- DL manuals

- Oki

- Printer

- C911 DICOM

- Maintenance Manual

Oki C911 DICOM Maintenance Manual

Summary of C911 DICOM

Page 1

C911 / c931 / c941 maintenance manual 120213b.

Page 2

Copyright information copyright © 2013 by oki data. All rights reserved disclaimer every effort has been made to ensure that the information in this document is complete, accurate, and up-to- date. The manufacturer assumes no responsibility for the results of errors beyond its control. The manufactu...

Page 3

45530603th rev.2 3 oki data confidential this manual provides an overview of method for maintaining the c911/c931/c941/ es9411/es9431/es9541 series. This manual is intended for maintenance staff. For more information about how to operate the c911/c931/c941/es9411/es9431/es9541 series, please refer t...

Page 4

45530603th rev.2 4 oki data confidential index 1. Configuration ................................................................. 1-1 1.1 system configuration .........................................................................................1-2 1.2 printer configuration .........................

Page 5

45530603th rev.2 5 oki data confidential 5.3.3 printing on stand-alone basis...................................................................5-54 5.3.4 button-pressed functions at power-on .....................................................5-54 5.4 setup after part replacement .....................

Page 6: Configuration

Oki data confidential 1. Configuration 1.1 system configuration ................................................................1-2 1.2 printer configuration .................................................................1-4 1.3 composition of optional items ..........................................

Page 7

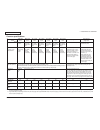

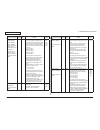

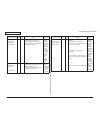

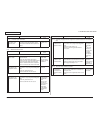

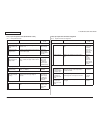

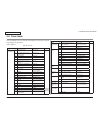

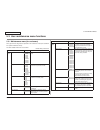

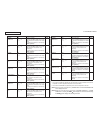

45530603th rev.2 1-2 oki data confidential 1. Configuration color lcd board(f1p) main board(f1y) ce1-main high volt(ahv) ddr3-ram sodimm x 1 2gb nand flash 1gbit spi flash 16mbit eeprom 64k ddr3 ram 512mb(on board) led head y led head m led head c led head k spi flash 8mbit id-up sensor input drivin...

Page 8

45530603th rev.2 1-3 oki data confidential 1. Configuration table 1-1 pcb list of c911/c931/c941/es9411/es9431/es9541 no name purpose remarks 1 f1y printer controller (pu/cu) for five-color models 2 f1y-2 printer controller (pu/cu) for four-color models 3 f1x spot color control used for five-color m...

Page 9

45530603th rev.2 1-4 oki data confidential 1. Configuration 1.2 printer configuration the internal part of the printer is composed of the following sections: • electrophotographic processing section • paper paths • controller (a combination pu/cu board) • operator panel • power supplies (high-voltag...

Page 10

45530603th rev.2 1-5 oki data confidential 1. Configuration 1.3 composition of optional items the following optional items are available for the apparatus. (1) optional tray unit (4) internal hard disk (2) optional tray unit with casters (3) high-capacity optional tray unit (three-layer of optional ...

Page 11

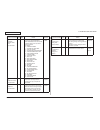

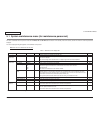

45530603th rev.2 1-6 oki data confidential 1. Configuration 1.4 specifications classification item specification c911dn/c931dn/ es9411dn/es9431dn c941dn/es9541dn dimension width 699mm depth 625mm(665mm/operator panel including dimension) height 640mm weight approx. 96.5kg approx. 116.5kg printing wi...

Page 12

45530603th rev.2 1-7 oki data confidential 1. Configuration classification item specification c911dn/c931dn/ es9411dn/es9431dn c941dn/es9541dn life printer life 1,500,000pages (a4 lef), five years monthly duty cycle (m=l/12, a=l/12/5) max.300,000 pages/month average 25,000 pages/month mtbf (2.3% dut...

Page 13

45530603th rev.2 1-8 oki data confidential 1. Configuration classification item specification c911dn/c931dn/ es9411dn/es9431dn c941dn/es9541dn operator panel lcd graphic panel with 480 × 272 dots with display of paper size led (color) 5 leds (green × 2, dark amber × 2, blue × 1) button 20 buttons • ...

Page 14

45530603th rev.2 1-9 oki data confidential 1. Configuration 1.5 interface specifications 1.5.1 usb interface specifications 1.5.1.1 usb interface overview (1) basic specifications usb (hi-speed usb supported) (2) transmission mode full speed (max. 12 mbps ± 0.25%) high speed (max. 480 mbps ± 0.05%) ...

Page 15

45530603th rev.2 1-10 oki data confidential 1. Configuration 1.5.2 network interface specifications 1.5.2.1 network interface overview basic specifications notwork protocol tcp/ip: network layer arp, ip, icmp, ipv6, ipsec transport layer tcp, udp application layer lpr, port9100, ftp, http, https, ip...

Page 16: Description Of Operation

Oki data confidential 2. Description of operation 2.1 electrophotographic process mechanism ..................................2-2 2.2 printing process .........................................................................2-5 2.3 low-voltage power supply ..............................................

Page 17

45530603th rev.2 2-2 oki data confidential 2. Description of operation (1) electrophotographic process the electrophotographic process is explained briefly below: 1. Charging a voltage is applied to the charging roller to electrically charge the surface of the opc drum. 2. Exposure the led head expo...

Page 18

45530603th rev.2 2-3 oki data confidential 2. Description of operation (4) development charged toner are adsorbed to the electrostatic latent image on the drum surface, thereby the electrostatic latent image is converted to the toner image. 1. The sponge roller supplies the toner to the development ...

Page 19

45530603th rev.2 2-4 oki data confidential 2. Description of operation (6) fusing the toner image transferred on the paper is fused to the paper by heat and pressure when the paper passes through between the portion of the fuser belt (mainly comprised with the fuser roller, the pat and the fuser bel...

Page 20

45530603th rev.2 2-5 oki data confidential 2. Description of operation 2.2 printing process the paper fed from tray 1 or tray 2, 3, 4 or 5 is fed by the paper feed roller, registration 1 roller, registration 2 roller and timing roller. When the paper is fed from the mpt, it is fed by the mpt paper f...

Page 21

45530603th rev.2 2-6 oki data confidential 2. Description of operation (2) paper feed from mpt 1. When the mpt clutch is on, the hopping motor is driven (to counterclockwise), transporting the paper until the in 2 sensor comes on. (when the hopping motor rotates to conunterclockwise and the mpt clut...

Page 22

45530603th rev.2 2-7 oki data confidential 2. Description of operation (3) intermediate transfer belt 1. When the intermediate transfer belt motor drives in the direction of the arrow, the intermediate transfer belt is rotated. The intermediate transfer belt unit is consisted of one first transfer r...

Page 23

45530603th rev.2 2-8 oki data confidential 2. Description of operation (5) 2 pass printing (function to automatically print on the same side of a sheet twice. (only 5-color model)) change over between the 2 pass route and reverse route by the separator. In the case of the print-job specified 2 pass,...

Page 24

45530603th rev.2 2-9 oki data confidential 2. Description of operation (7) fuser unit and paper ejection 1. As illustrated in figure 2-8, the fuser unit and the eject roller are driven by the dc motor. As the fuser motor drives (counterclockwise), the fuser roller rotates. And then, the fuser belt r...

Page 25

45530603th rev.2 2-10 oki data confidential 2. Description of operation (9) cover-opening motion of the color registration sensor and the density sensor 1. In the color registration sensor and the density sensor as illustrated in figure 2-10, the cam rotates with the reverse rotation of the feed mot...

Page 26

45530603th rev.2 2-11 oki data confidential 2. Description of operation outline of color registration correction the color registration is corrected by reading registration patterns that are printed on the belt with the color registration sensors located inside the sensor shutter under the belt unit...

Page 27

45530603th rev.2 2-12 oki data confidential 2. Description of operation outline of density correction the printing density is corrected by reading the correction pattern that is printed on the belt with the density sensor located inside the sensor shutter under the belt unit. Automatic start timing ...

Page 28

45530603th rev.2 2-13 oki data confidential 2. Description of operation process of the toner sensor detection toner low is detected by the toner sensor (optical sensor) arranged in the printer. The douser is mounted inside the id and rotates in synchronization with toner agitation. Detection may not...

Page 29

45530603th rev.2 2-14 oki data confidential 2. Description of operation counter specifications total page count mpt page count tray 1 page count tray 2 page count tray 3 page count tray 4 page count tray 5 page count color page count monochrome page count description total number of prints number of...

Page 30

45530603th rev.2 2-15 oki data confidential 2. Description of operation counter specifications (spot color only) spot color 1 spot color 2 definition total number of prints in combination of spot color and other colors total number of prints using spot color only count method: a4-basis or size indep...

Page 31

45530603th rev.2 2-16 oki data confidential 2. Description of operation a4/letter conversion table each count should increase, in relation to every sheet of paper, by the values in the table below. Paper size simplex duplex letter 1 2 executive 1 2 legal14/13.5/13 1 2 tabloid extra 2 4 tabloid 2 4 a...

Page 32

45530603th rev.2 2-17 oki data confidential 2. Description of operation 2.3 low-voltage power supply 2.3.1 operation low-voltage power supply pu/cu board to the fuser unit to the motor driver ac 24v 5v 5vs0 5vs ce1 asic power supply control cpu ac→24v main power switch ac→5v sub power supply main po...

