- DL manuals

- NCR

- Printer

- 7156

- Service Manual

NCR 7156 Service Manual

Summary of 7156

Page 1

Ncr 7156 thermal receipt and impact slip printer: service guide bd20-1437-a issue b september 1997.

Page 2

September 1998 ii disclaimer information in this document is subject to change without notice. Therefore, before using this document, consult your ncr sales representative for information that is applicable and current. Ncr reserves the right to improve products as new technology, components, softwa...

Page 3

September 1998 iii important information to the user in order to ensure compliance with the product safety, fcc and ce marking requirements, you must use the power supply, power cord, and interface cable which were shipped with this product or which meet the following parameters: power supply ul lis...

Page 4

September 1998 iv federal communications commission (fcc) radio frequency interference statement warning changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment. Note this equipment has been tested ...

Page 5: Quick Reference

September 1998 v quick reference this quick reference will direct you to key areas of the service guide. For a complete listing of topics, consult the table of contents or the index. Setting up the printer page 7 basic requirements for unpacking and installation, connecting the printer, turning it o...

Page 6: How to Use This Book

September 1998 vi how to use this book use this book as a general and technical reference manual and as a guide when replacing parts on the printer. The service guide is intended as a guide for service representatives, field engineers, and those who will be installing and learning about the 7156 pri...

Page 7: Contents

7156 service guide contents september 1998 vii contents section one: printer information and setup 1 chapter 1: about the 7156 printer 3 features ...................................................................................................................................... 4 receipt station.....

Page 8

Contents 7156 owner’s guide september 1998 viii verifying read of micr characters .............................................................................. 34 running the data scope mode....................................................................................... 35 testing the slip a...

Page 9

7156 service guide contents september 1998 ix chapter 7: disassembling and reassembling the thermal receipt mechanism 71 tools.......................................................................................................................... ................ 71 thermal printhead ................

Page 10

Contents 7156 owner’s guide september 1998 x chapter 10: hinge arm assembly and sensor bracket 105 tools.......................................................................................................................... .............. 105 disassembling the hinge arm assembly ....................

Page 11: 139

7156 service guide contents september 1998 xi section four: base feed assembly 139 chapter 15: removing the base/feed mechanism 141 tools.......................................................................................................................... .............. 141 preparation.............

Page 12: Section Five: Appendixes

Contents 7156 owner’s guide september 1998 xii section five: appendixes 163 appendix a: printer specifications 165 print specifications: both stations....................................................................................... 165 slip station specifications .................................

Page 13

7156 service guide contents september 1998 xiii appendix c: common pc board and extender cables 179 appendix d: ordering paper and supplies 181 ordering thermal receipt paper ........................................................................................ 181 ordering forms ....................

Page 14: Revision Record

Contents 7156 owner’s guide september 1998 xiv revision record issue date remarks a september 97 first printing b september 98 second printing, including minor revisions.

Page 15

7156 service guide section one: printer information and setup september 1998 1 section one: printer information and setup • chapter 1: about the 7156 printer • features • options • chapter 2: setting up the printer • what is in the box • choosing a location • setting dip switches • connecting the ca...

Page 17

7156 service guide chapter 1: about the 7156 printer september 1998 3 chapter 1: about the 7156 printer receipt cover receipt paper feed button front cover led extended slip table slip or check on line button paper status red led on line green led note: some 7156 models may appear slightly different...

Page 18: Features

Chapter 1: about the 7156 printer 7156 service guide september 1998 4 features the 7156 printer comes with several features and options. Receipt station • thermal printing • standard pitch (host selectable): 15.2 characters per inch, 44 columns • compressed pitch (host selectable): 19.0 characters p...

Page 19: Options

7156 service guide chapter 1: about the 7156 printer september 1998 5 general features • cover open sensors • industry standard rs-232c communication interface • history eerom for custom settings • power and communication support for a remote 2x20 pass-through display • audible tone (controlled by a...

Page 20

Chapter 1: about the 7156 printer 7156 service guide september 1998 6.

Page 21: What Is In The Box?

7156 service guide chapter 2: setting up the printer september 1998 7 chapter 2: setting up the printer this chapter describes some of the basic procedures for setting up the 7156 printer. See the 7156 setup guide or the 7156 owner’s guide for more information about loading the paper and installing ...

Page 22

Chapter 2: setting up the printer 7156 service guide september 1998 8 removing the packing material receipt cover 1 2 1. Once the printer is removed from the foam pack and plastic bag, open the receipt cover by pulling up on the front left corner. 2. Remove the paper roll, discard any packing materi...

Page 23

7156 service guide chapter 2: setting up the printer september 1998 9 front cover 3 4 3. Open the front cover and remove the foam restraint. 4. Remove the cardboard support from the slip table. 5. Remove the ribbon cassette and cables from the box. 6. Save all packing materials for future storing, m...

Page 24: Choosing A Location

Chapter 2: setting up the printer 7156 service guide september 1998 10 choosing a location the 7156 printer takes up relatively little counter space and may be set on or near the host computer. Make sure there is enough room to open the receipt cover to change the paper and to open the front cover t...

Page 25: Setting Dip Switches

7156 service guide chapter 2: setting up the printer september 1998 11 setting dip switches the dip switches, located behind the front cover, are used for three purposes: • to set communication parameters for the rs-232c communication interface (see appendix b for the switch settings) or to set addr...

Page 26: Connecting The Cables

Chapter 2: setting up the printer 7156 service guide september 1998 12 connecting the cables rs-232c models receive power from a power supply (remote) and use one cable for communication and a separate cable for power. Lcsio (rs-485) models receive power from the host computer (integrated) and use o...

Page 27

7156 service guide chapter 2: setting up the printer september 1998 13 cable access cover communication connector bottom of the printer power cable communication cable power connector cash drawer connector 1 cash drawer connector 2 strain relief bushings cable clamps.

Page 28

Chapter 2: setting up the printer 7156 service guide september 1998 14 lcsio (rs-485) models (integrated) the printer receives its power from a host computer and has one cable for power and communication. Follow these steps to connect the communication-power cable to the printer and host computer. S...

Page 29: Turning On The Printer

7156 service guide chapter 2: setting up the printer september 1998 15 turning on the printer paper status red led on line green led paper feed button on line button with recessed plunger on line button paper status red led on line green led paper feed button standard operator panel alternate versio...

