- DL manuals

- Oki

- Printer Accessories

- C610 Series

- Maintenance Manual

Oki C610 Series Maintenance Manual

Oki Data CONFIDENTIAL

C610n

Maintenance Manual

[Rev. 1]

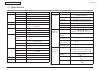

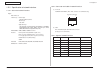

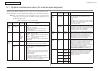

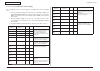

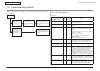

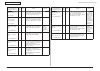

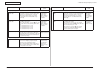

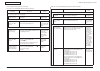

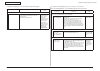

Related drawings

Drawing No.

Name

44205301TL

C610n Disassembly for Maintenance

44205301TR

C610n RSPL

BOM

Use for

Certification Body

Rev

Date

DCO No.

Contents

Design

Approval

Approval

Naoki Sunaga

Design

Naoki Sunaga

Name

C610n

Maintenance Manual

Check

Date

2009-12-18

Drawing No.

44205301TH

1

217

No.01

Summary of C610 Series

Page 1

Oki data confidential c610n maintenance manual [rev. 1] related drawings drawing no. Name 44205301tl c610n disassembly for maintenance 44205301tr c610n rspl bom use for certification body rev date dco no. Contents design approval approval naoki sunaga design naoki sunaga name c610n maintenance manua...

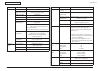

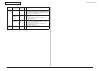

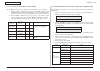

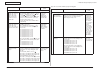

Page 2

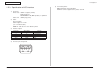

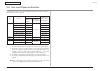

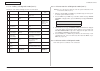

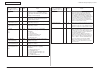

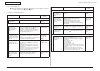

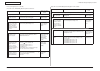

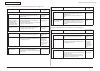

44205301th rev.1 2 / oki data confidential document revision history rev.No date corrected items person in charge no. Page description of change 1 2009-12-18 issue ped11 n. Sunaga rev.No date corrected items person in charge no. Page description of change.

Page 3

44205301th rev.1 3 / oki data confidential this manual provides an overview of method for maintaining the c610n. This manual is intended for maintenance staff. For more information about how to operate the c610n, please refer to user 's manual. Note! • manual may be revised and updated at any time w...

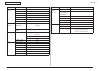

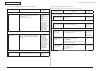

Page 4

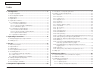

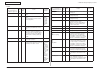

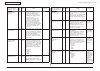

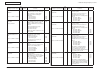

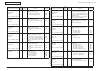

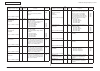

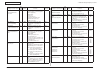

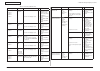

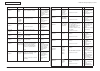

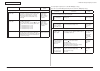

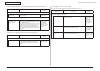

44205301th rev.1 4 / oki data confidential index 1. Configuration ........................................................................... 6 1.1 system configuration ............................................................................................ 7 1.2 the configuration of printer ......

Page 5

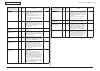

44205301th rev.1 5 / oki data confidential 5.3.1.3 switch scan test ................................................................................... 98 5.3.1.4 motor clutch test ................................................................................ 100 5.3.1.5 test print ..................

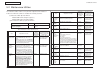

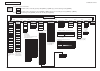

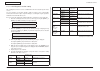

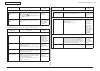

Page 6: Configuration

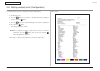

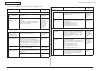

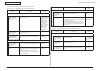

Oki data confidential 1. Configuration 1.1 system configuration .....................................................................7 1.2 the configuration of printer ...........................................................8 1.3 optional parts .......................................................

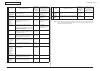

Page 7

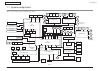

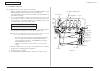

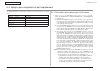

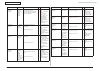

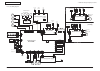

44205301th rev.1 7 / oki data confidential 1.Configuration environmental humidity feed clutch hopping clutch paper-feeding/ moving motor eep rom cd1 asic (1/2) acc (host usb) lan usb cu area option ram flash rom option sd memory card paper- feeding clutch mpt clutch duplex fan front sensor in sensor...

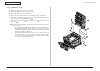

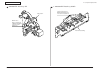

Page 8

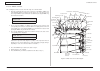

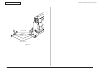

44205301th rev.1 8 / oki data confidential 1.Configuration air flow fig 1-2 1.2 the configuration of printer the parts in the c610n are shown as below. • electrophotography process mechanism • paper feed path • control part (cu part/ pu part) • operator panel • power part (high-voltage part/low-volt...

Page 9

44205301th rev.1 9 / oki data confidential 1. Configuration 1.3 optional parts the optional parts for this printer are shown as below. (1) optional tray(second tray/ third tray) (2) duplex unit (3) optional memory (4) sd memory card.

Page 10

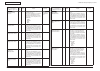

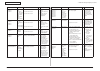

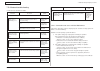

44205301th rev.1 10 / oki data confidential 1. Configuration 1.4 specifications division item dimension width 435mm depth 536mm height 340mm weight about 26kg width of print width of print letter size, vertical print speed engine speed (a4) 34ppm(color) 36ppm(mono) print start first print time 8sec(...

Page 11

44205301th rev.1 11 / oki data confidential 1. Configuration division item operation life printer operation life 420,000 pieces a4 transvers direction, 5years print duty (m=l/12, a=l/12/5) max 60,000 pages / month average 6,000 pages/ month mtbf (2.3% duty) not applicable mpbf 50,000 pages mttr with...

Page 12

44205301th rev.1 12 / oki data confidential 1. Configuration division item status switch/ sensor paper out have paper low none toner low have (y, m, c, k) cover open have temperature of fuser have paper size none (menu setting) stacker full have communication interface standard (on the pcb) • hi-spe...

Page 13

44205301th rev.1 13 / oki data confidential 1. Configuration 1.5 specification of interface 1.5.1 specification of usb interface 1.5.1.1 general of usb interface (1) spec. Usb (support hi speed usb ) (2) transmission mode full speed (maximum 12mbps 0.25%) high speed(maximum 480mbps 0.05%) (3) power ...

Page 14

44205301th rev.1 14 / oki data confidential 1. Configuration 1.5.2 specification of network interface 1.5.2.1 general of network interface spec. Network protocol tcp/ip sepc. Network layer arp, ip, icmp, ipv6, ipsec transfer layer tcp, udp application layer lpr, port9100, ftp, http, https, ipp, snmp...

Page 15

44205301th rev.1 15 / oki data confidential 1. Configuration 1.5.3 specification of acc interface 1) connector printer side: usb a receptacle (female) downstream port dusb-ara42-t11a (ddk product) or equivalent cable side: usb a plug (male) 2) cable hi-speed usb2.0 cable length: 2.0 m max. (use a sh...

Page 16: Operating Instructions

Oki data confidential 2. Operating instructions 2.1 electrophotographic processing mechanism ...............................17 2.2 printing process ...........................................................................21.

Page 17

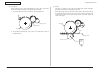

44205301th rev.1 17 / oki data confidential 2. Operating instructions (1) electrophotographic processing the general of electrophotography process is described as below. 1. Charging the voltage is impressed to ch roller, and the surface of opc drum is electrified. 2. Exposure led head irradiates lig...

Page 18

44205301th rev.1 18 / oki data confidential 2. Operating instructions (4) development the toner adheres to the electrostatic latent image on the surface of the drum, and the electrostatic latent image is changed into the toner image. 1. The sponge roller makes the toner adhere to the developing roll...

Page 19

44205301th rev.1 19 / oki data confidential 2. Operating instructions -+ -+ -+ -+ -+ -+ -+ -+ -+ -+ -+ -+ - - - id unit waste toner area toner cartridge drum cleaning blade (6) fusing when the paper passes through the heat roller and backup roller unit, heat and pressure are applied to the toner ima...

Page 20

44205301th rev.1 20 / oki data confidential 2. Operating instructions (9) belt cleaning the toner left on the transport belt is cleaned up by the belt cleaning blade, and all residual toner is collected in the waste toner box of the transport belt unit. Belt waste toner box transport belt belt clean...