Page 33

45530603th rev.2 2-18 oki data confidential 2. Description of operation 2.4 cover opening and closing detection switch the front cover opening/closing detection switch, the exit left cover opening/closing detection switch, and the toner cover opening/closing detection switch of this apparatus are ef...

Page 34

45530603th rev.2 2-19 oki data confidential 2. Description of operation 2.5 initialization processing description · the state of initialization is indicated by led (power supply led, initialization led 1, 2, 3). · the power supply led is blinking in first step. In the case of the power supply is abn...

Page 35: Installation

Oki data confidential 3. Installation 3.1 cautions, and do’s and don’ts ...................................................3-2 3.2 installation instructions ..............................................................3-3 3.3 cautions for mounting optional tray unit ...................................

Page 36

45530603th rev.2 3-2 oki data confidential 3. Installation 3.1 cautions, and do’s and don’ts • do not place the printer in any high-temperature location or a near heat source. • do not place the printer in a location where chemical reaction may occur (laboratory and such a place ). • do not place th...

Page 37

45530603th rev.2 3-3 oki data confidential 3. Installation 3.2 installation instructions • check to make sure that the apparatus is free from damage, dirt or other irregularities in its appearance. • ensure that none of the accessories to the apparatus is missing and that they are free from breakage...

Page 38

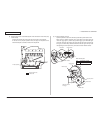

45530603th rev.2 3-4 oki data confidential 3. Installation 3.3 cautions for mounting optional tray unit gently lift the main unit by four or more people, and align the holes on the base to the 2 protrusions on the optional tray unit. Gently place the main unit on the optional tray unit. For the opti...

Page 39

45530603th rev.2 3-5 oki data confidential 3. Installation (2) loosen the nuts (upper-side) at the top of the feets (2 pieces) on the right of the apparatus. (3) rotate the nuts and bolts at the bottom of each foot to lower the feet..

Page 40

45530603th rev.2 3-6 oki data confidential 3. Installation (4) when each foot has reached the ground, tighten the upper-side nuts at the top to secure the tray unit..

Page 41

45530603th rev.2 3-7 oki data confidential 3. Installation 3.4 cautions for banner tray (1) turn off the printer. (2) open the toner replacement cover and the front cover. Stacker stacker handle handle custom-sized paper storage section handle (3) attach the banner tray onto the multi-purpose tray. ...

Page 42

45530603th rev.2 3-8 oki data confidential 3. Installation 3.Insert the protrusions of banner tray into the insertion points on both sides of the multi- purpose tray. (4) check that the banner tray is secured in place. (5) close the toner replacement cover and the front cover. (6) hold the banner tr...

Page 43

45530603th rev.2 3-9 oki data confidential 3. Installation (7) open the paper supporter and the auxiliary supporter of the multi-purpose tray. (8) lower the stacker towards the banner tray side. ≪ when remove ≫ ・check that there are no paper in the banner tray. (1) pull out the banner tray. 1. Open ...

Page 44

45530603th rev.2 3-10 oki data confidential 3. Installation 3.5 cautions for packing if packing the printer, close the toner change cover completely following procedure. Note! ・be sure to unplug the ac cable. ・packing when transport only. (1) power off the printer. B a c (2) remove the all toner car...

Page 45

45530603th rev.2 3-11 oki data confidential 3. Installation (5) fasten toner cartridge detect lever by adhesive tape. (6) fasten all toner cartridge detect lever as above procedure(4) to (5). (7) check the toner change cover close completely. Note! ・peel the adhesive tape from the printer when use t...

Page 46: Troubleshooting Procedure

Oki data confidential 4. Troubleshooting procedure 4.1 important notes to start the repair work ....................................4-2 4.2 matters to be checked before taking corrective actions against abnormalities ................................................................4-2 4.3 precautions...

Page 47

45530603th rev.2 4-2 oki data confidential 4. Troubleshooting procedure 4.1 important notes to start the repair work 4.2 matters to be checked before taking corrective actions against abnormalities 4.3 precautions when taking corrective actions against abnormalities 4.4 preparation for troubleshooti...

Page 48

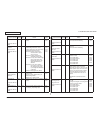

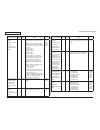

45530603th rev.2 4-3 oki data confidential 4. Troubleshooting procedure 4.5 troubleshooting methods when a trouble occurs with this printer, execute troubleshooting by following the steps de- scribed below. 4.5.1 lcd message list when the printer detects an unrecoverable error, the following service...

Page 49

45530603th rev.2 4-4 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code check fuser unit please see help for details off blink indicates that the fuser is not installed correctly. Error 320 check paper...

Page 50

45530603th rev.2 4-5 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code install new fuser unit fuser unit life please see help for details off blink alerts the end of the fuser life. This error is disp...

Page 51

45530603th rev.2 4-6 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code check paper in %tray% paper multi feed please see help for details off blink alerts that too long paper has been fed from the tra...

Page 52

45530603th rev.2 4-7 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code the data was deleted because a duplex printing error occurred check the paper and paper settings, then print again. To turn off t...

Page 53

45530603th rev.2 4-8 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code please change %tray% paper. Ensure %media_ size%, %media_ type% is installed. If printing fails, cancel and re-adjust tray settin...

Page 54

45530603th rev.2 4-9 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code receiving data timeout press ok button for restoration please see help for details varies blink this error appears when a stream ...

Page 55

45530603th rev.2 4-10 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code install %color% new image drum image drum life please see help for details off blink alerts (alarms) the end of the image drum l...

Page 56

45530603th rev.2 4-11 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code incompatible toner %color% please see help for details off blink the detected toner cartridge is not optimal. Invalid toner dete...

Page 57

45530603th rev.2 4-12 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code change %media_ size% %media_type% in %tray% press ok button please see help for details off blink indicates disagreement between...

Page 58

45530603th rev.2 4-13 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code non genuine belt unit please see help for details off blink indicates detection of a belt unit not suitable for this printer. Er...

Page 59

45530603th rev.2 4-14 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code incompatible fuser unit please see help for details off blink the detected fuser unit is not optimal. Incompatible fuser detecte...

Page 60

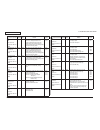

45530603th rev.2 4-15 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details error code check data message data write error varies varies indicates that writing of the message data for updating has failed. %code% is ...

Page 61

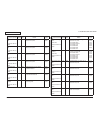

45530603th rev.2 4-16 oki data confidential 4. Troubleshooting procedure table 4-1-2 service call error list panel display cause check details result solution service call 001:error machine check exception hardware problem was detected (pcb failure or insufficient power capacity). (pdl only) when ce...

Page 62

45530603th rev.2 4-17 oki data confidential 4. Troubleshooting procedure panel display cause check details result solution power off/on 074:error xxxxxxxx 075:error xxxxxxxx detection of abnormal condition during image data expansion does this error recur? Yes power off/on. Replace the printer contr...

Page 63

45530603th rev.2 4-18 oki data confidential 4. Troubleshooting procedure panel display cause check details result solution service call 111:error a duplex unit for another model was detected. Is a duplex unit provided for this model installed? Yes install a correct duplex unit. Service call 112:erro...

Page 64

45530603th rev.2 4-19 oki data confidential 4. Troubleshooting procedure panel display cause check details result solution service call 128:error 01: fuser exhaust fan 1 02: low voltage fan 03: pu fan 05: station 1 id intake fan 09: second transfer adsorption fan 0a: fuser intake fan 0b: station 2 i...

Page 65

45530603th rev.2 4-20 oki data confidential 4. Troubleshooting procedure panel display cause check details result solution service call 135:error 09:fuser motor lock error remove the fuser. Does the motor run in motor testing? Yes replace the fuser. No do the following check on motors and pcbs. Is t...

Page 66

45530603th rev.2 4-21 oki data confidential 4. Troubleshooting procedure panel display cause check details result solution service call 167:error thermistor slope error is the error message displayed? Yes restore the power. Does this error recur? Yes after leaving the printer for 30 minutes, turn on...

Page 67

45530603th rev.2 4-22 oki data confidential 4. Troubleshooting procedure panel display cause check details result solution service call 241:error ~ 245:error engine program memory error 241: duplex flash memory error 242: option tray2 243: option tray3 244: option tray4 245: option tray5 power off/o...

Page 68

45530603th rev.2 4-23 oki data confidential 4. Troubleshooting procedure table 4-1-3 initializing panel display online indicator inspection lamp details initializing off off it is displayed until the system display language is determined immediately after the power is turned on. Initializing off off...

Page 69

45530603th rev.2 4-24 oki data confidential 4. Troubleshooting procedure table 4-1-4 normal lcd status message ( represents a blank line.) online indicator inspection lamp details ready to print on off indicates that the printer is in the online state. Offline off off indicates that the printer is i...

Page 70

45530603th rev.2 4-25 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details power save varies varies lights out at the same time when the printer enters the sleep/off mode and lights up when exits the sleep/off mode...

Page 71

45530603th rev.2 4-26 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details wait a moment message data writing varies varies indicates that message data to be updated is being written. Power off/on message data rece...

Page 72

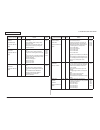

45530603th rev.2 4-27 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure %color% toner low varies on (blink) off indicates that amount of toner is low. When the menu button > [menus] > [system ad...

