- DL manuals

- Magmaweld

- Welding System

- RS 200 MK

- User Manual

Magmaweld RS 200 MK User Manual

Summary of RS 200 MK

Page 1

User manual mig/mag welding machine www.Magmaweld.Com rs 200 mk rs 300 mk rs 400 mk.

Page 2

Rs 200 mk / rs 300 mk / rs 400 mk 1 contents safety rules 1. Technical informations 1.1 general explanations 1.2 components of rs 200 mk / rs 300 mk / rs 400 mk 1.3 data plate 1.4 technical specifications 1.5 accessories 2. Installation 2.1 upon receipt and claims 2.2 installing and working reccomen...

Page 3

Rs 200 mk / rs 300 mk / rs 400 mk 2 identifying safety information these symbols are being used to identify potential risks. When seen a safety symbol in the manual, it must be understood that there is an injury risk and following instructions must be read carefully to avoid potential risks. While w...

Page 4

Safety rules breathing welding fumes can be hazardous to your health inhaling fumes and gases over a long period of time, generated during welding is dangerous and forbidden . Irritation of the eyes, nose and throat are symptoms of inadequate ventilation. Take immediate steps to improve ventilation....

Page 5

Safety rules noise can damage hearing noise from certain industrial processes or equipments can damage hearing. Wear approved ear protection if noise level is high. Working in small and confined places can be dangerous while welding and cutting in small, confined places, always have a trained watchp...

Page 6

Safety rules falling unit can cause injury wrong positioned power source or other equipment may cause serious injury to persons or damage to objects. While repositioning the power source always carry by using the lifting eye. Never pull cable, hose or torch. Always carry the gas cylinders separately...

Page 7

1.2 components of rs 200 mk / rs 300 mk / rs 400 mk technical information 1. Technical information 1.1 general explanations rs 200 mk, rs 300 mk, rs 400mk are 3 phase step controlled, constant voltage industrial compact mig/mag machines to weld all types of solid and flux cored wires in any kind of ...

Page 8

45 a / 16 v - 400 a / 34 v x 45 % 60 % 100 % 350 a 270 a 31,5 v 27,5 v cl.I. H u v 380 50 hz 1 s 1 ip 21 i a 22 1 i a 15 1 14,5kva 9,9 kva s t 32 a u v 18,5 - 45 0 i 2 u 2 3 r rs 400 mk 400 a 34 v i a 28 1 18,5kva 3 r seri no : en 60974-1 en 60974-10 magma mekatronİk makİne san. Ve tİc. A.Ş. Organiz...

Page 9

Rs 300 mk rs 200 mk rs 400 mk 1.5 accessories v kva a a v a a dc dc dc mm kg mm m/min 380 9.9 15 3x16 19 - 44 40 - 300 250 3x7 890x510x950 95 ip21 0.8/1.0 380 14.5 22 3x32 18,5 - 45 45 - 400 350 4x7 890x510x950 116 ip21 1.0/1.2 2 - 20 2/4 1 - 20 2/4 1.4 technical specifications technical information...

Page 10

2. Installation installation 2.1 upon receipt and claims ú ú ú ú standard pallet contains: power source earth cable gas hose user manual 2.2 installation and working recommendations • use lifting eyes or fork-lift to carry the machine. Do not lift the machine together with the gas cylinder. Transpor...

Page 11

2.4 welding connections 2.4.1 earth clamp connections figure 4: earth clamp connections connect the earth cable to one of the earth clamp sockets on the power source very tight. Sockets with different inductance values help the machine to weld with less spatter at a wider current range. For the smal...

Page 12

Rs 200 mk / rs 300 mk / rs 400 mk 11 before plugging your machine to the electrical line check with a voltmeter the correct voltages indicated at the plate of the machine and then insert the plug into the socket. Switch on the machine via power switch . Observe the fan noise and illumination of the ...

