- DL manuals

- Lab.gruppen

- Speakers

- PLM Series

- Operation Manual

Lab.gruppen PLM Series Operation Manual

Summary of PLM Series

Page 1

Rev. 1.0.2 item no. Om-plm operation manual plm ™ series powered loudspeaker management ™ systems.

Page 2: 1 Contents

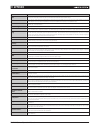

2 plm series operation manual 1 contents 1 contents...................................................................................................................................................2 2 approvals ...........................................................................................

Page 3: Contents 1

Plm series operation manual 3 contents 1 7.3.5 voltage clip limiter ...................................................................................................................20 7.3.6 temperature protection ........................................................................................

Page 4: 1 Contents

4 plm series operation manual 9.12.2.5.1 inter-sample voltage peak limiter (isvpl) ........................................................... 40 9.12.2.5.2 maxpeak level (maxpeaklvl) ............................................................................... 40 9.12.2.5.3 maxrms level (maxrmslv...

Page 5: Contents 1

Plm series operation manual 5 10.4 rj45 connectors ................................................................................................................................51 11 appendix .............................................................................................................

Page 6: 2 Approvals

6 plm series operation manual this equipment conforms to the requirements of the emc directive 2004/108/ec and the requirements of the low voltage directive 2006/95/ec. Standards applied: emc emission en55103-1, e3 emc immunity en55103-2, e3, with s/n below 1% at normal operation level. Electrical s...

Page 7: Warnings 3

Plm series operation manual 7 warnings 3 3.3 user responsibility 3.3.1 mains connection grounding your plm must be connected to a grounded socket outlet. 3.3.2 speaker output hazard plms are capable of producing hazardous output voltages. To avoid electrical shock, do not touch any exposed speaker w...

Page 8: 4 Welcome

8 plm series operation manual 4 welcome 4.1 introduction thank you for choosing the lab.Gruppen plm series of powered loudspeaker management systems for your sound reinforcement needs. We are confident that you will be pleased with the performance, unique features, configuration flexibility, reliabi...

Page 9: Welcome 4

Plm series operation manual 9 4.2.3 dolby lake processing and controller the plm series integrates seamlessly into the dolby lake processing environment. Two processing modules offer precise settings for gain, delay, crossover slope, equalization and limiting. Dolby lake processing features incorpor...

Page 10: 5 Installation

10 plm series operation manual the plm series products have no top or bottom vents; plm’s may be stacked directly on top of each other. It may be desirable to include a 1u spacer between plms to permit more convenient rear panel wiring. 5.3 rear mounting two rear support brackets, plus mounting hard...

Page 11: Installation 5

Plm series operation manual 11 for situations where rapid removal and replacement of units is of paramount importance, method 2 may be used as it does not involve any permanently secured fixing at the rear of the unit. Method 1: use washer for fixed installation. Figure 5-2 method 2: use tube for sl...

Page 12: 5 Installation

12 plm series operation manual 5.5 operating voltage the label adjacent to the mains (ac) input connector indicates the ac mains voltage for which the amplifier is wired and approved. The amplifier is built in two versions: 115 v and 230 v. Connect the mains cable (ac cord) only to an ac source of t...

Page 13: 6 Quick Guide Overview

Plm series operation manual 13 6 quick guide overview the plm’s front panel is based around a 2.5” daylight- readable 128 x 128 pixel backlit liquid crystal display (lcd), through which control and monitoring of most of the plm’s functions are performed via a simple menu system. Controls are grouped...

Page 14: Quick Guide Overview 6

14 plm series operation manual quick guide overview 6 mute enable select mute enable to allow muting via the soft button of the inputs to the dolby lake system, the power output channels, or both. The mute enable legend in the button flashes when the mode is selected. A second press will deselect th...

Page 15: 6 Quick Guide Overview

Plm series operation manual 15 6 quick guide overview see section 10 for full details of connector pinouts, etc. 6.2.1 input connectors and links analog inputs analog inputs are available on two standard xlr3f latching connectors. The inputs are electronically balanced using dolby’s patented iso-flo...

Page 16: 6 Quick Guide Overview

16 plm series operation manual 6 quick guide overview binding posts in this version, the power outputs for loudspeaker connection are available on four separate pairs of fully-enclosed binding posts. Speakon connectors in this version, the power outputs are simultaneously available on a single 8-pol...