Page 21

44205301th rev.1 21 / oki data confidential 2. Operating instructions 2.2 printing process the paper fed from tray 1 or tray 2, tray.3 is transferred by feeder roller, resister roller l, and transfer roller. It is transferred by mpt paper feed roller and resister roller u when the paper is fed from ...

Page 22

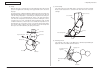

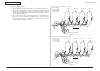

44205301th rev.1 22 / oki data confidential 2. Operating instructions (1) paper feeding from 1st tray 1. As figure 2-1 shows, a feed motor runs clockwise, a feed clutch engages and paper is fed (a feed roller rotates when the feed clutch engages). 2. After turning on an in1 sensor, the paper is fed ...

Page 23

44205301th rev.1 23 / oki data confidential 2. Operating instructions (3) transport belt 1. When the transport belt motor is rotated in the direction of the arrow, the transport belt is driven. As for the belt unit, a transfer roller is set over under each color drum. The belt is caught and installe...

Page 24

44205301th rev.1 24 / oki data confidential 2. Operating instructions (4) updown operation of id unit 1. The up and down operation of the id unit is done by driving the liftup motor. 2. Fig. 2-6 shows the operation of each id unit when color printing. When the liftup motor is rotated (counter clockw...

Page 25

44205301th rev.1 25 / oki data confidential 2. Operating instructions (5) fuse unit and paper delivery 1. The fuse unit and the delivery roller are driven by the dc motor as shown in fig. 2-8. When the fuse motor is rotated (counter clockwise), the heat roller will begin to rotate. The heat roller m...

Page 26

44205301th rev.1 26 / oki data confidential 2. Operating instructions general of color blur correction the color blur correction is operated by reading the pattern for correction printed on the belt with a sensor set in the sensor shutter under the belt unit. The pattern is detected by this sensor, ...

Page 27

44205301th rev.1 27 / oki data confidential 2. Operating instructions error-confirming method and error-solving method use the color blur correction test function in self-diagnostic mode to confirm the error. (see 5.3.1.6) error solving method • calibration(l or r), dynamicrange(l or r) check 1: whe...

Page 28

44205301th rev.1 28 / oki data confidential 2. Operating instructions general of the density correction the density correction is operated by reading the pattern for correction printed on the belt with a sensor set in the sensor shutter under the belt unit. Density correction auto-start timing • the...

Page 29

44205301th rev.1 29 / oki data confidential 2. Operating instructions error-confirming method and error-solving method use the density correction test function in self-diagnostic mode to confirm the error. (see 5.3.1.7) error solving method • calibration err, dens sensor err check 1: when the above ...

Page 30

44205301th rev.1 30 / oki data confidential 2. Operating instructions counter spec total printed page number mpt printed page number tray 1 printed page number tray 2 printed page number tray 3 printed page number color-printed page number mono-printed page number description total printed page numb...

Page 31

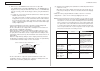

44205301th rev.1 31 / oki data confidential 2. Operating instructions a4/letter conversion table the paper is counted up as this sheet. Paper size simplex duplex letter 1 2 executive 1 2 legal14 1 2 legal13.5 1 2 legal13 1 2 a4 1 2 a5 1 2 a6 1 - b5 1 2 com-9 1 - com-10 1 - monarch 1 - dl 1 - c5 1 - ...

Page 32: Set Up

Oki data confidential 3. Set up 3.1 notes and precautions .................................................................33 3.2 unpack method ...........................................................................34 3.3 setting method ..............................................................

Page 33

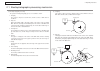

44205301th rev.1 33 / oki data confidential 3. Set up • do not set it in any high-temperature locations or near any heat sources. • do not set it in a place where the chemical reaction may occur (laboratory etc.). • do not set it near any liquid that may ignite such as alcohol and thinner. • do not ...

Page 34

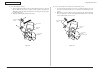

44205301th rev.1 34 / oki data confidential 3. Set up gripe (four gripes on all sides) 3.2 unpack method personal injuries may occur. Because the weight of the printer ( without duplex unit ) is approximately 31kg (in a state of packing), it needs more than two adults to lift it up. • take out the g...

Page 35

44205301th rev.1 35 / oki data confidential 3. Set up 60cm 20cm 20cm 100cm 70cm 3.3 setting method • set the printer under these conditions. Surrounding environment: 10~32 surrounding humidity: 20~80%rh (relative humidity) highest wet bulb temperature: 25 • protect the printer from dew formation. • ...

Page 36

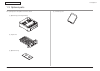

44205301th rev.1 36 / oki data confidential 3. Set up 3.4 list of equipments and accessories • make sure that the appearance of the equipment is not damaged or dirty etc. • make sure that the following accessories are supplied with your printer. • if you are missing any of these accessories, contact...

Page 37

44205301th rev.1 37 / oki data confidential 3. Set up 3.5 assembling method 3.5.1 assemble the main body of the printer remove the protective materials. (1) peel off the desiccant and the protection tape (six places) on the printer. (2) peel off the paper on the front of printer. (3) peel off the pr...

Page 38

44205301th rev.1 38 / oki data confidential 3. Set up (6) pull the retainer out in the direction of the arrow (1). Return the paper cassette to the main body of the printer. (7) press down the open button, and open the top cover. (8) remove the stopper (orange) when pressing down the lever of the fu...

Page 39

44205301th rev.1 39 / oki data confidential 3. Set up set the image drum cartridge. (1) take the image drum cartridge (four) out slowly. Note! • the image drum (green cylinder) is very fragile. Please pay special attention to handling it. • do not expose the image drum cartridge to direct sunshine a...

Page 40

44205301th rev.1 40 / oki data confidential 3. Set up (5) return the image drum cartridge back to the printer. (6) turn the lever of each starter toner cartridge in the direction of the arrow. (four levers) note! If the message of [%color% waste toner full.Replace toner.] on the control panel doesn'...

Page 41

44205301th rev.1 41 / oki data confidential 3. Set up (3) flex the paper back and forth. Do not fold or crease the paper. Straighten the edges on a level surface. (4) place the paper in the cassette with the side to be printed facing down. Note! • place the paper with the top of the page nearest the...

Page 42

44205301th rev.1 42 / oki data confidential 3. Set up set the paper in multi-paper tray. (1) open the multi-paper tray, and open the paper supporter. (2) match the manual insertion guide to the size of the paper. (3) flex the paper back and forth. Straighten the edges on a level surface. (4) place t...

Page 43

44205301th rev.1 43 / oki data confidential 3. Set up 3.5.2 cable connect power condition • keep the following items. Ac voltage : 110~127v ± 10%/ 220~240v ± 10% frequency of the power supply : 50hz or 60hz ± 2% • use the voltage adjusting transformer etc. When the power supply is unstable. • the ma...

Page 44

44205301th rev.1 44 / oki data confidential 3. Set up [back] button o i turn the power off. Note! If you turn off the power without properly shutting down, it may cause damage to the printer. Please follow the following procedure to turn the power off. (1) a message [shut down yes/no] appears. Be su...

Page 45

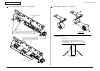

44205301th rev.1 45 / oki data confidential 3. Set up tab hole in the bottom tab hole in the bottom of the printer tab hole in the bottom of the printer 3.5.3 optional part installation and confirmation (1) installation of the optional tray unit (second/ third tray) it is a traditional paper tray fo...

Page 46

44205301th rev.1 46 / oki data confidential 3. Set up (1)-5. Set the number of tray by the printer driver. The printer driver setup for recognizing the option tray unit is required. If the printer driver is not set up, please set up the printer driver completely referring to the user's manual (setup...

Page 47

44205301th rev.1 47 / oki data confidential 3. Set up for windows pcl printer driver for windows vista, click on [start] => [control panel] => [printer]. For windows xp, click on [start] => [control panel] => [printer and other hardware] => [printers and faxes]. For windowsserver 2003, click on [sta...

Page 48

44205301th rev.1 48 / oki data confidential 3. Set up (2) installation of duplex unit this unit is used for printing on two sides of paper. Note! For two-sides printing, it is recommended to add expansion memory. For details, see "expansion memories." (2)-1. Turning off the printer power and disconn...

