- DL manuals

- Lab.gruppen

- Speakers

- PLM Series

- Operation Manual

Lab.gruppen PLM Series Operation Manual

Summary of PLM Series

Page 1

Rev. 1.0.5 item no. Om-plm operation manual plm ™ series powered loudspeaker management ™ systems.

Page 2: 1 Contents

2 plm series operation manual 1 contents 1 contents...................................................................................................................................................2 2 approvals ...........................................................................................

Page 3: Contents 1

Plm series operation manual 3 contents 1 7.3.4 current average limiter (cal) ..................................................................................................20 7.3.5 voltage clip limiter (vcl) ............................................................................................

Page 4: 1 Contents

4 plm series operation manual 9.13.2.1 gain .............................................................................................................................. 38 9.13.2.2 delay ..................................................................................................................

Page 5: Contents 1

Plm series operation manual 5 10.2.2 digital inputs and links .......................................................................................................... 48 10.3 speaker output connections....................................................................................................

Page 6: 2 Approvals

6 plm series operation manual this equipment conforms to the requirements of the emc directive 2004/108/ec and the requirements of the low voltage directive 2006/95/ec. Standards applied: emc emission en55103-1, e3 emc immunity en55103-2, e3, with s/n below 1% at normal operation level. Electrical s...

Page 7: Warnings 3

Plm series operation manual 7 warnings 3 3.3 user responsibility 3.3.1 mains connection grounding your plm must be connected to a grounded socket outlet. 3.3.2 speaker output hazard plms are capable of producing hazardous output voltages. To avoid electrical shock, do not touch any exposed speaker w...

Page 8: 4 Welcome

8 plm series operation manual 4 welcome 4.1 introduction thank you for choosing the lab.Gruppen plm series of powered loudspeaker management systems for your sound reinforcement needs. We are confident that you will be pleased with the performance, unique features, configuration flexibility, reliabi...

Page 9: Welcome 4

Plm series operation manual 9 seamless, plug-in integration of the industry-standard smaartlive analysis system. With this feature, operators can measure with smaartlive and make eq adjustments at the same time, using the same software controller on a wi-fi enabled tablet pc. (see the separate dolby...

Page 10: 5 Installation

10 plm series operation manual loom bends within a rack. In particular, the mains cable (ac cord) and its neutrik powercon connector require at least 120 mm (4.75 inches) clear rack depth behind the plm rear panel. The plm series products have no top or bottom vents; plm’s may be stacked directly on...

Page 11: Installation 5

Plm series operation manual 11 for situations where rapid removal and replacement of units is of paramount importance, the method shown in figure 5.3c may be used as it does not involve any permanently secured fixing at the rear of the unit. Figure 5.3c: use tube for slide-on installation figure 5.3...

Page 12: 5 Installation

12 plm series operation manual if the device malfunctions as a result of dirty dust filters, any required repairs are not covered by the warranty. 5.5 operating voltage the label adjacent to the mains (ac) input connector indicates the ac mains voltage for which the amplifier is wired and approved. ...

Page 13: Quick Guide Overview 6

Plm series operation manual 13 quick guide overview 6 the front panel controls, clustered around a 2.5” daylight readable lcd, perform most control and monitoring functions via a simple menu system. The two switch clusters on either side of the lcd include dedicated function keys as well as eight “s...

Page 14: Quick Guide Overview 6

14 plm series operation manual quick guide overview 6 pressing meter when in menu mode returns the screen to meter mode, and the home view is displayed. The display has two basic operating modes: meter (default) and menu. Menu pressing the menu button puts the screen display into menu mode, and the ...

Page 15: 6 Quick Guide Overview

Plm series operation manual 15 6 quick guide overview 6.2.1 input connectors and links see section 10 for full details of connector pinouts, etc. Analog inputs analog inputs are available on two standard xlr3f latching connectors. The inputs are electronically balanced and feature dolby’s patented i...

Page 16: 6 Quick Guide Overview

16 plm series operation manual 6 quick guide overview please contact plmsupport@labgruppen.Com for further information on bridge-mode operation. Binding posts in this version, the power outputs for loudspeaker connection are available on four separate pairs of fully-enclosed binding posts. Speakon c...