Page 73

45530603th rev.2 4-28 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure error postscript blink varies indicates that postscript interpreter has detected an error due to the following reasons. On...

Page 74

45530603th rev.2 4-29 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure fuser mount signal warning varies on indicates detection of an abnormal fuser mount signal. This warning is cleared when a...

Page 75

45530603th rev.2 4-30 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure %color% toner not installed varies on indicates that a toner cartridge is not installed. %color% yellow magenta cyan black...

Page 76

45530603th rev.2 4-31 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure belt reflex error varies on belt reflex check error. In the shipping mode, the pu firmware does not notify the cu firmware...

Page 77

45530603th rev.2 4-32 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure registration sensor error varies on color registration sensor error. In the shipping mode, the pu firmware does not notify...

Page 78

45530603th rev.2 4-33 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure *** flash error varies varies pu flush error (an error occurred during rewrite of the pu firmware or writing of led head i...

Page 79

45530603th rev.2 4-34 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure print restricted. Job rejected press ok button varies on notifies the user that the job has been cancelled because printin...

Page 80

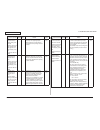

45530603th rev.2 4-35 oki data confidential 4. Troubleshooting procedure lcd status message ( represents a blank line.) online indicator inspection lamp details remedial measure file system operation failed press ok button varies on indicates that a file system error, other than any of the above-des...

Page 81

45530603th rev.2 4-36 oki data confidential 4. Troubleshooting procedure note! When replacing the pu/cu pcb, load the eeprom chip contents of the old board first, and copy them to the new board upon completion of the replacement. (refer to section 5.4.1 notes on pu/cu board replacement.) (1) lcd dis...

Page 82

45530603th rev.2 4-37 oki data confidential 4. Troubleshooting procedure 4.5.2 (1) lcd display error memo for connector names, see beside the connectors on each pcb where connector names are silkscreen printed. (1-1) lcd does not display anything. Check item check work actions to be taken at ng (1-1...

Page 83

45530603th rev.2 4-38 oki data confidential 4. Troubleshooting procedure (1-2) error message related to the control panel check item check work actions to be taken at ng (1-2-1) error message error message check the error contents by referring to the error message list. Follow the instruction. (1-3)...

Page 84

45530603th rev.2 4-39 oki data confidential 4. Troubleshooting procedure check item check work actions to be taken at ng (2-1-3) check the system connection connection condition of the control panel check contents of (1-1). The printer will not start operation until the control panel is detected and...

Page 85

45530603th rev.2 4-40 oki data confidential 4. Troubleshooting procedure (2-3) bad odors are generated. Check item check work actions to be taken at ng (2-3-1) locating the exact position of generating bad odor fuser unit remove the fuser unit and check the odor. Implement section (2-3-2). Low volta...

Page 86

45530603th rev.2 4-41 oki data confidential 4. Troubleshooting procedure error code message on the display screen sensor name(s) 375 check the lower side of duplex unit remove paper please see help for details. Duplex front 380 paper jam has occurred open right side cover please see help for details...

Page 87

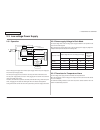

45530603th rev.2 4-42 oki data confidential 4. Troubleshooting procedure error code: 380, 390, 637 (1) if paper is set in the mp tray, remove it and close the tray. Outline drawing of jam locations fd stacker full sensor exit3 sensor exit2 sensor exit1 sensor fu stacker full sensor duplex in sensor ...

Page 88

45530603th rev.2 4-43 oki data confidential 4. Troubleshooting procedure error code: 381, 638, 639 note! As the temperature of the fuser unit is high, carefully do the following. Be sure to hold the handle to lift. When it is hot, wait until it cools down and start the work. (1) lift the opener of t...

Page 89

45530603th rev.2 4-44 oki data confidential 4. Troubleshooting procedure (6) if there is no remaining paper in the fuser unit, pull up the fuser unit’s lock lever (blue). (3) if there is remaining paper in the fuser unit, pull up the fuser unit’s jam release levers (blue). (4) ensure to slowly pull ...

Page 90

45530603th rev.2 4-45 oki data confidential 4. Troubleshooting procedure (9) if paper winds around the decurl unit, remove the decurl unit and pull out the remainning paper. Note! Pay attention to don't drop into the printer when remove the screws. Decurl unit.

Page 91

45530603th rev.2 4-46 oki data confidential 4. Troubleshooting procedure (10) set to the output unit and attach the screw. Note! Pay attention to don't drop into the printer when attach the screws. ① ② ② ① ② ① (11) hold the fuser unit’s handle with both hands and set to the output unit. (12) push do...

Page 92

45530603th rev.2 4-47 oki data confidential 4. Troubleshooting procedure (14) lift the opener and open the right side cover. Opener (15) slowly remove the remaining paper. (16) close the right side cover. (17) put the output unit back into the printer..

Page 93

45530603th rev.2 4-48 oki data confidential 4. Troubleshooting procedure error code: 382, 383, 389 note! As the temperature of the fuser unit is high, carefully do the following. Be sure to hold the handle to lift. When it is hot, wait until it cools down and start the work. (1) pull out the output ...

Page 94

45530603th rev.2 4-49 oki data confidential 4. Troubleshooting procedure (6) hold the fuser unit’s handle with both hands and remove the unit onto a flat surface. (7) pull up the fuser unit’s jam release levers (blue) and be sure to slowly pull out the remaining paper in the opposite direction from ...

Page 95

45530603th rev.2 4-50 oki data confidential 4. Troubleshooting procedure (9) set to the output unit and attach the screw. Note! Pay attention to don't drop into the printer when attach the screws. ① ② ② ① ② ① (11) push down the fuser unit’s lock lever (blue). (12) put the output unit back into the p...

Page 96

45530603th rev.2 4-51 oki data confidential 4. Troubleshooting procedure removing paper from the duplex unit (1) pull out the duplex unit. (2) remove the remaining paper. (3) put the duplex unit back into the printer..

Page 97

45530603th rev.2 4-52 oki data confidential 4. Troubleshooting procedure error code: 391, 392, 393, 394, 395, 631, 632, 633, 634, 635 example: in the case of tray 1 (1) open the tray side cover indicated by the error code. (2) remove the remaining paper. (3) close tray 1 side cover..

Page 98

45530603th rev.2 4-53 oki data confidential 4. Troubleshooting procedure error code: 370, 371, 373, 640, 641, 642 (1) pull out the duplex unit, and detach it by slightly lifting with both hands. If jammed paper cannot be seen in the printer or duplex unit, put the duplex unit back into the printer a...

Page 99

45530603th rev.2 4-54 oki data confidential 4. Troubleshooting procedure (5) check inside of the printer and slowly remove the remaining paper. (6) if the tip of the remaining paper is not visible, pull up the fuser unit’s lock lever (blue). (7) hold the fuser unit’s handle with both hands and remov...

Page 100

45530603th rev.2 4-55 oki data confidential 4. Troubleshooting procedure (9) hold the knob and push down the transfer roller unit. (10) if paper winds around the decurl unit, remove the decurl unit and pull out the remainning paper. Note! Pay attention to don't drop into the printer when remove the ...

Page 101

45530603th rev.2 4-56 oki data confidential 4. Troubleshooting procedure (12) hold the fuser unit’s handle with both hands and set to the output unit. Note ! Check the inside of the printer for remaining paper and then set the fuser unit. (11) set to the output unit and attach the screw. Note! Pay a...

Page 102

45530603th rev.2 4-57 oki data confidential 4. Troubleshooting procedure (13) push down the fuser unit’s lock lever (blue). Error code: 375, 650 (1) pull out the duplex unit and detach by slightly lifting it. (14) put the output unit back into the printer. (2) remove the remaining paper from the pri...

Page 103

45530603th rev.2 4-58 oki data confidential 4. Troubleshooting procedure (3) put the duplex unit back into the printer. (4) pull out the output unit and remove the remaining paper. If no paper remains in visible locations in the printer, follow the procedure below..

Page 104

45530603th rev.2 4-59 oki data confidential 4. Troubleshooting procedure (5) if the tip of the remaining paper is not visible, pull up the fuser unit’s lock lever (blue). (7) hold the knob, pull up the transfer roller unit, lift the paper guide, and remove the remaining paper. (6) hold the fuser uni...

Page 105

45530603th rev.2 4-60 oki data confidential 4. Troubleshooting procedure (8) hold the knob and push down the transfer roller unit. (9) if paper winds around the decurl unit, remove the decurl unit and pull out the remainning paper. Note! Pay attention to don't drop into the printer when remove the s...

Page 106

45530603th rev.2 4-61 oki data confidential 4. Troubleshooting procedure (13) put the output unit back into the printer. (11) hold the fuser unit’s handle with both hands and set to the output unit. Note ! Check the inside of the printer for remaining paper and then set the fuser unit. (10) set to t...

Page 107

45530603th rev.2 4-62 oki data confidential 4. Troubleshooting procedure error code: 384, 651 (1) open the left side cover. 4.5.2.(4) paper feed jam (error 391: 1st tray). (4-1) jam occurs immediately after the power is turned on. (1st tray) check item check work actions to be taken at ng (4-1-1) ch...

Page 108

45530603th rev.2 4-63 oki data confidential 4. Troubleshooting procedure (4-2) jam occurs immediately after the paper feed is started. (1st tray) check item check work actions to be taken at ng (4-2-1) check condition of the paper running path paper running path of the 1st tray unit check if paper i...

