- DL manuals

- MakerBot

- Printer

- Replicator 2X

- User Manual

MakerBot Replicator 2X User Manual

Summary of Replicator 2X

Page 3: Table of Contents

A welcome, let’s get started. 04 specifications 06 how it works 07 b setting up your makerbot replicator 2x experimental 3d printer 08 what’s in the box 10 makerbot replicator 2x diagrams 11 unpacking your makerbot replicator 2x 13 installing enclosure door handle 15 installing filament guide tubes ...

Page 4

Welcome, let’s get started. A.

Page 5

05 warning: the makerbot replicator 2x experimental 3d printer generates high temperatures and includes moving parts that can cause injury. Never reach inside the makerbot replicator 2x while it is in operation. Always allow the makerbot replicator 2x to cool down before reaching inside. Warning: do...

Page 6: Specifications

06 a welcome, let’s get started. Printing print technology: fused filament fabrication build volume: 9.7”w x 6.4”l x 6.1”h [24.6 cm x 16.3 cm x 15.5 cm] high 100 microns [0.0039 in] medium 270 microns [0.0106 in] low 340 microns [0.0133 in] positioning precision: xy: 11 microns [0.0004 in]; z: 2.5 m...

Page 7: How It Works

07 a welcome, let’s get started. The makerbot replicator 2x experimental 3d printer makes solid, three-dimensional objects out of melted makerbot filament. Your 3d design files are translated into instructions for the makerbot replicator 2x and sent to the machine via usb cable or sd card. Then the ...

Page 8

Setting up your makerbot ® replicator ® 2x experimental 3d printer b.

Page 9

09 when you set up your makerbot ® replicator ® 2x experimental 3d printer, remember that it was built and packaged very carefully at the makerbot factory. We hope you’ll take your time and be just as careful unpacking it and getting set up. Note: do not force or tear anything during unpacking and s...

Page 10: What’S In The Box

10 b setting up your makerbot replicator 2x experimental 3d printer what’s in the box makerbot abs filament [1lb spools] 2 2 2 1 spool holders handle and bolts filament guide tubes power supply and cable 1 1 3 1 makerbot tape applicator kapton tape sheets usb-a to usb-b cable sd card 1 4 1 1 ptfe-ba...

Page 11

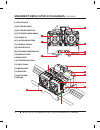

11 b setting up your makerbot replicator 2x experimental 3d printer makerbot replicator 2x diagrams [1] gantry system [2] lcd panel [3] heated build plate [4] build platform [5] threaded z-axis rod [6] enclosure door handle [7] filament guide tubes [8] extruder cable [9] extruders [10] filament spoo...

Page 12

12 b setting up your makerbot replicator 2x experimental 3d printer makerbot replicator 2x diagrams continued [1] fan guards [2] extruder fans [3] extruder nozzles [4] extruder lever arms [5] fan bolts [6] cartridge heaters [7] thermal cores [8] drive blocks [9] extruder cable mount [10] motor cable...

Page 13

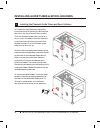

13 unpacking your makerbot replicator 2x 1a. Place the makerbot replicator 2x box on the ground. Open the box and remove the top cardboard sheet. 1b. Remove the makerbot replicator 2x user manual. We recommend that you review the manual to guide you through the setup process and keep it handy as you...

Page 14

14 b setting up your makerbot replicator 2x experimental 3d printer unpacking your makerbot replicator 2x continued 3a. Remove the two remaining protective foam pieces from the bottom of the makerbot replicator 2x’s box. 3b. Lift out the accessory box. This box contains the remaining items from the ...

Page 15

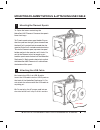

15 installing the enclosure door handle b setting up your makerbot replicator 2x experimental 3d printer 5a. Locate the handle kit in the accessory box. The kit includes your enclosure door handle and two buttonhead bolts. 5b. Open the enclosure door. To do this, reach through the top of the makerbo...