Page 17: 6 Quick Guide Overview

Plm series operation manual 17 6 quick guide overview the dolby lake controller plm edition software is easily installed by inserting the cd in the computer’s cd drive and allowing the auto-setup routine to run. Select install then dolby lake controller software from the installation window to initi...

Page 18: 7 Operation and Performance

18 plm series operation manual 7 operation and performance 7.1 introduction to operation this chapter provides comprehensive information on plm series connection, setup, operation and performance. The detailed information included here is essential to realizing the full functionality of the plm seri...

Page 19: Operation and Performance 7

Plm series operation manual 19 operation and performance 7 power ratings are based on a “real-life” duty cycle of 25 ms full power every 400 ms. Between bursts, a lower signal level applies, such that the continuous average power is 1/8th of the rated power. In reality, when some channels are delive...

Page 20: 7 Operation and Performance

20 plm series operation manual 7 operation and performance 7.3.2 current peak limiter (cpl) the output current peak limiter (cpl) ensures that the power output section will not be damaged by forcing it to deliver current levels at the outputs that exceed the maximum current ratings of the output tra...

Page 21: Operation and Performance 7

Plm series operation manual 21 if an output channel temperature fault condition arises, the output of the channel causing the condition will be muted. Temperature checking will continue thereafter at 0.5 second intervals, with the output remaining muted until the fault condition clears. 7.3.7 dc pro...

Page 22: 7 Operation and Performance

22 plm series operation manual 7 operation and performance channel led (in the right-hand soft function buttons) showing steady red. The adjacent fault message will show short circuit. It is also reported as a fault via the control network to the dlc plm edition software. The presence of a short cir...

Page 23

Plm series operation manual 23 signal flow and processing 8 8.1 signal flow figure 8.1 is a graphic presentation of the signal flow inside a plm. As is readily apparent, the plm is an unusually sophisticated system comprising many different subsections of both digital and analog technologies. To rea...

Page 24

24 plm series operation manual 8 signal flow and processing and therefore also the maximum output power. The isvpl setting is made via menu > module > limiters > isvpl, and can also be set from the dlc plm edition software. The sophisticated output section monitors faults and generates warnings when...

Page 25

Plm series operation manual 25 signal flow and processing 8 8.3 modules and frames a frame represents one physical plm on the network. A maximum of two modules are contained within each plm frame; these are referred to as module a and module b. The number of modules shown in a given frame is depende...

Page 26

26 plm series operation manual when a plm-specific loudspeaker type is loaded, its load characteristics are included. The load characteristics are stored in a file with a “.Mdl” suffix and is loaded with the module file with the same name. The plm’s loadsmart and speakersafe systems use this data to...

Page 27: Front Panel Interface 9

Plm series operation manual 27 9.1 front panel navigation 9.1.1 general description of navigation in the plm the majority of plm functions can be controlled and/ or monitored via the front-panel lcd display screen and associated switches and leds. The control system has two basic modes: meter mode a...

Page 28: 9 Front Panel Interface

28 plm series operation manual 9.2 key lock front panel it is possible to “lock out” the plm’s front panel buttons for security purposes. When this function is active, all control must be made via the control network. The lock is set by pressing and holding the top left-hand soft button and then sim...

Page 29: Front Panel Interface 9

Plm series operation manual 29 9.7 network activity led located above the rotary encoder is an ultra-bright white led. This led illuminates when there is network activity between the dlc plm edition software and the plm. The network activity led can be dimmed via the front panel by selecting frame m...

Page 30: 9 Front Panel Interface

30 plm series operation manual 9.10 soft-function buttons eight silicon rubber buttons are set adjacent to the display in two groups of four. These buttons are unlabelled because their functions change according to the on-screen page currently displayed. Figure 9.10: front panel soft function button...

Page 31: Front Panel Interface 9

Plm series operation manual 31 module input mute is within the dolby lake processing system and not at the physical inputs to the plm. This means it is possible to mute the input to one module, while mixing input sources together and feeding the sum to the second module. This is not possible with th...

Page 32: 9 Front Panel Interface

32 plm series operation manual network/ frame status module a input module b input not used channel output 1 channel output 2 channel output 3 channel output 4 1 2 3 4 5 6 7 8 figure 9.10a: front panel soft function buttons in fault/ warning mode the relationship between leds and inputs and outputs ...

