- DL manuals

- Napoleon

- Stove

- NPI45

- Installation And Operating Instructions Manual

Napoleon NPI45 Installation And Operating Instructions Manual

W415-0702 / B / 04.04.12

1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

1.12D

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleonproducts.com

SAFETY INFORMATION

!

WARNING

PLEASE READ ENTIRE MANUAL

BEFORE YOU INSTALL OR USE THIS

PELLET BURNING HEATER.

If the heater is not properly installed, a

house fi re may result causing personal

injury or loss of life.

- Authorities having jurisdiction (such as

municipal building department, fi re department,

fi re prevention bureau, etc.) should be consulted

before installation to determine the need to obtain

a permit.

- Contact local building or fi re offi cials about

restrictions and installation inspection

requirements in your area.

- This heater is hot while in operation. Keep

children, clothing and furniture away. Contact may

cause skin burns.

- Do not start a fi re with chemicals or fl uids such

as gasoline, engine oil, etc...

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

$10.00

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

!

WARNING

This appliance has been tested to ASTM E 1509, UL 1482, ULC S627 AND ULC S628.

NPS45

PELLET STOVE

NPI45

PELLET INSERT

Summary of NPI45

Page 1

W415-0702 / b / 04.04.12 1 installer: leave this manual with the appliance. Consumer: retain this manual for future reference. Never leave children or other at risk individuals alone with the appliance. Installation and operating instructions 1.12d wolf steel ltd., 24 napoleon rd., barrie, on, l4m 0...

Page 2: Table of Contents

W415-0702 / b / 04.04.12 2 note: changes, other than editorial, are denoted by a vertical line in the margin. Table of contents 1.0 installation overview 3 1.1 stove 3 1.2 insert 4 2.0 introduction 5 2.1 dimensions 6 2.1.1 stove 6 2.1.2 npi45 complete with ni800 flashing 6 2.1.3 npi45 complete with ...

Page 3: 1.0 Installation Overview

W415-0702 / b / 04.04.12 3 1.0 installation overview rating plate, see “rating plate information” section. Venting, see “venting” and “installation planning” sections. Floor, see “installation planning - floor protection requirements” section. See “outside air” section. Door, see “installing viewing...

Page 4

W415-0702 / b / 04.04.12 4 1.2 insert see the section minimum mantel clearances” drywall (or other combustible material) see the sections “venting” and “installation planning” see the section “enclosure clearances” side wall see the section “minimum clearances to combustibles” see the section “insta...

Page 5: 2.0 Introduction

W415-0702 / b / 04.04.12 5 2.0 introduction 3.8b ! Warning • this appliance is hot when operated and can cause severe burns if contacted. • do not operate appliance before reading and understanding operating instructions. Failure to operate appliance according to operating instructions could cause f...

Page 6

W415-0702 / b / 04.04.12 6 2.1 dimensions 22 3/8” 30 1/2” 22 3/8” 9 7/8” 11 3/4” 17 3/8” 1 1/8” 22 1/2” 26 5/8” 2.1.1 stove 2.1.2 npi45 complete with ni800 flashing 26 1/2” 12 1/2” 38 3/8” 29 5/16” 7 5/8” 20 3/8” 8” 12 3/4” 12 1/2” 22 1/2” 38 3/8” *32 5/8” 20 5/8” 2 1/4” 11 3/16” 20 5/8” 21 1/2” 2 3...

Page 7

W415-0702 / b / 04.04.12 7 26 1/2” 10 5/16” 7 5/8” 20 5/8” 2 3/4” 20 3/8” 8” 13 3/8” 10 5/16” 22 1/2” 46 7/16” * 30 3/4” 20 5/8” 2 1/4” 10 1/2” 4 1/4” center line of exhaust center line of air intake *in order to install flashing flush to a finished wall and centered within the opening the front ope...

Page 8

W415-0702 / b / 04.04.12 8 26 1/2” 10 5/8” 7 5/8” 20 5/8” 2 3/4” 46 7/16” 31” 20 3/8” 8” 22 1/2” 46 7/16” * 32 5/8” 20 5/8” 2 1/4” 11 3/16” 4 1/4” center line of exhaust center line of air intake *in order to install flashing flush to a finished wall and centered within the opening the front opening...

Page 9: Warning

W415-0702 / b / 04.04.12 9 2.2 specifications all wiring should be done by a qualified electrician and shall be in compliance with local codes. In the absence of local codes, use the current csa c22.1 canadian electric code (in canada) or the ansi/nfpa no. 70 national electric code in the united sta...