Page 16

16 b setting up your makerbot replicator 2x experimental 3d printer installing guide tubes & spool holders 6a. Locate the two filament guide tubes. Insert one end of a filament guide tube into the hole in the top of one of the extruders. Push the filament guide tube in as far as it will go. Insert t...

Page 17

17 mounting filament spools & attaching usb cable b setting up your makerbot replicator 2x experimental 3d printer 7a. Open the boxes containing the makerbot abs filament. Remove the spools from their bags. 7b. Fit each spool onto a spool holder. Ensure that the spool on the right [when viewed from ...

Page 18: Installing Enclosure Lid

18 b setting up your makerbot replicator 2x experimental 3d printer installing enclosure lid 9a. Locate the box containing the acrylic enclosure lid. The enclosure lid is shipped in a separate box and is not included in the same box as your makerbot replicator 2x. The box containing the enclosure li...

Page 19

10a. Locate the power supply and cable. Attach the cable to the power supply. 10b. Ensure that the power switch on the makerbot replicator 2x is set to the off position. 10c. Insert the power supply connector into the power input port on the back of the makerbot replicator 2x. Ensure that the flat s...

Page 20

Startup process: leveling, loading, testing c.

Page 21

21 the lcd keypad • four arrow buttons surround a central m button. Use the arrows to navigate through the lcd menus and the m button to make selections. • the left arrow often allows you to go back or cancel an action. • a solid red m means the makerbot replicator 2x is working. • a blinking red m ...

Page 22: Leveling The Build Plate

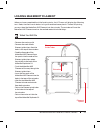

22 after the initial welcome message, the startup script will display the following: • if the build plate is too far from the extruder nozzles, or if one part of the plate is farther away from the nozzles than another part, your 3d prints might not stick to the build plate. • if the build plate is t...

Page 23: Leveling The Build Plate

23 leveling the build plate continued c startup process: leveling, loading, testing when directed by the lcd screen, tighten each of the three knobs underneath the build platform approximately four turns. To do this, you will need to raise the build platform. Grasp the black plastic arms at the side...

Page 24: Leveling The Build Plate

24 leveling the build plate continued c startup process: leveling, loading, testing the script will prompt you to adjust the knobs individually. As you adjust each knob, make sure the makerbot support card just slides between the nozzles and build plate. You should feel some friction on the support ...

Page 25: Loading Makerbot Filament

25 loading makerbot filament c startup process: leveling, loading, testing when you have completed the initial leveling tasks, the lcd menu will display the following text: “aaah, that feels much better. Let’s go on and load some plastic!” before 3d printing, you must load the makerbot abs filament ...

Page 26: Loading Makerbot Filament

26 loading makerbot filament continued locate where the filament guide tubes attach to the extruders. You must remove each filament guide tube from its hole in the top of the extruder. To remove the tubes, gently pull them out of the extruders. 2 detach the filament guide tubes c startup process: le...

Page 27: Loading Makerbot Filament

27 c startup process: leveling, loading, testing ensure that you feed the filament from the spool on the right side of the makerbot replicator 2x into the filament guide tube on the right side, and that you feed the filament from the spool on the left into the filament guide tube on the left. Feed t...

Page 28

28 aft er the extruders reach 230° c, the lcd panel will prompt you to load the makerbot abs filament into the right extruder. Click through the message until your makerbot replicator 2x asks you to press the m when you see plastic extruding. 5 press the m to continue loading makerbot abs filament c...

Page 29

29 c startup process: leveling, loading, testing watch the right extruder nozzle. After a few moments, you should see a thin string of the makerbot abs filament that you loaded come out of the nozzle. Press the m button to stop extrusion. Note: don’t be surprised if the filament that initially comes...

Page 30

30 loading makerbot abs filament continued c startup process: leveling, loading, testing push the guide tubes back into the openings on the tops of the extruders. 11 return the filament guide tubes watch the left extruder nozzle. After a few moments, you should see a thin string of the makerbot abs ...