Page 49

44205301th rev.1 49 / oki data confidential 3. Set up type name memory capacity (total memory capacity) none (standard) 256mb (256mb) mem256g +256mb (512mb) mem512d +512mb (768mb) notes! • the operation cannot be guaranteed when using an unspecified product. Please use oki product. • it is recommend...

Page 50

44205301th rev.1 50 / oki data confidential 3. Set up (3)-3. Remove the side cover. (3)-4. Install the memory. Screw side cover loose the screw (one place). Remove the side cover. Pull it outward to remove while holding the upper edge of the side cover to lift. Notes! • do not touch any electrical p...

Page 51

44205301th rev.1 51 / oki data confidential 3. Set up (3)-5. Install the side cover. (3)-6. Connect the power cord and printer cable to the printer, and turn the power on. Note! If the message [service call/031:fatal error] is displayed, please reinstall the memory. (3)-7. Print the setting content ...

Page 52

44205301th rev.1 52 / oki data confidential 3. Set up (4)-2. Open the top cover and front cover. Open the multi-purpose tray. Press down the open button, and open the top cover. (4)-3. Remove the side cover. Screw side cover loose the screw (one place). Remove the side cover. Pull it outward to remo...

Page 53

44205301th rev.1 53 / oki data confidential 3. Set up press the sd memory card until it clicks. (4)-6. Connect the power cord and printer cable to the printer, and turn the power on. Screw top cover front cover side cover install the side cover. Fix the side cover with the screw. (one place) close t...

Page 54

44205301th rev.1 54 / oki data confidential 3. Set up (4)-8. Set [sd memory card] by printer driver note! The authority of the computer administrator is required. For windows ps printer driver (for windows xp) for windows vista, click on [start] => [control panel] => [printer]. For windows xp, click...

Page 55

44205301th rev.1 55 / oki data confidential 3. Set up for mac os x when the optional device has been added into in mac os x before installing the printer driver, the device information is gotten automatically. However, if the printer is connected by [ip print] and [bonjour (rendezvous)], the device ...

Page 56

44205301th rev.1 56 / oki data confidential 3. Set up 3.6 setting content print (configuration) to confirm the printer operates normally, please print the [configuration]. (1) set a4 paper in tray. (2) press the button for several times so that [print information] is displayed, and press down the bu...

Page 57

44205301th rev.1 57 / oki data confidential 3. Set up 3.7 connecting method note! Please refer to user’s manual for operation environment. Prepare for usb cable notes! • the printer cable is not included. Provide the usb2.0 cable for special user. • when connecting the cable in [hi-speed] mode of us...

Page 58

44205301th rev.1 58 / oki data confidential 3. Set up note! Refer to user’s manual for operation environment. Prepare for ethernet cable note! The ethernet cable and hub is not included in printer. Provide the ethernet cable and hub for special user. Network interface connector turn the printer and ...

Page 59

44205301th rev.1 59 / oki data confidential 3. Set up 3.8 user used paper confirmation load the paper used by user, set the media type/weight, print the setting content/demo, and confirm if the toner is chipped off. Type thickness settings of control panel [thickness of paper] settings of printer dr...

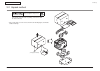

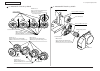

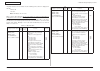

Page 60: Component Replacement

Oki data confidential in this chapter, the procedures for replacement of part and assembly and unit are described. The replacement procedure is described by removal of the parts. Please install the new parts with following the replacement procedure in reverse order. The parts (such as , )shown in th...

Page 61: Warning

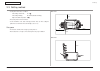

44205301th rev.1 61 / oki data confidential 4. Component replacement 4.1 precautions on component replacement (1) remove the ac cord and the interface cable before replacing the parts. (a) remove the ac cord according to the following procedure. Switch the power switch of printer off “o”. Disconnect...

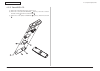

Page 62

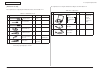

44205301th rev.1 62 / oki data confidential 4. Component replacement [maintenance tool] the required tools for replacing the pcb and the unit are shown in table 4-1-1. Table 4-1-1 maintenance tools no. Maintenance tools amount purpose note 1 no. 2-200 magnetic driver 1 3 - 5mm screw 2 no. 3-100 driv...

Page 63

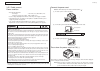

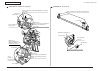

44205301th rev.1 63 / oki data confidential 4. Component replacement 4.2 method of component replacement in this chapter, the replacement of parts and assemblies is described by the disassemble figures. 4.2.1 belt unit (1) open the top cover. (2) remove the id unit . (3) rotate the lock lever (blue,...

Page 64

44205301th rev.1 64 / oki data confidential 4. Component replacement 4.2.2 fuser unit (1) open the top cover. (2) push up the fix lever of fuser unit in the direction of arrow, and remove the fuser unit . Top cover fix lever of fuser unit (blue) fix lever of fuser unit (blue) 4.2.3 left side cover (...

Page 65

44205301th rev.1 65 / oki data confidential 4. Component replacement 4.2.4 right side cover (1) open the top cover. (2) open the feeder unit. (3) loose the screw (silver, no:41723901) and remove the right side cover . 4.2.5 faceup tray (1) draw out the duplex unit . (2) open the faceup tray in the d...

Page 66

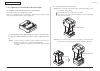

44205301th rev.1 66 / oki data confidential 4. Component replacement 4.2.6 rear cover (1) open the faceup tray. (2) remove the two screws (silver, no:42920406). (3) as shown in fig 2, insert the minus driver into the hole a to disengage the claw a (2 place). (4) disengage the claw b (2 places) and p...

Page 67

44205301th rev.1 67 / oki data confidential 4. Component replacement 4.2.8 control pcb (1) open the top cover. (2) remove the right side cover. (see section 4.2.4) (3) remove the rear cover. (see section 4.2.6) (4) remove the eight screws (silver, no:42920406), remove the connector and disengage the...

Page 68

44205301th rev.1 68 / oki data confidential 4. Component replacement 4.2.9 top cover assy (1) remove the left side cover. (see section 4.2.3) (2) remove the right side cover. (see section 4.2.4) (3) remove the rear cover. (see section 4.2.6) (4) remove the plate shield and take the control pcb out. ...

Page 69

44205301th rev.1 69 / oki data confidential 4. Component replacement 4.2.11 control panel assy (1) open the top cover. (2) insert the minus driver into the upper side of the slit (3 places) to disengage the claws on the control panel assy , remove the connector and take the control panel assy out. S...

Page 70

44205301th rev.1 70 / oki data confidential 4. Component replacement 4.2.12 board ibg/ lcd (1) remove the control panel assy. (see section 4.2.11) (2) remove the screws (black, no:42932708) (2 places), remove the connector and cable of lcd and remove the board ibg . (3) remove the screws (black, no:...

Page 71

44205301th rev.1 71 / oki data confidential 4. Component replacement (9) remove the lever lock , compression spring , torsion spring , button switch , cable assy from the frame panel . Frame panel assy 4.2.13 frame panel assy (1) open the top cover. (2) open the feeder unit. (3) remove the left side...

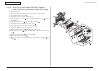

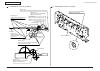

Page 72: Warning

44205301th rev.1 72 / oki data confidential 4. Component replacement 4.2.14 low voltage power supply/low voltage fan/ hopping motor/ fuse motor claw d claw e air tb4 tb3 cn6 cn2 cn1 cu/pu pcb power connenctor ac switch fuser i/f connenctor low-voltage power supply for cn6 short plug note! Cn6: a con...

Page 73

44205301th rev.1 73 / oki data confidential 4. Component replacement 4.2.15 guide eject assy/ color regist assy/ board-pry (1) remove the left side cover, right side cover, rear cover, top cover assy. (see section 4.2.3, 4.2.4, 4.2.6, 4.2.9) (2) remove the control pcb and low-voltage power supply. (...