Page 109

45530603th rev.2 4-64 oki data confidential 4. Troubleshooting procedure 4.5.2.(5) feed jam (error 380) (5-1) jam occurs immediately after the power is turned on. Check item check work actions to be taken at ng (5-1-1) check condition of the paper running path paper running path in the vicinity of t...

Page 110

45530603th rev.2 4-65 oki data confidential 4. Troubleshooting procedure check item check work actions to be taken at ng (5-2-4) check the system connection hopping motor drive cable check the connection condition of the cable. Visually check if the connector is connected in the half-way only or not...

Page 111

45530603th rev.2 4-66 oki data confidential 4. Troubleshooting procedure check item check work actions to be taken at ng (6-1-3) motor operation check hopping motor confirm that the hopping motor works normally by using the motor & clutch test of the self-diagnostic mode. Replace the pu/cu pcb or ho...

Page 112

45530603th rev.2 4-67 oki data confidential 4. Troubleshooting procedure (7-2) jam occurs immediately after a paper is taken into printer. Check item check work actions to be taken at ng (7-2-1) check condition of the paper running path paper running path between the registration roller 2 and the fu...

Page 113

45530603th rev.2 4-68 oki data confidential 4. Troubleshooting procedure (7-3) jam occurs in the middle of paper running path. Check item check work actions to be taken at ng (7-3-1) motor operation check feed motor driver, belt motor driver and fuser motor confirm that the hopping motor, belt motor...

Page 114

45530603th rev.2 4-69 oki data confidential 4. Troubleshooting procedure 4.5.2.(8) paper unloading jam (error 382) (8-1) paper unloading jam occurs immediately after the power is turned on. Check item check work actions to be taken at ng (8-1-1) check condition of the paper running path paper runnin...

Page 115

45530603th rev.2 4-70 oki data confidential 4. Troubleshooting procedure check item check work actions to be taken at ng (8-2-4) check the system connection fuser motor drive cable check the connection condition of the cables. Visually check the pu/cu pcb dcheat connector for half-way connection, sl...

Page 116

45530603th rev.2 4-71 oki data confidential 4. Troubleshooting procedure check item check work actions to be taken at ng (9-2-3) check condition of the paper running path paper inverting transport path check that any foreign materials such as paper chip or blue do not exist that hampers the smooth m...

Page 117

45530603th rev.2 4-72 oki data confidential 4. Troubleshooting procedure 4.5.2.(11) id unit up / down error (service calls 143-01: k, -02: c, -03: m, -04: y, -05: w/cl) (11-1) error occurs during the up movement of the id unit check item check work actions to be taken at ng (11-1-1) installation sta...

Page 118

45530603th rev.2 4-73 oki data confidential 4. Troubleshooting procedure (12-2) error occurs approx. 1 minute after the power is turned on. Check item check work actions to be taken at ng (12-2-1) temperature increase of fuser unit thermostat, heater heater of the fuser unit is controlled of its tem...

Page 119

45530603th rev.2 4-74 oki data confidential 4. Troubleshooting procedure 4.5.2.(14) print speed is slow. (performance is low.) (14-1) print speed decreases. Check item check work actions to be taken at ng (14-1-1) media weight setting media weight that is specified for the print check if the wrong m...

Page 120

45530603th rev.2 4-75 oki data confidential 4. Troubleshooting procedure 4.5.2.(16) option tray unit cannot be recognized. (16-1) option tray unit cannot be recognized. Check item check work actions to be taken at ng (16-1-1) option tray pcb option tray pcb fuse measure the resistance of option tray...

Page 121

45530603th rev.2 4-76 oki data confidential 4. Troubleshooting procedure 4.5.2.(18) toner sensor error (errors 5400 to 5405) (18-1) error caused by the consumable items. Check item check work actions to be taken at ng (18-1-1) installation conditions of consumables id unit is the stopper (orange) re...

Page 122

45530603th rev.2 4-77 oki data confidential 4. Troubleshooting procedure (18-2) error caused by the defective mechanism check item check work actions to be taken at ng (18-2-1) mechanical load applied to the id unit id unit check if a heavy mechanical load is being applied to the id unit due to brea...

Page 123

45530603th rev.2 4-78 oki data confidential 4. Troubleshooting procedure check item check work actions to be taken at ng (19-1-2) environment condition sharp change of environment condition is the environment condition changed sharply from a low temperature environment to a high environment conditio...

Page 124

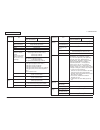

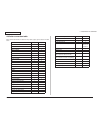

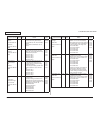

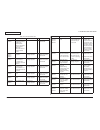

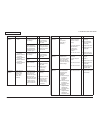

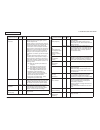

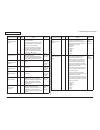

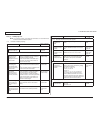

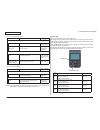

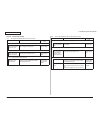

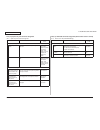

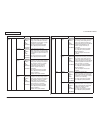

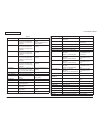

45530603th rev.2 4-79 oki data confidential 4. Troubleshooting procedure 4.5.2.(20) wiring diagram cn relay(4) cn relay(3) cn cn relay(2) cn cn (2) cn cn1 pask(8) drawer (7p×2) drawer (7p×2) head5 head4 head3 head2 cnswled amp(9) pne liftup side_covopn cassns amp(7) sns amp(6) m m m m id5 id4 id3 id...

Page 125

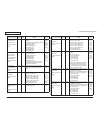

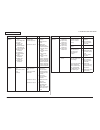

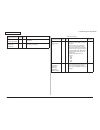

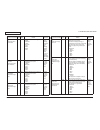

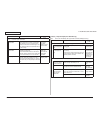

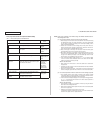

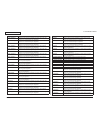

45530603th rev.2 4-80 oki data confidential 4. Troubleshooting procedure b stain on white print a overall faded-out blurred c entirely white h d black banding/ black streaking in vertical direction e cyclic abnormality f white banding/ white streaking in vertical direction causing of slipping and we...

Page 126

45530603th rev.2 4-81 oki data confidential 4. Troubleshooting procedure 4.5.3.(1) color has faded-out and blurred entirely. (refer to figure 4-2 a) (1-1) color are faded-out and blurred. Check item check work actions to be taken at ng (1-1-1) toner remaining amount of toner check if the message "pr...

Page 127

45530603th rev.2 4-82 oki data confidential 4. Troubleshooting procedure 4.5.3.(2) stain on white print. (refer to figure 4-2 b) (2-1) stain on white print (partial stain) check item check work actions to be taken at ng (2-1-1) id unit exposure of drum to light is the drum left in a circumstance in ...

Page 128

45530603th rev.2 4-83 oki data confidential 4. Troubleshooting procedure 4.5.3.(3) white print (refer to figure 4-2 c) (3-1) white print over entire page check item check work actions to be taken at ng (3-1-1) toner condition remaining amount of toner confirm that sufficient amount of toner remains ...

Page 129

45530603th rev.2 4-84 oki data confidential 4. Troubleshooting procedure 4.5.3.(5) periodic abnormalities (refer to figure 4-2 e) (5-1) periodic abnormality occurs in vertical direction check item check work actions to be taken at ng (5-1-1) cycle image drum check that the cycle is 125 mm. Replace t...

Page 130

45530603th rev.2 4-85 oki data confidential 4. Troubleshooting procedure 4.5.3.(7) solid black printing. (7-1) solid black printing over the whole page check item check work actions to be taken at ng (7-1-1) high voltage contacting condition ch terminal check that the terminal coming from the printe...

Page 131

45530603th rev.2 4-86 oki data confidential 4. Troubleshooting procedure 4.5.3.(9) white dot on printing. (9-1) white dot of streaking in horizontal direction (refer to figure 4-2 i) check item check work actions to be taken at ng (9-1-1) print adjustment transfer setting if appear white dot at cyan...

Page 132

45530603th rev.2 4-87 oki data confidential 4. Troubleshooting procedure 4.5.4 network troubleshooting (1) printing/communication is not available. Check item check work actions to be taken at ng (1) check the link lamp check if the link lamp (green) is illuminating or not. Check if the hub and a pr...

Page 133

45530603th rev.2 4-88 oki data confidential 4. Troubleshooting procedure (2) print speed is slow. Check item check work actions to be taken at ng (1) check the link lamp. Check if the link lamp (green) is illuminating or not. Check if the hub and a printer are connected normally. Re-connect the netw...

Page 134

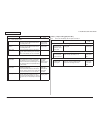

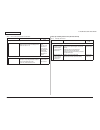

45530603th rev.2 4-89 oki data confidential 4. Troubleshooting procedure if any of the following errors occurs, check the corresponding fuse on the pu/cu control pcb or high voltage power supply board. (refer to table 4-6.) table 4-6 fuse error fuse name error description insert point resistance pri...

Page 135

45530603th rev.2 4-90 oki data confidential 4. Troubleshooting procedure f1h board(head relay) f1y rev2 ddr3 5v 24v 5vs sub power second side fuse interrelation n36100a etc 5vs always on expept off mode and deepsleep is on +5vs0 vref +5v cpu host usb head c,m,y,k +3.3vhead g-lan phy (realtek) spi ro...