Page 31

31 c startup process: leveling, loading, testing loading makerbot abs filament continued wait a few minutes for the extruded abs plastic to cool, then pull it away from the nozzles. You can discard this extra plastic. Don’t touch the nozzles; they may still be hot. Don’t leave plastic clinging to th...

Page 32

32 c startup process: leveling, loading, testing after you have successfully leveled the build platform and loaded the makerbot abs filament into the extruders, the lcd panel will ask you: “how’d it go? Ready to make something?” select “yes” and the lcd panel will display: “awesome! We’ll go to the ...

Page 33

33 c startup process: leveling, loading, testing making a test object from the sd card continued test objects available on the sd card chain links file name: chain links make time: 12 minutes design by: sal thingiverse: 28405 nut and bolt set file name: nut and bolt make time: 27 minutes design by: ...

Page 35: Notes

35 notes c startup process: leveling, loading, testing.

Page 36

Making an object with makerbot makerware d.

Page 37

37 how to make an object using a computer and makerbot ® makerware ™ . D making an object with makerbot makerware ™.

Page 38: Using Makerware

38 using makerware d making an object with makerbot makerware 1c. Open the installer and follow the directions to install the software. 1d. Use the supplied usb cable to connect your makerbot replicator 2x to your computer. 1a. Go to the computer you plan to connect to your makerbot replicator 2x an...

Page 39: Using Makerware

39 thingiverse is a website where makerbot users and others can share design fi les. 2a. Open a browser session and go to thingiverse.Com. Use the search fi eld at the upper right to search for “minimalist nyc buildings.” your search results should include “minimalist nyc buildings by jonmonaghan.” ...

Page 40: Using Makerbot Makerware

40 using makerbot makerware continued 3 open makerware [1] camera home: resets makerware to the default view of the object. [2] +/-: zoom in and out. You can also use the scroll wheel on your mouse to zoom in and out. [3] look: click the look button or hit the l key to go into look mode. In this mod...

Page 42: Using Makerbot Makerware

Minimalist nyc buildings design by: jonmonaghan thingiverse: 12762 42 4a. Click on the add button. Navigate to the location of the file flatiron.Stl and select it. The file will open at the center of the build plate. 4b. Select the move button and click and drag the flatiron building to the left. 4c...

Page 43: Using Makerbot Makerware

43 4e. Click on the flatiron building to select it. Hold down the shift key and click on the woolworth building. Then release the shift key. Both models should be selected. 4f. Select the scale button. Click and drag to change the size of both models together. 4 open the .Stl files in makerbot maker...

Page 44: Using Makerbot Makerware

44 tip: if you plan to print from an sd card instead of directly from makerware, select “export to a file” at the top of the make dialog instead of “make it now.” if your makerbot replicator 2x is not connected to your computer, “export to file” will be selected automatically. 5 save and make your f...

Page 45: Using Makerbot Makerware

5c. Accept the default settings and click the make it! Button. Makerware will slice your model and send it to your makerbot replicator 2x for 3d printing. Tip: you can cancel a slice or print by clicking the x at the corner of the slicing progress bar or the cancel button in the status submenu. 5 sa...

Page 46

E troubleshooting, diagnostics, and maintenance.

Page 47

47 this chapter describes basic troubleshooting and maintenance tasks. For details on more advanced troubleshooting and maintenance tasks, go to makerbot.Com/support. E troubleshooting, diagnostics, and maintenance.

Page 48: Troubleshooting

Can’t load makerbot filament into the extruder(s) run the unload script to heat your extruder and set the extruder lever arm to the open position. The extruder lever arm is open when it points out towards the side of the makerbot replicator 2x and closed when it points in towards the other extruder....

Page 49: Troubleshooting

Problem solution 49 e troubleshooting, diagnostics, and maintenance troubleshooting continued extruder makes a clicking noise when loading makerbot filament this may mean your extruder is blocked. Try unloading and reloading your makerbot filament. If you have trouble reloading, you may have a piece...