Page 74

44205301th rev.1 74 / oki data confidential 4. Component replacement air claw b claw b (black) (silver) claw a 4.2.16 fan(fuser) / belt motor/ high-voltage board/ cover open switch (1) remove the left side cover. (see section 4.2.3) (2) remove the screw (silver, no:42920406) and connector, and remov...

Page 75

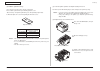

44205301th rev.1 75 / oki data confidential 4. Component replacement 4.2.18 cover assy front/ board-rsf/mpt hopping roller/ frame assy separator/ feeder assy regist (1) open the top cover. (2) remove the plate shield and remove the connector. (see section 4.2.8) (3) disengage the claws of stay l . (...

Page 76

44205301th rev.1 76 / oki data confidential 4. Component replacement 4.2.19 board-prz/ liftup motor/ hopping motor/ paper end sensor/ hopping sensor/ cassette sensor (1) remove the left side cover, right side cover, rear cover, top cover unit, feeder assy regist. (see section 4.2.3, 4.2.4, 4.2.6, 4....

Page 77

44205301th rev.1 77 / oki data confidential 4. Component replacement ×4 a b a b side plate assy e ring (re3-sk) 4.2.20 feed roller (1) remove the cassette. (2) remove the latch and remove the feed roller (2 pieces) . Latch.

Page 78

44205301th rev.1 78 / oki data confidential 4. Component replacement 4.2.21 shaft eject assy (fu)/ shaft eject assy(fd/ eject sensor (1) remove the eject assy. (see section 4.2.15) (2) disengage the claws (2 places), and disassemble the assy into guide eject lower and guide eject upper . (3) remove ...

Page 79

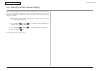

44205301th rev.1 79 / oki data confidential 4. Component replacement 4.3 oiling spots class amount of grease (cc) w(mm) sample s a b c d e f 0.0005 0.003 0.005 0.01 0.03 0.05 0.1 1.24 2.25 2.67 3.37 4.86 5.76 7.26 w this chapter shows the oiling spots. Do not oil the other spots that are not shown h...

Page 80

44205301th rev.1 80 / oki data confidential 4. Component replacement 44259301pa gear assy.-hp -1 44259101pa plate-assy.-side r holder-gear-a em-30l class c apply a normal amount of molykote (em-30l) to the whole circle of hatched areas. Em-30l class c apply a normal amount of molykote (em-30l) to th...

Page 81

44205301th rev.1 81 / oki data confidential 4. Component replacement -2 44259101pa plate-assy.-side r stopper-gearid gear-idle-z44 gear-idle-drumz24-102 gear-liftup-z121z34 spacer-coupling grease prohibition em-30l class c apply a normal amount of molykote (em-30l) to the end surface. Em-30l class c...

Page 82

44205301th rev.1 82 / oki data confidential 4. Component replacement -4 44259101pa plate-assy.-side r -5 44259101pa plate-assy.-side r gear-liftupr-z32 gear-liftup- z83z25 gear-liftup-z121z34 gear-idle liftup-z28 link-liftup-r motor-pulse-liftup gear-liftupr-z32 (5) gear-liftuplinkr-z56 em-30l class...

Page 83

44205301th rev.1 83 / oki data confidential 4. Component replacement 43074904pa plate-assy.-side-l 42071401pa holder assy.-regist-l gear-liftup-z32 em-30l class b apply a small amount of molykote (em-30l) to the hatched areas. Em-30l class a apply a small amount of molykote (em-30l) to the hatched a...

Page 84

44205301th rev.1 84 / oki data confidential 4. Component replacement 44261901pa feeder assy.-regist roller-pressure 5mm 5mm 13mm 10mm roller-regist-u em30l class c apply a normal amount of molykote (em-30l) to the hatching areas (shaft). Em30l class c apply a normal amount of molykote (em-30l) to th...

Page 85

44205301th rev.1 85 / oki data confidential 4. Component replacement 44259801pa guide-assy. -eject-u shaft-assy.-eject(fu) shaft-assy.-eject(fd) gear-idle-exit-z36 em-30l class c apply a normal amount of molykote (em-30l) to surface of the post (bearing portion). Em-30l class c apply a normal amount...

Page 86

44205301th rev.1 86 / oki data confidential 4. Component replacement cover-assy.-top plate-assy.Side r spring-torsion-l spring-torsion-r panmotoroil class c apply a normal amount of panmotoroil to the portion of the slot of solid coiling of this torsion-spring using a brush. (2 places) (at both side...

Page 87

44205301th rev.1 87 / oki data confidential 4. Component replacement cover-sensor-c.Regist em-30l class a apply a small amount of molykote (em30-l) to the hatched areas (both side, 8 places). The surface of cover-sensor-c.Regist should not be stained with molykote. Plate-sensor-c.Regist gear assy.-s...

Page 88

44205301th rev.1 88 / oki data confidential 4. Component replacement method of amount grease not allowed to stain the area with grease. Em-30l class s after assemble to , apply a minimum amount of molykote (em-30l) to the sliding portions of and (the hatched areas). 43301601pa roller-assy. -bias(fu)...

Page 89

44205301th rev.1 89 / oki data confidential 4. Component replacement -2 44258901pa cassette-assy-px755 plate-receive em-30l class b apply a normal amount of molykote (em-30l) to the hatched area.(2 palces).

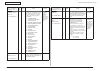

Page 90: Maintenance Menu

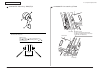

Oki data confidential 5. Maintenance menu adjustment of this printer can be performed from the maintenance utilities by entering the corresponding menu from the keyboard of the operator panel. This printer contains the maintenance menu in addition to the normal operation menus. Select an appropriate...

Page 91

44205301th rev.1 91 / oki data confidential 5. Maintenance menu 5.1 system maintenance menu (for maintenance engineer) while pressing the menu+ and menu- keys, turn on the power to enter the maintenance menu. The menu indications are shown in english only regardless of the destination of the printer...

Page 92

44205301th rev.1 92 / oki data confidential 5. Maintenance menu category item (1st line) value (2nd line) df function change password - changes the password. When the enter switch is pressed after entering in this menu, the messages "new password" and "verify password" are displayed enabling user to...

Page 93

44205301th rev.1 93 / oki data confidential 5. Maintenance menu 5.2 maintenance utilities the maintenance utilities enables user to perform the adjustment shown in table 5-2. Details of the maintenance utilities are available in the following documents. (1) maintenance utilities operation manual: 42...

Page 94

44205301th rev.1 94 / oki data confidential 5. Maintenance menu item adjustment contents maintenance utilities operation manual item number operation on the operator panel (item number corresponds to that of the maintenance manual.) 14 menu setup value confirmation displays the setup values that hav...

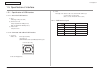

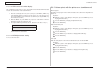

Page 95

44205301th rev.1 95 / oki data confidential 5. Maintenance menu 5.3 maintenance menu functions 5.3.1 self-diagnostic mode this section describes the self-diagnostic level 0 and level 1 respectively. 5.3.1.1 operation panel the following description on operating the self-diagnostic is premised on the...

Page 96

44205301th rev.1 96 / oki data confidential 5. Maintenance menu test print print execute test pattern test cassette *1 page color duplex*1 [menu+] level1 (1) how to select the menu items menu items can be selected by pressing either [menu+] or [menu-] key, and executed by pressing [enter]. Xxxxx xxx...

Page 97

44205301th rev.1 97 / oki data confidential 5. Maintenance menu 5.3.1.2 ordinary self-diagnostic mode (level 1) menu items of the ordinary self-diagnostic mode are shown below. Item self-diagnostic menu adjustment contents maintenance utilities 1 switch scan test switch scan entry sensor check and s...

Page 98

44205301th rev.1 98 / oki data confidential 5. Maintenance menu 5.3.1.3 switch scan test this self-diagnostic menu is used to check the entry sensor and the switch. 1. Enter the self-diagnostic mode (level 1) and press the menu+, menu- key until "switch scan" is displayed in the upper row of the dis...

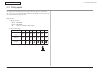

Page 99

44205301th rev.1 99 / oki data confidential 5. Maintenance menu table 5-3 switch scan details asterisk mark (*) is displayed in the lower row of display area. * 1: “l” is displayed when the cover is opened. Display area, upper row 1 2 3 4 details display area, lower row details display area, lower r...