Page 136

45530603th rev.2 4-91 oki data confidential 4. Troubleshooting procedure printer control pcb - fuse location component side f23 f24 f25 f22 f5 f9 f2 f4 f3 fuse rating.

Page 137

45530603th rev.2 4-92 oki data confidential 4. Troubleshooting procedure driver relay pcb - fuse location component side control panel pcb - fuse location f33 f32 f2 f4 f33 f5.

Page 138

45530603th rev.2 4-93 oki data confidential 4. Troubleshooting procedure duplex unit pcb/option tray pcb - fuse location print head relay pcb - fuse location f502 f502.

Page 139

45530603th rev.2 4-94 oki data confidential 4. Troubleshooting procedure spot color pcb - fuse location.

Page 140

45530603th rev.2 4-95 oki data confidential 4. Troubleshooting procedure high-voltage power supply pcb - fuse location low-voltage power supply pcb - fuse location.

Page 141

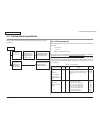

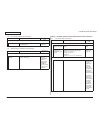

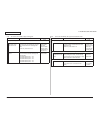

45530603th rev.2 4-96 oki data confidential 4. Troubleshooting procedure (1) source tray switch part no. 2052000p4000 model no: hs12-001 size bit no. Tray1 〜 5 1 2 3 4 no cassette h h h h a3 nobi,18" h h l l 17"(tabloid) l h l l a3 l h h l b4 h h h l legal 14/13.5 h l h l legal 13 h l h h a4 (sef) l...

Page 142: Maintenance Menus

Oki data confidential the printer can be adjusted by using maintenance utility or button operation on its operation panel. On the panel, maintenance menus are provided in addition to general menus. Select the menu intended for each adjustment purpose. 5.1 system maintenance menu (for maintenance per...

Page 143

45530603th rev.2 5-2 oki data confidential 5. Maintenance menus 5.1 system maintenance menu (for maintenance personnel) this menu is activated when the power is turned with the back, ok and on line buttons held down in the standby mode of the device, and then the window to enter the password is disp...

Page 144

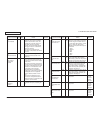

45530603th rev.2 5-3 oki data confidential 5. Maintenance menus 5.2 maintenance utility the adjustments described in table 5-2 should be executed on using maintenance utility. Details on the utility are as follows: (1) maintenance utility operation manuals: 42678801fu01 version 30.8 or higher (japan...

Page 145

45530603th rev.2 5-4 oki data confidential 5. Maintenance menus item adjustment section in maintenance utility operation manual operation from operation panel (section in this maintenance manual) 11 pu log file save function stores pu log flies. Section 2.4.1.2.16 unavailable 12 counter/ toner infor...

Page 146

45530603th rev.2 5-5 oki data confidential 5. Maintenance menus 5.3 user maintenance menu functions 5.3.1 maintenance menu (for end-users) some general menu categories are equivalent to the maintenance menus (but are different form system maintenance menus). The items available in this menus are as ...

Page 147

45530603th rev.2 5-6 oki data confidential 5. Maintenance menus item settings functions print adjust mptray x adjust 0.00 millimeter +0.25 millimeter to +2.00 millimeter -2.00 millimeter to -0.25 millimeter to the paper fed from mp tray, adjusts the position of a whole printing image (in 0.25-millim...

Page 148

45530603th rev.2 5-7 oki data confidential 5. Maintenance menus item settings functions print adjust tray1 duplex x adjust 0.00 millimeter +0.25 millimeter to +2.00 millimeter -2.00 millimeter to -0.25 millimeter to the paper fed from tray 1, during the front-side printing of duplex printing (when f...

Page 149

45530603th rev.2 5-8 oki data confidential 5. Maintenance menus item settings functions print adjust tray2 overprint x adjust 0.00 millimeter +0.25 millimeter to +2.00 millimeter -2.00 millimeter to -0.25 millimeter to the paper fed from tray 2, during the second printing of spot-color over printing...

Page 150

45530603th rev.2 5-9 oki data confidential 5. Maintenance menus item settings functions print adjust tray4 x adjust 0.00 millimeter +0.25 millimeter to +2.00 millimeter -2.00 millimeter to -0.25 millimeter to the paper fed from tray 4, adjusts the position of a whole printing image (in 0.25-millimet...

Page 151

45530603th rev.2 5-10 oki data confidential 5. Maintenance menus item settings functions print adjust tray5 duplex x adjust 0.00 millimeter +0.25 millimeter to +2.00 millimeter -2.00 millimeter to -0.25 millimeter to the paper fed from tray 5, during the front-side printing of duplex printing (when ...

Page 152

45530603th rev.2 5-11 oki data confidential 5. Maintenance menus item settings functions print adjust transfer roller cleaning execute in order to prevent the occurrence of dirt on the backside due to the dirty second transfer roller, cleans the second transfer roller. High humid mode mode 1 mode 2 ...

Page 153

45530603th rev.2 5-12 oki data confidential 5. Maintenance menus item settings functions admin setup panel setup near life status enable disable sets the display control of lcd when a near-life warning for drum, fuser, and belt occurs. When enabled, displays the near- life warning. When disabled, do...

Page 154

45530603th rev.2 5-13 oki data confidential 5. Maintenance menus item settings functions admin setup time setup time setting 01/01/2000 00:00 to 01/01/2009 00 :00 to 12/31/2091 23 :59 01/01/2000 00 :00 to 01/01/2009 00 :00 to 31/12/2091 23 :59 sets the time. Date is displayed by the format according...

Page 155

45530603th rev.2 5-14 oki data confidential 5. Maintenance menus item settings functions admin setup others setup hdd setup format partition pcl common ps formats a specified partition. [conditions for display] - when hdd is installed - “boot menu"-"hdd setup"-"enable hdd" is “yes” - "admin setup"-"...

Page 156

45530603th rev.2 5-15 oki data confidential 5. Maintenance menus item settings functions admin setup others setup job cancel setup cancel key behavior short long off sets an operation when pressing the job cancel button. Short: executes canceling a job by pressing bhte button (2sec. Or less) long: e...

Page 157

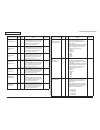

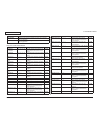

45530603th rev.2 5-16 oki data confidential 5. Maintenance menus (1) menu option display switching the level in a shaded area xxxxx can be displayed only from another one. Use the menu or menu button to display the menu option shown in a non-shaded area xxxxx . Self-diagnostic mode layout (overall) ...

Page 158

45530603th rev.2 5-17 oki data confidential 5. Maintenance menus level0 (1) menu option display switching hold down the back or on line button or momentarily press the menu or menu button to display the option shown in a shaded area xxxx . Press the menu or menu button to display the menu option sho...

Page 159

45530603th rev.2 5-18 oki data confidential 5. Maintenance menus level1 (1) menu option display switching use the menu or menu button to select the option shown in a shaded area ( xxxxx ), and press ok to execute the option. Use ok to display the option shown in a non-shaded area ( xxxxx ), and use ...

Page 160

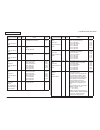

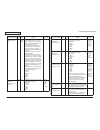

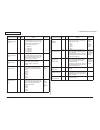

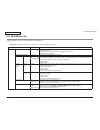

45530603th rev.2 5-19 oki data confidential 5. Maintenance menus 5.3.2.2 normal self-diagnostic mode (level 1) the normal self-diagnostic mode menus are as follows: option self-diagnosis menu adjustment maintenance utility 1 switch scan test switch scan checks input sensor and switch no.18 2 motor c...

Page 161

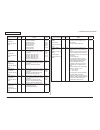

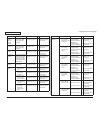

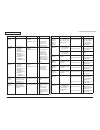

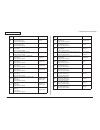

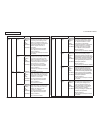

45530603th rev.2 5-20 oki data confidential 5. Maintenance menus fd stacker full sensor exit3 sensor exit2 sensor exit1 sensor fu stacker full sensor duplex in sensor duplex bottom sensor duplex rear sensor paper thickness sensor in2 sensor mpt paper end sensor mpt last sheet detection sensor tray1 ...

Page 162

45530603th rev.2 5-21 oki data confidential 5. Maintenance menus joboff home sensor spot color duct switch toner sensor id up/down sensor exit cover sensor fu stacker cover sensor exit unit open switch fuser release sensor second transfer position sensor tray1 paper size switch tray2 paper size swit...

Page 163

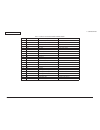

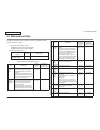

45530603th rev.2 5-22 oki data confidential 5. Maintenance menus table 5-3 switch scan detail 1 2 3 4 5 upper display detail lower display detail lower display detail lower display detail lower display detail lower display in1 in2 in3 wr fin in1 sensor h: no paper exists. L: paper exists. In2 sensor...

Page 164

45530603th rev.2 5-23 oki data confidential 5. Maintenance menus 1 2 3 4 5 upper display detail lower display detail lower display detail lower display detail lower display detail lower display bf tag * 2 1st tag uid of the belt / fuser line uid: ***h 2nd tag uid of the belt / fuser line uid: ***h t...

