- DL manuals

- Panasonic

- All in One Printer

- DP-3530

- Service Manual

Panasonic DP-3530 Service Manual

Order Number: MGCS041001C0

H21

Digital Imaging Systems

DP-3510/4510/6010

DP-3520/4520/6020

DP-3530/4530/6030

[ Version 5.2 ]

This service information is designed for experienced repair technicians only and is not intended for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt within this service information by anyone else could result in serious injury or death.

WARNING

© 2006 Panasonic Communications Co., Ltd.

All rights reserved. Unauthorized copying and distribution is

a violation of law. Published in Japan.

Summary of DP-3530

Page 1

Order number: mgcs041001c0 h21 digital imaging systems dp-3510/4510/6010 dp-3520/4520/6020 dp-3530/4530/6030 [ version 5.2 ] this service information is designed for experienced repair technicians only and is not intended for use by the general public. It does not contain warnings or cautions to adv...

Page 2: Boards (Pcbs).

2 the contents of this service manual and the specifications are subject to change without notice. Panasonic communications co., ltd. Reserves the right to make improvements in the product design without reservation and without notice. Published in japan. Information regarding lead-free (pbf) solder...

Page 3: Important Notice

3 important notice please read this notice completely before installing any optional accessories. As failure to properly install the additional board or connector with the power on (only the front power switch off) could damage the copier’s spc or sc board. Please follow the instructions below: 1. I...

Page 4

4 hinweis:.

Page 5: Precautions

5 precautions power and ground connection cautions ensure that the plug connection is free of dust. In a damp environment, a contaminated connector can draw a significant amount of current that can generate heat and eventually cause fire if left unattended over an extended period of time. Always use...

Page 6: Operating Safeguards

6 once a month, unplug the machine and check the power cord for the following. If you notice any unusual condition, contact the authorized panasonic dealer . The power cord is plugged firmly into the receptacle. The plug is not excessively heated, rusted, or bent. The plug and receptacle are free of...

Page 7: Operating Safeguards

7 operating safeguards do not place a magnet near the safety switch of the machine. A magnet can activate the machine accidentally, resulting in injuries. Do not use a highly flammable spray or solvent near the machine. It can cause fire. When copying a thick document, do not use excessive force to ...

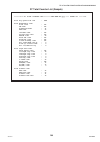

Page 8: Table of Contents

Table of contents 8 specifications table................................. 10 1.1. Copy function........................................ 10 1.2. Fax, printer, network scanner and internet fax functions ........................... 18 1.3. System combination.............................. 27 1.4. Option...

Page 9: Table Of Contents

Table of contents 9 8.14. Installing the fax communication board (da-fg600)................................323 8.15. Installing the hard disk drive unit (da-hd60) ............................................332 8.16. Installing the accounting software (da-wa10) .........................................

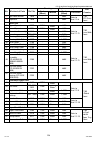

Page 10: 1 Specifications Table

10 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1 specifications table 1.1. Copy function items description remarks dp-3510/ 3520/3530 dp-4510/ 4520/4530 dp-6010/ 6020/6030 basic specifications 1 type console 2 platen fixed 3 original position left 4 recording paper path center ...

Page 11

11 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 17 maximum tray capacities front loading universal paper tray paper tray usa and canada ltr : 20 lb (75 g /m 2 ) other destinations a4 : 80 g /m 2 capacity 1,550 sheets x 1 550 sheets x 1 auto size setting yes (2nd tray only) low l...

Page 12

12 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 28 occupancy area (w x d) 47.2 x 29.6 in (1,200 x 753 mm) includes bypass paper tray. 29 weight 251 lb (114 k g ) 258 lb (117 k g ) 258 lb (117 k g ) main unit only, without i-adf. 283 lb (128.5 k g ) 290 lb (131.5 k g ) 290 lb (13...

Page 13

13 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 8 electronic sorting board standard (32 mb) codec + 32 mb memory optional image memory 1 (16 mb) yes only one of three available types can be installed. Optional image memory 2 (64 mb) yes optional image memory 3 (128 mb) yes featu...