Page 100

44205301th rev.1 100 / oki data confidential 5. Maintenance menu 5.3.1.4 motor clutch test this self-diagnostic menu is used to test the motor and clutch. 1. Enter the self-diagnostic mode (level 1) and press the menu+, menu- key until "switch scan" is displayed in the upper row of the display area....

Page 101

44205301th rev.1 101 / oki data confidential 5. Maintenance menu table 5-4 unit name display drive restriction condition remarks id motor to be driven when all of the id (k/y/m/c) are removed. − belt motor to be driven when all of the id (k/y/m/c) are removed. − fuser_rls − − regist motor − − t1 hop...

Page 102

44205301th rev.1 102 / oki data confidential 5. Maintenance menu 5.3.1.5 test print this self-diagnostic menu is used to print the test pattern that is built inside pu. Other test patterns are stored in the controller. This test print cannot be used to check the print quality. Diagnosis for the abno...

Page 103

44205301th rev.1 103 / oki data confidential 5. Maintenance menu 4. While the message "print execute" that is set by the operation specified in step 2 is being displayed, press the enter key and the test print is executed with the setting value that has been set by steps 2 and 3. Pressing the cancel...

Page 104

44205301th rev.1 104 / oki data confidential 5. Maintenance menu • during printing, the following messages are displayed. P=*** w=*** p : number of test print copies (unit: copies) w : print waiting time (unit: second) • displays are switched by pressing the menu+ key. T=*** u=***[###] h=***%l=***[#...

Page 105

44205301th rev.1 105 / oki data confidential 5. Maintenance menu • displays are switched by pressing the menu+ key. Tr1:k**y**m**c** tr2:k**y**m**c** trl : transfer voltage parameter vtr1 table id number [unit: hex) tr2 : transfer voltage parameter vtr2 table id number [unit: hex) • displays are swi...

Page 106

44205301th rev.1 106 / oki data confidential 5. Maintenance menu 5.3.1.6 color registration correction test this self-diagnostic menu item is used for the color registration error adjustment and to investigate cause of the error of a printer. If the color registration error is recognized by the colo...

Page 107

44205301th rev.1 107 / oki data confidential 5. Maintenance menu 4. Repeat steps 2 and 3 as required. 5. Pressing the [back] terminates the test. (returns to the status of step 1.) color registration correction test items display details reg adj execute executing the color registration correction re...

Page 108

44205301th rev.1 108 / oki data confidential 5. Maintenance menu when the [cancel] key is pressed while test is in progress (while the [on line] lamp is lighting), the screen returns to the state of step 2. > the same as the key operations of step 2. During execution of dens adj execute. > setup of ...

Page 109

44205301th rev.1 109 / oki data confidential 5. Maintenance menu 5.3.1.8 consumable item counter display this self-diagnostic menu is used to display the consumption status of the consumable items. 1. Enter the ordinary self-diagnostic mode and press the menu+, menu- key until "consumable status" is...

Page 110

44205301th rev.1 110 / oki data confidential 5. Maintenance menu 5.3.1.9 number of print copies counter display this self-diagnostic menu is used to display status of the number of copies of a printer. 1. Enter the ordinary self-diagnostic mode and press the menu+, menu- key until "printer status" i...

Page 111

44205301th rev.1 111 / oki data confidential 5. Maintenance menu 5.3.1.11 self-diagnostic function setting this self-diagnostic menu is used to set valid/invalid of the error detection by the various sensors. The error detection can be made invalid or valid for locating source of abnormality. Howeve...

Page 112

44205301th rev.1 112 / oki data confidential 5. Maintenance menu 5.3.1.12 led head serial number display this self-diagnostic menu item is used to check whether the downloaded led head data matches the serial number of the actual led head. 1. Enter the self-diagnostic mode (level 1) and press the me...

Page 113

44205301th rev.1 113 / oki data confidential 5. Maintenance menu 5.3.3 functions of keys at power on functions of the respective keys when the printer power is turned on are displayed below. Each of the following keys becomes valid if the key is kept pressed until "ram check" is displayed in the upp...

Page 114

44205301th rev.1 114 / oki data confidential 5. Maintenance menu 5.4 setups upon completion of part replacement the adjustments that are required upon completion of part replacement are described below. Replacement parts adjustment contents led head see note. Not required drum cartridges (y, m, c, k...

Page 115

44205301th rev.1 115 / oki data confidential 5. Maintenance menu (2) switching to the shipping mode (maintenance utilities operation manual section 2.4.1.1.10.4) when the board is replace with the new board, the new board has been set in the factory working mode. Therefore, it should be switched to ...

Page 116

44205301th rev.1 116 / oki data confidential 5. Maintenance menu 5.5 density control manual setting when a printer is shipped from the factory, the automatic density correction mode has been set in "automatic". If a printer is used after the density correction mode is set to "manual", density may ch...

Page 117

44205301th rev.1 117 / oki data confidential 5. Maintenance menu 5.6 printer boot menu list while pressing the set button, turn on the power to display the boot menu. Memo to display the boot menu, entry of password is required. Default value of password is "aaaaaa". Category item setting value func...

Page 118

44205301th rev.1 118 / oki data confidential 5. Maintenance menu category item setting value function storage setup check file system execute resolves the un-match between the actual (free) space and displayed free space of file system, and recovers the control data (fat information.) check all sect...

Page 119: Periodic Maintenance

Oki data confidential 6. Periodic maintenance 6.1 cleaning ....................................................................................120 6.2 how to clean the led lens array ...............................................121 6.3 how to clean the pickup roller ..................................

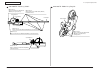

Page 120

44205301th rev.1 120 / oki data confidential 6. Periodic maintenance clean inside and outside of the printer with clean dry cleaning cloth and small vacuum cleaner (hand cleaner) as required. Note! Be careful not to touch the image drum terminals, the led lens array and the led head connectors. 6.1 ...

Page 121

44205301th rev.1 121 / oki data confidential 6. Periodic maintenance 6.2 how to clean the led lens array if the white banding, white stripe (white drop-out, light printing) in the vertical direction occurs on the print surface, clean the led lens array. Perform cleaning of the led head. If any light...

Page 122

Oki data confidential 44205301th rev.1 122 / 6. Periodic maintenance (3) wipe the lens surface (at the four positions) of the led head with soft tissue paper gently and lightly. Note! Do not use the solvents such as methyl alcohol or thinner for cleaning the led head lens because they can damage the...

Page 123

44205301th rev.1 123 / oki data confidential 6. Periodic maintenance 6.3 how to clean the pickup roller if the vertical banding in the vertical direction occurs on the print surface, clean the pickup roller. Note! Be sure to use a soft cloth or the like for cleaning the pickup roller. Otherwise, the...

Page 124

44205301th rev.1 124 / oki data confidential 6. Periodic maintenance 6.4 how to clean inside of printer clean inside of the printer. Toner can adhere to the metal shaft located in between the fuser and the cyan image drum cartridge depending on the print patter. Perform cleaning of inside of the pri...

Page 125

Oki data confidential 44205301th rev.1 125 / 6. Periodic maintenance (4) remove the fuser unit. Personal injuries may occur. The fuser unit gets very hot. Be very careful not to touch the fuser unit with your hands. If it got hot, stop the work and wait until it cools down. After it has cooled down,...

Page 126

Oki data confidential 7. Troubleshooting and repair procedure 7.1 before starting the repair work ..................................................127 7.2 confirmation items before taking corrective action against abnormalities ..........................................................................

Page 127

44205301th rev.1 127 / oki data confidential 7. Troubleshooting and repair procedure 7.1 before starting the repair work (1) confirm the basic check/inspection points described in user’s manual. (2) get the information/status from client at the time when the trouble has occurred as much in details a...

Page 128

44205301th rev.1 128 / oki data confidential 7. Troubleshooting and repair procedure 7.5 troubleshooting method when a trouble occurs in this printer, perform troubleshooting by following the steps described below. 7.5.1 lcd message list initializing panel display (the mark indicates no message in t...