Page 30

Chapter 2: setting up the printer 7156 service guide september 1998 16 running the print test by power cycling the printer rs-232c models 1. Press the on line button (or plunger) to put the printer off-line. Use a paper clip or other pointed object to depress the plunger on models with that item. Th...

Page 31

7156 service guide chapter 2: setting up the printer september 1998 17 sample print test for rs-232c models.

Page 32

Chapter 2: setting up the printer 7156 service guide september 1998 18 sample print test for lcsio (rs-485) models.

Page 33: Cleaning The Printer

7156 service guide chapter 2: setting up the printer september 1998 19 cleaning the printer cleaning the cabinet the external cabinet materials and finish are durable and resistant to these items: • cleaning solutions • lubricants • fuels • cooking oils • ultraviolet light there is no scheduled main...

Page 34

Chapter 2: setting up the printer 7156 service guide september 1998 20

Page 35: Chapter 3: Diagnostics

7156 service guide chapter 3: diagnostics september 1998 21 chapter 3: diagnostics the following diagnostic tests are available for the 7156: • level 0 diagnostics performed during the startup cycle • level 1 diagnostics (setup mode) available in a dedicated environment and accessed through the dip ...

Page 36: Level 1 Diagnostics

Chapter 3: diagnostics 7156 service guide september 1998 22 level 1 diagnostics level 1 diagnostics (setup mode) allow you to change the settings for various printer functions and to run certain tests using the dip switches. Keep the following information in mind when changing the settings: • the se...

Page 37

7156 service guide chapter 3: diagnostics september 1998 23 setting printhead resistance this function changes the setting for the thermal printhead resistance. The setting must match the character (a-d, 0-3; or a-h) stamped on the heatsink in back of the printhead, visible by removing the top cover...

Page 38

Chapter 3: diagnostics 7156 service guide september 1998 24 setting partial cut distance this function changes the length of the partial knife cut: the higher the number, the longer the cut. Caution: the dip switches are pre-set at the factory and should generally not be changed. If you must change ...

Page 39

7156 service guide chapter 3: diagnostics september 1998 25 setting data error and data buffer options (rs-232c models only) this function allows you to select the handling of data reception errors and to select the size of the data buffer. Caution: the dip switches are pre-set at the factory and sh...

Page 40

Chapter 3: diagnostics 7156 service guide september 1998 26 ignoring/using the carriage return this function allows the printer to ignore or use the carriage return (hexadecimal 0d) command depending on the application. Some applications expect the command to be ignored while others use the command ...

Page 41

7156 service guide chapter 3: diagnostics september 1998 27 checking and adjusting the micr check reader (common board and rs-232c models) the adjustment described in this section cancels or sharply reduces extraneous signals picked up by the magnetic ink character recognition (micr) check reader. U...

Page 42

Chapter 3: diagnostics 7156 service guide september 1998 28 7. Insert a blank slip into the slip station from the left side so that it covers the micr read head, but does not come into contact with the feed rolls. See the illustration on the facing page. The slip should be the same thickness as a no...

Page 43

7156 service guide chapter 3: diagnostics september 1998 29 adjust the micr check reader paper top of printer paper feed button potentiometers led micr read head carriage assembly feed roll assembly the procedures to adjust the micr check reader involve setting the dip switches and adjusting the two...

Page 44

Chapter 3: diagnostics 7156 service guide september 1998 30 3. Set both potentiometers (on the pc board) to mid range using a screwdriver. 4. Adjust the lower potentiometer (r9) on the pc board either direction. The green led should be on before you adjust the potentiometer. 5. Press the paper feed ...

Page 45

7156 service guide chapter 3: diagnostics september 1998 31 access the micr amplifier board do the following steps to remove the receipt and top covers. Be sure there is paper in the receipt bucket. 1. Turn the power to the printer off by turning the host computer off. 2. Remove the receipt cover by...

Page 46

Chapter 3: diagnostics 7156 service guide september 1998 32 front of printer paper off switch 1 is shown in the off position on dip switch front cover 2. Close the front cover. 3. Insert a blank slip into the slip station so that it covers the micr read head, but does not come into contact with the ...

Page 47

7156 service guide chapter 3: diagnostics september 1998 33 3. Press the paper feed button on the pc board to take a noise sample. Repeat steps 2 and 3 until the lowest number of characters is printed. You may need to adjust the potentiometer both directions to get the best setting. If ok is printed...

Page 48

Chapter 3: diagnostics 7156 service guide september 1998 34 5. Align the hinges. 6. Push down gently until the cover snaps into place. 7. Close the receipt cover. 8. Open the front cover and set the dip switches back to the settings for normal operation (on-line mode). See “appendix b: communication...

Page 49

7156 service guide chapter 3: diagnostics september 1998 35 10. Close the front cover and press the on line button (or plunger) on those models. The green led flashes when the printer cycles. The settings are entered into eerom. 11. Press the reset button (under the dip switches) on those models to ...

Page 50

Chapter 3: diagnostics 7156 service guide september 1998 36 exit the data scope mode 1. Open the front cover and set the dip switches to the following settings: switch 7 is always off. Switch 8: on = knife, off = non-knife switch 1 switch 2 switch 3 switch 4 switch 5 switch 6 on off off on off off 2...

Page 51

7156 service guide chapter 3: diagnostics september 1998 37 note: the operator panel may differ depending on the model. To put the printer on- or off-line, use a paper clip or other pointed object to depress the plunger (in place of the on line button) on models with that item. 1. Open the front cov...

Page 52

Chapter 3: diagnostics 7156 service guide september 1998 38 on off off off off on 2. On models with the on line button (or plunger) on top of the printer, close the front cover and press the on line button (or plunger). The green led flashes when the printer cycles. The settings are entered into eer...

Page 53: Level 2 Diagnostics

7156 service guide chapter 3: diagnostics september 1998 39 the green led flashes when the printer cycles. The settings are entered into eerom. The printer begins printing the sample receipt. Note: if the sample receipt via feed button option is selected (see the dip switch settings above), the prin...

Page 54

Chapter 3: diagnostics 7156 service guide september 1998 40 variations of the character sets with a partial cut between each variation. See the samples on the following pages. The samples do not show the character sets. The tests end with a partial cut, then begin again. Several feet of paper can be...

Page 55

7156 service guide chapter 3: diagnostics september 1998 41 sample print test for rs-232c models the character sets are not shown in the sample printout..

Page 56

Chapter 3: diagnostics 7156 service guide september 1998 42 sample print test for lcsio (rs-485) models the character sets are not shown in the sample printout..