Page 14

14 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 centering mode yes mirror mode no others (inverting adf & adu) 2-page copy mode yes ldr → ltr x 2 (a3 → a4 x 2, b4 → b5 x 2) 2 in 1 yes 4 in 1 yes 6 in 1 yes 8 in 1 yes booklet mode yes copy from 4 single-sided pages to 1 booklet m...

Page 15

15 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 electronic counter yes digital sky shot mode yes check / slip mode yes 3 control panel display wide touch panel lcd status lamp yes green : scanning / printing red : alarm / warning key original size yes copy size yes keypad yes cl...

Page 16

16 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 toner waste container full yes add paper (no paper) yes add paper (under 50 sheets) no paper jam indication yes paper jam location yes service alert call yes user error yes machine error yes history of jam errors yes 4 main unit to...

Page 17

17 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 adu copy productivity (ltr / a4) when ejecting to outer tray transport method stackless 1 → 2 1 copy 45% throughput 5 copies 75% 10 copies 90% pm cycle 1 pm cycle major pm 120k 120k 240k minor pm (cleaning) - - 120k packing configu...

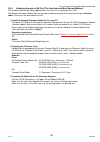

Page 18: 1.2.

18 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.2. Fax, printer, network scanner and internet fax functions 1.2.1. Fax function items description remarks dp-3510/ 3520/3530 dp-4510/ 4520/4530 dp-6010/ 6020/6030 main specifications 1 compatibility g3 itu-t std. & non-std. (pcc)...

Page 19

19 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 8 adf capacity 70 sheets face-up, feed from top page 9 collation stack yes face down printer mechanism 1 recording method lp 2 recording speed 35 ppm (a4 horizontal) 45 ppm (a4 horizontal) 60 ppm (a4 horizontal) 3 recording resolut...

Page 20

20 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 7 max. Station name characters 15 8 direct dialing (monitor dialing) yes voice mode 9 automatic redialing yes 10 manual redialing yes 11 line monitor speaker yes available for line-1 only 12 chain dialing (hybrid dial) yes in monit...

Page 21

21 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4 overlap printing yes page end approx. 0.51 in (13 mm) 5 receive to memory yes 6 distinctive ring detector (drd) no 7 90 degree rotation reception yes 8 duplex printing yes polling 1 polling yes 2 turnaround polling no 3 multi-sta...

Page 22

22 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 identifications 1 logo yes 25 characters 2 multiple logo no 3 character id yes 16 characters 4 numeric id yes 20 digits special communications 1 password xmt / rcv yes 2 selective reception yes tsi check 3 relay xmt request no 4 re...

Page 23

23 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.2.2. Printer function items description remarks dp-3510/ 3520/3530 dp-4510/ 4520/4530 dp-6010/ 6020/6030 interface 1 centronics parallel i/f centronics parallel interface ieee-1284 compliant 2 lan (network) ethernet 10base-t/ 100...

Page 24

24 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.2.3. Network scanner function items description remarks dp-3510/ 3520/3530 dp-4510/ 4520/4530 dp-6010/ 6020/6030 interface 1 centronics parallel i/f no ieee-1284 compliant 2 lan (network) ethernet 10base-t/ 100base-tx 3 usb port ...

Page 25

25 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.2.4. Internet fax function items description remarks dp-3510/ 3520/3530 dp-4510/ 4520/4530 dp-6010/ 6020/6030 main specifications 1 communication protocols tcp / ip smtp / mime 2 max. Modem speed na 3 coding scheme mh / mmr / jbi...

Page 26

26 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 10 mail header email header print selection yes all or from / to / subject only subject line random entry lan features 1 internet fax communication yes a3 communication is available with parameter setting 2 internet mail reception ...

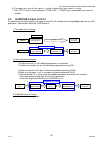

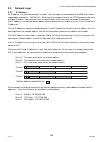

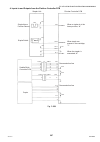

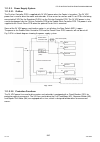

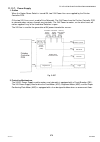

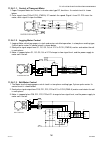

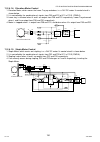

Page 27: 1.3.