Page 129

44205301th rev.1 129 / oki data confidential 7. Troubleshooting and repair procedure panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details checking sectors nnn% off off displays that a sector of sd card is being checked. Check process of the sector is v...

Page 130

44205301th rev.1 130 / oki data confidential 7. Troubleshooting and repair procedure normal panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure ready to print on off indicates that a printer is in the online status. − offline off off ...

Page 131

44205301th rev.1 131 / oki data confidential 7. Troubleshooting and repair procedure panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure cancelling job blink varies indicates that canceling of a printing without permission is in progr...

Page 132

44205301th rev.1 132 / oki data confidential 7. Troubleshooting and repair procedure warning panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure %color% toner low varies on (blink) (off) toner amount is low. Displayed in a combination...

Page 133

44205301th rev.1 133 / oki data confidential 7. Troubleshooting and repair procedure panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure %color% toner sensor error varies on toner sensor warning: indicates the printer has a toner sens...

Page 134

44205301th rev.1 134 / oki data confidential 7. Troubleshooting and repair procedure panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure %color% image drum life varies on indicates that the image drum has reached end of life. This sta...

Page 135

44205301th rev.1 135 / oki data confidential 7. Troubleshooting and repair procedure panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure sensor calibration error varies on sensor adjustment error because the pu firmware does not notic...

Page 136

44205301th rev.1 136 / oki data confidential 7. Troubleshooting and repair procedure panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure usb hub unsupported please detach it varies varies indicates a usb hub not supported by the print...

Page 137

44205301th rev.1 137 / oki data confidential 7. Troubleshooting and repair procedure panel display (the mark indicates no message in the upper row.) on line lamp inspection lamp details remedial measure file system operation failed press online button varies on indicates that a file system error oth...

Page 138

44205301th rev.1 138 / oki data confidential 7. Troubleshooting and repair procedure if a printer detects an un-recoverable error, the following service call error is displayed on the lcd. Service call nnn: error note! Nnn indicates an error code. When a service call is displayed, the error code and...

Page 139

44205301th rev.1 139 / oki data confidential 7. Troubleshooting and repair procedure display on operator panel on line lamp inspection lamp contents code nnn change paper in mptray %media_size% %media_type% press online button please see help for details off blink indicates that the paper size of th...

Page 140

44205301th rev.1 140 / oki data confidential 7. Troubleshooting and repair procedure display on operator panel on line lamp inspection lamp contents code nnn install paper cassette %tray% please see help for details off blink indicates that paper feeding is not possible because cassette has been rem...

Page 141

44205301th rev.1 141 / oki data confidential 7. Troubleshooting and repair procedure display on operator panel on line lamp inspection lamp contents code nnn open cassette paper remain %tray% please see help for details off blink additional paper is detected when a paper jam has occurred. Error 632 ...

Page 142

44205301th rev.1 142 / oki data confidential 7. Troubleshooting and repair procedure display on operator panel on line lamp inspection lamp contents code nnn install duplex unit please see help for details off blink indicates that the duplex unit is removed. If this error is detected, printing is st...

Page 143

44205301th rev.1 143 / oki data confidential 7. Troubleshooting and repair procedure display on operator panel on line lamp inspection lamp contents code nnn check data program data receive error off on indicates that an error has occurred during reception of the nic program data for upgrading. %dlc...

Page 144

44205301th rev.1 144 / oki data confidential 7. Troubleshooting and repair procedure table 7-1-2 service call error list display cause error details remedial measure restart the printer. 002: error~ 007: error 009: error~ 011: error cpu exception does the error display recur? Yes no if the ram dimm ...

Page 145

44205301th rev.1 145 / oki data confidential 7. Troubleshooting and repair procedure display cause error details remedial measure service call 081: error parameter integrity check either eeprom or flash rom cannot read/write normally. Turn the printer power off and then back on. If the error symptom...

Page 146

44205301th rev.1 146 / oki data confidential 7. Troubleshooting and repair procedure display cause error details remedial measure service call 150: error~ 153: error the id unit fuse has blown out. (150=y, 151=m, 152=c, 153=k) is the id unit installed normally? Does this error recur? Does the printe...

Page 147

44205301th rev.1 147 / oki data confidential 7. Troubleshooting and repair procedure display cause error details remedial measure service call 176: error 177: error the backup roller thermistor has detected an abnormal temperature (high temperature or low temperature.) does this error recur? Does th...

Page 148

44205301th rev.1 148 / oki data confidential 7. Troubleshooting and repair procedure display cause error details remedial measure re-start the printer. 918: error duplex fan alarm caution fan error inside the duplex unit. Does the error recur when the power is turned off once and back on? Does the e...

Page 149

44205301th rev.1 149 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2 preparation for troubleshooting note! When replacing the cu/pu board, read the eeprom chip contents of the old board first, and copy them to the new board upon completion of the replacement. (refer to section ...

Page 150

44205301th rev.1 150 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (1) lcd display error memo for the numbers from through after name of the respective connectors, refer to section 7.5.2 (19) "wiring diagram". (1-1) lcd does not display anything. Check item check work action...

Page 151

44205301th rev.1 151 / oki data confidential 7. Troubleshooting and repair procedure check item check work action to be taken at ng (1-1-5) lsi operation check i/f signal supplied from the cu/pu board to the operator panel board. Check if the signal is output to the ope connector of the cu/pu board ...

Page 152

44205301th rev.1 152 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (2) abnormal operations of printer after the power is turned on (2-1) any operation does not start at all. Check item check work action to be taken at ng (2-1-1) check the peripherals of the power supplies pr...

Page 153

44205301th rev.1 153 / oki data confidential 7. Troubleshooting and repair procedure check item check work action to be taken at ng (2-2-3) check the jumping phenomena of gear tooth. (abnormal load of the consumable item) operating conditions of the respective motors check if operations of the respe...

Page 154

44205301th rev.1 154 / oki data confidential 7. Troubleshooting and repair procedure (3) paper jams when paper jams occur or paper remains in the printer, "paper jam", or "paper remain" is displayed on the operation panel. By pressing the help button, a method to remove the paper is displayed, remov...

Page 155

44205301th rev.1 155 / oki data confidential 7. Troubleshooting and repair procedure open cassette paper remain [tray name] open cassette paper jam [tray name] when the above messages are displayed. Tray1 is applied here as an example. (1) pull the displayed tray. (2) remove paper. (3) return the tr...

Page 156

44205301th rev.1 156 / oki data confidential 7. Troubleshooting and repair procedure open cover paper remain front cover open cover paper jam front cover when the above messages are displayed. (1) open the multipurpose tray. (2) push up the center handle (blue), to open the front cover. (3) slowly p...

Page 157

44205301th rev.1 157 / oki data confidential 7. Troubleshooting and repair procedure open cover paper remain top cover open cover paper jam top cover when the above messages are displayed. (1) open the top cover. (2) touch the screw with a hand to discharge static. (3) 2uninstall the four image drum...

Page 158

44205301th rev.1 158 / oki data confidential 7. Troubleshooting and repair procedure jam release lever (b) if you do not see the top edge of paper pull up the jammed paper slowly while pushing the jam release lever of the fuser unit. (c) if paper is jammed in the fuser unit pull the lock levers (2 l...

Page 159

44205301th rev.1 159 / oki data confidential 7. Troubleshooting and repair procedure check duplex unit paper remain check duplex unit paper jam when the above messages are displayed. (1) hold and press down the jam release lever of the duplex unit to open the duplex unit cover. (2) release jammed pa...

Page 160

44205301th rev.1 160 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (3) paper feed jam (error code 391: 1st tray) (3-1) jam occurs immediately after the power is turned on. (1st tray) check item check work action to be taken at ng (3-1-1) check condition of the paper running ...

Page 161

44205301th rev.1 161 / oki data confidential 7. Troubleshooting and repair procedure check item check work action to be taken at ng (3-2-4) check the system connection paper feed motor drive cable check the connection condition of the cable. Check if the connector is connected in the half- way only ...