Page 57: Chapter 4: Troubleshooting

7156 service guide chapter 4: troubleshooting september 1998 43 chapter 4: troubleshooting this chapter gives information on test points and field effect transistors (fets), and provides tables to help in determining the cause of printer malfunctions. Test points test points are located on the pc bo...

Page 58

Chapter 4: troubleshooting 7156 service guide september 1998 44 field effect transistors (fets) common pc board (newer printer models) fets are located on the pc board and can be used to diagnose motor, solenoid, and printhead problems. There are a maximum of 34 fets located on the pc board: • carri...

Page 59

7156 service guide chapter 4: troubleshooting september 1998 45 note: the common pc board is used in newer 7156 models for both rs-232c and lcsio (rs-485). The board has either a 9-pin connector for rs-232c (as shown) or a 15-pin connector for lcsio (rs-485). Rs-232c pc board (older models) fets are...

Page 60

Chapter 4: troubleshooting 7156 service guide september 1998 46 impact printhead knife micr solenoid receipt feed motor forms comp solenoid slip feed motor thermal printhead carriage motor cash drawer 1 & 2 lcsio (rs-485) pc board (older models) fets are located on the pc board and can be used to di...

Page 61: Mechanical Problems

7156 service guide chapter 4: troubleshooting september 1998 47 impact printhead knife micr solenoid receipt feed motor forms comp solenoid slip feed motor thermal printhead carriage motor mechanical problems problem possible causes what to do knife does not operate bad knife home switch. Check the ...

Page 62

Chapter 4: troubleshooting 7156 service guide september 1998 48 problem possible causes what to do printer does not function when turned on printer not plugged in. Confirm that printer cables are properly connected on both ends. Make sure the ground wire is properly connected. See “connecting the ca...

Page 63

7156 service guide chapter 4: troubleshooting september 1998 49 problem possible causes what to do carriage homes incorrectly jammed carriage. Turn off the power to the printer and place the feed rolls in the down position. Move the carriage to see if the carriage moves freely. If the carriage does ...

Page 64: Printing Problems

Chapter 4: troubleshooting 7156 service guide september 1998 50 printing problems problem possible causes what to do red led flashes (rs-232c only) receipt paper is low: about 4.5 meters, ± 3 meters, (15 feet, ± 10 feet) of paper left.* change the receipt paper to avoid running out of paper part way...

Page 65

7156 service guide chapter 4: troubleshooting september 1998 51 problem possible causes what to do light print in impact printing worn ribbon cassette. Check for wear in the ribbon cassette. Platen gap too large. Check and adjust the platen gap (.018 inches). See chapter 5. Problem possible causes w...

Page 66: Forms Feeding Problems

Chapter 4: troubleshooting 7156 service guide september 1998 52 forms feeding problems problem possible causes what to do forms not feeding into impact printer failed paper feed motor. Use the fets test to see if the paper feed motor has failed. See “field effect transistors (fets)” in this chapter....

Page 67: Electronic Problems

7156 service guide chapter 4: troubleshooting september 1998 53 electronic problems problem possible causes what to do power voltage too low/high improper connections in printer. Check that connections in the printer are proper. See the section in chapter 8 that applies to this unit’s pc board. Ac s...

Page 68

Chapter 4: troubleshooting 7156 service guide september 1998 54 check micr head solenoid with an ohmmeter. Reading should show about 30 ohms. Note about the micr check reader: the micr feature has been factory adjusted for a normal operating environment. However, additional devices, such as crt moni...

Page 69: Chapter 5: Adjustments

7156 service guide chapter 5: adjustments september 1998 55 chapter 5: adjustments this chapter describes adjusting the paper low sensor and adjusting the platen gap. For other adjustment procedures, such as adjusting the micr check reader and the printhead resistance, see “level 1 diagnostics” in “...

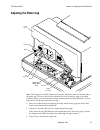

Page 70

Chapter 5: adjustments 7156 service guide september 1998 56 the paper low sensor is set at the factory to detect when there are 4 ½ meters, ± 3 meters (15 feet, ± 10 feet), of receipt paper remaining. The sensor can be adjusted to detect less or more paper remaining. It is recommended, however, that...

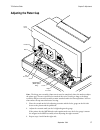

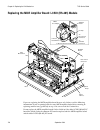

Page 71: Adjusting The Platen Gap

7156 service guide chapter 5: adjustments september 1998 57 adjusting the platen gap printhead left eccentric screw platen screw right eccentric front cover micr magnet (micr option only) note: the hinge arm assembly (front cover) must be completely closed in order to adjust the platen gap. The cove...

Page 72

Chapter 5: adjustments 7156 service guide september 1998 58.

Page 73: Tools

7156 service guide chapter 6: removing the thermal receipt mechanism september 1998 59 chapter 6: removing the thermal receipt mechanism this is the first of three related chapters which deal with the thermal receipt mechanism. In this chapter you will remove the thermal receipt mechanism from the p...

Page 74: Removing The Receipt Cover

Chapter 6: removing the thermal receipt mechanism 7156 service guide september 1998 60 removing the receipt cover receipt cover paper roll silicone fluid.

Page 75

7156 service guide chapter 6: removing the thermal receipt mechanism september 1998 61 caution: before working on the printer be sure that the power has been turned off. Wear a grounded wrist strap and use a static mat or other esd protected work surface. Note: some 7156 models may appear slightly d...

Page 76

Chapter 6: removing the thermal receipt mechanism 7156 service guide september 1998 62 disassembling and reassembling the receipt cover disassemble the receipt cover by removing the platen (only on non-knife models). Note: if you are changing the stationary knife blade, you must replace the entire r...

Page 77: Removing The Top Cover

7156 service guide chapter 6: removing the thermal receipt mechanism september 1998 63 removing the top cover note: some 7156 models may appear slightly different than what is shown in the illustration. The procedures are the same for all models unless otherwise noted. 1. Open the front cover. 2. Us...

Page 78

Chapter 6: removing the thermal receipt mechanism 7156 service guide september 1998 64 disconnecting cables from the common pc board the common pc board replaces older rs-232c and lcsio (rs-485) pc boards. The board is populated differently for each interface. See “removing the pc board” in chapter ...

Page 79

7156 service guide chapter 6: removing the thermal receipt mechanism september 1998 65.