Page 165

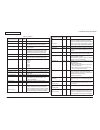

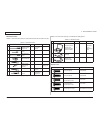

45530603th rev.2 5-24 oki data confidential 5. Maintenance menus table 5-4 tray 1 to 5 casette size paper size sensor response lower display tray 1 2 3 4 px753 t1 casette size t2 casette size t3 casette size t4 casette size t5 casette size h h h h no cassette h h l l a3n l h l l tabloid l h h l a3 h...

Page 166

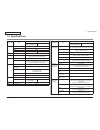

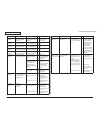

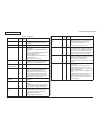

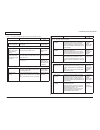

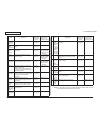

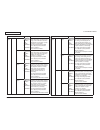

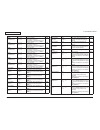

45530603th rev.2 5-25 oki data confidential 5. Maintenance menus job offset motor id up/down solenoid fuser exhaust fan cu fan fuser exhaust fan2 fuser intake fan duplex fan second transfer adsorption fan belt motor toner supply motor low voltage fan pu fan station 5 id intake fan 2path solenoid dup...

Page 167

45530603th rev.2 5-26 oki data confidential 5. Maintenance menus table5-5 panel display driven unit conditions for driving limitation s1-id motor station 1 id motor, low-voltage fan, pu fan, id exhaust fan, id intake fan, fan before fuser, duplex fan spot-color duct cover is closed. All ids (s1/s2/s...

Page 168

45530603th rev.2 5-27 oki data confidential 5. Maintenance menus panel display driven unit conditions for driving limitation t2 lift_up motor tray 2 lift-up motor the tray is removed. T2 hopping motor tray 2 hopping motor tray 2 hopping clutch the tray is removed. T2 feed clutch tray 2 hopping motor...

Page 169

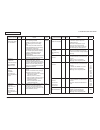

45530603th rev.2 5-28 oki data confidential 5. Maintenance menus 5.3.2.5 test print the test printing is used for printing test patterns stored in the pu. Other patterns are stored in the controller. This test print cannot be used to check the print quality. Diagnosis for the abnormal print image sh...

Page 170

45530603th rev.2 5-29 oki data confidential 5. Maintenance menus display settings default function duplex 3 pages stack off sets the selection of the number of stacked sheets for duplex print. 3 pages stack: performs duplex print with 3 pages stacked off: performs simplex printing. 1 pages stack: pe...

Page 171

45530603th rev.2 5-30 oki data confidential 5. Maintenance menus table 5-7-2 media weight category setting value media weight ultra light light medium light medium medium heavy heavy ultra heavy1 ultra heavy2 ultra heavy3 ultra heavy4 ultra heavy5 auto table 5-7-3 media size category setting value m...

Page 172

45530603th rev.2 5-31 oki data confidential 5. Maintenance menus • the following message appears when a test pattern is printed. P=*** w=*** p: number of test-print pages (unit: sheets) w: belt temperature wait time (unit: seconds) • the displays are switched to the following by pressing the menu or...

Page 173

45530603th rev.2 5-32 oki data confidential 5. Maintenance menus belt=xxxx(***) belt: xxxx = belt temperature [unit: ˚c] (***) = belt thermistor scanning ad value [unit: hex] thick=***um mpt w=***mm thick --- media weight detection value [unit: µm] mpt w --- mpt paper width detection value [unit: mm...

Page 174

45530603th rev.2 5-33 oki data confidential 5. Maintenance menus ③ pressing the cancel button during the test cancels the test (turning on the online lamp), restoring the state of step 2. Same button operation as of reg adj execute in (2) ① write start position adjustment is executed and the lower l...

Page 175

45530603th rev.2 5-34 oki data confidential 5. Maintenance menus displayed error name contents s1-sf range(r) detects an abnormal color-registration correction value in the right position of s1 vertical-scanning fine adjustment s1-sf range(l) detects an abnormal color-registration correction value i...

Page 176

45530603th rev.2 5-35 oki data confidential 5. Maintenance menus displayed error name contents s3-range(h) detects an abnormal color-registration correction value in s3 main- scanning adjustment s4-range(h) detects an abnormal color-registration correction value in s4 main- scanning adjustment displ...

Page 177

45530603th rev.2 5-36 oki data confidential 5. Maintenance menus upper line of the display lower line of the display details memory fine adj s2 [y-r] ***, ***, *** pattern detection value in the right position of s2 led vertical-scanning fine adjustment sram fine adj s2 [y-r] ***, *** fine adj s2 [x...

Page 178

45530603th rev.2 5-37 oki data confidential 5. Maintenance menus 5.3.2.7 density adjustment test the density adjustment test is used for performing a density adjustment function test and displaying the result of it to judge whether the density adjustment mechanism is proper. Chapter 2 “overview on d...

Page 179

45530603th rev.2 5-38 oki data confidential 5. Maintenance menus density adjustment test items sub menu details dens adj execute executes density adjustment. Dens adj par-set sets a control value for auto density adjustment. Note) must not use. Dens adj result displays the result of density adjustme...

Page 180

45530603th rev.2 5-39 oki data confidential 5. Maintenance menus upper line of the display lower line of the display details memory l_duty dens-s2 v01=***hs01=***h 01-03:first processing for averaging density 04-06: second processing for averaging density v0x: density sense value [hex] s0x: density ...

Page 181

45530603th rev.2 5-40 oki data confidential 5. Maintenance menus upper line of the display lower line of the display details memory 1: ****v -***v d.P +***v -**v upper left: standard ch voltage upper right: db voltage at bg adjustment lower left: ch offset voltage when dirt is detected lower right: ...

Page 182

45530603th rev.2 5-41 oki data confidential 5. Maintenance menus 1. Enter the self-diagnostic-mode(level1) and, until the following message appears, press the menu or menu button. Media wt adjust pa 2. Press the ok button. The following message appears. Press the menu or menu button until the intend...

Page 183

45530603th rev.2 5-42 oki data confidential 5. Maintenance menus edit thickness data selection items upper line of the display lower line of the display details memory s a m p l e page p=* p: measurement page count p value can be set from 1 to 9 by a cursor. Default: 3 (note2) sram thickness : p=1 t...

Page 184

45530603th rev.2 5-43 oki data confidential 5. Maintenance menus upper line of the display lower line of the display details memory paper thickness:p=4 set=***um out=***um in the fourth sheet set: setting weight [µ m] out: weight [µ m]when detected by the standard sensitivity (1.4µ m) (note 1) sram ...

Page 185

45530603th rev.2 5-44 oki data confidential 5. Maintenance menus upper line of the display lower line of the display details memory n-paper sample:p=8 max ad = * * * h v=*.*** in the eighth sheet change of min/max display with a cursor ad: ad value at the absence of the media [hex] v: voltage at the...

Page 186

45530603th rev.2 5-45 oki data confidential 5. Maintenance menus ≪ zero point adjustment of media thickness sensor ≫ 1.Enter the adjustment menu 1-1.Enter pu menu press the 「menu+」,「menu-」,「ok」,「back」 button together more than 5 sec and stop the press when appear the following display. Diagnostic mo...

Page 187

45530603th rev.2 5-46 oki data confidential 5. Maintenance menus 5.3.2.9 adjustment of paper width sensor this function is used to adjust the detection value of the mpt paper width sensor and display the implementation results (adjustment value). For adjustment, the media width should be a determine...

Page 188

45530603th rev.2 5-47 oki data confidential 5. Maintenance menus pressing the back button returns to the display of “width sns adj rslt”. (7) pressing the cancel button during the test cancels the test, restoring the state of step 2 ≪ when width sns adj rslt (reference to the results of paper width ...

Page 189

45530603th rev.2 5-48 oki data confidential 5. Maintenance menus table 5-8-3 panel display when paper sensor sensitivity adjustment (width sns adj exe) ends upper line of the display lower line of the display details details ok / error name width sns adj rslt upper line: “ok” is displayed for the no...

Page 190

45530603th rev.2 5-49 oki data confidential 5. Maintenance menus 5.3.2.10 consumable counter display the consumable counter display is used for viewing the usage of consumables. 1. Enter the self-diagnostic mode and, until consumable status appears, press the menu or menu button (the menu button dis...

Page 191

45530603th rev.2 5-50 oki data confidential 5. Maintenance menus 5.3.2.11 print counter display the print counter display is used for viewing print counter values. 1. Enter the self-diagnostic mode and, until printer status appears, press the menu or menu button. Then press the ok button. (the menu ...

Page 192

45530603th rev.2 5-51 oki data confidential 5. Maintenance menus 5.3.2.13 self-diagnostic function setting the self-diagnostic function setting is used for enabling or disabling the error detection by sensors. The detection can be enabled or disabled temporarily for troubleshooting research. Allowin...

Page 193

45530603th rev.2 5-52 oki data confidential 5. Maintenance menus 5.3.2.14 led head serial number display the led head serial number display is used for viewing whether downloaded data about led heads agrees with the serial numbers marked on the led heads. 1. Enter the self-diagnostic mode and, until...

Page 194

45530603th rev.2 5-53 oki data confidential 5. Maintenance menus 5.3.2.16 error code display the error code display is used for display the error code of the error occurred, and distinction the factor of the error. 1. Enter the self-diagnostic mode and, until “error code” appears, press the menu or ...

