Summary of Duo

Page 1

Operating instructions pallas duo.

Page 2: Index

2 index 1 general ------------------------------------------------------------------3 2 presentation-----------------------------------------------------------4 to 5 3 general installation notes------------------------------------------------6 4 installation instructions-----------------------------...

Page 3: 1 General

3 1 general we thank you for having chosen the pallas duo, we hope that this product will give you complete satisfaction. The greatest care was taken with its manufacture . The pallas duo is delivered in a cardboard box together with a by-pass (optional). Please check the softener carefully, in the ...

Page 4: 2 Presentation

4 2 presentation view of the softener salt lid salt storage control timer resin tanks control valve by-pass (bronze option) raw water inlet treated water outlet flexible tubes (option) drain connection.

Page 5: 2 Presentation

5 2 presentation the valve alternates automatically between the service and regeneration cycles. With the valve in service, it is possible to change the time of day, the valve program or initiate a regeneration. Program button regeneration initiation button indicator : valve in service- diode allumi...

Page 6: 3 General Installation Notes

6 3 general installation notes 1 pressure a minimum pressure of 1,8 bar (30psi) is necessary in order that the valve regenerates correctly. Do not exceed 8.0 bar (120 psi). If the case arises a pressure regulator must be installed before the installation 2 electrical connection make sure that the po...

Page 7: 4 Installation Notes

7 4 installation notes when you choose the site for your pallas duo, please take into account the following points and procedures: 1) to install your pallas duo in the chosen place, ensure that the floor is clean, flat and stable (if necessary, put a board under the softener to ensure a level area )...

Page 8: 5 Programming

8 5 programming 1. Programming the time of day press the - or + keys to adjust the time of day per minute. Prolonged holding of either the - or + keys will accelerate the changes. 2. Programming the valve 2.1. Enter the programming mode press and hold both of the - and + keys for 5 seconds to enter ...

Page 9: 6 Description of Function

9 6 description of function regeneration volumetric immediate under normal operation, the display alternates between the time of day,the volume remaining and the tank in service. (u1 or u2). The volume display is in litres. Progressively with the use, the volume remaining display decreases from the ...

Page 10: 7 Wiring Diagram

10 7 wiring diagram up flow.

Page 11: 7 Wiring Diagram

11 7 wiring diagram up flow + chlorinator.

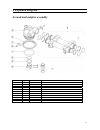

Page 12: 8 Exploded Diagram

12 8 exploded diagram power head - up flow (ref : 28396).

Page 13: 8 Exploded Diagram

13 8 exploded diagram power head - up flow (ref : 28396) item qty part no description 1 1 10218 microswitch 2 1 10302 insulator 3 2 10339 nut 4 1 11086 screw m3 x 0.50 5 2 11335 screw fillister head # 4-40 x 0.19 6 2 11663 lock washer 7 4 13296 screw # 6-20 x 0.50 8 1 13547 strain relief 9 1 14896 g...

Page 14: 8 Exploded Diagram

14 8 exploded diagram power head - up flow + chlorinator (ref : 28363).

Page 15: 8 Exploded Diagram

15 8 exploded diagram power head - up flow + chlorinator (ref : 28363) item qty part no description 1 1 10218 microswitch 2 1 10302 insulator 3 2 10339 nut 4 1 11086 screw m3 x 0.50 5 2 11335 screw fillister head # 4-40 x 0.19 6 2 11663 lock washer 7 2 11882 switch stand off 8 4 13296 screw # 6-20 x...

Page 16: 8 Exploded Diagram

16 8 exploded diagram valve body assembly (ref : 28238) item qty part no description 1 1 13361 spacer injector 2 1 13497 air disperser 3 1 14906 end plate 4 1 14928 end plug stud 5 4 15137 screw hex washer head 10-24 x 3/8" 6 1 28246 injector assembly 9100 uf 7 1 28173 piston lower assembly 9000 uf ...

Page 17: 8 Exploded Diagram

17 8 exploded diagram second tank adaptor assembly item qty p/n description 1 1 18303-01 o'ring 2 1 18569 retainer tank seal 3 1 19054 o'ring 4 1 40673 2 nd tank adapter 5 1 40538 o'ring retainer 32mm 6 1 61419 distributor adapter kit 10 1 13304-01 o'ring 7 2 13255 clip 8 2 14202-01 screw a 1 28243-...

Page 18: 8 Exploded Diagram

18 8 exploded diagram water meter ¾ assembly item qty part no description 1 1 19797 meter body assy ¾" turbine 2 2 19569 clip, flow meter 3 2 13314 screw hex washer head 8 - 18 x .60

Page 19: 9 Fault Finding

19 9 fault finding problem cause remedy 1. Softener fails to regenerate. A. Electrical service to unit has been interrupted. A. Assure permanent electrical supply (check fuse, plug, pull, chain or switch). B. Timer is defective. B. Replace timer. C. Motor is defective. C. Replace motor. D. Water met...

Page 20: 9 Fault Finding

20 9 fault finding problem cause remedy 8. Softener fails to draw brine. Drain line flow control is plugged. A. Clean drain line flow control b. Injector is plugged. B. Clean injector c. Injector screen plugged. C. Clean screen. D. Line pressure is too low. D. Increase line pressure to 25 psi min e....

Page 21: 10 Appendix A

21 10 appendix a capacity setting at various hardness figures ppm as caco³ ºf ºclark ºdh litres softened water 150 15 10.5 8.4 2000 160 16 11.2 9.0 1875 170 17 11.9 9.5 1765 180 18 12.6 10.1 1667 190 19 13.3 10.6 1579 200 20 14.0 11.2 1500 210 21 14.7 11.8 1429 220 22 15.4 12.3 1364 230 23 16.1 12.9...