Page 17: 6 Quick Guide Overview

Plm series operation manual 17 6 quick guide overview the dolby lake controller plm edition software is easily installed by inserting the cd in the computer’s cd drive and allowing the auto-setup routine to run. Select install then dolby lake controller software from the installation window to initi...

Page 18: 7 Operation and Performance

18 plm series operation manual 7 operation and performance 7.1 introduction to operation this chapter provides comprehensive information on plm series connection, setup, operation and performance. The detailed information included here is essential to realizing the full functionality of the plm seri...

Page 19: Operation and Performance 7

Plm series operation manual 19 operation and performance 7 power ratings are based on a “real-life” duty cycle of 25 ms full power every 400 ms. Between bursts, a lower signal level applies, such that the continuous average power is 1/8th of the rated power. In reality, when some channels are delive...

Page 20: 7 Operation and Performance

20 plm series operation manual 7 operation and performance for details.) note that the maximum isvpl setting of 153 v is greater than the 150 v maximum peak voltage available from the example plm 10000q. Other models may differ. This is to accommodate the small degree of production spread of maximum...

Page 21: Operation and Performance 7

Plm series operation manual 21 message temp flt:psu. In either case, a report is also sent via the control network to the dlc plm edition software. However, before the monitored components reach their maximum permitted temperature, a warning is given by the appropriate leds (as above) first turning ...

Page 22: 7 Operation and Performance

22 plm series operation manual 7 operation and performance 7.3.9 short circuit protection a low impedance or short circuit at the power output terminals is detected when the output current is high (current peak limiter is active) and, simultaneously, the peak output voltage is less than 42 v. When t...

Page 23

Plm series operation manual 23 signal flow and processing 8 8.1 signal flow the design of the input stage of the plm has sufficient headroom to make it almost impossible for signal clipping to occur. Because of the integration of the dolby lake processing system in the plm, there are four separate p...

Page 24

24 plm series operation manual 8 signal flow and processing the sophisticated output section monitors faults and generates warnings when appropriate; warnings are displayed on the front panel of the plm and also sent as messages over the control network. These indications allow the operator to adjus...

Page 25

Plm series operation manual 25 signal flow and processing 8 8.3 modules and frames a frame represents one physical plm on the network. A maximum of two modules are contained within each plm frame; these are referred to as module a and module b. The number of modules shown in a given frame is depende...

Page 26

26 plm series operation manual its load characteristics are included. The plm’s loadsmart and speakersafe systems use this data to verify and monitor the loads before and during performance. See dolby lake controller user manual plm edition addendum for more information concerning loadsmart and spea...

Page 27: Front Panel Interface 9

Plm series operation manual 27 9.1 front panel navigation 9.1.1 general description of navigation in the plm the majority of plm functions can be controlled and/ or monitored via the front-panel lcd display screen and associated switches and leds. The control system has two basic modes – meter mode ...

Page 28: 9 Front Panel Interface

28 plm series operation manual 9.2 key lock front panel it is possible to “lock out” the plm’s front panel buttons for security purposes. When this function is active, all control must be made via the control network. The lock is set by simultaneously pressing the top and bottom left-hand soft butto...

Page 29: Front Panel Interface 9

Plm series operation manual 29 9.7 network activity led located above the rotary encoder is an ultra-bright white led. This led illuminates when there is network activity between the dlc plm edition software and the plm. The network activity led can be dimmed via the front panel (frame, front, dimmi...

Page 30: 9 Front Panel Interface

30 plm series operation manual the current isvpl values for output channels 1 to 4 are displayed on the right hand of the screen and the ring surrounding the rotary encoder is illuminated indicating that the rotary encoder is active. Figure 9-4 3. Pressing the adjacent soft buttons to the displayed ...

Page 31: Front Panel Interface 9

Plm series operation manual 31 two of these mutes may be controlled from the plm front panel by using the mute enable button; these are: module input mutes ▸ power output mutes ▸ for safety it is not possible to change either of these mutes without first selecting mute enable. It is also possible to...

Page 32: 9 Front Panel Interface

32 plm series operation manual these mutes are located within the plm’s power output stage. When the selected output is muted, the soft button’s integral led turns red and the text amp-ch mute is displayed in inverse video. When unmuted, the integral led turns green (unless any other output warning ...