Page 195

45530603th rev.2 5-54 oki data confidential 5. Maintenance menus 5.3.3 printing on stand-alone basis this printer can print the following printing on a stand-alone-basis. Settings prints information, including printer menu settings, program versions and control block configuration. Network prints ne...

Page 196

45530603th rev.2 5-55 oki data confidential 5. Maintenance menus 5.4 setup after part replacement the following describes the adjustments necessary after part replacement: replaced part adjustment led head not necessary. Drum cartridge (yellow, magenta, cyan, black,spot color) not necessary. Fuser u...

Page 197

45530603th rev.2 5-56 oki data confidential 5. Maintenance menus enter 11-digits number which consists of adding 0 (single-byte) before 10-digits number. (enter “0ae01234567”) revision number • the pu serial number is ten digits from the sap serial number. The rest two digits are the revision number...

Page 198

45530603th rev.2 5-57 oki data confidential 5. Maintenance menus 5.5 manual density adjustment setting this printer is shipped with the auto density adjustment mode enabled. When the mode is disabled by a user, the printer may print density out of adjustment while being used. Manually perform densit...

Page 199

45530603th rev.2 5-58 oki data confidential 5. Maintenance menus 5.6 boot menu list to display boot menu, turn on the printer while holding down the enter button. Memo displaying boot menu requires entry of a password. The password defaults to six as (aaaaaa). Option settings function boot menu ente...

Page 200: Replacement of Parts

Oki data confidential 6. Replacement of parts this chapter describes the procedures of the field replacement of parts, assemblies and units. The procedures are to detach them. Reverse the procedures to attach them. The reference part numbers used in this manual (such as and ) do not identical to the...

Page 201

45530603th rev.2 6-2 oki data confidential 6. Replacement of parts (2) do not disassembly the printer so long as it operates properly. (3) minimize disassembly. Do not detach the parts not shown in the part replacement procedure. (4) use the replacement tools specified. (5) deal disassembly in the o...

Page 202

45530603th rev.2 6-3 oki data confidential 6. Replacement of parts maintenance tools: table 6-1-1 shows the tools necessary to replace printed-circuit boards and units in this priter. Table 6-1-1: maintenance tools no. Maintenance tool quantity use remarks 1 no. 2-200 screwdriver with magnetic tip 1...

Page 203

45530603th rev.2 6-4 oki data confidential 6. Replacement of parts 6.2 part replacement procedure this section describes the procedure for replacing the parts and assemblies shown in the disassembly diagram. 6.2.1 toner cartridge (1) open the toner change cover. 6.2.2 image drum (1) open the front c...

Page 204

45530603th rev.2 6-5 oki data confidential 6. Replacement of parts (2) gently lift the handle (blue) upwards, and remove the photoreceptor from the lower side taking care that your hand does not touch the drum on the lower side (green cylindrical section). ❶ ❷ note! ・ensure not to touch or damage th...

Page 205

45530603th rev.2 6-6 oki data confidential 6. Replacement of parts 6.2.3 belt unit (1) open the front cover. (2) remove the waste toner box from the printer..

Page 206

45530603th rev.2 6-7 oki data confidential 6. Replacement of parts (3) rotate the center lever (blue) to the right. (4) rotate the belt unit lock lever knobs (blue / two pieces at left and right) to the left, and pull these lock levers to front-side. (5) hold the handle and pull out the belt unit, h...

Page 207

45530603th rev.2 6-8 oki data confidential 6. Replacement of parts 6.2.4 transfer roller unit (1) pull out the ej-rail unit. (2) pull up both tips of the transfer roller unit's lock levers (blue). (3) hold the transfer roller unit's label parts (blue) and remove it..

Page 208

45530603th rev.2 6-9 oki data confidential 6. Replacement of parts 6.2.5 fuser unit (1) pull out the ej-rail unit. (2) pull up the fuser unit's lock lever (blue). (3) hold the fuser unit's handle with both hands and remove it..

Page 209

45530603th rev.2 6-10 oki data confidential 6. Replacement of parts 6.2.6 waste toner box (1) open the front cover. (2) remove the waste toner box from the printer..

Page 210

45530603th rev.2 6-11 oki data confidential 6. Replacement of parts 6.2.7 led head (1) detach the image drum and belt unit.(refer to section 6.2.2 and 6.2.3) (2) remove the cover-assy-front.(refer to section 6.2.18) (3) put up these left and right remainded hinges, and put down the led head ① . (4) ...

Page 211

45530603th rev.2 6-12 oki data confidential 6. Replacement of parts ① (①) [assembling process] (1) pull out the head cable to the left of led head. (2) hitch the calw of back, and warp the holder by led head, and hitch the claw of front side. Back side front side (3) connect the back side connector ...

Page 212

45530603th rev.2 6-13 oki data confidential 6. Replacement of parts 6.2.8 cassette-assy / guide-assy-tail / label-tray / indicator-paper-size (1) remove the cassette-assy ① . (2) remove the guide-assy-tail ② . (3) remove the label-tray ③ . (4) remove the indicator-paper-size ④ . ① ② ③ ④ > power on a...

Page 213

45530603th rev.2 6-14 oki data confidential 6. Replacement of parts 6.2.9 cover-assy-tc (1) open the cover-assy-tc and detach the toner cartridge. (refer to section 6.2.1) (2) remove the four screws (black)(8mm) ① and remove the cover-assy-tc ② . 6.2.10 cover-assy-op-panel (1) open the cover-assy-tc...

Page 214

45530603th rev.2 6-15 oki data confidential 6. Replacement of parts 6.2.11 lever-stacker-full (1) remove the cover-assy-op-panel.(refer to section 6.2.10) (2) remove the screw ① and remove the hdd cover ② . (2) remove the eight screws (silver) (6mm) ③ to detach the cover-rear ④ . (3) remove two claw...

Page 215

45530603th rev.2 6-16 oki data confidential 6. Replacement of parts 6.2.13 guide-assy-eject-m (1) open and remove the cover-assy-jam-clear ① . (2) remove the cover-rear.(refer to section 6.2.11) (3) remove the plate-sheild-f1d.(refer to section 6.2.20) (4) remove the motor-fan-assy.(refer to section...

Page 216

45530603th rev.2 6-17 oki data confidential 6. Replacement of parts 6.2.15 cover-assy-top-b (1) remove the toner cartridge and image drum. (refer to section 6.2.1,6.2.2) (2) remove the eject-assy-joboff. (refer to section 6.2.12) (3) remove the spot color duct.(for 5-color model only) (4) remove the...

Page 217

45530603th rev.2 6-18 oki data confidential 6. Replacement of parts 6.2.17 duplex-board(board-fit-1) (duplex unit control pcb) (1) remove the duplex-unit. (refer to section 6.2.16) (2) remove the screw(black)(8mm) ① and three screws(silver)(6mm) ② and remove the cover-dup-top ③ from the duplex-unit....

Page 218

45530603th rev.2 6-19 oki data confidential 6. Replacement of parts 6.2.19 filter-front / motor-fan / board-f1e(external led pcb) (1) remove the cover-assy-front.(refer to section 6.2.18) (2) remove the two screws(black)(8mm) ① and remove the cover-cable ② . (3) remove the six screws(black)(8mm) ③ a...

Page 219

45530603th rev.2 6-20 oki data confidential 6. Replacement of parts 6.2.21 board-ahv( high-voltage power supply pcb) (1) remove the board-f1y and board-f1x.(refer to section 6.2.20) (2) remove the guide-cable-powdrv ① . (3) remove the five screws(silver)(6mm) ② and remove the plate-box-mainpcb ③ . (...

Page 220

45530603th rev.2 6-21 oki data confidential 6. Replacement of parts 6.2.23 board-ahr(high-voltage relay pcb) (1) remove the motor-assy-id.(refer to section 6.2.22) (2) remove the ten screws(silver)(6mm) ① and remove the board-ahr ② . 6.2.24 board-tagrw/ffc-cable/motor-fan (1) remove the plate-box-ma...

Page 221: Warning

45530603th rev.2 6-22 oki data confidential 6. Replacement of parts 6.2.25 low-voltage-power-unit/low-voltage-fan/ geard-motor (1) remove the plate-cover-mainpcb.(refer to section 6.2.20) (2) remove the three screws(silver)(8mm) ① and remove the cover-rear-bottom ② . (3) remove the twelve screws(sil...

Page 222

45530603th rev.2 6-23 oki data confidential 6. Replacement of parts 6.2.27 belt-drive-assy/fuser-drive-assy/belt-mini- pitch (1) remove the motor-assy-id.(refer to section 6.2.22) (2) remove the motor-fan.(refer to section 6.2.24) (3) remove the four screws(silver)(6mm) ① and remove the contact-id-a...

Page 223

45530603th rev.2 6-24 oki data confidential 6. Replacement of parts 6.2.30 clutch(feeder-assy) (1) remove the mpt-unit.(refer to section 6.2.28) (2) remove the two screws(silver)(6mm) ① and remove the holder-gear-ow ② . (3) remove the two gear ③ , ④ . (4) remove the e-type ring ⑤ and remove the clut...

Page 224

45530603th rev.2 6-25 oki data confidential 6. Replacement of parts 6.2.31 frame-assy-tc/frame-assy-tc-r (1) remove the cover-assy-top-b.(refer to section 6.2.15) (2) remove the plate-shield-f1d.(refer to section 6.2.20.) (3) disconnect four cables and spot color kit connector. ② ① ×2 ⑥ ×4 ⑤ ×20 ③ ×...