Page 33: Front Panel Interface 9

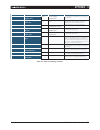

Plm series operation manual 33 front panel interface 9 9.11 warning and fault indications the following table gives indications for warning (yellow) and fault/clip/mute (red) conditions, listed separately. Additional information in table 11.1. Warning led led number on screen warning text event log ...

Page 34: 9 Front Panel Interface

34 plm series operation manual 9.12 meter mode in meter mode, there are three possible screen displays, referred to as “views”. Pressing the meter button scrolls through the three views in turn: home, module and temperature. Each of the three views provides different information about the plm’s perf...

Page 35: Front Panel Interface 9

Plm series operation manual 35 9.12.1 meter view 1 – home view 1 aux fault/warning y-10sub -50 cl3w fault/warning y-10 -24 fault/warning home - - - - sub fault/warning -45 lo fault/warning -11 mid fault/warning -13 - ∞ - ∞ - ∞ hi fault/warning -09 -02 Ω a 1 a 2 a 3 b 1 figure 9.12.1: home (default) ...

Page 36: 9 Front Panel Interface

36 plm series operation manual temperature view provides information about the current operating temperatures within the plm and loudspeakers. Frame block: line 1 ▸ temp meters flag – confirms temperature view line 2 ▸ (blank) line 3 ▸ power supply temperature meter, denoted by ‘psu’. A bargraph met...

Page 37: Front Panel Interface 9

Plm series operation manual 37 9.13 menu mode 9.13.1 menu view menu module input cfg attenuation dante load mon. Frame prst frame figure 9.13.1: menu mode view most plm operating functions are accessed via the menu system in menu mode. These include adjustment of gain, selection of input type, limit...

Page 38: 9 Front Panel Interface

38 plm series operation manual delay is adjustable in increments of 0.1 ms. Maximum input delay is 1.8 s, and maximum output delay is 100 ms which is the default delay setting unless another range has been specified in the module settings. The module delay parameters may also be adjusted from the do...

Page 39: Front Panel Interface 9

Plm series operation manual 39 9.13.2.5.1 inter-sample voltage peak limiter (isvpl) the purpose of the isvpl is to prevent the voltage at the plm’s output terminals exceeding a pre- determined value. Selecting isvpl (soft button 2) permits adjustment of this value, in the range 17.8 v to 153 v (mode...

Page 40: 9 Front Panel Interface

40 plm series operation manual it can be seen from figure 8.1 that each processing module – a and b – is fed with a signal which is a mix of the two input signals selected by the two input routers. In the simplest configuration, the input mixers will be set so that the signal selected by router 1 fe...

Page 41: Front Panel Interface 9

Plm series operation manual 41 in forced selection mode, one of the four priorities is permanently “forced” to be the selected input, whatever its input type. The selected router (router 1 or router 2) may be set to auto select mode or forced selection mode with soft button 4. The rotary encoder scr...

Page 42: 9 Front Panel Interface

42 plm series operation manual to adjust attenuation for two or three channels: only one channel or all channels may be adjusted at one time. 9.13.5 frame submenu this submenu is selected by pressing soft button 5, labeled ‘frame’, from the menu top page. Menu frame label ---- frame info frame rst f...

Page 43: Front Panel Interface 9

Plm series operation manual 43 9.13.5.2.1 firmware version (‘fw version’) selecting this option displays a page showing the version numbers of the various firmware elements within the plm. This information may be of relevance if a technical issue should arise; factory technical staff will probably r...

Page 44: 9 Front Panel Interface

44 plm series operation manual 9.13.5.6 display adjustments this option is selected by pressing soft button 8, (front) from menu è frame. The parameters of the display screen itself may be adjusted here, to suit ambient lighting conditions. 9.13.5.6.1 display contrast press soft button 2 and use the...

Page 45: Front Panel Interface 9

Plm series operation manual 45 loadsmart verification menu load mon. Configure # of cabinets in parallel figure 9.13.7: loadsmart option view 9.13.7.1 configure # of cabinets in parallel this option (soft button 2) allows the user to enter the number of speaker cabinets connected to each plm output ...

Page 46: 9 Front Panel Interface

46 plm series operation manual 9 front panel interface see dlc user manual plm edition for for further information regarding dante implementation. 9.13.8.1 using the plm as a “break-in box” any plm on a dante network may act as the means of inputting audio signals (analog or aes/ebu) into the networ...

