- DL manuals

- Oki

- Scanner

- S900

- Service Manual

Oki S900 Service Manual

Summary of S900

Page 1

S900 service manual 031103a.

Page 2: Contents

S900 ---------------------------------------------------------------------------------------------------------------------------------------------- ii contents 1. Introduction ...............................................................................................................................

Page 3

S900 ------------------------------------------------------------------------------------------------------------------------------------------------- iii 7. Disassembly .....................................................................................................................................

Page 5: 1. Introduction

S900 1-1 1. Introduction 1.1 general notes for servicing 1.2 general description 1.3 specifications this manual is intended to be used by maintenance engineers. It describes areas to be maintained, the detailed installation, and the component replacement procedures as well as the main trouble shooti...

Page 6

S900 1-2 1.2 general description the s900 provides you a fast and affordable access to color digital copying by simply connecting the product to a color printer. This new way to make digital copies is cost effective, and it produces dramatically better copies result than regular analog copiers. The ...

Page 7

S900 1-3 copy specification printer language pcl connector interface ieee 1394 cable copy area 297 x 431 mm (11.19" x 16.97") multiple copies up to 99 copy mode speed, finetext, photo enlarge / reduce whole page (93%) 25%~400% in 1% increment/decrement pre-set scales copy features paper size auto de...

Page 9: Transportation

S900 2-1 2. Unpacking, installation, and transportation 2.1 precautions of installation 2.2 unpacking procedure 2.3 installation 2.4 placing the original 2.5 transportation 2.1 precautions of installation pay attention to the following matters before unpacking and installation. • do not install in a...

Page 10

S900 2-2 1. Auto document feeder (optional) 5. Ieee1394 cable (for printer connection) 2. S900 main unit 6. Power adapter 3. Usb cable (for computer connection) 7. Cross cable 4. Cd (service tool) 8. Power cord (us, uk, europe, australia) 6 5 4 3 1 2 7 8.

Page 11

S900 2-3 2.3 installation 2.3.1 unlocking the scan unit the scan unit is locked during transport to protect the scanning mechanism from being damaged. Be sure to unlock the scan unit before using the machine. 1). Locate the lock switch at the left side of the machine. 2). Push the lock switch down t...

Page 12

S900 2-4 2.3.2 connecting the ieee 1394 cable 1. Connect one end of the ieee 1394 cable (included) to your printer. 2. Connect the other end to the printer port of your s900. 2.3.3 connecting the adf cable (optional) connect the adf cable, which is attached to the document cover to the adf port..

Page 13

S900 2-5 2.3.4 setting up the optional adf (auto document feeder) 1. Raise the adf tray to about 45 degrees. 2. Pull down the wire leg beneath the adf tray. 3. Pull out the adf tray extension to its full length. 2.3.5 connecting the power and turning on the machine 1. Press the power switch to the “...

Page 14

S900 2-6 4. Press the power switch to the “i” position to turn on your s900. After showing the warming up message, the lcd display prompts the copy ready status. 2.4 placing the original you can load the paper from the s900 either in the adf (automatic document feeder) or on the glass. If you need t...

Page 15

S900 2-7 2.4.2 placing document(s) in the adf 2.4.2.1 notice on using the adf before using the adf, please make sure that your paper meets the following specifications: • document(s) can range in size from 4.5 by 5.5 inches to 11.69 by 16.54 inches (a3). • document(s) can range in weight from 14 to ...

Page 16

S900 2-8 2.4.2.2 placing document(s) in the adf 1. Make sure your document is free of staples, paper clips and is not torn out. 2. If you have multiple pages, fan your document(s) to avoid occasional paper jam. The adf can hold up to 50 pages at one time. 3. Place your document(s) with the text face...

Page 17: 3. Parts Identification

S900 3-1 3. Parts identification 3.1 external view 3.1 external view 3.1.1 front view 1. Document cover 2. Control panel 1 2.

Page 18

S900 3-2 3.1.2 rear view 1. Printer port 2. Service port 3. Usb port 4. Adf port 5. Power jack 1 2 3 4 5.