Page 80

Chapter 6: removing the thermal receipt mechanism 7156 service guide september 1998 66 disconnecting cables from the older rs-232c pc board use these instructions to disconnect cables from the older rs-232c pc board. This board is replaced by the common pc board. See “disconnecting cables from the c...

Page 81

7156 service guide chapter 6: removing the thermal receipt mechanism september 1998 67.

Page 82

Chapter 6: removing the thermal receipt mechanism 7156 service guide september 1998 68 disconnecting cables from the older lcsio (rs-485) pc board use these instructions to disconnect cables from the older lcsio (rs-485) pc board. This board is replaced by the common pc board. See “disconnecting cab...

Page 83

7156 service guide chapter 6: removing the thermal receipt mechanism september 1998 69 j12 micr assembly j13 thermal printhead frame ground.

Page 84

Chapter 6: removing the thermal receipt mechanism 7156 service guide september 1998 70 removing the thermal receipt mechanism front cover screw thermal receipt mechanism thermal mount rear latches 1. Open the front cover. 2. Loosen the screw, in front of the thermal receipt mechanism, which holds it...

Page 85: Receipt Mechanism

7156 service guide chapter 7: disassembling and reassembling the thermal receipt mechanism september 1998 71 chapter 7: disassembling and reassembling the thermal receipt mechanism this is the second of three related chapters which deal with the thermal receipt mechanism. In this chapter you will re...

Page 86: Thermal Printhead

Chapter 7: disassembling and reassembling the thermal receipt mechanism 7156 service guide september 1998 72 thermal printhead removing the printhead left support knife ground strap printhead assembly printhead spring printhead cable rotating blade frame caution: electro static discharge may damage ...

Page 87

7156 service guide chapter 7: disassembling and reassembling the thermal receipt mechanism september 1998 73 replacing the printhead the mechanism should be facing you with the printhead area toward you. See the illustration on the previous page. Note: take note of the character (a-d, 0-3; or a-h) s...

Page 88: Knife Assembly

Chapter 7: disassembling and reassembling the thermal receipt mechanism 7156 service guide september 1998 74 knife assembly the knife assembly is optional and is not present in all printers. Removing the knife assembly set screw rotating blade left support knife ground strap knife drive arm receipt ...

Page 89

7156 service guide chapter 7: disassembling and reassembling the thermal receipt mechanism september 1998 75 note: if you are replacing the rotating blade, you must change all parts contained in the knife kit. 1. Remove the knife home switch assembly. 2. Remove the set screw and knife actuator arm. ...

Page 90: Knife Motor

Chapter 7: disassembling and reassembling the thermal receipt mechanism 7156 service guide september 1998 76 knife motor the knife assembly is optional and is not present on all printers. Removing the knife motor knife motor 1. Remove the two screws and washers holding the knife motor. 2. Pull the k...

Page 91: Switches

7156 service guide chapter 7: disassembling and reassembling the thermal receipt mechanism september 1998 77 switches removing the switches paper out switch cover open switch knife home switch knife motor retaining plate note: the knife motor must be removed before the paper out switch can be remove...

Page 92

Chapter 7: disassembling and reassembling the thermal receipt mechanism 7156 service guide september 1998 78 replacing the switches see the illustration on the previous page. 1. For each switch, reattach the faston terminals on the harness to the rearmost spade on the switch. 2. Replace the paper ou...

Page 93: Paper Low Sensor

7156 service guide chapter 7: disassembling and reassembling the thermal receipt mechanism september 1998 79 paper low sensor removing the paper low sensor snap rivets center pin paper low sensor screws foam pad note: the paper low sensor is not available on certain models. Check with your ncr sales...

Page 94: Paper Feed Motor

Chapter 7: disassembling and reassembling the thermal receipt mechanism 7156 service guide september 1998 80 paper feed motor removing the paper feed motor paper feed motor note: order the paper feed motor kit if you are replacing the paper feed motor. The kit contains the paper feed motor, two wash...

Page 95: Tools

7156 service guide chapter 8: replacing the thermal receipt mechanism september 1998 81 chapter 8: replacing the thermal receipt mechanism this is the third of three related chapters which deal with the thermal receipt mechanism. In this chapter you will replace the thermal receipt mechanism on the ...

Page 96

Chapter 8: replacing the thermal receipt mechanism 7156 service guide september 1998 82 replacing the thermal receipt mechanism front cover screw thermal receipt mechanism thermal mount rear latches.

Page 97

7156 service guide chapter 8: replacing the thermal receipt mechanism september 1998 83 note: before positioning the thermal receipt mechanism on the thermal mount, write down the letter on the label on the back of the printhead. You may need to reset the thermal printhead resistance after replacing...

Page 98

Chapter 8: replacing the thermal receipt mechanism 7156 service guide september 1998 84 reconnecting cables to the common pc board the common pc board replaces both the rs-232c and the lcsio (rs-485) pc boards. The board is populated differently for each interface. See “removing the pc board” in cha...

Page 99

7156 service guide chapter 8: replacing the thermal receipt mechanism september 1998 85.

Page 100

Chapter 8: replacing the thermal receipt mechanism 7156 service guide september 1998 86 reconnecting cables to the older rs-232c pc board this board is the older rs-232c pc board. It is replaced by the common pc board. See “reconnecting cables to the common pc board” earlier in this chapter and “rem...

Page 101

7156 service guide chapter 8: replacing the thermal receipt mechanism september 1998 87.

Page 102

Chapter 8: replacing the thermal receipt mechanism 7156 service guide september 1998 88 reconnecting cables to the older lcsio (rs-485) pc board this board is the older lcsio (rs-485) pc board. It is replaced by the common pc board. See “reconnecting cables to the common pc board” earlier in this ch...

Page 103

7156 service guide chapter 8: replacing the thermal receipt mechanism september 1998 89 j12 micr assembly j13 thermal printhead frame ground.

Page 104: Replacing The Top Cover

Chapter 8: replacing the thermal receipt mechanism 7156 service guide september 1998 90 replacing the top cover front cover large snap top cover cantilever left snap rear latching tabs right rear corner right rear corner note: some 7156 models may appear slightly different than what is shown in the ...

Page 105: Replacing The Receipt Cover

7156 service guide chapter 8: replacing the thermal receipt mechanism september 1998 91 replacing the receipt cover receipt cover paper roll silicone fluid 1. Hold the receipt cover vertically over the hinge brackets in the printer cabinet and align the hinges. 2. Push down gently until the cover sn...