Page 162

44205301th rev.1 162 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (4) feed jam (error code 380) (4-1) jam occurs immediately after the power is turned on. Check item check work action to be taken at ng (4-1-1) check condition of the paper running path paper running path of ...

Page 163

44205301th rev.1 163 / oki data confidential 7. Troubleshooting and repair procedure check item check work action to be taken at ng (4-2-4) check the system connection paper feed motor drive cable check the connection condition of the cable. Check if the connector is connected in the half- way only ...

Page 164

44205301th rev.1 164 / oki data confidential 7. Troubleshooting and repair procedure (5-2) jam occurs immediately after paper feed is started. (multipurpose tray) check item check work action to be taken at ng (5-2-1) check condition of the paper running path paper running path of the multipurpose t...

Page 165

44205301th rev.1 165 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (6) paper running jam (error code 381:) (6-1) jam occurs immediately after the power is turned on. Check item check work action to be taken at ng (6-1-1) check condition of the running path. Paper running pat...

Page 166

44205301th rev.1 166 / oki data confidential 7. Troubleshooting and repair procedure check item check work action to be taken at ng (6-2-4) check the system connection paper feed motor drive cable, id motor drive cable, belt motor drive cable, id up motor drive cable, fuser motor drive cable check t...

Page 167

44205301th rev.1 167 / oki data confidential 7. Troubleshooting and repair procedure (6-4) jam occurs immediately after paper has reached the fuser. Check item check work action to be taken at ng (6-4-1) motor operation check fuser motor confirm that the fuser motor works normally by using the motor...

Page 168

44205301th rev.1 168 / oki data confidential 7. Troubleshooting and repair procedure check item check work action to be taken at ng (7-1-4) check the system connection signal cable for relay board, exit sensor cable check that ffc is normally inserted at the relay connector of the cu/pu board and at...

Page 169

44205301th rev.1 169 / oki data confidential 7. Troubleshooting and repair procedure (7-3) paper unloading jam occurs in the middle of paper running path. Check item check work action to be taken at ng (7-3-1) motor operation check fuser motor confirm that the fuser motor works normally by using the...

Page 170

44205301th rev.1 170 / oki data confidential 7. Troubleshooting and repair procedure (8-2) two-sided printing jam occurs during taking in the paper into duplex unit. Check item check work action to be taken at ng (8-2-1) solenoid operation check duplex solenoid confirm that the duplex solenoid works...

Page 171

44205301th rev.1 171 / oki data confidential 7. Troubleshooting and repair procedure (8-4) two-sided printing jam occurs during transporting paper inside the duplex unit. Check item check work action to be taken at ng (8-4-1) sensor lever operation check dup-r, dup-f sensor lever remove the duplex u...

Page 172

44205301th rev.1 172 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (10) id unit up/down error (service call 140 to 143) (10-1) error occurs during the up movement of the id unit check item check work action to be taken at ng (10-1-1) check the mechanical load during the up m...

Page 173

44205301th rev.1 173 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (11) fuser unit error (error 170 to 177) (11-1) error occurs immediately after the power is turned on. Check item check work action to be taken at ng (11-1-1) thermistor is defective note) upper thermistor, l...

Page 174

44205301th rev.1 174 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (12) motor fan error (error code 122, 127, 128, 918, 051) (12-1) the low voltage power supply fan does not rotate immediately after the power is turned on. Check item check work action to be taken at ng (12-1...

Page 175

44205301th rev.1 175 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (13) print speed is slow. (performance is low.) (13-1) print speed decreases. Check item check work action to be taken at ng (13-1-2) media weight setting media weight that is specified for the print check if...

Page 176

44205301th rev.1 176 / oki data confidential 7. Troubleshooting and repair procedure check item check work action to be taken at ng (14-2-2) check the system connection check the system connection from the cu/pu board to the option tray board (v7y pcb). Check that the cable between the cu/pu board o...

Page 177

44205301th rev.1 177 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (16) toner cartridge cannot be recognized. (error code 540, 541, 542, 543) (16-1) error caused by the consumable items. Check item check work action to be taken at ng (16-1-1) consumable items installation co...

Page 178

44205301th rev.1 178 / oki data confidential 7. Troubleshooting and repair procedure (16-3) error caused by the defective mechanism check item check work action to be taken at ng (16-3-1) mechanical load applied to the id unit id unit check if a heavy mechanical load is being applied to the id unit ...

Page 179

44205301th rev.1 179 / oki data confidential 7. Troubleshooting and repair procedure 7.5.2. (18) humidity sensor error (error code 123) (18-1) humidity sensor error check item check work action to be taken at ng (18-1-1) check the system connection connection between the cu/pu board and operator pan...

Page 180

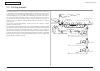

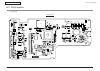

44205301th rev.1 180 / oki data confidential 7. Troubleshooting and repair procedure hvolt fuser motor (dc) belt motor id motor (dc) id up motor rfid antenna board-pol toner-low sensor toner-low sensor toner-low sensor toner-low sensor paper-end sensor hopping sensor cover open switch internal therm...

Page 181

44205301th rev.1 181 / oki data confidential 7. Troubleshooting and repair procedure 7.5.3 troubleshooting the abnormal images a overall faded-out blurred b stain on white print c entirely white d black banding/ black streaking in vertical direction e cyclic abnormality f white banding/ white streak...

Page 182

44205301th rev.1 182 / oki data confidential 7. Troubleshooting and repair procedure 7.5.3.(1) color has faded-out and blurred entirely. (refer to figure 7-2a.) (1-1) color are faded-out and blurred. Check item check work action to be taken at ng (1-1-1) toner remaining amount of toner check if the ...

Page 183

44205301th rev.1 183 / oki data confidential 7. Troubleshooting and repair procedure 7.5.3.(2) stain on white print (refer to figure 7-2b.) (2-1) stain on white print (partial stain) check item check work action to be taken at ng (2-1-1) id unit exposure of drum to light is the drum left in a circum...

Page 184

44205301th rev.1 184 / oki data confidential 7. Troubleshooting and repair procedure 7.5.3.(3) white print (refer to figure 7-2c.) (3-1) white print over entire page check item check work action to be taken at ng (3-1-1) toner condition remaining amount of toner confirm that sufficient amount of ton...

Page 185

44205301th rev.1 185 / oki data confidential 7. Troubleshooting and repair procedure 7.5.3.(4) black banding/black streaking in vertical direction (4-1) thin vertical line (with color) (refer to figure 7-2d.) check item check work action to be taken at ng (4-1-1) id unit condition filming of the id ...

Page 186

44205301th rev.1 186 / oki data confidential 7. Troubleshooting and repair procedure 7.5.3.(6) heavy color registration error (6-1) display of the message "color adjustment is in progress" appears only short time. Check item check work action to be taken at ng (6-1-1) result of color registration er...

Page 187

44205301th rev.1 187 / oki data confidential 7. Troubleshooting and repair procedure ground charge roller developer roller toner feed roller figure 7-3.

Page 188

44205301th rev.1 188 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4 network troubleshooting (1) print cannot be activated from utilities. Check item check work action to be taken at ng (1) check the link lamp check if the link lamp (green) is illuminating or not. Check if the ...

Page 189

44205301th rev.1 189 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.1.1 is the certificate created? Log-on in as the administrator, and select "security" "encryption (ssl/tls)". If the following screen is displayed, certificate of the printer is not created yet. (the same scre...

Page 190

44205301th rev.1 190 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.1.3 check version number of the web browser check version number of the web browser in use. How to check version number. For internet explorer launch the browser and select "help" "version information". Recomm...

Page 191

44205301th rev.1 191 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.1.4 confirm encryption strength of a printer version display of the browser that is confirmed by section "7.5.4.1.3 check version number of the web browser" has description on encryption strength of the browse...

Page 192

44205301th rev.1 192 / oki data confidential 7. Troubleshooting and repair procedure 5. Check the "encryption strength". 6. Set the "encryption strength" to "weak" and press the "apply" button. 7. Check the setup contents, and press "ok". 9. If the printer is displayed in the printer list, the setup...