Page 19: 4. Theory Of Operation

S900 4-1 4. Theory of operation 4.1 introduction 4.2 main control unit 4.1 introduction figure 5.1 theory of operation the reflected rays of the your original as shown in the above figure 5.1 pass through the lens and creates an image on the ccd (charge-coupled device). Then, according to the differ...

Page 20

S900 4-2 4.2.1 system diagram figure 5.2 shows the system block diagram. Figure 5.2 system block diagram image processor main board control section optical unit lamp unit inverter power adapter lcd display & control panel 24v to printer cpu adf ieee 1394 controller rj-45 mac/phy. Usb 2.0 controller ...

Page 21

S900 4-3 4.2.2 main control circuit mips cpu controls this s900. The cpu is configured with a 2.5mb external rom, a 128mb external ram working area. I/o address maps: • rom area: flash layout loader system firmware scanner firmware printer profile • external ram working area: 256kb 256kb 0x1e000000 ...

Page 22

S900 4-4 4.2.3 video circuit: the video circuit of this s900 includes: 1. Ccd driving circuit and motor control signal 2. Ccd signal processing circuit. 1. Ccd driving circuit & motor control signal the ccd driving circuit is used to generate correct signals to the ccd, so that the ccd may generate ...

Page 23

S900 4-5 cds ccd signal processor cds cds pga pga pga ccd mux adc r g b dout the ccd signal processor includes all the necessary circuitry to perform three-channel conditioning and sampling. The signal chain consists of three-channel correlated double sampling (cds) and programmable gain adjustment ...

Page 24

S900 4-6 4.2.4 panel and lcd module circuit the circuit for panel and lcd module controls the function of the entire module including the lcd display, the push button on the control panel, and led display. Pin assignment of lcd module pin no. Name function 1 d.G. Digital ground 2 kpdata0 data bus bi...

Page 25

S900 4-7 4.2.5 sensor input the sensor input includes home position sensor, hall effect sensor, and paper size sensor. (1) home position sensor the home position of the carrier motor is detected by photo sensor. The photo transistor transmission to the photo sensor receiver circuit is shown below. F...

Page 26

S900 4-8 (4) paper size sensor the paper size is detected by ir sensor. The ir transistor transmission to the ir sensor receiver circuit is shown below. Figure 5.5 paper size sensor 4.2.6 sub power supply circuit the sub power supply circuit is provided for the internal analog circuit. The circuit c...

Page 27

S900 4-9 4.2.7 power supply in this system, there is only one type of power supply. Please see table 5.1 for details. Table 5.1 power adapter type characteristic wall-mount input voltage range 100-240v input current (max.) 1.4a input frequency 50-60hz max. In-rush current(@115vac, cold start) 4a out...

Page 29: 5. Troubleshooting

S900 5-1 5. Troubleshooting 5.1 troubleshooting flowchart 5.2 tables this section locates and resolves the causes of trouble so the s900 is always in good working condition. The trouble modes, relevant units and maintenance methods are described below. When a problem occurs, troubleshoot the problem...

Page 30

S900 5-2 5.1 troubleshooting flowchart 5.1.1 power on to s900 ready figure 5.1 power on to s900 ready power on lcd shows booting up . Message no yes see table 5-1 wait for command from control panel or pc lcd shows copy menu info.

Page 31

S900 5-3 5.1.2 copy operation figure 5.2 copy operation flow chart copier online troubleshooting check printer online? Scanning performed printing completed image not clear noises generated end no yes yes yes yes yes no no yes no no see table 5-2 see table 5-3 see table 5-5 see table 5-6 no see tabl...

Page 32

S900 5-4 5.1.3 contorl panel operation copier online troubleshooting lcd shows message value setting wait for key pressing no yes yes end no see table 6-7 figure 5.3 control panel operation see table 5-7.

Page 33

S900 5-5 5.2 tables the following tables provide detailed troubleshooting information. Table 5.1 the lcd does not display. Table 5.2 printer does not react. Table 5.3 optical path or hardware problem. Table 5.4 printer does not print. Table 5.5 image not clear. Table 5.6 noise generated. Table 5.7 l...