Page 106

Chapter 8: replacing the thermal receipt mechanism 7156 service guide september 1998 92 note: after reassembling the thermal receipt mechanism, you may need to reset the thermal printhead resistance and the partial cut distance. See “setting printhead resistance” and “setting partial cut distance” i...

Page 107

7156 service guide section three: print mechanism september 1998 93 section three: print mechanism • chapter 9: removing the print mechanism • preparation • removing the sensor bracket • removing the pc board • removing the thermal mount • removing the hinge arm assembly • removing the micr amplifie...

Page 109: Tools

7156 service guide chapter 9: removing the print mechanism september 1998 95 chapter 9: removing the print mechanism this is the first of six related chapters which deal with the print mechanism. In this chapter you will remove the print mechanism from the printer. In chapters 10 through 13 you will...

Page 110: Preparation

Chapter 9: removing the print mechanism 7156 service guide september 1998 96 preparation caution: before working on the printer be sure that the power has been turned off. Wear a grounded wrist strap and use a static mat or other esd protected work surface. 1. Disconnect the communication and power ...

Page 111: Removing The Sensor Bracket

7156 service guide chapter 9: removing the print mechanism september 1998 97 removing the sensor bracket screw cantilever led sensor cable connector sensor bracket latch tab caution: electro static discharge may damage the pc board. Wear a grounded wrist strap and use a static mat or other esd prote...

Page 112: Removing The Pc Board

Chapter 9: removing the print mechanism 7156 service guide september 1998 98 removing the pc board electronics assembly screw pcb shield cantilever.

Page 113

7156 service guide chapter 9: removing the print mechanism september 1998 99 if you are removing the pc board because of a failure, read the following information. If you are removing the pc board in order to remove or replace another item, go directly to step 1. Be sure to read the caution first. O...

Page 114: Removing The Thermal Mount

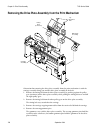

Chapter 9: removing the print mechanism 7156 service guide september 1998 100 removing the thermal mount torx® screws screws print mechanism thermal mount base ground clip 1. Unscrew the three torx® screws on the front of the print mechanism. 2. Unscrew the two screws on the right side of the therma...

Page 115

7156 service guide chapter 9: removing the print mechanism september 1998 101 removing the hinge arm assembly front cover extension spring carriage drive mechanism ribbon cassette torsion spring 1. Open the hinge arm assembly and remove the extension spring connecting the hinge arm assembly to the r...

Page 116

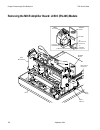

Chapter 9: removing the print mechanism 7156 service guide september 1998 102 removing the micr amplifier board: lcsio (rs-485) models base print mechanism motor harness cord keeps amplifier board amplifier board micr assembly lc chip j1 read head harness j2 interconnect connector interconnect conne...

Page 117

7156 service guide chapter 9: removing the print mechanism september 1998 103 if you are removing the micr amplifier board because of a failure, read the following information. If you are removing the micr amplifier board in order to remove or replace another item, go directly to step 1. Be sure to ...

Page 118: Removing The Print Mechanism

Chapter 9: removing the print mechanism 7156 service guide september 1998 104 removing the print mechanism base solenoid wires screw w/washer screw w/washer print mechanism read head harness buck coil harness micr solenoid harness motor harness 1. Open the wire clip retainers on the cantilever and i...

Page 119: Tools

7156 service guide chapter 10: hinge arm assembly and sensor bracket september 1998 105 chapter 10: hinge arm assembly and sensor bracket this is the second of six related chapters which deal with the print mechanism. In this chapter you will disassemble and reassemble the hinge arm assembly (front ...

Page 120

Chapter 10: hinge arm assembly and sensor bracket 7156 service guide september 1998 106 disassembling the hinge arm assembly front cover gear e-ring pressure roll assembly hinge assembly screw screw pressure roll bearing orientation of the hinge arm assembly for this procedure is upside-down with th...

Page 121

7156 service guide chapter 10: hinge arm assembly and sensor bracket september 1998 107 reassembling the hinge arm assembly orientation of the hinge arm assembly for this procedure is upside-down with the gears of the pressure roll assembly to the left and front. See the illustration on the previous...

Page 122

Chapter 10: hinge arm assembly and sensor bracket 7156 service guide september 1998 108 disassembling the sensor bracket led sensor cable assembly sonsor bracket light pipe 1. Remove the light pipe by pushing the arm of the light pipe forward and pulling the light pipe up and off the sensor bracket....

Page 123: Chapter 11: Micr Assembly

7156 service guide chapter 11: micr assembly september 1998 109 chapter 11: micr assembly this is the third of six related chapters which deal with the print mechanism. In this chapter you will remove and replace the micr assembly on the print mechanism. Note: the micr assembly is an optional item; ...

Page 124

Chapter 11: micr assembly 7156 service guide september 1998 110 removing the micr assembly from the print mechanism cantilever micr assembly silicone fluid silicone fluid push read head screw gray wire read head buck coil assembly buck coil assembly read head ground harness micr solenoid solenoid ha...

Page 125

7156 service guide chapter 11: micr assembly september 1998 111 removing the micr bracket assembly note: on certain lcsio (rs-485) models an extender cable (available in a kit) is used to connect the micr solenoid cable to the common pc board. 1. Disconnect the micr solenoid cable from the pc board....

Page 126

Chapter 11: micr assembly 7156 service guide september 1998 112 replacing the micr assembly on the print mechanism replacing the buck coil assembly 1. Place the buck coil assembly into the slot on the cantilever and rotate it until it snaps into place. 2. Replace and tighten the screw holding the bu...

Page 127: Tools

7156 service guide chapter 12: carriage assembly september 1998 113 chapter 12: carriage assembly this is the fourth of six related chapters which deal with the print mechanism. In this chapter you will remove the carriage assembly from the print mechanism, disassemble and reassemble the carriage as...

Page 128

Chapter 12: carriage assembly 7156 service guide september 1998 114 removing the carriage assembly from the print mechanism printhead cable timing belt anti-rotation bearing cassette drive rack & l-bracket l-bracket screw l-bracket screw carriage shaft carriage shaft screw cantilever carriage assemb...

Page 129

7156 service guide chapter 12: carriage assembly september 1998 115 7. Remove the printhead cable from the strain relief on the top of the cantilever. Disassembling the carriage assembly orientation of the carriage assembly is with the gears to the front and top. Note: see the parts information manu...