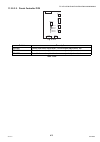

27 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.3. System combination document sensor and motor scanner unit expansion flash memory card 4 or 8mb main pc board (sc pc board) pcl6 emulation option ps/pcl6 emulation option network scanner option internet fax option image memory ...

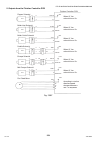

Page 28: 1.4.

28 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.4. Options and supplies list q options option name option number remark printer controller module for pcl6 da-pc600 for dp-3510 / 4510 / 6010 multi page description language controller module for ps/pcl6 da-mc600 printer controll...

Page 29

29 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: pcl6 is a page description language of the hewlett-packard company. Ps/ps3 is a page description language of the adobe systems company. Q supplies note: the part number(s) may differ for other than usa and canada destinations...

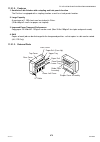

Page 30: 1.5.

30 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.5. External view 1. Standard configuration 2. With optional system console configuration manufacturer's name and address factory id product complies with dhhs rules 21 cfr subchapter j in effect at date of manufacture. (for usa o...

Page 31

31 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3. Space requirements with options 3.9 in (100 mm) 3.9 in (100 mm) 3.9 in (100 mm) 3.9 in (100 mm) 11.8 in (300 mm) 19.9 in (505 mm) 11.4 in (290 mm) 11 in (280 mm) 23.6 in (600 mm) 29.5 in (750 mm) 29.8 in (758 mm) copier + finish...

Page 32

32 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.5.1. Serial number contents the contents of the 11-digit serial number is as follows: 2 3 4 5 6 1 sequential production number 5-digit sequential production number 00001 ~ 99999 = 1 ~ 99,999 units a0001 ~ y9999 = 100,000 ~ 329,97...

Page 33: 1.6.

33 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.6. Control panel dp-3510/3520/4510/4520/6010/6020 dp-3530/4530/6030 print data status active dp-6030

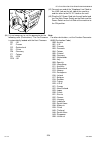

Page 34: 1.7.

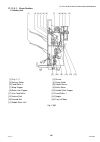

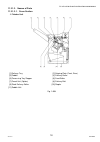

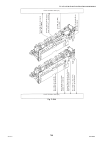

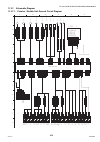

34 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.7. Fans and motors adf paper feed motor adf feed motor scanning motor corona wire cleaning motor ozone fan dust fan hopper motor main motor drum motor suction fan lift motor (tray 1) lift motor (tray 2) lift motor (tray 3) lift m...

Page 35: 1.8.

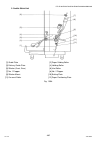

35 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.8. Sensors sheet bypass size sensor sheet bypass np sensor paper size sensor platen cover (adf) open sensor platen cover (adf) angle sensor adf original length sensor2 adf original length sensor1 adf original width sensor1 adf or...

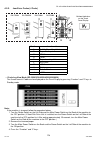

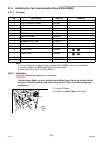

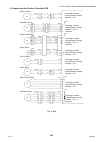

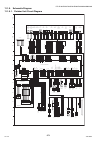

Page 36: 1.9.

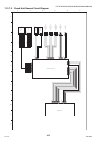

36 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 1.9. Clutches and switches 1.10. Pc boards pickup roller solenoid (tray 1) paper feed roller clutch (tray 1) pickup roller solenoid (tray 2) paper feed roller clutch (tray2) pickup roller solenoid (tray 3) paper feed roller clutch ...

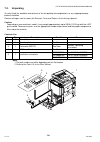

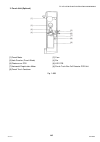

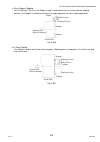

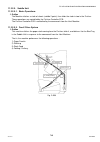

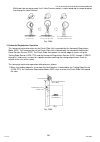

Page 37: 2 Disassembly Instructions

37 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2 disassembly instructions 2.1. General disassembly pertinent disassembly instruction sections are shown below. 3000-sheet tray (lct) 2.2.19. I-adf 2.2.3. Hopper unit 2.2.6. System console 2.2.18. Pc boards 2.2.16. Toner waste cont...