Page 47: Back Panel Interface 10

Plm series operation manual 47 10.1 power inlet a neutrik nac3 series powercon connector rated at 32 a is fitted to the rear of the plm for ac mains input. The power cable (ac cord) supplied with the plm has the mating connector ready-fitted, but may require a mains (ac) plug specific to your countr...

Page 48: 10 Back Panel Interface

48 plm series operation manual the aes/ebu digital audio format uses a balanced electrical configuration similar to balanced analog audio. The pinout is shown in table 10-2. Aes/ebu wiring table pin 1 ground/shield pin 2 hot (+) pin 3 cold (-) table 10.2.2: aes connector wiring and pin out note that...

Page 49: Back Panel Interface 10

Plm series operation manual 49 10.3 speaker output connections the plm is available with either 4 mm binding posts or neutrik speakon connectors for the outputs. The plm is capable of bridge-mode operation; however, the present system management software does not support this mode and therefore brid...

Page 50: 10 Back Panel Interface

50 plm series operation manual 10.4 rj45 connectors link sec prim act link act switched 10/100 base-tx figure 10.4a: rear panel dante ethercon network connectors the network connections of the plm are on two neutrik ethercon rj45 sockets. The second connector may be used for linking multiple plms, o...

Page 51: Appendix 11

Plm series operation manual 51 appendix 11 11.1 faults and warnings overview the various fault or warning conditions that may arise in the plm are indicated by the tricolor leds in the eight soft function buttons around the display. Because each led indicates several types of faults or warnings, a b...

Page 52: 11 Appendix

52 plm series operation manual displayed text event log text category type description amp ch. Mute amp channel mute mute status amplifier mute the audio signal has been muted in the power output stage audio fault frame fault: audio interface fault audio interface fault an internal audio fault has a...

Page 53: Appendix 11

Plm series operation manual 53 appendix 11 displayed text event log text category type description temp flt:psu temp fault: power supply unit fault power supply temperature the temperature of the plm’s psu has exceeded its safety limit temp flt:vc temp fault: speaker voice coil fault speaker voice c...

Page 54: 11 Appendix

54 plm series operation manual 11.2 maintenance during normal operation your plm will provide trouble-free service. The main user maintenance is to periodically clean the dust filters behind the front grilles. The two grilles can be removed by undoing the knurled-head screws, and the foam filter ele...

Page 55: Appendix 11

Plm series operation manual 55 appendix 11 table 11.4: plm 10000q current draw and thermal dissipation specifications plm 10000q level load rated power line current *2) watt *1) thermal dissipation 120 vac 230 vac in out dissipated btu/hr kcal/hr standby, with remote power off. 4.8 0 4.8 16 4 powere...

Page 56: 11 Appendix

56 plm series operation manual term description 10/100base-t 10base-t and 100base-t are it industry-speak for two different standards of ethernet network. In broad terms, the older 10base-t operates at 10mbps but has now been largely supplanted by the 100mbps 100base-t. Access point see wireless acc...

Page 57: Appendix 11

Plm series operation manual 57 term description finite impulse response (filter) an alternative design of crossover filter realisable in the digital domain, providing linear phase characteristics. Fir filtering is provided in the dolby lake processing within the plm. Floating an analog balanced inpu...

Page 58: 11 Appendix

58 plm series operation manual term description pal short for power average limiter, pal is proprietary lab.Gruppen circuit which provides additional amplifier protection. The pal ensures that the power drawn by the psu from the ac mains does not exceed the fuse or breaker ratings. Parallel two or m...

Page 59: Application Guide 12

Plm series operation manual 59 application guide 12 12.1 i/o panels system interconnection on-site is made quicker and simpler if racks are prewired internally to connection panels. If the panels are fitted to the front of the rack, all audio, loudspeaker, network and power cables may then be simply...

Page 60: 12 Application Guide

60 plm series operation manual to provide the appropriate headroom at the input stage. (adjustments made in i/o config window, input configuration, left side.) input mixer. This setting should be left at “0” or most setups. If only one input channel is used, the other can be set to “- inf”. (adjustm...