Page 130

Chapter 12: carriage assembly 7156 service guide september 1998 116 note: the groundstrap on the printhead remains on the printhead. If you are replacing the printhead, use the groundstrap from the old printhead. 2. Remove the ribbon idler gear (the gear with a flat surface) on the right side of the...

Page 131

7156 service guide chapter 12: carriage assembly september 1998 117 11. Flip the top of the folded portion of the cable into the tab at the top and back part of the carriage assembly. Replacing the carriage assembly on the print mechanism orientation of the print mechanism is with the cantilever sid...

Page 132

Chapter 12: carriage assembly 7156 service guide september 1998 118 g. Loop the cable back around and thread the cable through the strain relief. 5. Replace the timing belt on the drive plate assembly by pushing on the pulley gear (tensioner) and pulling the timing belt over and off the pulley gear....

Page 133: Tools

7156 service guide chapter 13: drive plate assembly september 1998 119 chapter 13: drive plate assembly this is the fifth of six related chapters which deal with the print mechanism. In this chapter you will remove the drive plate assembly from the print mechanism, disassemble and reassemble the dri...

Page 134

Chapter 13: drive plate assembly 7156 service guide september 1998 120 removing the drive plate assembly from the print mechanism pulley gear (tensioner) top grommet pins drive plate assembly carriage assembly orientation for removing the drive plate assembly from the print mechanism is with the car...

Page 135

7156 service guide chapter 13: drive plate assembly september 1998 121 5. Pull back on the whole drive plate assembly to pull it off the top of the cantilever. 6. Pull up on the whole drive assembly to remove the bottom of the drive plate assembly from the cantilever. Disassembling the drive plate a...

Page 136

Chapter 13: drive plate assembly 7156 service guide september 1998 122 right grommet timing belt tie-warp mounting plate interrupt sensor assembly snap rivet pin e-ring timing wheel home flag torsion spring e-ring e-ring pulley flange pulley flange pulley gear and bearing pulley gear and bearing com...

Page 137

7156 service guide chapter 13: drive plate assembly september 1998 123 reassembling the drive plate assembly orientation for the reassembly of the drive plate assembly is with the assembly upside down with the motor shaft on the right. See the illustration on the previous page to aid in reassembling...

Page 138

Chapter 13: drive plate assembly 7156 service guide september 1998 124 9. Replace the interrupt sensor assembly. A. Slide the interrupt sensor assembly into place on the drive plate. B. From underneath the drive plate assembly, push the pin head of the snap rivet and the snap rivet through the hole ...

Page 139: Tools

7156 service guide chapter 14: replacing the print mechanism september 1998 125 chapter 14: replacing the print mechanism this is the sixth of six related chapters which deal with the print mechanism. In this chapter you will replace the print mechanism in the printer. Note: some 7156 models may app...

Page 140

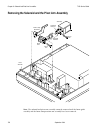

Chapter 14: replacing the print mechanism 7156 service guide september 1998 126 replacing the print mechanism base solenoid wires screw w/washer screw w/washer print mechanism read head harness buck coil harness micr solenoid harness motor harness.

Page 141

7156 service guide chapter 14: replacing the print mechanism september 1998 127 orientation of the print mechanism when replacing it in the printer is with the carriage assembly facing you and the drive plate assembly to the back. Caution: do not force the print mechanism into the printer base or da...

Page 142

Chapter 14: replacing the print mechanism 7156 service guide september 1998 128 replacing the micr amplifier board: lcsio (rs-485) models base print mechanism motor harness cord keeps amplifier board amplifier board micr assembly lc chip j1 read head harness j2 interconnect connector interconnect co...

Page 143

7156 service guide chapter 14: replacing the print mechanism september 1998 129 you must use three extender cables (available in a kit) to connect the following three cables to the common pc board: • micr read head cable • micr buckhead cable • micr solenoid cable note: in addition, a longer cable f...

Page 144

Chapter 14: replacing the print mechanism 7156 service guide september 1998 130 replacing the hinge arm assembly front cover extension spring carriage drive mechanism ribbon cassette torsion spring 1. Position the hinges of the hinge arm assembly (front cover) on the brackets of the cantilever. 2. P...

Page 145: Replacing The Thermal Mount

7156 service guide chapter 14: replacing the print mechanism september 1998 131 replacing the thermal mount torx® screws screws print mechanism thermal mount base ground clip 1. Position the thermal mount on the base and on the cantilever. 2. Screw in the two screws holding the thermal mount to the ...

Page 146: Replacing The Pc Board

Chapter 14: replacing the print mechanism 7156 service guide september 1998 132 replacing the pc board motor harness motor connector cord keeps interconnect harness cord keep buck coil mount screw three wires two wires.

Page 147

7156 service guide chapter 14: replacing the print mechanism september 1998 133 note: this wiring is required only on older pc boards. If you are replacing the pc board because of a failure, read the following information. If you are putting the pc board back in after removing or replacing another i...

Page 148

Chapter 14: replacing the print mechanism 7156 service guide september 1998 134 enhanced common pc board connectors.

Page 149

7156 service guide chapter 14: replacing the print mechanism september 1998 135 rs-232c pc board connectors.

Page 150

Chapter 14: replacing the print mechanism 7156 service guide september 1998 136 lcsio (rs-485) pc board connectors j12 micr assembly j13 thermal printhead frame ground.

Page 151: Adjusting The Platen Gap

7156 service guide chapter 14: replacing the print mechanism september 1998 137 adjusting the platen gap printhead left eccentric screw platen screw right eccentric front cover micr magnet (micr option only) note: the hinge arm assembly (front cover) must be completely closed in order to adjust the ...

Page 152

Chapter 14: replacing the print mechanism 7156 service guide september 1998 138 adjusting the micr check reader anytime the print mechanism has been removed or disassembled, the magnetic ink character recognition (micr) check reader must be adjusted. See the following two sections in “chapter 3: dia...

Page 153

7156 service guide section four: base feed assembly september 1998 139 section four: base feed assembly • chapter 15: removing the base/feed mechanism • preparation • separating mechanisms from the base/feed mechanism • chapter 16: forms compensation arm assembly • removing the forms compensation ar...

Page 155: Tools

7156 service guide chapter 15: removing the base/feed mechanism september 1998 141 chapter 15: removing the base/feed mechanism this is the first of six related chapters which deal with the base/feed mechanism. In this chapter you will separate mechanisms from the base/feed mechanism. In the followi...