Page 38: 2.2.

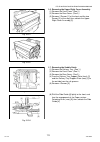

38 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2. Disassembly instructions 2.2.1. Filters (1) turn the power switches to the off position. (2) disconnect the ac power cord (4911). (3) open the right cover . (4) remove 3 screws (h8). (5) remove the right side rear cover (117)....

Page 39

39 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (9) remove the ozone filter 2 cover (106). (10) remove the ozone filter 2 (107). Usa and canada> (11) remove 9 screws (h8). (12) remove the rear upper cover (110). (13) remove the ozone filter 4 (4226)..

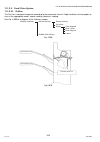

Page 40

40 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (14) remove 2 screws (21). (15) pull the rear frame 2 (3910) and remove the ozone filter 4 (4226). Note: to prevent rear frame 2 from warping, do not pull hard on it..

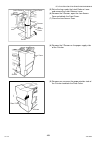

Page 41

41 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.2. Toner waste container (1) open the right cover . (2) remove 3 screws (h8). (3) remove the right side rear cover (117). (4) remove the toner waste container (4108)..

Page 42

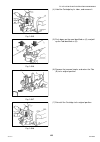

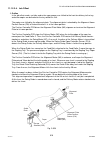

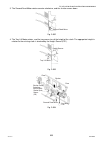

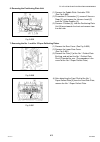

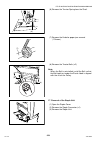

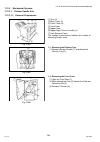

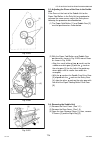

42 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.3. Inverting-automatic document feeder (i-adf) unit (1) lift up the original tray assembly. (2) clean the exit roller (814). (3) open the adf cover . (4) clean the pickup roller (511), paper feed roller (508), separation roller...

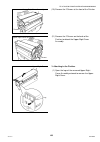

Page 43

43 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (6) remove the paper feed roller shaft (505) assembly in the arrow direction. (7) remove the paper feed roller (508). (8) move the pickup bracket . (9) remove 2 snap rings (h7). (10) remove the pickup roller shaft (510). (11) remov...

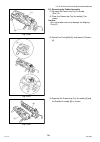

Page 44

44 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (12) remove 3 screws (j9). (13) remove the lower opening and shutting guide 1 (601). (14) remove the separation roller assembly. (15) remove the snap ring (h6). Note: when reinstalling, make sure that the snap ring is installed pro...

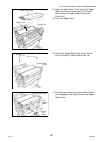

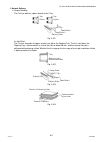

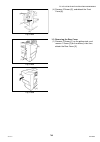

Page 45

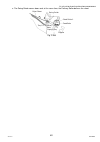

45 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (16) remove the separation roller shaft (607). (17) remove the separation roller (610). Note: when reassembling the separation roller, make sure that the yellow tooler's die on the side of the roller is positioned as illustrated (f...

Page 46

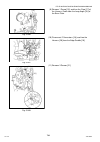

46 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (24) remove 1 screw (j2). (25) loosen 3 screws (h8). (26) lift up the original tray assembly. (27) remove the adf rear cover (627). (28) remove 1 screw (21). (29) remove the front adf cover bracket (529). (30) release the adf cover...

Page 47

47 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (32) remove 1 screw (21). (33) remove the registration guide 2 (721). (34) clean the registration roller 2 (818). (35) remove the snap ring (g6). (36) remove the d8 bearing (822). (37) remove 2 snap rings (g6). (38) remove the clut...

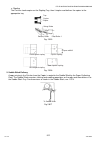

Page 48

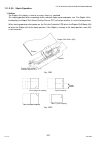

48 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (40) remove the registration roller 2 (818). (41) remove 2 registration guide sheets 1 (1119) and 2 registration guide sheets 2 (1120). Caution: do not remove the 3 indicated screws. Note: when reinstalling the registration guide s...

