Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50374.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...

30 congratulations... ...On an excellent choice. We thank you for the preference accorded to our products. Lamborghini caloreclima has been actively present in italy and throughout the world since 1959 with a widespread network of agents and dealers to constantly guarantee the presence of our produc...

31 general instructions ● this booklet constitutes an integral and essential part of the product. Read carefully the instructions contained in this booklet as they provide important directions regarding the safety of installation, use and maintenance. Preserve this booklet with care for any further ...

32 description futuria 24 plus mb w top perfectly air-tight with respect to its surroundings, this unit is suitable for heating water to temperatures below boiling point at atmospheric pressure. Fully automatic, the futuria plus boiler is governed by an electronic microprocessor-operated control box...

33 to be carried out by qualified personnel. The system must be installed in an area free from corrosive vapours and must comply with the legal standards in force regarding evacuation of combustion by-products. It is especially recommended that standards concerning safety, construction and flue posi...

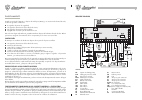

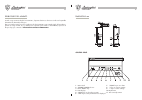

34 main components legend 1 air bleed valve 2 control electrode 3 fan 4 ignition electrodes 5 board 6 transformer 7 fume pressure switch 8 ntc 2 return sensor 9 heating circuit expansion tank 10 circulating pump 11 safety valve 12 lack of water pressure switch 13 filling cock 14 drain cock 15 hot wa...

35 dimensions mm 3/4” Ø heating delivery 3/4” Ø heating return 1/2” Ø cold water inlet 1/2” Ø hot water outlet 3/4” Ø gas inlet technical features boiler version: mod. C type c13-c33-c43-c53-c83 max. Water temperature 90 ° c category: i 2h rated gas pressure: natural gas 20 mbars heating circuit ope...

36 water supply connection fit the assembly template up against the wall. Then fit all the piping: system delivery, system return, cold water, hot water, gas, condensation discharge and electrical power supply for the room thermostat. Once the pipes have been fitted the end fittings can be unscrewed...

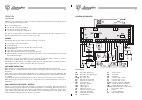

37 water supply circuit legend a gas b cold water inlet c hot water outlet d system delivery e system return 1 system deliver y control sensor 2 air bleed valve 3 control electrode 4 nozzle connection 5 ignition electrodes 6 ignition transformer 7 fan 8 air pressure switch 9 system return control se...

38 electrical connections - wiring diagrams the boiler must be connected to an earthed, single-phase 230v-50 hz mains supply by means of a three-wire cable, ensuring that connections to the line and neutral terminals are made correctly. A bipolar switch must be used with contacts opening to at least...

39 principle diagram legend cir system circulating pump psg safety gas pressure switch pa air pressure switch ph 2 o water pressure switch e.A. Ignition electrode e.R. Detection electrode tra transformer ig main switch vg1 gas valve 1 vg2 gas valve 2 vd 3-way valve e/i summer/winter switch ta room t...

40 assembly diagram legend cir system circulating pump psg safety gas pressure switch pa air pressure switch ph 2 o water pressure switch e.A. Ignition electrode e.R. Detection electrode tra transformer ig main switch vg gas valve 1-2 m1 pa27 terminal board vd 3-way valve e/i summer/winter switch ta...

41 flue exhaust installation ● concentric flue exhaust: max length 3 m ● double flue pipe (intake + delivery): max length 50 m. Attention: use only air intake/ fumes evacuation kits produced by lamborghini caloreclima. Double flue pipe the flue pipe should slope slightly upward ( a gradient of about...

42 when the unit is switched on (or when it is reset), and where no heat has been requested, the system runs through the following procedure: ● 5 second safety pause; ● 15 seconds 3-way valve activation; ● 60 seconds circulator activation; ● circulator and 3-way valve switched off. This cycle is run...

43 system filling bring the 3-way valve into the manual position. Open the inlet valve slowly until the system reaches a working pressure (indicated on the hydrometer) of approximately 1 bar, then close it. Check that the automatic air bleed valve has its cap loosened, run the circulator to eliminat...

44 operating sequence (display only) step function 0 pause, no heat required 1 pre-ventilation 2 ignition 3 burner ignited (heating system mode) 4 burner ignited (hot water mode) 5 air pressure switch control 6 burner off (water temp. More than 5 ° c warmer than setting) 7 post-circulation pump in h...