Page 10: Warning

W415-0702 / b / 04.04.12 10 2.4 general information thank you for purchasing a wolf steel ltd. Pellet appliance. This appliance is designed for use with pelletized wood only. Please read this entire manual before installation and use of this pellet fuel-burning room appliance. Failure to follow thes...

Page 11

W415-0702 / b / 04.04.12 11 high limit switch: your appliance is equipped with a high limit switch. In the event that the temperature of the appliance approaches an unsafe operating temperature, this switch will shut down the pellet feed, which will eventually shut down the unit. If this happens, it...

Page 12: Sample

W415-0702 / b / 04.04.12 12 2.5 rating plate information for rating plate location, see “installation overview” section. This illustration is for reference only. Refer to the rating plate on the appliance for accurate information. Sample - install and use only in accordance with the manufacturer’s i...

Page 13: 3.0 Installation Planning

W415-0702 / b / 04.04.12 13 3.0 installation planning check with local building offi cials for any permits required for installation of this pellet appliance and notify your insurance company before proceeding with installation. Before installing we recommend placing the appliance outside and load 5...

Page 14: Warning

W415-0702 / b / 04.04.12 14 3.3 stove minimum clearance to combustibles through the wall installations complete with outside air interior vertical vents 3.3.1 straight installation do not install into any area having less than 48" (ceiling to appliance bottom, excluding hearth height). ! Warning thr...

Page 15

W415-0702 / b / 04.04.12 15 3.3.3 alcove installation requirements (minimum) minimum alcove dimensions 30” 48” 35” stove.

Page 16

W415-0702 / b / 04.04.12 16 99.2b thermal protector: this appliance must be installed on a non-combustible thermal protector that extends to the front, sides and back of the appliance as per the minimum requirements below. Note: floor protection is required for spark and ash shielding, and for limit...

Page 17: Warning

W415-0702 / b / 04.04.12 17 29.4a installation into a manufactured home or mobile home should be installed in accordance with the manufactured home construction and safety standard, title 24 cfr, part 3280, in the united states or the mobile home standard, can/csa z240 mh series, in canada. The appl...

Page 18: 4.0 Venting

W415-0702 / b / 04.04.12 18 4.0 venting 4.1 type of vent 4.2 installing the pellet vent 4.3 venting the pellet appliance must be an approved 3" or 4" diameter type "l" or "pl" vent, vented to the outside or connect the vent to a factory built type "a" chimney using an adaptor; and/or stainless steel...

Page 19

W415-0702 / b / 04.04.12 19 4.4 pellet vent termination the vent termination must have an approved cap (to prevent water from entering) or a 45° downturn. If the termination is located on a windy side of the house, a shield is recommended to prevent soot from build- ing up on the side of the house. ...

Page 20

W415-0702 / b / 04.04.12 20 4.5.1 horizontal exhaust through wall installation 4.5.2 through the wall with vertical rise / horizontal termination floor protection 12” minimum outside air (recommended) 6” minimum 3” minimum wall thimble 11 5/8” 5’ maximum 17” wall thimble outside air (recommended) 3”...

Page 21

W415-0702 / b / 04.04.12 21 4.5.3 minimum inside vertical clearances outside air (recommended) (installation showing inlet of out- side air in ventilated crawl space) ceiling support vent must maintain 3” clearance to combus- tibles. Vertical cap roof flashing storm collar floor protection 3” 2” 4.5...

Page 22

W415-0702 / b / 04.04.12 22 4.5.5 hearth mount installation floor protection 6” min clean-out tee outside air (recommended) floor protect recommended) out outside air (r storm collar vertical cap storm co chimney cap bring outside air to the heater pellet liner flue cover pellet vent for installatio...

Page 23: Warning

W415-0702 / b / 04.04.12 23 4.6 insert venting installation examples 4.6.1 typical existing masonry installation ! Warning prior to installation: when installing the insert into a masonry fi replace, do not remove any bricks or masonry. Do not weaken the structure, or reduce the protection for combu...

Page 24

W415-0702 / b / 04.04.12 24 4.6.2 factory built fireplace prior to installation: do not weaken the structure or reduce the protection for combustible materials to less then that required by the national building code. Bolted or screwed together pieces (smoke shelf / defl ectors) may be removed, but ...