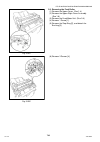

Page 49

49 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (42) open the lower opening and shutting guide assembly. (43) lift up the original tray assembly. (44) nudge the inverting guide assembly towards the right side to open it. (45) remove 2 screws (21). (46) remove the inverting guide...

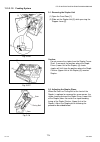

Page 50

50 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.4. Scanner unit 2.2.4.1. Scanner lamp, ccd assembly (1) move the scanning lamp to the position where it can be replaced. (see sect. 5.1.7. F8-00.) (2) remove 2 screws (h8). (3) remove the right platen cover (112). (4) remove th...

Page 51

51 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (8) disconnect 2 harnesses on the inverter pc board (1209). (9) remove 2 screws (f10). (10) remove the inverter pc board (1209). (11) remove the scanning lamp (1228). Note: ensure that the scanning lamp harness is reinstalled prope...

Page 52

52 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (12) remove 5 screws (21). (13) remove the ccd cover (1213). (14) disconnect 2 harnesses on the ccd pc board (cn850 and cn851). Important: before proceeding, make a note of the position of the alignment pointer. If the ccd is not r...

Page 53

53 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (17) remove 2 screws (20). (18) disconnect 2 harnesses on the sensors. (19) remove 2 multi beam sensors (1309). (20) remove 1 screw (20). (21) disconnect the harness on the sensor. (22) remove the multi beam sensor (1309). (23) cle...

Page 54

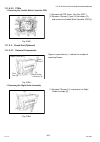

54 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.4.2. Scanning motor (1) remove 9 screws (h8). (2) remove the rear upper cover (110). (3) remove 2 screws (21). (4) remove the harness clamp 2 (3501). (5) disconnect the adf harness . (6) open the adf unit. (7) remove 2 screws (...

Page 55

55 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (9) remove 2 screws (h8). (10) remove the left platen cover (111). (11) remove 2 screws (h8). (12) remove the right platen cover (112). (13) remove 2 screws (n6). (14) remove 4 screws (h8). (15) remove the rear platen cover (113). ...

Page 56

56 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.5. Control panel unit (1) open the front cover . (2) swing the hopper unit in the direction of the arrow as illustrated. (3) remove the battery holder . (4) remove 7 screws (21). (5) remove the lower control panel cover (101)..

Page 57

57 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (6) turn the control panel unit upside down. (7) disconnect 4 harnesses on the pnl1 pc board (cn220, cn221, cn222 and cn224). (8) remove 1 screw (21). (9) disconnect 4 harnesses on the pnl1 pc board (cn223, cn225, cn229 and cn230)....

Page 58

58 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (12) disconnect the harness on the pnl2 pc board (cn251). (13) remove 7 screws (f10). (14) remove the pnl2 pc board (323). (15) disconnect the harness on the inv pc board (cn2). (16) remove 2 screws (f10). (17) remove the inv pc bo...

Page 59

59 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (22) remove 4 screws (f10). (23) remove the pnl3 pc board (313). (24) remove 2 screws (h4). (25) remove 2 screws (h4). (26) remove the lcd module (328). (27) remove the touch panel (327). Note: reinstall the battery holder after re...

Page 60

60 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.6. Hopper unit (1) open the front cover. (see sect. 2.2.5.) (2) swing the hopper unit to the right side. (see sect. 2.2.5.) (3) rotate the toner bottle counter-clockwise and remove it. (4) clean any toner residue from the lower...

Page 61

61 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (8) remove 2 screws (21). (9) remove the hopper motor (1414)..

Page 62

62 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.7. Developer unit (1) open the front cover. (see sect. 2.2.5.) (2) swing the hopper unit to the right side. (see sect. 2.2.5.) (3) remove 1 screw (j9). (4) remove the connector cover (3930). (5) disconnect the harness . (6) pul...

Page 63

63 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (10) release 3 latch hooks and remove the upper developer cover (1601). (11) install the developer exchange knob (1405). (12) turn the developer unit upside down over a suitable container and dump the used developer and toner by ro...