Page 33: Front Panel Interface 9

Plm series operation manual 33 an ‘event log’ file records these faults (with date and time stamp) within the plm. See chapter 5.3 of the dlc user manual plm edition addendum for further information on accessing the event log. A detailed description of each warning can be found in table 12-1. Front ...

Page 34: 9 Front Panel Interface

34 plm series operation manual warning led led number on screen warning text event log text amp temp warning channel 5~8 temp warn:ch temp.Warning; channel fewer speakers channel 5~8 under spkr cnt under speaker count more speakers channel 5~8 over spkr cnt over speaker count mag temp warning channe...

Page 35: Front Panel Interface 9

Plm series operation manual 35 9.11 meter mode in meter mode, there are three possible screen displays, referred to as “views”. Pressing the meter button scrolls through the three views – home, module and temperature - in turn. Each of the three views provides different information about the plm’s p...

Page 36: 9 Front Panel Interface

36 plm series operation manual output blocks: line 1 ▸ channel name – displays name assigned to plm’s power output channel (e.G. Lf1 etc.). This data item is also displayed in most of the parameter adjustment pages in menu mode. Line 2 ▸ output meter showing signal level at the plm’s power output st...

Page 37: Front Panel Interface 9

Plm series operation manual 37 line 2 ▸ (blank) line 3 ▸ input meter showing signal level at the module input. A numeric indication of peak level is also provided at the right-hand end of the meter. Line 4 ▸ (blank) block 4 is unused in meter mode. Output blocks: line 1 ▸ output voltage meter, denot...

Page 38: 9 Front Panel Interface

38 plm series operation manual pressing exit at any time reverts the displays to the ‘next level up’, and any altered parameters are retained automatically. Note that soft button 1 does not have any options associated with it in any of the submenu levels. The text in block 1 confirms menu mode, and ...

Page 39: Front Panel Interface 9

Plm series operation manual 39 9.12.2 module submenu this submenu is selected by pressing soft button 2, named module from the menu top page. Menu user gain delay polarity mute limiters amp gain module figure 9-18 the options available are as follows: 9.12.2.1 user gain this option is selected by pr...

Page 40: 9 Front Panel Interface

40 plm series operation manual which compression commences. Thus, the greater the value (negatively), the “softer” the knee. A setting of 0 db implies a “hard-knee” characteristic. The limitermax corner parameter may also be adjusted from the dlc plm edition software. 9.12.5.5.5 maxrms attack (maxrm...

Page 41: Front Panel Interface 9

Plm series operation manual 41 (5–8) turn red when the module output mutes are applied from this menu page. On exiting the menu system, it will be seen that they remain red – indicating a mute condition – and the screen blocks will display mod. Out mute . 9.12.3 input routing and settings submenu th...

Page 42: 9 Front Panel Interface

42 plm series operation manual current sensitivity/offset value, and using the rotary encoder. All input selection and sensitivity parameters may also be adjusted from the dlc plm edition software. 9.12.3.2 isofloat this option is selected by pressing soft button 4 (isofloat) from menu è input cfg. ...

Page 43: Front Panel Interface 9

Plm series operation manual 43 once the menu è input cfg è aes term page is displayed, the rotary encoder can be used to change the termination setting from unterminated to terminated. 9.12.4 attenuation submenu this submenu is selected by pressing soft button 4, labeled attenuation from the menu to...

Page 44: 9 Front Panel Interface

44 plm series operation manual 9.12.5.2.5 serial number (‘serial no.’) this displays the plm’s serial number. Note that this is embedded in the plm, and therefore cannot be removed or altered if the plm is stolen. 9.12.5.3 frame reset this option is selected by pressing soft button 4, (frame rst) fr...

Page 45: Front Panel Interface 9

Plm series operation manual 45 the information displayed is: block 2: ip address ▸ block 3: mac address ▸ block 4: frame id ▸ block 5: network statuses: ▸ primary network connection * secondary network connection * dlc plm edition software on/off-line * block 6: ip mask ▸ 9.12.5.4.1 ip address this ...

Page 46: 9 Front Panel Interface

46 plm series operation manual the load results page gives four items of information per output channel: confirmation of speaker fingerprint assigned ▸ to the channel. If none has been assigned, no model will be displayed. Result of speaker cabinet count; this will either ▸ be ok or wrong estimated ...