Page 25: 5.0 Framing (Insert Only)

W415-0702 / b / 04.04.12 25 5.0 framing (insert only) ! Warning risk of fire! In order to avoid the possibility of exposed insulation or vapour barrier coming in contact with the appliance body, it is recommended that the walls of the appliance enclosure be “finished” (ie: drywall / sheetrock), as y...

Page 26: Warning

W415-0702 / b / 04.04.12 26 ! Warning 5.1 installation into a combustible enclosure outside air is mandatory for a combustible built-in enclosure install. When installing the insert as a "built-in" appliance, it is important to maintain the clearances to combustibles, see "minimum clearance to combu...

Page 27: Warning

W415-0702 / b / 04.04.12 27 5.2 minimum enclosure clearances 5.3 minimum clearance to combustibles ! Warning the stand-offs located on the back of the insert must not be removed when installing the insert into a built-in combustible enclosure. 6” non-combustible floor protection 40” 2 3/4” 7 5/8” 27...

Page 28: Warning

W415-0702 / b / 04.04.12 28 5.4 minimum mantel clearances ! Warning risk of fire, maintain all specified air space clearances to combustibles. Failure to comply with these instructions may cause a fire or cause the appliance to overheat. Ensure all clearances (i.E. Back, side, top, vent, mantel, fro...

Page 29: Warning

W415-0702 / b / 04.04.12 29 ! Warning glass may be hot, do not touch glass until cooled. The door latches are part of a safety system and must be properly engaged. Do not operate the appliance with latches disengaged. Before door is removed turn the appliance off and wait until appliance is cool to ...

Page 30

W415-0702 / b / 04.04.12 30 6.2 flashing installation a. Secure the right fl ashing to the right side of the appliance using two of the #8 x 1/2" screws. B. Remove the two control panel securing screws, discard the screws and shipping bracket. C. Secure the control panel to the right fl ashing using...

Page 31: 7.0 Wiring Diagram

W415-0702 / b / 04.04.12 31 7.0 wiring diagram ! Warning do not use this appliance if any part has been under water. Call a qualified service technician immediately to have the appliance inspected for damage to the electrical circuit. Risk of electrical shock or explosion. Do not wire 110v to the va...

Page 32: 8.0 Operating Instructions

W415-0702 / b / 04.04.12 32 8.0 operating instructions 8.1 proper pellet loading 8.2 start up cycle before loading pellets into the hopper fi rst transfer the pellets from it’s original plastic bag to a metal bucket. Keep in mind that the auger stops when the lid is opened. If the lid is opened for ...

Page 33

W415-0702 / b / 04.04.12 33 8.5 controls 8.4 lighting instructions after fi lling the hopper with pellets, switch the control to manual so that you have full control of the appliance until you have familiarized yourself with its functions. Do not try to operate your appliance with the viewing door o...

Page 34

W415-0702 / b / 04.04.12 34 8.6 control adjustment on / off use this button to turn the heater on and off. Heat pressing the heat up arrow (red) will increase the heat level one setting. Pressing the heat down arrow (white) will decrease the heat level one setting. During start-up the power light wi...

Page 35

W415-0702 / b / 04.04.12 35 8.7 installing a thermostat or remote control 8.8 shutdown instructions push the "on/off" button. Your appliance will cycle down and the blower will remain operating until your appliance has cooled. An optional millivolt thermostat is available to help keep the room tempe...

Page 36: 9.0 Normal Operating Sounds

W415-0702 / b / 04.04.12 36 9.0 normal operating sounds * * note: "quiet mode" (nps45 only) this feature disables the convection blower when the stove is in pilot/ standby mode regardless of control setting. The blower will activate during ignition to cool components then it will shut-down again. Wh...

Page 37: Warning

W415-0702 / b / 04.04.12 37 the front of the appliance becomes very hot during operation. Let the appliance cool completely before conducting service. ! Warning 10.0 maintenance 10.1 daily (whenever using the appliance) 40.2 ashes should be placed in a metal container with a tight fi tting lid. The ...

Page 38: Warning

W415-0702 / b / 04.04.12 38 with the appliance cool (or wearing heat resistant gloves), slide the heat exchange cleaner rod up and down several times to prevent the build up of ash on the heat exchange tubes. Keep the viewing door closed so the fl y ash does not enter the room. Note: more frequent c...

