Max. Output(w) battery voltage: v cell and capacity capacity : mm ( " ) charging time: min. 330 0 - 1,100 0 - 4,000 18 li-ion 3.0 ah yes yes yes yes 10 (3/8) 13 (1/2) 26 (1-1/16) 20 (13/16) 3.2 (7.0) including battery bl1830 [3.5 (7.7) measured by epta regulation] 22 with dc18ra models no. Descripti...

P 2/ 14 [1] necessary repairing tools caution: remove the battery and the bit from the machine for safety before repair/ maintenance in accordance with the instruction manual! R epair description code no. 1r003 retaining ring s pliers sr-2 removing / installing ring spring 19 removing ring spring 29...

[2] lubrication (cont.) r epair p 3/ 14 fig. 2 item no. Description portion to lubricate lubricant amount striker ball bearing 606zz compression spring 7 disassemble tool holder section as illustrated in fig. 3. Retaining ring s-7 piston joint armature flat washer 12 swash bearing section 40 41 51 5...

R epair p 4/ 14 [3] disassembly/assembly [3] -2. Change lever disassembling assembling change lever drill mode lock button pushing lock button into change lever, turn change lever fully to drill mode until it stops. Remove change lever by levering up it with slotted head screwdriver, inserted betwee...

R epair p 5/ 14 bearing room of gear housing complete 4x40 tapping screws (4 pcs.) gear housing complete holder cap cover motor housing complete ball bearing 6000ddw of armature (behind the fan) [3] disassembly/assembly [3] -4. Armature 1) remove holder cap cover by inserting slotted screwdriver bet...

R epair p 6/ 14 [3] disassembly/ assembly [3] -5. Torque limiter section (cont.) assembling do the reverse of disassembling steps. Note: do not forget to assemble flat washer 28 between torque limiter section and inner housing complete. Refer to fig. 12. [3] disassembly/assembly [3] -6. Needle beari...

R epair p 7/ 14 disassembli ng 1) referring to "[3] -5. Torque limiter section", disassemble ring spring 29, washer 31, compression spring 32 and spur gear 51 from tool holder complete. Refer to figs. 11 to 14. 2) holding gear housing complete in vise and 1r038, tap ring spring 28 in tool holder com...

[3] disassembly/assembly [3] -7. Impact bolt section (cont.) disassembling assembling fig. 29 note: use an extra piston cylinder as a jig. Never use piston cylinder that is to be assembled to the machine. 2) push ring spring 28 with piston cylinder until it fits to the inner groove of tool holder co...

[3] disassembly/assembly [3] -8. Swash bearing section (cont.) disassembling fig. 32 fig. 33 6) move piston cylinder to the rear dead center position (fig. 32). 7) remove swash bearing section from inner housing by pulling in the direction of the arrow. Then, remove change plate from the groove of c...

[3] disassembly/assembly [3] -8. Swash bearing section (cont.) disassembling assembling 1r032 1r033 fig. 39 swash bearing 10 helical gear 26 retaining ring s-7 compression spring 7 spur gear 10 cam shaft cam shaft clutch cam 1) assemble swash bearing section using 1r032, 1r033, 1r291 and arbor press...

[[3] disassembly/assembly [3] -8. Swash bearing section (cont.) r epair assembling p 11/ 14 4) move piston cylinder to the rear dead center position. (fig. 42) 5) insert the pole of swash bearing 10 into the hole of piston joint as illustrated in fig. 43. 6) insert ring 8 (the end of swash bearing s...

R epair oval hole of f/r change lever protrusion of switch p 12/ 14 [3] disassembly/assembly [3]-9. F/r change lever, wave washer, cushion and rubber pin 5 in housing set fit the protrusion of switch into oval hole of f/r change lever and assemble them to housing l. Assembling refer to fig. 47. Rubb...

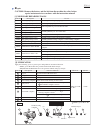

P 13/ 14 m aintenance program it is recommended to replace the following parts shown below and apply lubricant to the specific parts designated in figs.2 and 3 when replacing carbon brushes. 1 cap 35 40 o ring 16 38 ring spring 28 29 steel ball 7.0 35 cushion ring 13 37 o ring 9 c ircuit diagram red...

P 14/ 14 w iring diagram brush holder rib a route all of the fet lead wires on the right side of rib a. Terminal heat sink fet yoke unit bend connecting terminal to housing set (l) side as illustrated above. Switch fix the brush holder’s lead wires (red and black) with lead wire holder. Switch put t...