Page 50: Extruder Disassembly

50 e troubleshooting, diagnostics, and maintenance extruder disassembly problem solution troubleshooting continued object won’t stick to build plate (continued) if you continue to have adhesion problems, loosen each of the plate-leveling knobs about a quarter of a turn to bring the plate slightly cl...

Page 51: Extruder Disassembly

51 e troubleshooting, diagnostics, and maintenance extruder disassembly continued 5. Unplug the motor wire harness from the top of the extruder motor and slide the motor assembly out of the extruder. 6. The extruder is now broken down into its main assemblies. To remove any filament stuck in the the...

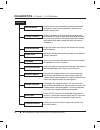

Page 52: Diagnostics

Utilities monitor mode displays the current temperature of the extruder and build plate. When printing an object, displays the percent completed. Level build plate script that walks you through the process of leveling the build plate. Home axes moves the build plate and the extruder to the default “...

Page 53: Diagnostics

53 e troubleshooting, diagnostics, and maintenance info and settings bot statistics displays the estimated total hours and minutes of building in the lifetime of your makerbot replicator 2x and the duration in hours and minutes of the last build. General settings optional settings and information. S...

Page 54: Diagnostics

54 e troubleshooting, diagnostics, and maintenance over time, the kapton tape on your build plate will be scratched and torn and you will need to replace it with one of the die-cut kapton sheets that came in the makerbot replicator 2x package. 1. Peel off the old kapton tape and discard it. 2. Take ...

Page 55: Maintenance

55 e troubleshooting, diagnostics, and maintenance maintenance continued 4. Peel off the plastic backing bit by bit, smoothing the newly exposed kapton tape as you go. Use the tape applicator from the makerbot replicator 2x package to remove bubbles. If you don’t have the tape applicator, use a cred...

Page 56: Maintenance

56 e troubleshooting, diagnostics, and maintenance maintenance continued 8. Squeeze a small amount of the ptfe- based grease directly onto the exposed area of the dowel inside the idler pulley and manually move the pulley back and forth to spread the grease. Lubricating the threaded rod and the x-ax...

Page 57: Glossary Of Terms

Glossary of terms 57 e troubleshooting, diagnostics, and maintenance abs: acrylonitrile butadiene styrene is a widely used thermoplastic, and the primary material used for making things on the makerbot replicator 2x. Build platform: the support for the heated build plate. The build platform includes...

Page 58: Glossary Of Terms

Glossary of terms continued 58 e troubleshooting, diagnostics, and maintenance makerbot filament: 1.75mm diameter plastic welding rod. This is the feedstock for your makerbot replicator 2x. Makerbot filament comes in abs, pla and pva plastics. The replicator 2x is optimized for abs. Makerware: free ...

Page 59: Contact Us

Contact us 59 e troubleshooting, diagnostics, and maintenance support sales feedback makerbot.Com/support our website has extensive documentation and troubleshooting information about your makerbot replicator 2x experimental 3d printer. It’s a great resource when you want to try to solve issues quic...

Page 60: Terms Of Service

60 f terms of service terms of service please read these terms of service (“terms”) carefully before using this website or ordering from makerbot industries, llc (“makerbot”). Your use of the website www.Makerbot.Com (“website”) confirms your unconditional acceptance of the following terms. If you d...

Page 61: Terms Of Service

61 f terms of service terms of service continued attributes than those listed, or may actually carry a different price than that stated on this website. In addition, we may make changes in information about price and availability without notice. 5. Use of website. The design of this website and all ...

Page 62: Terms Of Service

62 f terms of service transmission, disclosure, publication, broadcast, development, manufacturing and/or marketing in any manner whatsoever for any or all commercial or non-commercial purposes. We may, but are not obligated to, monitor or review any user communications. We will have no obligation t...

Page 63: Terms Of Service

Equipment, or other property caused by or arising from your access to, use of, or browsing this website, or your downloading of any information or materials from this website. In no event will makerbot industries or any of its respective officers, directors, employees, shareholders, affiliates, agen...

Page 64

Makerbot one metrotech center, 21st floor, brooklyn, ny support@makerbot.Com makerbot.Com.