Page 225

45530603th rev.2 6-26 oki data confidential 6. Replacement of parts 6.2.32 plate-fix-pivot (1) remove the frame-assy-tc-f and frame-assy-tc.(refer to section 6.2.31) (2) remove the plate-fix-pivot ① . (for c941 : ten, for c911/c931 : eight) ① ×10 ≪ attention of assembling ≫ attach the lock out of tc...

Page 226

45530603th rev.2 6-27 oki data confidential 6. Replacement of parts 6.2.34 motor-assy-geard (1) remove the frame-assy-tc and frame-assy-tc-r.(refer to section 6.2.31) (2) remove the two screws(black)(8mm) ① and remove the geard-motor ② . (3) remove the two screws(black)(8mm) ③ and remove the geard-m...

Page 227

45530603th rev.2 6-28 oki data confidential 6. Replacement of parts 6.2.36 guide-assy-eject-lower-sp / frame-assy-tr2 / decurl-assy (1) remove the ej-rail-unit.(refer to section 6.2.35) (2) remove the three screws(silver)(6mm) ① and remove the cover-lsd-f ② . (3) remove the round-head screw(black)(6...

Page 228

45530603th rev.2 6-29 oki data confidential 6. Replacement of parts 6.2.37 gear-assy-oneway-z33/gear-assy-oneway- z33-r/board-f1l(rail unit relay pcb) (1) remove the lsd-unit.(refer to section 6.2.36) (2) remove the cover-pcb-lsd ① . (3) disconnect all cables from the board and remove the screw(silv...

Page 229

45530603th rev.2 6-30 oki data confidential 6. Replacement of parts 6.2.39 roller-assy-regist-2/roller-assy-synchro/ regist-sensor-assy_753 (1) remove the cover-top.(refer to section 6.2.15) (2) remove the mfp-unit.(refer to section 6.2.28) (3) remove the cover-in-f ① . (4) remove the two screws(sil...

Page 230

45530603th rev.2 6-31 oki data confidential 6. Replacement of parts 6.2.41 motor-assy-regist (1) remove the roller-assy-regist-2/roller-assy-synchro/regist-sensor-assy_753. (refer to section 6.2.39) (2) remove the four screws(silver)(6mm) ① and remove the motor-assy-regist ② . 6.2.40 waste toner ful...

Page 231

45530603th rev.2 6-32 oki data confidential 6. Replacement of parts 6.2.43 hopping-unit (1) remove the mpt-unit.(refer to section 6.2.28) (2) remove the two screws(silver)(6mm) ① and remove the cover-side-r ② . (3) remove the two screws(silver)(6mm)③and remove the cover-guide-tray-assy ④. (4) remove...

Page 232

45530603th rev.2 6-33 oki data confidential 6. Replacement of parts 6.2.45 board-f1k(cassette sensor relay pcb) (1) remove the roller-assy-regist-t.(refer to section 6.2.44) (2) remove the five screws(silver)(6mm) ① and remove the hopping-assy ② . (3) remove the two screws(silver)(6mm) ③ and remove ...

Page 233

45530603th rev.2 6-34 oki data confidential 6. Replacement of parts 6.2.47 sensor-assy-front/motor-fan (1) open the cover-front. (2) remove the four claws and remove the cover-in-a ① . (3) remove the screw(silver)(6mm) ② and remove the sensor-assy-front ③ . (4) remove the two round-head screws(black...

Page 234

45530603th rev.2 6-35 oki data confidential 6. Replacement of parts 6.2.49 paper feed roller (1) press and hold the power switch for approximately 1sec. To switch off the power supply. (2) check that the operation panel is completely turned off, and then switch off the main power supply. 6.2.48 hold...

Page 235

45530603th rev.2 6-36 oki data confidential 6. Replacement of parts (3) pull out tray 1. (4) while expanding the claws of feed roller in outside direction, remove them from the axial..

Page 236

45530603th rev.2 6-37 oki data confidential 6. Replacement of parts (5) similarly, remove the remaining two paper feed rollers..

Page 237

45530603th rev.2 6-38 oki data confidential 6. Replacement of parts 6.3 portions lubricated portions lubricated are shown in this section. The other portions must not be lubricated. Lubrication is not required during assembly or disassembly, except that the lubricant specified must be applied to por...

Page 238

45530603th rev.2 6-39 oki data confidential 6. Replacement of parts ① 45239501pa motor-assy-joboff ② 45173601pa retard assy apply a harves to the all over the gear gear-z50-z20 class c apply a normal amount of molykote to the gear teeth and shaft grease prohibition at the post. Class c apply a norma...

Page 239

45530603th rev.2 6-40 oki data confidential 6. Replacement of parts ③ 45175001pa plate-assy-retard ④ 45529101pa plate-assy-motor-b class c apply a normal amount of molykote to the all over the gear teeth gear-feed_z20 class c apply a normal amount of molykote to the gear teeth and shaft gear-idle-re...

Page 240

45530603th rev.2 6-41 oki data confidential 6. Replacement of parts ⑤ 45176101pa hopping-assy ⑥ 45177901pa roller-regist-sub assy-t class c apply a normal amount of molykote to the all over the gear teeth gear-feed_z20 class c apply a normal amount of molykote to the inside of the e-ring groove roll...

Page 241

45530603th rev.2 6-42 oki data confidential 6. Replacement of parts ⑦ -1 45180501pa case-cassette-assy ⑦ -2 45180501pa case-cassette-assy class b apply a normal amount of molykote in the state the gear-lift-up is stayed at the bottom, put the grease to the range of turning the tooth of gear-coupling...

Page 242

45530603th rev.2 6-43 oki data confidential 6. Replacement of parts ⑧ 45187301pa plate-assy.-front ⑨ -1 45189701pa belt-drive-assy class a apply a small amount of molykote class c apply a small amount of molykote to the all shaft apply a molykote from tip to 1/3 area of shafts bracket-belt-caulking.

Page 243

45530603th rev.2 6-44 oki data confidential 6. Replacement of parts ⑨ -2 45189701pa belt-drive-assy ⑩ 45192101pa fuser-drive-assy class c apply a normal amount of molykote(em30lp) to the all over the shaft class c apply a normal amount of molykote(em30lp) to the all over the gear class e apply a nor...

Page 244

45530603th rev.2 6-45 oki data confidential 6. Replacement of parts ⑪ 45194301pa mpt-gear-assy ⑫ -1 45192901pa motor-assy-regist class c apply a normal amount of molykote to the all over the gear and shaft class c apply a normal amount of molykote(em30lp) to the all over the shaft class c apply a no...

Page 245

45530603th rev.2 6-46 oki data confidential 6. Replacement of parts ⑫ -2 45192901pa motor-assy-regist ⑬ 45199101pa plate-assy-side-ra class c apply a normal amount of molykote(em30lp) to the all over the shaft and gear gearse prohibition at the this position class c apply a normal amount of molykote...

Page 246

45530603th rev.2 6-47 oki data confidential 6. Replacement of parts ⑭ 45171801pa motor-assy-geard ⑮ 45206601pa motor-assy-id class f apply a large amount of molykote to all over the gear class c apply a normal amount of molykote(em30lp) to all over the gear and shaft class c apply a normal amount of...

Page 247

45530603th rev.2 6-48 oki data confidential 6. Replacement of parts ⑯ 45207501pa gear-assy-dv ⑰ 45209301pa shaft-assy-drum class f apply a large amount of molykote (em-30lp) to the gear-dv grease prohibition at the coupling class c apply a normal amount of molykote (em-30lp) to the ball class f appl...

Page 248

45530603th rev.2 6-49 oki data confidential 6. Replacement of parts ⑱ 45221401pa feeder-assy ⑲ 45228601pa roller-assy-regist-2 class c apply a normal amount of molykote(em-30lp) to the all over the gear gear-cl-z28 class c apply a normal amount of molykote (em-30lp) to the d-cut of the post apply a ...

Page 249

45530603th rev.2 6-50 oki data confidential 6. Replacement of parts ⑳ 45228701pa roller-regist-subassy-r2 ㉑ 45230601pa roller-assy-synchro class c apply a normal amount of molykote(em-30lp) to the all over the gear and shaft gear-feed-z28 class c apply a normal amount of molykote(em-30lp) to the ins...

Page 250

45530603th rev.2 6-51 oki data confidential 6. Replacement of parts ㉒ 45230701pa roller-regist-subassy-s ㉓ 45231901pa regist-sensor-assy apply a harves to gear-eject-lower apply a harves to gear-eject-lower harves prohibition: oneway gear/ same axial gear/shaft class e apply a normal amount of molyk...

Page 251

45530603th rev.2 6-52 oki data confidential 6. Replacement of parts ㉔ -1 45233601pa guide-assy-eject-m_753-c1 ㉔ -2 45233601pa guide-assy-eject-m_753-c1 class c apply a normal amount of molykote (em-30lp) to the bush class c apply a normal amount of molykote (em-30lp) to the gear and shaft bush bush ...

Page 252

45530603th rev.2 6-53 oki data confidential 6. Replacement of parts ㉕ -1 452862xxpa ej-rail-unit ㉕ -2 452862xxpa ej-rail-unit apply a harves to the slider link class c apply a normal amount of molykote(em-30lp) 2places class c apply a normal amount of molykote(em-30lp) 2places.

Page 253