Page 61: Application Guide 12

Plm series operation manual 61 configured with this gain setting and will not be automatically compensated if changes are made. This configuration scheme, though unusual, allows for backwards compatibility with other dolby products. (set in lab.Gruppen info, control tab.) the following details can a...

Page 62: 12 Application Guide

62 plm series operation manual parameter list: input clip: 0 dbfs amp gain: 35 db snr: 114.2 db absolute noise floor = -71.3 dbu figure 12.2b illustrates how to achieve the lowest possible output noise; however, this is not a recommended setup parameter list: input clip: 0 dbfs amp gain: 22 db snr: ...

Page 63: Application Guide 12

Plm series operation manual 63 when using analog inputs: figure 12.4a illustrate how to minimize absolute noise within the plm, while limiting available spl. Parameter list: input clip: 12 dbu amp gain: 22 db snr: 105.5 db absolute noise floor = -71.5 dbu spl is limited to -8.9 db relative to clip i...

Page 64: 12 Application Guide

64 plm series operation manual when using analog inputs (continued): figure 12.2c illustrates how moderate noise with extreme spl can be achieved. The reason why the spl will be extremely high here is that so much headroom is available at the input and withiin the processing stage. This makes it pos...

Page 65: Application Guide 12

Plm series operation manual 65 12.4 speaker configurations connecting two speakers in parallel to a plm power output presents a load to the amplifier which is half the impedance of that presented by one speaker. Thus the current that two speakers will attempt to draw from the output stage is double ...

Page 66: 12 Application Guide

66 plm series operation manual 12.5.3 interconnecting digital audio some interconnection methods commonly used with analog audio may not possible when using aes/ ebu digital audio. If it is required to connect an aes/ ebu output to multiple aes/ebu inputs (such as multiple plms), one of the followin...

Page 67: Application Guide 12

Plm series operation manual 67 application guide 12 for transmission distances up to 100 m, use a screened twisted-pair cable, ideally with an impedance of 110 ohms at all frequencies up to 12 mhz. Cable meeting these requirements will generally be marketed as being suitable for digital audio. Some ...

Page 68: 12 Application Guide

68 plm series operation manual that rate. If failing to lock to the incoming clock the clock status will be reported as slipping and the audio signal will be distorted. 44.1 khz: includes sample rates equal to the base ▸ as well as the multiples 88.2 and 176.4 khz. 48 khz: includes sample rates equa...

Page 69: Application Guide 12

Plm series operation manual 69 12.7 firmware upgrades this chapter describes the process for upgrading firmware in the plm. As responsible manufacturers, lab.Gruppen and dolby adopt a policy of continuous product development. As with all software-based products, it may be desirable from time to time...

Page 70: 12 Application Guide

70 plm series operation manual figure 12.7.1a: firmware update utility step one please select and use a wired networks with a fixed ip address for performing firmware upgrades. A loss of network connectivity could result in a failed firmware upgrade. The plms on the network will appear in a list 5. ...

Page 71: Application Guide 12

Plm series operation manual 71 figure 12.7.1e: firmware update utility completion page cycle the power of each plm by turning the 9. Power switch off, and then either removing the powercon connector from the rear of each plm or switching off all power to the plm racks at source. Then reconnect the p...

Page 72: 12 Application Guide

72 plm series operation manual tif the new firmware includes upgrades for 9. The amplifier, or the front panel functions, these upgrades will be initialized automatically. Activity and progress will be indicated on the front panel. After an upgrade of the amplifier firmware, the unit will reboot aut...

Page 73: Specifications Plm 10000Q

Plm series operation manual 73 technical specifications 13 following are the technical specifications for the plm series plm 10000q. These figures are accurate at the time of printing but please note that all figures are subject to change without notice. For the most accurate and current information...

Page 74: 14 Warranty

74 plm series operation manual 14 warranty general this product is manufactured by lab.Gruppen, and it is warranted to be free from any defects caused by components or factory workmanship, under normal use and service, for a period of six (6) years from date of purchase from an authorized lab.Gruppe...

Page 75

L a b . G r u p p e n a b • s w e d e n i n t e r n a t i o n a l c o n t a c t • i n f o @ l a b g r u p p e n . C o m u s c o n t a c t • i n f o u s @ t c e l e c t r o n i c . C o m w w w . L a b g r u p p e n . C o m.