Page 34

S900 5-6 5.2.1 lcd does not display table 5.1 cause relevant unit check method maintenance method unplugged from outlet none visual check insert the ac plug into the outlet dc power unplugged from unit none visual check insert the dc power adapter cable into the unit ac voltage failure none ac outle...

Page 35

S900 5-7 5.2.3 scanning is not performed table 5.3 cause relevant unit check method maintenance method scanner cable failure scanner cable visual check attach the scanner cable main pcb replace the pcb scanner link failure scan module visual check replace the scan module 5.2.4 printer does not print...

Page 36

S900 5-8 5.2.5 image unclear table 5-5 cause relevant unit check method maintenance method lamp too dark lamp visual check replace the lamp dirt on flatbed glass flatbed glass visual check clean the flatbed glass with isopropyl alcohol printer toner low printer toner visual check check printer toner...

Page 37

S900 5-9 5.2.7 lcd does not show message after command table 5-7 cause maintenance method lcd module cable failure attach the lcd module cable and secure it firmly lcd problem replace the lcd module push button failure replace the lcd module.

Page 38

S900 5-10 5.2.8 s900 is not connected to the network table 5.8 cause maintenance method rj-45 connector is not plugged in plug the connector in network cable is damaged replace the cable for your information, the assigned ip address for s900 and your computer should be: s900’s ip address subnet mask...

Page 39

S900 5-11 5.2.9 error codes in lcd lcd message lcd message action copy function disabled. Please download the printer profile. Check printer cable or status. 1. Check if the printer cable has been correctly connected. 2. Check if the printer is turned on. 3. Restart the s900 unit and your printer. 4...

Page 40

S900 5-12 info code meaning action 20004 printer offline please check printer. 20011 ~ 20019 copy job error reset scanner, and then try again. If the code still appears, contact your dealer. 20021 ~ 20029 1394 protocol error reset scanner and printer, and then try again. If the code still appears, c...

Page 41

S900 5-13 5.3 clearing the paper jam 1. Press the push button on the adf front cover and open the cover to the left. 2. Gently pull out the jammed paper. 3. Close the adf cover. Adf push button document.

Page 43: 6. Preventive Maintenance

S900 6-1 6. Preventive maintenance 6.1 cleaning this s900 is designed to be maintenance free. However, it is suggested to perform preventive maintenance in the shorter term either every 6 months or every 60,000 sheets scanning to ensure a consistently optimum performance. 6.1 cleaning the document g...

Page 45: 7. Disassembly

S900 7-1 7. Disassembly 7.1 service tools 7.2 lubricants 7.3 procedure for disassembly and reassembly 7.1 service tools table 7.1 describes the maintenance tools necessary for the maintenance of this equipment. No. Name description 1 standard screwdriver idler pulley module screw 2 philips screwdriv...

Page 46

S900 7-2 7.2 lubricants this section describes the items to check and the places to lubricate when maintenance parts are replaced. 7.2.1 mechanical unit lubrication this lubrication method: 1 - a - c - y 1. Positions need to be lubricated: the positions need to be lubricated is indicated in numbers....

Page 47

S900 7-3 positions need to be lubricated 2 sliding rod 1 sliding guide.

Page 48

S900 7-4 7.3 procedure for disassembly and reassembly 7.3.1 notes on disassembly (1) clean the disassembly and assembly location. (2) disconnect the power cable and remove the dc plug from the outlet before disassembly and assembly. (3) follow the disassembly and assembly procedures. Never loosen th...

Page 49

S900 7-5 7.3.3 control panel (1) remove the document cover as described in the preceding section 7.3.2. (2) raise the main unit as shown below. Remove the three fixing screw of the control panel. (3) lay down the main unit. Loosen the control panel pcba assembly by lifting it up. Disconnect the flat...

Page 50

S900 7-6 7.3.4 upper housing (1) remove document cover as described in the subsection 7.3.2. (2) remove control panel pcba as described in subsection 7.3.3. (3) remove the fixing screws of the control panel. (4) remove the bottom housing of the control panel by detaching the hook. (5) loosen the fix...

