- DL manuals

- Kemppi

- Welding System

- Master S 400

- Operating Instructions Manual

Kemppi Master S 400 Operating Instructions Manual

Master S

400, 500

Operating manual

Bruksanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Brugsanvisning

Instrukcja obsługi

Manual de utilização

Инструкции по эксплуатации

Bruksanvisning

操作手册

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

RU

SV

ZH

Summary of Master S 400

Page 1

Master s 400, 500 operating manual bruksanvisning gebrauchsanweisung manual de instrucciones käyttöohje manuel d’utilisation manuale d’uso gebruiksaanwijzing brugsanvisning instrukcja obsługi manual de utilização Инструкции по эксплуатации bruksanvisning 操作手册 en da de es fi fr it nl no pl pt ru sv z...

Page 3: Operating Manual

Operating manual english.

Page 4

En contents 1. Introduction ......................................................................................................................... 3 1.1 general ....................................................................................................................................... ...

Page 5

En 1. Introduction 1.1 general congratulations on choosing the master s series power source. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintena...

Page 6

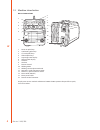

En 1.3 machine introduction master s 400 and 500 1. 5. 7. 9. 12. 6. 8. 16. 10. 4. 11. 13. 14. 15. 2. 3. 1. Power on pilot lamp 2. Overheating pilot lamp 3. Cv mode pilot lamp 4. Vrd on pilot lamp 5. Amperage meter display 6. Voltage meter display 7. Arcforce 8. Hotstart 9. Remote control 10. Welding...

Page 7

En 2. Installation 2.1 before use the product is packed in cartons designed specifically for them. However, always make sure before use that the products have not been damaged during transportation. Check also that you have received the components you ordered and the instruction manuals needed. Prod...

Page 8

En 2.4 welding and earth return cable connections 2.4.1 choosing welding polarity in mma welding you can change the welding polarity by choosing (+) or (–) cable connector. Typically, in mma welding, the welding cable is connected to the positive (+) pole connection socket and the earth return cable...

Page 9

En 3.2 operation functions 3.2.1 power source note! Always switch the machine on and off from main switch. Do not use the mains plug for switching! Note! Never watch the arc without a proper face shield designed for arc welding! Protect yourself and the surroundings against welding arc and hot spatt...

Page 10

En 3.2.3 activation and setup parameter adjustment 1. Press remote selection button (11) for at least 3 seconds, until the text ”set” appears on the screen. 2. Choose the needed parameter with the welding current adjustment knob (6). 3. To select the required parameter, press the remote selection bu...

Page 11

En 3.3 mma welding in manual metal arc welding (mma), the filler material is melted from the electrode to the weld pool. The rate of welding current is selected on the basis of the electrode size and welding position. The arc forms between the electrode tip and work piece. The melting electrode coat...

Page 12

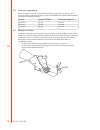

En site your equipment in a suitable location, ensuring there is adequate cable length to complete the weld pass. Before you start welding, ensure you are comfortably positioned in front of the work piece, and that you are well balanced with your weight equally distributed. Ensure that the power sou...

Page 13

En 3.4 tig welding note! In tig welding the welding cable must be connected to the negative (-) pole connection socket and the earth return cable to the positive (+) pole connection socket. Select your required welding parameters according to the manufacturer’s filler material recommendations and th...

Page 14

En 3.5 carbon arc gouging constant voltage (cv) mode is recommended to be used with carbon arc gouging. In cv mode the voltage is adjusted. Gouging is also possible in mma mode. Refer to the table below for voltage and amperage settings. Electrode voltage (v) / cv mode amperage (a) / mma mode 6.35 m...

Page 15

En 4. Maintenance note! Watch out for mains voltage when handling electric cables! Degree and circumstances of machine utilisation should be taken into consideration when planning product maintenance. Careful use and preventive maintenance helps to avoid unnecessary production disturbances and break...

Page 16

En 5. Troubleshooting the control panel will display any errors of the system. Error code numbers are shown in the display and can be compared to the table below. 5.1 troubleshooting power on light is not illuminated. There is no electrical power to the machine. • check the mains electrical supply i...

Page 17

En 5.2 control panel error codes error 1 (e1) power source is not calibrated. Calibrate power source. Error 2 (e2) undervoltage check the mains network connection and fuses. Error 3 (e3) overvoltage check the mains network connection and fuses. Error 4 (e4) overheating. Also the overheating pilot la...

Page 18

En 6. Ordering codes master s 400 6321400 master s 500 6321500 master s 400 cel including cellulose welding characteristic 632140001 master s 500 cel including cellulose welding characteristic 632150001 welding cable 50 mm², 5 m 6184501h 70 mm², 5 m 6184701h earth return cable 50 mm², 5 m 6184511h 7...

Page 20

Www.Kemppi.Com 1910110 1418 kemppi oy kempinkatu 1 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46...