103710 control devices control panel x 37 included with power source w007700 remote x...

Page 28

En accessories cooling unit fastcool 10 6068100 supersnake gt02s sub feeder 10 m 6153100 supersnake gt02s sub feeder 15 m 6153150 supersnake gt02s sub feeder 20 m 6153200 supersnake gt02s sub feeder 25 m 6153250 supersnake gt02s w sub feeder 10 m 6154100 supersnake gt02s w sub feeder 15 m 6154150 su...

Page 29

En 10. Technical data fastmig™ x 450 connection voltage 3~50/60 hz 400 v, -15…+20 % rated power 60 % ed 22.1 kva 100 % ed 16.0 kva connection cable ho7rn-f 4g6 (5 m) fuse (delayed) 35 a output 40 °c 60 % ed 450 a 100 % ed 350 a welding current and voltage range mma 15 a/20 v – 450 a/46 v mig 20 a/12...

Page 30

Www.Kemppi.Com 1903450 1312 kemppi oy kempinkatu 1 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46...