Page 13

3.5 loading the wire spool and threading the wire figure 15: loading the wire spool unscrew the spool support nut . Place the mig/mag wire spool through the spool support and screw the spool support nut tightly. (figure 15). (33) (34) (35) (33) 34 33 35 figure 16: threading the wire 3.4 choosing and...

Page 14

3.6 adjusting the gas flow practical adjustment of the gas flow rate (co , ar, mix) is 10 times of the diameter of the wire. Diameter of the wire: 1,2 mm gas flow rate: 10 x 1,2 = 12 lt/min 2 example: unlock the wire pressure assembly during gas flow adjustment. For accurate gas flow rate adjustment...

Page 15

4. Welding welding in order to obtain good welding characteristics, free wire length has to be adjusted by the following instructions. The diameter of the wire and the distance between the nozzle and the contact tip is important. Figure 20: arc lengths short arc globular transfer spray arc d d d 0-3...

Page 16

Welding 1 1 2 7.1 80 18 1 1 2 7.1 80 18 1 1 2 7.1 80 18 1 1 2 7.1 80 18 1 1 2 7.1 80 18 1 1 2 7.1 80 18 1 1 2 7.1 80 18 2 1 4 8.3 90 19 2 1 4 8.3 90 19 2 1 4 8.3 90 19 2 1 4 8.3 90 19 2 1 4 8.3 90 19 2 1 4 8.3 90 19 2 1 4 8.3 90 19 3 1 7 13 120 20 3 1 7 13 120 20 3 1 7 13 120 20 3 1 7 13 120 20 3 1 ...

Page 17

Open the covers of the machine and clean with dry air. Or 5. Maintenance and troubleshooting 5.1 e periodic maintenanc clean the labels on the m a c h i n e . R e p a i r o r replace the worn out labels. Repair or replace the worn out welding cables. Clean and tighten the weld terminals. Check the i...

Page 18

5.3 troubleshooting trouble reason remedy maintenance and troubleshooting machine does not work. Contact your authorized technical service. Wire feeder doesn’t work. Torch doesn’t perform the triggering. Wire feeder works but wire is not fed. The drive roll is not appropriate for the wire diameter. ...

Page 19

Spare parts list for rs 200 mk / rs 300 mk / rs 400 mk appendix 1 1 2 4 3 6 7 8 9 1 1 12 10 5 } 13 14 15 16 17 26 27 18 19 20 21 22 23 24 25 28 rs 200 mk / rs 300 mk / rs 400 mk 18.

Page 20

Spare parts list for rs 200 mk / rs 300 mk / rs 400 m k appendix 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 no changeover switch (1-7) wire feeding speed adjustmend knob potentiometer - 10k w elding socket 35-70 switch for 2/4 function selection electronic board - e...

Page 21

Description abbreviation s1 s2 tr1 tr2 f1 f2 f3 f4 p1 m1 m2 v1 c1 br1 l1 coarse step switch fine step switch main transformer control transformer fuse - wire feeding motor and wire feeding card - cooling ventilator - co heater fuse fuse 2 (500va) 380/220-42-28-0/15-0 list of the components in the el...

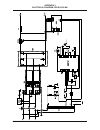

Page 22

Electrical diagram for rs 200 mk appendix 3 earth torch switch wire speed 2-4 switch rs 200 mk / rs 300 mk / rs 400 mk 21.

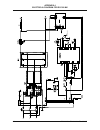

Page 23

Electrical diagram for rs 300 mk appendix 4 earth torch switch wire speed 2-4 switch rs 200 mk / rs 300 mk / rs 400 mk 22.

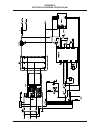

Page 24

Electrical diagram for rs 400 mk appendix 5 earth torch switch wire speed 2-4 switch rs 200 mk / rs 300 mk / rs 400 mk 23.

Page 25

+90 236 226 27 00 +90 236 226 27 28 factory made in tÜrkİye organize sanayi bölgesi 5.Kısım 5503. Sokak no:1 manİsa www.Magmaweld.Com owm 05.12.2011.