Page 39: Warning

W415-0702 / b / 04.04.12 39 to clean the burn pot, open the door and knock away any debris on the burn pot. If severely clogged, remove the burn pot to gain better access. If removing the burn pot set aside on a non-combustible surface. Once removed, discard all material that has accumulated in the ...

Page 40: Warning

W415-0702 / b / 04.04.12 40 the firebox becomes very hot during operation. Let the appliance cool completely before conducting service. Disconnect the power cord prior to conducting service. The following section details extensive maintenance procedures. We strongly suggest these items be carried ou...

Page 41

W415-0702 / b / 04.04.12 41 note: do not attempt this maintenance without a replacement exhaust blower motor mounting gasket. A. Remove the six nuts holding the exhaust blower motor in place. B. Pull the motor out being careful not to damage the wiring, unplug the two wires that are connecting the m...

Page 42: Warning

W415-0702 / b / 04.04.12 42 vent system should be cleaned using chimney sweep brushes. We recommend this be done by a qualifi ed chimney sweep. 40.13 flyash will deposit along sections that are horizontal make sure the cap is free of debris (especially if it has a screen that could become blocked). ...

Page 43: 11.0 Replacements

W415-0702 / b / 04.04.12 43 11.0 replacements contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally all parts can be ordered through your authorized dealer / distributor. For warranty replacement parts, a photocopy of the original invoice will...

Page 44

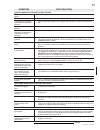

W415-0702 / b / 04.04.12 44 tp - replacements common components ref part no. Description 34 w460-0004 receptacle 36 w300-0038 glass, front 37 w300-0037 glass, side 38* w562-0022 glass gasket 39 w290-0122 exhaust gasket 40 w010-1612 exhaust collar 41 w010-0219 exhaust cover 43 w010-1673 right louvre ...

Page 45

W415-0702 / b / 04.04.12 45 nps45 accessories ref part no. Description 68* nphe-40 hopper extension (increases hopper capacity from 55 lbs to 100 lbs pellets) npi45 accessories ref part no. Description 69 ni800 8" black flashing with black trim 70* gicsk arched cast iron surround 71 ak8 adaptor kit ...

Page 46

W415-0702 / b / 04.04.12 46 12 10 16 15 26 25 22 2 29 13 14 5 28 24 27 40 39 41 42 7 8 21 1 3 33 9 11.1 common replacement parts.

Page 47

W415-0702 / b / 04.04.12 47 46 29 50 34 50 52 46 51 45 47 48 49 49 13 21 30 44 43 56 6 11.2 nps45 replacement parts.

Page 48

W415-0702 / b / 04.04.12 48 67 20 29 58 41 38 43 44 63 57 60 6 11.3 npi45 replacement parts.

Page 49

W415-0702 / b / 04.04.12 49 62 66 64 67 37 36 prpp40 npl41 63 69 71 73 ni800 ak9 ak8 11.4 common accessory parts 11.5 npi45 accessory parts.

Page 50: 12.0 Troubleshooting

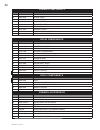

W415-0702 / b / 04.04.12 50 12.0 troubleshooting symptom test solution appliance shuts off and the #2 light flashes vacuum hose or fi ttings are blocked - unhook the air hose from the vacuum switch and blow through it. If air fl ows freely, the hose and tube are fi ne. If air will not fl ow through ...

Page 51

W415-0702 / b / 04.04.12 51 symptom test solution appliance shuts off and the #3 light flashes the hopper is out of pellets - refi ll the hopper. The hopper lid is open. - close the hopper lid the burnpot is not seated completely into the burner housing. - insure the burnpot locating notch engages w...

Page 52

W415-0702 / b / 04.04.12 52 symptom test solution convection blower shuts off and comes back on the convection blower is overheating and tripping the high limit switch - try lubricating the convection blower and clean any dust off the windings and fan blades. If lubricating the blower does not help,...

Page 53: 13.0 Warranty

W415-0702 / b / 04.04.12 53 13.0 warranty napoleon® warrants its products against manufacturing defects to the original purchaser only. Registering your warranty is not necessary. Simply provide your proof of purchase along with the model and serial number to make a warranty claim. Provided that the...

Page 54: 14.0 Service

W415-0702 / b / 04.04.12 54 14.0 service history 43.1.

Page 55: 15.0 Notes

W415-0702 / b / 04.04.12 55 15.0 notes 44.1.

Page 56

W415-0702 / b / 04.04.12 56.