- DL manuals

- Oki

- Printer

- C910

- Troubleshooting Manual

Oki C910 Troubleshooting Manual

Summary of C910

Page 1

C910 / c930 troubleshooting guide distributed at the oki data a3/c9 service training classes. Rev. 3.20 troubleshooting guide page 1.

Page 2

This page intentionally left blank troubleshooting guide page 2.

Page 3

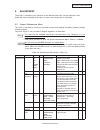

Oki data confidential 5. Adjustment the printer is adjusted by key operation on the maintenance utility and the operator panel. Select the menu according to the items to adjust and the purpose of adjustment. 5.0 system maintenance menu this menu is launched by turning on the power source while keepi...

Page 4

Table 5-0. Maintenance menu display table (2/2) during the engine self-diagnosis mode, switch operations and the lcd display is instructed by the engine firmware, therefore, it will vary from the specifications of the controller firmware operations. Note that the engine self-diagnosis mode can also ...

Page 5

Y m+y m c k y m+y m c k 5.0.1 id check pattern print (“test print menu” item) this pattern can be used to investigate the cause (plain identification of problem or check cycle of problem) resulting from the id or led head. Cmyk are each composed of a 20% duty pattern. (printing 2 sheets) test patter...

Page 6

Maintenance menu category maintenance menu item (1st line) eeprom reset save menu setting restore menu power save plain paper black set- ting plain paper color set- ting transparency black setting transparency color setting df * * * * * * * * value (2nd line) execute execute execute enable disable 0...

Page 7

5.1.2 engine maintenance mode engine maintenance mode tests the basic operation of the print engine components. 5.1.2.1 operation panel instructions on self-diagnosis operations is based on the following operation panel layout, as a prerequisite. Troubleshooting guide page 7.

Page 8

5.1.2.2 regular self-diagnosis mode (level 1) the regular self-diagnosis mode menu is as follows. • switch scan test • motor and clutch test • execute test pattern • initialize nvm • consumable counter display • consumable continual counter display 5.1.2.2.1 how to enter self-diagnosis mode (level 1...

Page 9

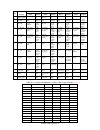

5.1.2.3 switch scan test this self-diagnosis is sued to check the input sensor and switch. Switch scan 1. Keep the [menu+] and [menu-] keys pressed until [switch scan] appears at the top of the display and operations goes into the regular diagnosis mode. (the [menu+] key = increment test item / the ...

Page 10

No5-1 stacker full fd snsno5-1 stacker full fd sns no32-1no32-1 dup in1 snsdup in1 sns 15-1 mpt pe sns15-1 mpt pe sns 15-2 mpt pe sns215-2 mpt pe sns2 16-1 mpt hopping sns16-1 mpt hopping sns 8-1 hum sns, 8-2 temp sns8-1 hum sns, 8-2 temp sns 6-4 media weight sns6-4 media weight sns 1-3 wr sns1-3 wr...

Page 11

H:off l:on h:on l:off h:on l:off frequency ad value: ***h h:up l:down uid:****h port level h, l h:on l:off port level h, l h:open l:close port level h, l port level h, l port level h, l port level h, l port level h, l table 5-1-1 switch scan details no. 1 detail top of the display display 2 detail d...

Page 12

H:open l:close h:paper present l:paper absent h:home position l:except in the home position h:home position l:except in the home position h:not to drive l:drive h/l:clock h:paper detect position l:except in the paper detect position h:open l:close table 5-1-2 paper size detection, various paper type...

Page 13

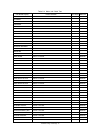

5.1.2.4 motor/clutch test this self-diagnosis routine is used to test the motor and clutch. 1. Continue to press the [menu+] and [menu-] keys until “motor & clutch test” appears at the top of the display and the operation enters the self-diagnosis (level 1) mode. The [menu+] key = increment test ite...

Page 14

Fan pu board id motor(k) id motor(y) id motor(m) id motor(c) toner supply (ky) toner supply (mc) job offset tray1 geared motor tray2 motor tray2 geared motor tray2 feed motor tray2 roller clutch regist motor regist clutch 2ndclutch tray1 motor = mpt motor fan power dup motor 2 dup motor 1 exit solen...

Page 15

Table 5-2 motor and clutch test unit name display k-id motor y-id motor m-id motor c-id motor belt motor fuser motor fuser rls regist motor regist clutch mpt motor mpt lift up exit solenoid facedown solenoid registration shutter job offset tray1 motor tray2 motor tray3 motor tray4 motor tray5 motor ...

Page 16

Unit name display fin shift motor fin staple exec fin saddle exec fin saddle transfer fin saddle clutch fin punch hole fin punch reg inv motor a inv motor b inv separater inv pressure solenoid inv regist clutch fan power fan pu-board fan fuser fan belt fan id toner supply k toner supply y toner supp...