Page 64

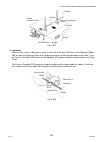

64 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (15) clean the developer unit (1632) with a dry soft cloth. Caution: clean the developer and toner residue from the encircled areas thoroughly as shown in the illustrations. If not properly cleaned, problems related to static charg...

Page 65

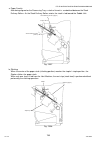

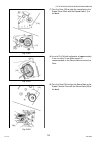

65 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.8. Drum unit (1) open the front cover. (see sect. 2.2.5.) (2) swing the hopper unit to the right side. (see sect. 2.2.5.) (3) pull the developer release lever (3823) out and turn it clockwise. (4) turn the lifting lever (2327) ...

Page 66

66 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 caution: the opc drum is sensitive to light. To prevent optical exposure problems, do not expose the opc drum to direct sunlight or bright light (even if it is a 1000-lux fluorescent lamp). (7) cover the drum with 2 sheets of white...

Page 67

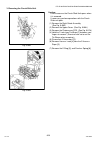

67 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (12) release 2 latch hooks and remove the frame cover (1805). (13) remove 4 screws (21). (14) remove the front fixation plate (1822). (15) turn the front drum bushing (1820) counter-clockwise and remove it. (16) remove 4 screws (21...

Page 68

68 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (18) turn the rear drum bushing (1842) clockwise and remove it. (19) remove the opc drum (1811). (20) remove the blade pressure spring (1807). (21) remove 1 screw (20). (22) remove the cleaning blade (1847) assembly..

Page 69

69 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: when reinstalling the cleaning blade assembly, make sure that the hooks are properly attached. (23) release 4 latch hooks and remove the front and rear cleaning felt (1849, 1848) assemblies. (24) clean the density sensor (cds...

Page 70

70 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (28) clean the corona grid (1919) with a soft cloth, saturated with isopropyl alcohol (29) remove the front and rear block sheets (1911 and 1920). (30) remove the corona wire (1915) and the tension spring (1914). (31) remove the cl...

Page 71

71 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (32) clean the corona case (1906) with a soft cloth or a cotton swab, saturated with isopropyl alcohol..

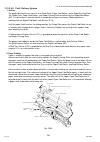

Page 72

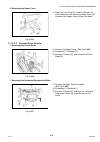

72 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.9. Auto duplex unit (adu) (1) open the front cover. (see sect. 2.2.5.) (2) swing the hopper unit to the right side. (see sect. 2.2.5.) (3) turn the lifting lever (2327) counter-clockwise. (4) pull the adu unit out. (5) clean th...

Page 73

73 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (8) clean the intermediate roller (2403). (9) clean the registration roller (2430). (10) pull out the 1st paper tray. (11) remove 1 screw (25). (12) remove the right lock plate (3810). (13) remove 1 screw (21). (14) remove the left...

Page 74

74 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (15) remove the adu unit (2351). (16) remove 1 screw (24). (17) remove the lifting lever (2327). (18) remove 1 screw (23). (19) remove the registration release knob (2328). (20) remove 3 screws (21). (21) remove the inner cover (23...

Page 75

75 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (27) remove the registration gear (2344). (28) remove 2 snap rings (k9). (29) remove the 2 bearings (822). (30) remove 2 screws (f10). (31) remove 2 e-rings (j7). (32) remove the intermediate roller gear (2621). (33) remove 2 beari...

Page 76

76 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (38) remove the registration roller (2430). (39) remove the intermediate roller (2403)..

Page 77

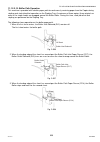

77 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.10. Corona unit 2 (1) open the front cover. (see sect. 2.2.5.) (2) swing the hopper unit to the right side. (see sect. 2.2.5.) (3) pull out the adu unit. (see sect. 2.2.9.) (4) remove the corona unit 2 (2352). (5) remove the fr...

Page 78

78 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (12) disconnect the harness . (13) pull out the led pc board (2343). (14) remove the led knob (2319)..

