- DL manuals

- Kemppi

- Welding System

- Master S 400

- Service Manual

Kemppi Master S 400 Service Manual

Summary of Master S 400

Page 1

Kemppi oy service manual master s 400 500

Page 2

Kemppi oy contents 1. Read this first ........................................................................................................................................... 1 2. General.................................................................................................................

Page 3

Service manual master s 400 and 500 version 1.1 5.9.2014 1 kemppi oy 1. Read this first 560vdc or higher are inside the machine before removing any covers or commencing any testing or measurement disconnect the power source from the mains voltage dangerous dc voltage may still exist after the remova...

Page 4

Service manual master s 400 and 500 version 1.1 5.9.2014 2 kemppi oy 2. General master family has a high quality dc mma welding sources for industrial applications. Current range is 30-400a for 400a model and 30-500a for 500a model vrd function and cv mode are standard features arc force and hot sta...

Page 5

Service manual master s 400 and 500 version 1.1 5.9.2014 3 kemppi oy 3.2. Wiring diagram latest version with better quality is available at kemppi channel..

Page 6

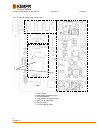

Service manual master s 400 and 500 version 1.1 5.9.2014 4 kemppi oy 3.3. Construction back front right side left side panel left side.

Page 7

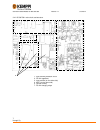

Service manual master s 400 and 500 version 1.1 5.9.2014 5 kemppi oy 3.4. Assembly 1.Cellu coil (optional) 2. Secondary rail 3. Z002 secondary rectifier 4. Main transformer 5. Z001 main circuit card 6. Primary heat sink support/insulator 2. 3. 4. 5. 6. 1..

Page 8

Service manual master s 400 and 500 version 1.1 5.9.2014 6 kemppi oy 3.4.1. S 400 z001 main circuit card structure 1. 2. 5. 6. 4. 1. Input varistors 2. Input rectifier protection circuit 3. Dc-link capacitors 4. Input rectifier (on the other side) 5. Igbt (on the other side) 6. Control circuitry 7. ...

Page 9

Service manual master s 400 and 500 version 1.1 5.9.2014 7 kemppi oy 3.4.2. S 500 z001 main circuit card structure 1. 4. 5. 7. 3. 1. Input rectifier protection circuit 2. Dc-link capacitors 3. Input rectifier (on the other side) 4. Igbt (on the other side) 5. Control circuitry 7. Dc-link charging re...

Page 10

Service manual master s 400 and 500 version 1.1 5.9.2014 8 kemppi oy 3.4.3. P001 panel card structure 1. Pulse potentiometer 2. 7-segment displays for voltage 3. X1 flat cable connector 4. 7-segment displays for current 5. Power on led 6. Overheat led 7. Led for cv mode 8. Led for vrd function 9. Ar...

Page 11

Service manual master s 400 and 500 version 1.1 5.9.2014 9 kemppi oy 3.5. Description of operation master s is divided in to six functional parts z001 main circuit card with control circuitry over voltage protection igbt based power section with full bridge architecture. Switching frequency is dual ...

Page 12

Service manual master s 400 and 500 version 1.1 5.9.2014 10 kemppi oy 3.6. Setup functions and error codes 3.6.1. Setup functions and menu setu p can be entered by pressing “remote” button as long as text “set” appears in the display. Parameters can be browsed with potentiom eter and by pressing sho...

Page 13

Service manual master s 400 and 500 version 1.1 5.9.2014 11 kemppi oy 3.6.2. Error codes and error log menu machine can show several error codes and they are automatically saved to error log file. This log file can save up to 10 errors. Error code description possible reason e1 no calibration data r...

Page 14

Service manual master s 400 and 500 version 1.1 5.9.2014 12 kemppi oy for example: latest error was primary over voltage: 0.E3 one before that was phase watch error: 1.E9 no more error in the log, so other error rows are empty: 2.E-, 3.E-, 4.E- and so on error log can be exited whenever by long pres...

Page 15

Service manual master s 400 and 500 version 1.1 5.9.2014 13 kemppi oy resetting the calibration data to factory values: rot ate potentiometer until “fac” appears in the display and select it with short press of “a/v” button, display shows “off”. Change value with potentiometer to “res” and when exit...

Page 16

Service manual master s 400 and 500 version 1.1 5.9.2014 14 kemppi oy 4. Service instructions 4.1. Measurements and tests master has only few measurements that can be done because control circuitry is integrated to z001 card and panel does have only potentiometer and few press buttons. 4.1.1. Z001 m...

Page 17

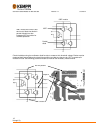

Service manual master s 400 and 500 version 1.1 5.9.2014 15 kemppi oy check the diodes using the multimeter diode function to measure their threshold voltage. Diodes must be measured both forward bias and reverse bias condition to make sure they are ok. Ntc is measured in resistance mode. See follow...

Page 18

Service manual master s 400 and 500 version 1.1 5.9.2014 16 kemppi oy igbt diode positive test lead negative test lead result igbt 1 output 1 dc-link positive 0,2-0,7vdc igbt 2 output 2 dc-link positive 0,2-0,7vdc igbt 3 ground output 1 0,2-0,7vdc igbt 4 ground output 2 0,2-0,7vdc igbt 1 dc-link pos...

Page 19

Service manual master s 400 and 500 version 1.1 5.9.2014 17 kemppi oy 4.1.2. Secondary rectifier use dmm diode function to measure both branches. Conductive stage is 0,25-0,45vdc. 4.1.3. Cooling fans cooling fans get the power from the +24vdc line. Voltages can be measured in the x17 connector (fan1...

Page 20

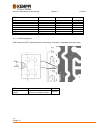

Service manual master s 400 and 500 version 1.1 5.9.2014 18 kemppi oy 4.2. Semiconductor installation it is a must be to use torque screwdriver while tightening any power components onto the heat sink. See following sections for tightening torques. 4.2.1. Rectifier and igbt modules master s has sold...

Page 21

Service manual master s 400 and 500 version 1.1 5.9.2014 19 kemppi oy 4.3. Calibration procedure calibration is not normally needed to be done. Spare part cards are calibrated in factory and will keep their range while installed in to the machine. If calibration parameters are accidentally modified,...

Page 22

Service manual master s 400 and 500 version 1.1 5.9.2014 20 kemppi oy 4.4. Final testing after the machine repair and low voltage tests, it is good practice to carry out some load tests and finish with some test welds. Only then is it possible to guarantee the machine is working correctly. 4.4.1. Lo...

Page 23

Service manual master s 400 and 500 version 1.1 5.9.2014 21 kemppi oy 4.4.2. Test welding test welding is important for having final and reliable information, if the maintenance / repair has been made successfully. In some cases a load bank test alone does not give the absolute truth if the machine ...

Page 24

Service manual master s 400 and 500 version 1.1 5.9.2014 22 kemppi oy 5. Notes.