User’s manual spinnit ebm 2.1 manual paper drill before operating this equipment, please read these instructions completely and keep these operating instructions for future reference. 485 hague street, rochester, ny 14606 u.S.A. Tel: 585-436-1934 fax: 585-464-8665 www.Lasscowizer.Com info@lasscowize...

Table of contents 1 - introduction 1.1 1.2 1 - introduction 1.1 - your new ebm-2.1 paper drill 1.2 - shipping damage inspection remove the machine from the carton and inspect for any shipping damage. If any damage is present, report the damage to the carrier immediately; failure to do so may void an...

2 - safety 2.1 - safety instructions page 02 all operators must read and understand the users manual including all safety instructions before using this equipment. Failure to fully understand the safety instructions can result in personal injury. If after reading the manual you are still uncertain a...

Avertissement: ne pas exposer À la pluie et ne pas utiliser dans les emplacements humides 2 - safety 2.2 - warning labels page 03 warning: do not expose to rain or use in damp locations. English french.

Page 04 in the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a match...

Page 05 3 - setting up your machine 3.1 - loose items inventory please remove and inspect the following items: 3.2 - accessories warning use recommended accessories. Only use accessories approved by a lassco-wizer. The use of improper acces- sories may cause risk of injury to persons. Fm4-4007: side...

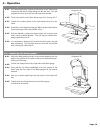

3 - setting up your machine 3.3 - installing the table assembly page 06 grasping the table and depressing the release handles to unlock the release pin, slide the v-bars located on the underside of the table into the v-rollers on the base of the machine as shown. Please note that one of the table st...

3 - setting up your machine 3.4 - assembly and installation of the back-gauge page 07 3.4.1 diagram 3-50 assemble the backgauge by placing the black fiber washer (ebm-76) over the threaded stud. Place the clamp bracket (ez-1028) on the threaded stud with the knob end toward the center of the assembl...

3 - setting up your machine 3.6 - installing the chip bag page 08 3.6.1 3.6.2 attach the chip bag as shown by stretching the open end over the top hook of the chip chute. Continue fitting it around the entire edge of the chip chute making sure it is snug. Be sure to empty the chip bag regularly as ne...

Page 09 4 - operation 4.1 - protective guard 4.2.1 4.2.2 4.2.3 4.2.4 4.2.5 4.2.6 4.2.7 caution: drill bits may be hot after use. Allow drill bits to cool down before touching. Before removing or installing the drill bits, disconnect or lock-out the power supply. 4.2 - drill bit removal and installat...

4 - operation page 10 4.3 - leveling the drill bits 4.3.1 4.3.2 4.3.3 4.3.4 4.3.5 4.3.6 we recommend using a piece of card stock on the table when leveling the drill bits to avoid drilling into the drill strip. This will lengthen the life of your drill bits and keep them sharper. To level the drill ...

4 - operation 4.5 - drilling procedures page 11 4.5.1 when you are ready to drill, set the product to be drilled on the table and make sure it is secure using the paper side stops. Turn the machine on and holding the product firmly in place with one hand, pull down on the handle raising the table up ...

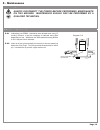

5 - maintenance page 12 5.2 - annual lubrication 5.2.1 5.2.2 diagram 5-10 lubricating your ebm-2.1 should be done at least once every 12 months; however, it may be necessary to lubricate more often depending on use. Whenever the table starts becoming difficult to lift, it may be time to lubricate. In...

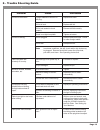

6 - trouble shooting guide 6.1 - determining the cause and correction to certain problems page 13 problem cause correction drill bit not concentric. Foreign material in chuck or in drill plug. Inspect and clean. Drill bit is bent. Replace drill bit. Drill bit not seated in chuck properly. Reinsert d...

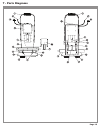

7 - parts diagrams 7.1 - front, rear, and side views page 14.

7 - parts diagrams 7.2 - internal views page 15.

7 - parts diagrams 7.3 - parts list page 16 ez-108a: handle assembly fm5-5006: rocker switch (on/off) ez-117a: shroud assembly fmm5-5514: chuck fm5-5011: chuck release guard hollow drill bit ebm2-0111a: pressure foot assembly 3s-14: table scale ez-1010l: table release handle (left) ez-1010r: table r...