Page 79

79 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.11. Fuser unit (1) open the front cover. (see sect. 2.2.5.) (2) swing the hopper unit to the right side. (see sect. 2.2.5.) (3) open the upper exit cover. (4) push the release lever (8136) down in order to free the exit guide 7...

Page 80

80 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (10) release the harnesses from hooks. (11) remove 1 screw (l6). (12) remove the solenoid (2012) assembly. (13) remove 1 screw (k2). (14) remove the solenoid (2012). (15) remove 2 screws (k1). (16) remove the cleaning web unit ..

Page 81

81 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (17) remove 1 screw (21). (18) remove the rear cleaning web frame (2002). (19) remove the cleaning web roller (2007) (red). (20) remove the cleaning web (2003) (white). Note: when reinstalling, make sure that the cleaning web is sp...

Page 82

82 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 follow steps (27) ~ (32) below. [for dp-3510/4510/6010, skip to steps (33) ~ (36)] (27) remove 2 snap rings (h6). (28) remove the upper paper exit guide (2223). (29) remove 2 screws (36). (30) remove the upper separator bracket (21...

Page 83

83 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (35) remove 5 tension springs (2219). (36) remove 5 upper separators (2227). (37) remove 1 screws (36). (38) remove 1 screw (k2). (39) remove the rear fuser cover (2031). (40) remove 2 screws (16). (41) remove 2 fuser lamps (2027, ...

Page 84

84 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (42) release the harness from hooks. (43) remove 1 screw (16). (44) loosen 1 screw inside of the jam release knob by turning clockwise. (45) remove the jam release knob (2022). Note: the jam release knob and screw are assembled. (4...

Page 85

85 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (54) remove 1 screw (b2). (55) remove the upper front guide (2102). (56) remove 2 screws (36). (57) remove the lower front guide (2113). (58) remove 2 screws (k4). (59) remove 1 screw (k2). (60) remove the upper fuser bracket (2115...

Page 86

86 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (63) remove the pressure roller (2205). (64) remove 2 pressure roller bearings (2204). Note: before removing, note the position and/or direction of the pressure roller bearings for proper reinstallation..

Page 87

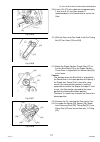

87 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.12. Lsu (1) open the sheet bypass . (2) open the right cover . (3) remove 2 screws (21). (4) remove the lsu cover (115). (5) remove the right platen cover . (see sect. 2.2.4.) (6) remove 2 screws (20). (7) remove the lsu shield...

Page 88

88 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (10) remove 3 screws (l1). (11) remove the lsu (4030). (12) turn the lsu upside down. (13) clean the lsu glass with a soft cloth, saturated with isopropyl alcohol..

Page 89

89 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.13. Paper feed module (1) open the right cover (2908). (2) clean the intermediate rollers (3005, 3010) with a soft cloth, saturated with isopropyl alcohol. (3) remove 1 screw (j4). (4) remove the right cover (2908). (5) push th...

Page 90

90 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (9) remove the 1st paper feed module . (10) remove 1 screw (21). (11) remove the front feed guide (3122). (12) remove the bushing 2 (208) and one way clutch (3205). (13) lift the reverse roller (3219) assembly and remove the feed r...

Page 91

91 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (14) remove the snap ring (h7). (15) remove the pickup roller (3211). Note: when reinstalling, make sure that the latches and the notches are aligned as illustrated. (16) remove the snap ring (h6). (17) remove the reverse roller (3...

Page 92

92 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (18) disconnect the harness . (19) remove 1 screw (j4). (20) remove the 2nd paper feed module . Note: follow the instructions for steps (10)~(17) of the 1st paper feed module. (21) remove the snap ring (g6). (22) remove the 3 inter...

Page 93

93 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.14. Sheet bypass unit (1) remove the lsu cover . (see sect. 2.2.12.) (2) clean the front and rear pickup rollers (4603, 4611). (3) pull out the adu (2351). (see sect. 2.2.9.) note: ref. No. 2351 does not include all individual ...