Page 193

44205301th rev.1 193 / oki data confidential 7. Troubleshooting and repair procedure solution: set the encryption strength to "weak". How to change encryption strength with telnet note! Telnet cannot be used if it remains in the default setting. To change the encryption strength, telnet must be set ...

Page 194

44205301th rev.1 194 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.2 print operation is not possible if print operation is not possible by using the encrypted ipp printer, check the followings. Establish connection by "https://. 1) if the printer setting page is displayed, th...

Page 195

44205301th rev.1 195 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.3 cannot create certificate when certificate cannot be created, the following causes are probable. Take an appropriate measure by referring to the following items. * required input items are not fully entered ...

Page 196

44205301th rev.1 196 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.4.2 "network card is initialized" if network card is initialized (to default setup) while creation of certificate of certifying authority is in progress (during the period starting from creation of csr up unti...

Page 197

44205301th rev.1 197 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.5 other questionnaires other probable questionnaires are described below. 7.5.4.5.1 time required for creation of certificate it takes several ten seconds for creation of certificate. 7.5.4.5.2 communication t...

Page 198

44205301th rev.1 198 / oki data confidential 7. Troubleshooting and repair procedure 2. Press the "general" tab of the displayed certificate information, and press "install certificate" button. 3. The "certificate import wizard" is displayed. Install certificate in accordance with the displayed proc...

Page 199

44205301th rev.1 199 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.6 restrictions when using internet explore 7 several restrictions are imposed when using internet explore 7. This is because security restriction became more severe in ie7. 7.5.4.6.1 warning indication when ss...

Page 200

44205301th rev.1 200 / oki data confidential 7. Troubleshooting and repair procedure 7.5.4.7 network function restrictions on sleep mode network functions restrict the sleep mode of each printer as follows. 7.5.4.7.1 disabled sleep mode 1) with ipsec enabled 2) with netbeui enabled 3) with netware e...

Page 201

44205301th rev.1 201 / oki data confidential 7. Troubleshooting and repair procedure if the following error is issued, check the corresponding fuse of the cu/pu control board and high voltage power supply board. (refer to table 7-6.) table 7-6 fuse error fuse name error description insert point resi...

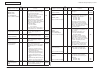

Page 202: Connection Diagrams

Oki data confidential 8. Connection diagrams 8.1 resistance value check .............................................................203 8.2 parts location .............................................................................207 8.3 f/w version number ...........................................

Page 203

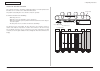

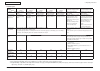

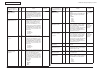

44205301th rev.1 203 / oki data confidential 8. Connection diagrams 8.1 resistance value check unit electrical circuit diagram, connection part outside view resistance value transport belt motor m 1 2 3 4 between pin-1 and pin-2: 3.4 Ω between pin-3 and pin-4: 3.4 Ω id motor ip2 ip3 across both ends...

Page 204

44205301th rev.1 204 / oki data confidential 8. Connection diagrams unit electrical circuit diagram, connection part outside view resistance value id up/down motor m 1 2 3 4 between pin-1 and pin-2: 6.1 Ω between pin-3 and pin-4: 6.1 Ω fuser unit motor ip1 ip2 across both ends of ip1 and ip2: 1 Ω or...

Page 205

44205301th rev.1 205 / oki data confidential 8. Connection diagrams unit electrical circuit diagram, connection part outside view resistance value feed motor m 1 2 3 4 between pin-1 and pin-2: 3.4 Ω between pin-3 and pin-4: 3.4 Ω both-sided print motor m 1 2 3 4 between pin-1 and pin-2: 3.2 Ω betwee...

Page 206

44205301th rev.1 206 / oki data confidential 8. Connection diagrams unit electrical circuit diagram, connection part outside view resistance value fuser unit b - 6 upper roller heater #1 upper roller heater #2 a - 6 b - 1 a - 1 thermostat upper thermistor b - 4 b - 5 lower thermistor a - 2 a - 3 fra...

Page 207

44205301th rev.1 207 / oki data confidential 8. Connection diagrams 8.2 parts location (1) cu/pu pcb component side test2 rm24 rm5 r60 c65 osclan1 bat1 c66 c54 c44 lan usb2 cp7 ic17 f11 c90 c84 c85 1 2 7 1 4 usb1 bf2 r203 r241 r192 r201 r272 r273 r42 r200 r202 rm36 1 1 1 1 20 20 20 20 rm35 rm34 rm33...

Page 208

44205301th rev.1 208 / oki data confidential 8. Connection diagrams soldering side r712 c537 c540 c530 c511 d506 r529 r528 q501 c550 c549 r540 c551 r552 r553 r560 r574 r575 c649 r592 r593 r609 r610 r611 r612 c674 r613 r614 c675 r615 c676 r616 r617 r618 r688 r718 r714 r620 r621 r622 r623 r624 r625 c6...

Page 209

44205301th rev.1 209 / oki data confidential 8. Connection diagrams (2) rellay pcb component side soldering side fuser s1 c1 exit c2 lcr j1 cp1 dens rcr puif 8 1 4 1 24 1 5 1 4 1 3 1 bfuse bfucut.

Page 210

44205301th rev.1 210 / oki data confidential 8. Connection diagrams (3) both-sided printing control pcb component side soldering side main1 1 j11 13 j8 j9 j20 cp2 sns03 sns12 1 1 6 6 j24 j21 j18 osc j3 j26 j2 j4 j12 j13 j25 j19 j17 j1 j31 j32 j33 j29 j27 j6 j7 j10 j28 j5 j15 j16 j30 j34 j35 1 1 3 1 ...

Page 211

44205301th rev.1 211 / oki data confidential 8. Connection diagrams (4) second tray control pcb soldering side main1 main2 1 j11 13 14 1 j8 j9 j20 cp2 sns03 sns12 1 1 6 6 j24 j21 j18 osc j3 j26 j2 j4 j12 j13 j25 psz j19 5 1 j17 j1 j31 j32 j33 j29 j27 j6 j7 j10 j28 j5 j15 j16 j30 j34 j35 1 1 3 1 4 cl...

Page 212

44205301th rev.1 212 / oki data confidential 8. Connection diagrams (5) control panel pcb (6) toner low sensor pcb sw1 sw0 led2 led1 sw7 sw6 sw2 cn3 hsns 1 sw3 sw5 sw4 r533 r524 r527 r523 r640 r521 r633 r637 r635 r634 r632 c519 c518 c517 c516 c515 c514 c513 c512 r636 r645 r646 r641 r642 r639 r638 r5...

Page 213

44205301th rev.1 213 / oki data confidential 8. Connection diagrams (7) entrance sensor pcb wr in2 in 1 cn r1 r2 5 1 (8) color adjustment sensor pcb (9) high-voltage power supply pcb s n s c n c e a k cn4 cn2 cn3 cn1 tr-k tr-m tr-y tr-c.

Page 214

44205301th rev.1 214 / oki data confidential to the po wer connector of the pu pcb to the fuser unit i/f connector note : 100v system shor ting plug is mounted. 230v system shor ting plug is not mounted. Tb4 tb3 cn6 cn2 cn1 shor ting plug f or cn6 8. Connection diagrams (10) low-voltage power supply...

Page 215

44205301th rev.1 215 / oki data confidential 8. Connection diagrams (12) transfer belt unit fuse transfer belt unit (for consumable parts) transfer belt unit relay pcb contactor point contactor point fuse.

Page 216

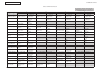

44205301th rev.1 216 / oki data confidential 8. Connection diagrams 8.3 f/w version number 8.3.1 rom control number rom nameplate version number fill-out version date cu f/w 44267201fy02 nic f/w 44267201fy03 pu f/w 44267201fy04 remarks rev. File rev. Nic f/w web page file rev. Rev. File rev. 5 2009....

Page 217

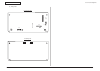

44205301th rev.1 217 / 217 oki data confidential 8. Connection diagrams 8.3.2 rom version check and display (1) perform the menu map printing and confirm that the f/w version number has been upgraded. (2) fill out the rom label that is attached to the location shown below in accordance with the down...