Page 51

S900 7-7 7.3.5 document cover sensor pcba (1) remove document cover as described in the subsection 7.3.2. (2) remove upper housing as described in preceding section 7.3.4. (3) move the optical chassis to the center as illustrated below. (4) loosen the fixing screw to remove the paper sensor pcba. Op...

Page 52

S900 7-8 7.3.6 paper sensor pcba (1) remove upper housing as described in preceding section 7.3.4. (2) loosen the fixing screw to remove the paper sensor pcba. Fixing screw.

Page 53

S900 7-9 7.3.7 main control board assembly (1) turn the machine over to reveal the bottom. Loosen the fixing screws of the metal cover from the bottom housing. (2) raise the main board to disconnect the cables. (3) loosen all flat cables. (4) loosen the fixing screws of the scsi connector with prope...

Page 54

S900 7-10 7.3.8 motor belt (1) remove upper housing. (see preceding section 7.3.4) (2) move the optical chassis to the center as illustrated below. (3) loosen the fixing screw of the belt to detach the left end of the belt. (4) remove the other end of the belt from the hook. • note during the reinst...

Page 55

S900 7-11 7.3.9 optical chassis disassembling procedure (1) remove the upper housing. (see section 7.3.4 ) (2) remove the main control pcba. (see section 7.3.5) (3) remove the motor belt. (see section 7.3.6) (4) remove the fixing screws of the sliding rod, then pull it out gently as illustrated belo...

Page 56

S900 7-12 (5) remove the flat cable of the optical chassis as illustrated below. (6) hold the right side of the optical chassis to remove it gently from the machine. (be careful not to touch the ccd board as well as the lamp in the optical chassis.) • note: 1. While reinstalling the optical chassis,...

Page 57

S900 7-13 7.3.10 ccfl inverter pcba (1) remove the optical chassis. (see preceding section 7.3.7). (2) remove the fixing screw of the cover. (3) disconnect the ccfl inverter cable and ccfl inverter pcba cable. Ccfc inverter pcba removal optical chassis fixing screw ccfl inverter pcba.

Page 58

S900 7-14 7.3.11 lamp assembly (1) remove the optical chassis. (see section 7.3.7) (2) disconnect all cables of the lamp assembly. (3) detach the lamp from the lamp holder. Lamp assembly lamp assembly optical chassis lamp assembly lamp cable.

Page 59

S900 7-15 7.3.12 motor unit (1) remove the optical chassis and the ccfl inverter pcba. (see section 7.3.7 and 7.3.8) (2) remove the lamp assembly. (see preceding section 7.3.9) (3) loosen the fixing screw to remove the motor mount as shown in the figure below. (4) loosen the fixing screw and disconn...

Page 61: 8. Parts

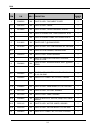

S900 8-1 8. Parts 8.1 spare parts list 8.1 spare parts list please find the following spare parts list and its illustration..

Page 62

S900 8-2.

Page 63

S900 8-3.

Page 64

S900 8-4 item p/n rev. Description order q'ty 1 53085301 100 s-parts: ass'y, document cover 1 1-1 50810701 100 s-parts: ass'y, hinge 1 2 56734801 100 s-parts: ass'y, upper housing, a3 size 1 3 100 s-parts: sliding rod, 12x553,sum1214, ni 6u 1 4 100 s-parts: sliding frame, 621x12x28x1.6/ni 6u 1 5 513...

Page 65

S900 8-5 others a-1 56638402 100 s-parts: ac power cord: 125v/10a, 1.8m(ul/csa) 1 b 56416802 100 s-parts: adaptor: 24v/2.0a, 100~240v/50~60hz 1 c 56640201 100 s-parts: usb 2.0 cable 1 d 010 cd: oki s900 1 e 56638901 010 s-parts: cross cable: internet cable, 8p 4c, 1.8m 1 f 010 carton: 710x280x680, o...