Page 47: Front Panel Interface 9

Plm series operation manual 47 see dlc user manual plm edition for for further information regarding dante implementation. 9.12.8.1 break in physical line any plm on a dante network may act as the means of inputting audio signals (analog or aes/ebu) into the system. The audio is embedded in the dant...

Page 48: 10 Back Panel Interface

48 plm series operation manual pin 1: ground/shield pin 2: hot (+) pin 3: cold (-) figure 10-2 when paralleling analog inputs of several plms, either by using the link connectors or an external paralleling system, bear in mind that the drive capability of the source’s output stage (typically a mixin...

Page 49: Back Panel Interface 10

Plm series operation manual 49 1 2 3 hot scrn hot scrn unbalanced output (typically phono) balanced input (xlr) figure 10-4 10.2.1.2 iso-float electronic balancing the plm’s electronic input balancing circuits use dolby laboratories patented iso-float system. The iso-float technology combines the be...

Page 50: 10 Back Panel Interface

50 plm series operation manual 3+ 2- 4+ 2+ 1- 1+ 4- 3- 1+ 1- 2+ 2- 3+ 3- 4+ 4- nl4 plm output channels 1 & 2 nl4 plm output channels 3 & 4 nl8 plm output channels 1 - 4 figure 10-7 users will find it convenient to use either the nl4 connectors or the nl8 depending on the installation situation. Both...

Page 51: Back Panel Interface 10

Plm series operation manual 51 back panel interface 10 10.3.2 binding post output connectors ch 2 ch 1 ch 4 ch 3 class 2 wiring speaker outputs figure 10-8 binding post versions of the plm are fitted with four pairs of black and red 4 mm binding posts. Each pair provides the output from one power ou...

Page 52: 11 Appendix

52 plm series operation manual 11.1 faults and warnings overview indication of the various fault or warning conditions that may arise in the plm is given by the tricolor leds in the eight soft buttons around the display. Because each led indicates several types of fault or warning, a brief textual d...

Page 53: Appendix 11

Plm series operation manual 53 appendix 11 displayed text event log text category type description temp warn:ch temp.Warning; channel warning amp temperature high temperature in amplifier power stage temp flt:ch temp fault: amp channel fault temperature in amplifier power stage exceeds safety limit ...

Page 54: 11 Appendix

54 plm series operation manual displayed text event log text category type description service psu frame fault: unit needs service fault psu fault a fault has developed in the psu. This is not a user- servicable fault and the unit should be returned to your dealer. Input clip n/a clip input clip the...

Page 55: Appendix 11

Plm series operation manual 55 11.5 factory default settings modules: modules: 2 x 2 aux levels: unity (all gain adjustments) eq: all eq flat polarity: in phase maxrms: 20 db maxpeak: 21 db input mutes on autoselect on input sensitivity: +26 dbu dante disabled. Aes/ebu terminated isofloat enabled is...

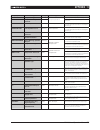

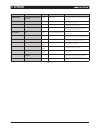

Page 56: 11 Appendix

56 plm series operation manual plm 10000q level load rated power line current *2) watt *1) thermal dissipation 115 vac 230 vac in out dissipated btu/hr kcal/hr standby, with remote power off. 4.8 0 5 16 4 powered on, idling. 145 0 145 496 125 amp (i) watt pink noise (1/8 rated power) 16 Ω / ch. 660 ...

Page 57: Appendix 11

Plm series operation manual 57 term description 10/100base-t 10base-t and 100base-t are it industry-speak for two different standards of ethernet network. In broad terms, the older 10base-t operates at 10mbps but has now been largely supplanted by the 100mbps 100base-t. Access point see wireless acc...

Page 58: 11 Appendix

58 plm series operation manual term description dbu dbu’s are usually used instead of voltages to describe signal levels in audio systems. A signal level of 0 dbu may be taken as 0,775vrms. Delay it is possible to delay into the audio signal in each of the plm’s inputs and/or output channels to time...

Page 59: Appendix 11

Plm series operation manual 59 term description in-rush current when power is applied to a piece of electronic equipment, the initial current taken by the psu can be very high as the various capacitors in the circuitry charge up. This is called the in-rush current. In the case of power amplifiers, w...

Page 60: 11 Appendix

60 plm series operation manual term description pal short for power average limiter, pal is proprietary lab.Gruppen circuit which provides additional amplifier protection. The pal ensures that the power drawn by the psu from the ac mains does not exceed the fuse or breaker ratings. Parallel two or m...