Page 156: Preparation

Chapter 15: removing the base/feed mechanism 7156 service guide september 1998 142 preparation caution: before working on the printer be sure that the power has been turned off. Wear a grounded wrist strap and use a static mat or other esd protected work surface. 1. Turn off the host computer or unp...

Page 157

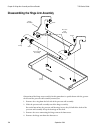

7156 service guide chapter 15: removing the base/feed mechanism september 1998 143 separating mechanisms from the base/feed mechanism forms compensation arm assembly forms guide assembly solenoid and pivot arm assemblies paper feed motor assembly caution: electro static discharge may damage the pc b...

Page 158

Chapter 15: removing the base/feed mechanism 7156 service guide september 1998 144.

Page 159: Tools

7156 service guide chapter 16: forms compensation arm assembly september 1998 145 chapter 16: forms compensation arm assembly this is the second of six related chapters which deal with the base/feed mechanism. In this chapter you will remove, disassemble, reassemble and replace the forms compensatio...

Page 160

Chapter 16: forms compensation arm assembly 7156 service guide september 1998 146 removing the forms compensation arm assembly compression spring compression spring forms compensation arm arm arm pivot arm shaft pivot arm assembly 1. Raise the forms compensation arm assembly by pulling up the pivot ...

Page 161

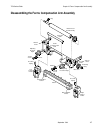

7156 service guide chapter 16: forms compensation arm assembly september 1998 147 disassembling the forms compensation arm assembly pivot arm shaft bottom feed roll assembly e-ring forms compensation arm retaining ring idler gear platen torx® screw torx® screw washer washer adjusting eccentric right...

Page 162

Chapter 16: forms compensation arm assembly 7156 service guide september 1998 148 orientation for disassembling the forms compensation arm assembly is with the gears of the bottom feed roll assembly on your right and the pivot arm shaft toward you and to the top. 1. Remove the pivot arm shaft by sli...

Page 163

7156 service guide chapter 16: forms compensation arm assembly september 1998 149 7. Replace the bottom feed roll shaft by sliding the left side of the shaft into the left side slot and then snapping the right side of the shaft into place on the forms compensation arm assembly. 8. Replace the e-ring...

Page 164

Chapter 16: forms compensation arm assembly 7156 service guide september 1998 150

Page 165: Tools

7156 service guide chapter 17: forms guide assembly september 1998 151 chapter 17: forms guide assembly this is the third of six related chapters which deal with the base/feed mechanism. In this chapter you will remove, disassemble, reassemble, and replace the forms guide assembly. To remove and dis...

Page 166

Chapter 17: forms guide assembly 7156 service guide september 1998 152 removing the forms guide assembly pivot arm solenoid forms guide assembly tab tab note: some 7156 models may appear slightly different than what is shown in the illustration. The procedures are the same for all models unless othe...

Page 167

7156 service guide chapter 17: forms guide assembly september 1998 153 disassembling the forms guide assembly torsion spring arm stop forms guide slip sensor assembly 1. Disconnect the torsion spring from the arm stop and the snap leg on the forms guide. 2. Remove the stop arm from the forms guide. ...

Page 168

Chapter 17: forms guide assembly 7156 service guide september 1998 154 replacing the forms guide assembly in the base pivot arm slot sensor assembly wires note: some 7156 models may appear slightly different than what is shown in the illustration. The procedures are the same for all models unless ot...

Page 169: Tools

7156 service guide chapter 18: solenoid and pivot arm assemblies september 1998 155 chapter 18: solenoid and pivot arm assemblies this is the fourth of six related chapters which deal with the base/feed mechanism. In this chapter you will remove and replace the solenoid and you will remove, disassem...

Page 170

Chapter 18: solenoid and pivot arm assemblies 7156 service guide september 1998 156 removing the solenoid and the pivot arm assembly forms stop pivot arm pivot arm pivot arm pin clevis pin clevis pin solenoid pull-link solenoid plunger solenoid note: the solenoid and pivot arm assembly cannot be rem...

Page 171

7156 service guide chapter 18: solenoid and pivot arm assemblies september 1998 157 removing the solenoid orientation for removing the solenoid assembly is with the paper feed motor to the right and front of the base. Caution: keep the solenoid away from the pc board. The solenoid is magnetic and ca...

Page 172

Chapter 18: solenoid and pivot arm assemblies 7156 service guide september 1998 158.

Page 173: Tools

7156 service guide chapter 19: paper feed motor assembly september 1998 159 chapter 19: paper feed motor assembly this is the fifth of six related chapters which deal with the base/feed mechanism. In this chapter you will remove and replace the paper feed motor assembly. To remove and disassemble th...

Page 174

Chapter 19: paper feed motor assembly 7156 service guide september 1998 160 removing the paper feed motor assembly paper feed motor asembly tabs 1. Remove the paper feed motor assembly by unsnapping the tabs from underneath. 2. Press back the tabs at the top of the motor. 3. Pry the paper feed motor...

Page 175: Mechanism

7156 service guide chapter 20: replacing mechanisms in the base/feed mechanism september 1998 161 chapter 20: replacing mechanisms in the base/feed mechanism this is the sixth of six related chapters which deal with the base/feed mechanism. In this chapter you will replace mechanisms and assemblies ...

Page 176: Finishing

Chapter 20: replacing mechanisms in the base/feed mechanism 7156 service guide september 1998 162 reassembling mechanisms in the base assembly note: the paper feed motor, solenoid & pivot arm assemblies, forms guide assembly and the forms compensation assembly must be assembled in the base before me...

Page 177: Section Five: Appendixes

7156 service guide section five: appendixes september 1998 163 section five: appendixes there are four appendixes in this section which include the following information: • appendix a: printer specifications • print specifications: both stations • slip station specifications • power requirements • e...

Page 179

7156 service guide appendix a: printer specifications september 1998 165 appendix a: printer specifications print specifications: both stations thermal receipt station slip station printhead fixed 448 print elements direct thermal fixed head line of dots bi-directional logic seeking serial dot matri...

Page 180: Slip Station Specifications

Appendix a: printer specifications 7156 service guide september 1998 166 slip station specifications general information • prints on checks, single part forms, or multiple-part (up to five) forms • automatic or manual insertion of documents from the front or from the side • prints on the front or ba...

Page 181: Environmental Requirements

7156 service guide appendix a: printer specifications september 1998 167 power from power supply the power supply must provide a +24v line of power to the printer, which must be regulated ± 5% at the printer. Surge protection must be provided. To do this, place a 2.0 ampere time delay fuse on the +2...