Page 17

C drum k drum y drum m drum drive roller drive roller conveyor belt density / color gap sensor mpt hopping sensor mpt pe sensor wr sensor in2 sensor dup f sensor dup r sensor dup-in sensor dup-in2 sensor in1 sensor looseness sensor exit sensor stacker full fu sensor stacker full fd sensor job-off se...

Page 18

Other sensors 1 paper empty sensor this sensor checks whether the paper cassette is empty or not. 2 paper near-end sensor this sensor checks whether the paper cassette will be empty soon or not. 3 mbf paper empty sensor this sensor checks whether there is paper in the front feeder. 4 mbf hopping swi...

Page 19

5.1.2.5 test print this self-diagnostic routine is used to print the test pattern in the pu. Other test patterns are stored in the controller. 1. Continue to press the [menu+] and [menu-] keys until “test print” appears at the top row of the display, and the system is in the self-diagnosis (lever 1)...

Page 20

Display output bin punch offset staple mode staple number invert function printer face down finisher upper bin finisher lower bin punch on/off offset on/off staple mode off rear corner center corner front corner saddle stitch set the number of sheets to be stapled (0 to 50). * when the staple mode i...

Page 21

Pattern 1 pattern 2 pattern 3 pattern 4 pattern 7 pattern 5 pattern 6 print test pattern pattern no. 0 1 2 3 4 5 6 7 print pattern none (blank page) 2 by 2 4 by 4 horizontal line slanted line vertical line vertical band full troubleshooting guide page 21.

Page 22

P=*** t=*** u=*** [###] h=***% l=***[###] ktr=*.**kv ytr=*.**kv mtr=*.**kv ctr=*.**kv kr=*.**ua yr=*.**ua mr=*.**ua cr=*.**ua • the following message appears when printing. P: test print sheets (unit: number of sheets) u: upper-side heater temperature measurement value[setting] (unit: °c) l: lower-s...

Page 23

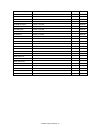

7.5.1 lcd message list when the printer detects errors that can be restored, it displays a service call error on the lcd, as shown below. Service call nnn: error nnn is an error code. When a service call is displayed, the error code and accompanying error information is displayed on the bottom row o...

Page 24

Judgment yes no yes no yes no yes no no yes no no no yes no no yes yes cause cu pcb flash rom error flash file system error ps+pcl model cu rom is mounted on a non-ps model unit. Cu type mismatch cu rom model mismatches unit. Operator panel error cu fan error cpu cooling fan of cu pcb is abnormal. I...

Page 25

Judgment yes yes yes yes yes no no no yes yes yes yes yes yes yes yes no yes yes cause when turning on the power, detected engine sram read / write error. When turning on the power, detected error in engine eeprom test total. When turning on the power, failed to detect the eeprom (presence). Error d...

Page 26

Judgment yes no yes yes yes yes yes no yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes cause after turning on the power or when cover is closed, the sensor detects that the unit is missing. Color id up/ down error is detected. This is indicated when the toner feed switch error or the ton...

Page 27

Judgment yes yes no yes yes yes yes no yes yes yes yes yes yes cause thermistor indicates low temperature (cold) error. Wrong fuser standard the engine detects commu- nication is not possible with the optional unit. 180: envelope feeder (unused) 181: duplex unit 182: tray2 unit 183: tray3 unit 184: ...

Page 28

Judgment yes no yes no yes yes no yes no yes yes cause rfid reader i/ f error engine program memory error the printer engine cover is open. After turning on the power or when cover is closed, the sensor detects that the unit is missing. This indicates that the motor has overheated and that the print...

Page 29

Judgment yes no yes yes no yes no yes no yes no yes no yes no yes no yes no yes no cause after turning on the power or when cover is closed, the sensor detects that the unit is missing. After turning on the power or when cover is closed, the sensor detects that the unit is missing. Id unit life fuse...

Page 30

Judgment yes no yes no yes no yes no yes yes no yes no yes yes no yes no yes no yes no yes no yes no cause paper jam in paper supply from cassette 1, 2, 3, 4 or 5. Paper jam detected between black id and fuser. Paper jam detected in fuser or between fuser and paper output area. Paper jam detected wh...

Page 31

Judgment yes no no yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes cause paper near-end detection cannot write to hdd. Gddc error belt slit sensor error duplex fan0 alarm detection duplex 24v abnormal current detection yellow image drum lock error magenta image drum lock error cyan i...

Page 32

Judgment yes yes yes yes yes yes yes yes yes yes yes cause waste toner transfer motor lock error sub-cpu clock frequency error duplex cpu clock fre- quency error inverter cpu clock fre- quency error trya2 cpu clock fre- quency error trya3 cpu clock fre- quency error trya4 cpu clock fre- quency error...

Page 33

Repetitive marks on printout distance between marks affected roller replacement part 3.71” image drum replace image drum cartridge 2.50” development roller replace image drum cartridge 2.27” toner supply roller replace image drum cartridge 1.73” charge roller replace image drum cartridge 4.45” fuser...