Page 61: Appendix 11

Plm series operation manual 61 term description termination aes/ebu digital audio interconnections must be correctly terminated for reliable operation. The 110 ohm terminations must be set ‘on’ at the beginning and end of a set of daisy-chained digital audio equipment such as plms, and ‘off’ at any ...

Page 62: 12 Application Guide

62 plm series operation manual 6 x plm and 115 v mains supply. If the mains supply is 115 v and the system requirement is 6 plms, then the mains capacity would need to be able to supply two 3 x 30 a circuits. There are two methods of achieving this: two racks, each with three 230 v version plms ▸ an...

Page 63: Application Guide 12

Plm series operation manual 63 amp gain. Corresponds to the gain that you would have available in a conventional system if the amplifier was outside the plm. It should retain the same settings as in the module file that is loaded: the limiter and output gain settings in the output stage of the modul...

Page 64: 12 Application Guide

64 plm series operation manual when using aes (or dante) inputs: figure 12-2 illustrates the recommended configuration of the plm when using a digital input source. Parameter list: input clip: 0 dbfs amp gain: 35 db snr: 114.2 db absolute noise floor = -71.3 dbu figure 12-3 illustrates how to achiev...

Page 65: Application Guide 12

Plm series operation manual 65 when using analog inputs: figure 12-4 illustrates how to minimize absolute noise within the plm, while limiting available spl. Parameter list: input clip: 12 dbu amp gain: 22 db snr: 105.5 db absolute noise floor = -71.5 dbu spl is limited to -8.9 db relative to clip i...

Page 66: 12 Application Guide

66 plm series operation manual when using analog inputs (continued): figure 12-6 illustrates how moderate noise with extreme spl can be achieved. The reason why the spl will be extremely high here is that so much headroom is available at the input and withiin the processing stage. This makes it poss...

Page 67: Application Guide 12

Plm series operation manual 67 digital audio is data, not audio. It therefore requires different handling and interconnection techniques from line level analog audio. This section of the manual gives some guidance for those unfamiliar with these techniques. 12.5.1 aes/ebu digital audio the plm is ab...

Page 68: 12 Application Guide

68 plm series operation manual referred to as the latency of a piece of equipment. Ultimately, the delays may become large enough to be audible and lead to phasing problems. For this reason, it is desirable to use digital interconnections rather than analog ones between the various components of a d...

Page 69: Application Guide 12

Plm series operation manual 69 in the input signal, and thus should only be used in situations where the received aes/ebu signal is known to be of good quality. In a situation where the digital audio signal has suffered deterioration resulting in jitter, it may be necessary to use a distribution amp...

Page 70: 12 Application Guide

70 plm series operation manual users should experiment with cable lengths in rehearsal situations to discover what maximum length can be used, and then to not use more than 75% of this length “on the road”. It is also good practice to ensure that interconnect cables (particularly mixer- stage) of va...

Page 71: Application Guide 12

Plm series operation manual 71 tap 6. Update; tap ok to the warning message. Figure 12-10 the plms will be updated with the latest 7. Firmware. A green tick indicates successful update and the percentage value indicates the progress of the firmware update of that unit. A red cross indicates the firm...

Page 72: 12 Application Guide

72 plm series operation manual tap ok to the warning message that advises 12. That the backup file will be recalled. This file will reload the plms with the data that was present prior to the upgrade process. 12.7 hot swapping plm devices. Should it be necessary to swap one plm device for another wi...

Page 73: Specifications Plm 10000Q

Plm series operation manual 73 technical specifications 13 following are the technical specifications for the plm series plm 10000q. These figures are accurate at the time of printing but please note that all figures are subject to change without notice. For the most accurate and current information...

Page 74: 14 Warranty

74 plm series operation manual 14 warranty general this product is manufactured by lab.Gruppen, and it is warranted to be free from any defects caused by components or factory workmanship, under normal use and service, for a period of six (6) years from date of purchase from an authorized lab.Gruppe...

Page 75

L a b . G r u p p e n a b • s w e d e n i n t e r n a t i o n a l c o n t a c t • i n f o @ l a b g r u p p e n . C o m u s c o n t a c t • i n f o u s @ t c e l e c t r o n i c . C o m w w w . L a b g r u p p e n . C o m.