Page 182: Dimensions and Weight

Appendix a: printer specifications 7156 service guide september 1998 168 dimensions and weight height 178 mm (7.0 inches) height with cover open 280 mm (11.0 inches) width 229 mm (9.0 inches) depth 264 mm (10.4 inches) depth with extended slip table 347 mm (13.7 inches) weight 4.6 kg (10.1 pounds), ...

Page 183: Rs-232C Connectors

7156 service guide appendix b: communication information september 1998 169 appendix b: communication information rs-232c connectors rs-232c power cable connector cash drawer connector and pin assignments pin 1 pin 6 pin number cash drawer 1 connector cash drawer 2 connector 1 frame ground frame gro...

Page 184

Appendix b: communication information 7156 service guide september 1998 170 rs-232c communication connector pin assignments rs-232c 25-pin to 9-pin cable diagram note: this information is provided for testing and troubleshooting only..

Page 185

7156 service guide appendix b: communication information september 1998 171 rs-232c 9-pin to 9-pin cable diagram note: this information is provided for testing and troubleshooting only. Lcsio (rs-485) connector and pin assignments 24 volts power ground power ground 5 volts ground data b not used 9 1...

Page 186: Dip Switch Settings

Appendix b: communication information 7156 service guide september 1998 172 dip switch settings the dip switches are located on the pc board behind the front cover. They are used to set the rs-232c parameters and lcsio (rs-485) address bits as shown in the following tables. Note: the switches can al...

Page 187

7156 service guide appendix b: communication information september 1998 173 note: the following options are set with the printer in the setup mode. See “level 1 diagnostics” in the “diagnostics” chapter for more information. Dip switch settings for data error and data buffer options (choose one from...

Page 188: Commands

Appendix b: communication information 7156 service guide september 1998 174 commands the commands control all operations and functions of the 7156 printer, from selecting the size and placement of characters and graphics on the receipt or slip to feeding and cutting the paper. The 7156 commands emul...

Page 189

7156 service guide appendix b: communication information september 1998 175 printer function commands hexadecimal code command 1a 1b 6d partial knife cut 1b 07 generate tone 1b 14 n set column 1b 20 n set character right-side spacing (not implemented) 1b 24 etc. Set absolute starting position 1b 32 ...

Page 190

Appendix b: communication information 7156 service guide september 1998 176 printer function commands hexadecimal code command receipt station commands in chapter 6 of the owner’s guide. Print characteristics commands these commands control what the printed information looks like and are listed in n...

Page 191

7156 service guide appendix b: communication information september 1998 177 graphics commands these commands print graphics data and are listed in numerical order of their hexadecimal codes. Graphics commands hexadecimal code command 1b 24 etc. Set absolute starting position 1b 2a m etc. Set bit ima...

Page 192

Appendix b: communication information 7156 service guide september 1998 178 bar code commands these commands print bar codes on the receipt station and are listed in numerical order of their hexadecimal codes. Hri means human readable interface. Bar code commands hexadecimal code command 1d 48 n sel...

Page 193

7156 service guide appendix c: common pc board and extender cables september 1998 179 appendix c: common pc board and extender cables the common pc board replaces the older rs-232c and the older lcsio (rs-485) pc boards. When the common pc board replaces the lcsio (rs-485) pc board with the micr che...

Page 194

Appendix c: common pc board and extender cables 7156 service guide september 1998 180 amplifier board interconnect cable micr solenoid extender cable solenoid connector read head connector motor connector buck coil extender cable buck coil connector read head extender cable 3. Connect the micr read ...

Page 195: Ordering Forms

7156 service guide appendix d: ordering paper and supplies september 1998 181 appendix d: ordering paper and supplies thermal receipt paper, ribbon cassettes, and forms can be ordered. Documentation is also available. Ordering thermal receipt paper the 7156 requires “fax grade” thermal paper with th...

Page 196: Ordering Ribbon Cassettes

Appendix d: ordering paper and supplies 7156 service guide september 1998 182 to order forms, contact your sales representative or order from ncr at the following address or toll free number: ncr media products division 9995 washington church road miamisburg, oh 45342 voice: 1(800)543-8130 (toll fre...

Page 197: Ordering Documentation

7156 service guide appendix d: ordering paper and supplies september 1998 183 ordering documentation contact your sales representative to order the following documentation: • 7156 thermal receipt and impact slip printer: setup and user’s guide (bd20-1435-a) • 7156 thermal receipt and impact slip pri...

Page 198

Appendix d: ordering paper and supplies 7156 service guide september 1998 184.

Page 199: Index

7156 service guide index september 1998 185 index —7— 7156 printer adjustments, 53 clearance, 11 dimensions, 11, 168 environmental requirements, 167 features, 4 installation, 7 location, 10 options, 5 ordering supplies, 181 power requirements, 166 power supply, ordering, 182 reliability, 167 repacki...

Page 200

Index 7156 service guide september 1998 186 —d— data scope mode, 35 density, of print, 168 diagnostics, 21 level 0, 21 level 1, 22 level 2, 39 level 3, 39 print tests, 39 startup, 21 dimensions, of printer, 10, 168 dip switches. See switch settings documentation ordering, 183 drive plate assembly di...

Page 201

7156 service guide index september 1998 187 level 0 diagnostics, 21 level 1 diagnostics, 22 data scope mode, 35 ignoring/using carriage return, 26 micr check reader, 27, 30 micr check reader (amplifier board), 30 partial cut distance, 24 print continuous slip, 37 print sample check, 36 print sample ...

Page 202

Index 7156 service guide september 1998 188 platen removing, 62 replacing, 62 platen gap adjusting, 55, 137 power applying to printer, 15 power voltage too low/high, 51 power cables connecting, 12 power requirements, 166 power supply ordering, 182 print density, receipt, 168 print mechanism, impact ...

Page 203

7156 service guide index september 1998 189 —t— test points, 43 testing the printer, 15, 39 thermal mount removing, 100 replacing, 131 thermal paper ordering, 181 requirements, 181 suppliers, 181 thermal printhead cleaning, 19 print density, 168 removing, 72 replacing, 73 thermal receipt mechanism d...

Page 204

Index 7156 service guide september 1998 190

Page 206

Bd20-1437-a issue b 0998 ncr is the name and mark of ncr corporation © 1997, 1998 ncr corporation printed in u.S.A..