45 to gain access to the phase number press the mode button once (an indicator light to the right of the 1 st figure comes on). Press step to display all the available phases. List of parameters indicated by 1 st figure on display (values can be adjusted by the user). Example: indicator light step n...

46 data display (monitor system) real-time data (not modifiable) regarding unit operation can be checked on the monitor. Press mode twice (a flashing indicator light appears to the right of the 1 st figure). Press step to display all the available phases. Notes phase n ° parameter sistema acqua cald...

47 the boiler control box is equipped with a microprocessor that memorises and signals any faults or shutdowns. The fault type is indicated by a code. The meaning of each code is given in the table below: fault code (read-only display) 1 st figure fault 2 nd figure 0 1 2 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ...

48 should there be a fault the system will shut down and flash the fault type on the display. Check for proper operating conditions (gas tap open, proper feed pressure etc.) and press reset. Should the fault persist contact your local lamborghini assistance centre. By pressing mode and step simultan...

49 from 10 to 60 (x 100) min/max r.P.M. In heating mode f 00 = modulation working. From 01 to 100% manual fan speed control. Chimney- sweep function. Fan speed control e d 0x = room thermostat 1x = ntc4 sensor (outdoor sensor) boiler type 1, figure as in heating 2, figure as in hot water x0 = 3-way ...

50 when setting has been completed press r.P.M. Settable at start between 80 and 100% of absolute value. Start r.P.M. N from 00 to 99 (units) l min. R.P.M. From 05 to 60 (x 100) min. R.P.M. J from 00 to 90 (units) max r.P.M. In heating mode g from 10 to 60 (x 100) max r.P.M. In hot water mode h max ...

51 - set the access code (62) (see page 48) - press mode - press step to display the relative phase (f-g) - use the +/- keys to set the desired r.P.M. - press store to enter the variation. Varying fan r.P.M. Gas valve adjustment the boilers leave the factory already set to their minimum and maximum ...

52 when leaving the factory the burners are set to operate with natural gas. For the calibration see the table below: burner pressure curve - output gas - nozzle calibration ∆ p servo = pressure jump measured between points upstream and downstream of nozzle. ∆ p servo delivery burner nozzle min. Max...

52 when leaving the factory the burners are set to operate with natural gas. For the calibration see the table below: burner pressure curve - output gas - nozzle calibration ∆ p servo = pressure jump measured between points upstream and downstream of nozzle. ∆ p servo delivery burner nozzle min. Max...

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50374.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50374.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...

11 dear user... ...You have entered into possession of a product that is the result of a careful design and advanced production systems ensuring high-top operational reliability and saving. Read carefully this guide in order to know any detail concerning the product’s operation system. The “lamborgh...

12 general instructions ● this booklet constitutes an integral and essential part of the product and should be preserved for any further consultation. Read carefully the instructions contained in this booklet as they provide important directions regarding the operation of the appliance, allowing a g...

13 instructions for the use ● in case of breakdown and/or malfunctioning of the appliance, disconnect it avoiding any attempt of repair or direct intervention. Call exclusively professionally qualified personnel. Any repair must be carried out by an after-sale service centre “lamborghini service” au...

14 checks and maintenance ● before starting up the boiler ask qualified personnel “lamborghini service” to check: a) that the data on the information plate corresponds to that required by the gas, electrical and water supply networks; b) that the pipes which branch off from the boiler are lined with...

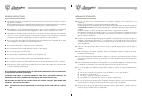

15 dimensions mm control panel 1 main switch 2 summer/winter selector 3 boiler “reset” key 4 data display 5 “mode” key to select the program 6 “step” key to select parameters to be displayed 7 “store” key to save data 8 “+” key to increase settings 9 “-” key to reduce settings 10 hydrometer 11 hot w...

16 adjustments 1) press (mode) . An indicator light on the left-hand display comes on. 2) press (step) to phase 4. 3) press the (+) (-) buttons to modify the hot water temperature. 4) press (store) to memorise the data. 5) press (mode) twice to enter the new temperature setting. Button function on/o...

17 the boiler control box is equipped with a microprocessor that memorises and signals any faults or shutdowns. The fault type is indicated by a flashing code. The meaning of each code is given in the table below: fault code 1 st figure fault 2 nd figure 0 1 2 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4...

18 should there be a fault the system will shut down and flash the fault type on the display. Check for proper operating conditions (gas tap open, proper feed pressure etc.) and press reset. Should the fault persist contact your local lamborghini assistance centre. Resetting 23 dimensiones mm tabler...

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50374.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...