Page 94

94 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (12) remove 4 screws (25). (13) remove the feed cover (4638) assembly. (14) remove the snap ring (h6). (15) remove the paper feed roller (4608). (16) remove the feed roller (4612)..

Page 95

95 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.15. Paper exit transportation (1) open the lower exit cover (8011). (2) remove 2 screws (h8). (3) remove the exit cover 3 (8003). (4) open the front cover. (see sect. 2.2.5.) (5) open the paper exit cover. (see sect. 2.2.11.) (...

Page 96

96 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.16. Pc boards (1) remove the rear upper plate . (see sect. 2.2.4.2.) (2) disconnect all harnesses on the drv pc board. (3) remove 7 screws (21). (4) remove the drv pc board (8601). (5) remove 4 screws (21). (6) remove the sc co...

Page 97

97 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (8) remove 6 screws (21). (9) remove the sc pc board (8401). (10) remove 2 screws . (11) remove the prt pc board (8402). (12) remove 5 screws (h8). (13) remove 1 screw (m5). (14) remove the rear lower cover (108). (15) remove the t...

Page 98

98 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (17) remove 5 screws (21). (18) remove the spc pc board (8501). (19) remove 3 screws (21). (20) remove nfl pc board (8603) assembly. (21) disconnect 2 harnesses on the nfl pc board (cn132 and cn133). (22) remove 2 screws (21). (23)...

Page 99

99 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (25) remove 4 screws (21). (26) remove the paper exit motor (8127) assembly. (27) disconnect 3 harnesses . (28) open the front cover. (see sect. 2.2.5.) (29) pull out 1st paper tray. (30) remove 2 screws (21). (31) remove the lvps ...

Page 100

100 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (34) disconnect the all harnesses on the dc pc board (cn141, cn142, cn143, cn144 and cn145). (35) remove 2 screws (21). (36) remove the dc pc board (8701). (37) remove 7 screws (21). (38) remove the heat sink (3311). (39) remove 6...

Page 101

101 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (43) pull out the acd pc board (8704) assembly. (44) disconnect the harness on the acd pc board (cn102). (45) disconnect 2 harnesses on the acd pc board (cn103 and cn104). (46) remove 6 screws (21). (47) remove the acd pc board (8...

Page 102

102 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.17. Drive unit (1) remove the toner waste container . (see sect. 2.2.2.) (2) remove the rear upper plate . (see sect. 2.2.4.2.) (3) remove the rear lower plate and sc cover bracket . (see sect. 2.2.16.) (4) disconnect all harn...

Page 103

103 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (11) remove 2 screws (21). (12) remove the fan (4219) assembly. (13) remove 2 screws (20). (14) remove the fan (4221) assembly. (15) remove 2 screws (h8). (16) remove the rear cover (9301). (17) remove 4 screws (21). (18) remove t...

Page 104

104 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (19) open the front cover. (see sect. 2.2.5.) (20) move the hopper unit. (see sect. 2.2.5.) (21) pull out the adu (2351) and drum unit (1852). Note: ref. No. 2351 and 1852 do not include all individual parts. (22) remove the fuser...

Page 105

105 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (29) remove the pin (2743). (30) remove 2 screws (21). (31) move the harness bracket (3525). (32) disconnect the harness on the toner waste sensor. (33) disconnect the harness on the hvps (cn101). (34) lift up the toner waste pipe...

Page 106

106 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (35) remove 3 screws (21). (36) remove the hvps bracket (3611). (37) remove 5 screws (21). (38) remove the hvps (8705). (39) remove 1 screw (21). (40) remove the belt cover (2824). (41) release the f belt (2820)..

Page 107

107 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (42) disconnect 2 harnesses . (43) remove 3 screws (21). (44) remove the fan assembly . (45) disconnect 8 harnesses . (46) release the harnesses from 7 clamps. (47) remove 13 screws (25). (48) remove the drive unit . (49) remove e...

Page 108

108 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (50) remove the drum drive shaft (2704). (51) remove 4 e-rings (j7 and k5), 2 snap rings (g6), 2 pins (2840) and 6 gears (2806 x 2, 2808, 2833, 2834 and 2835). (52) remove 11 screws (21). (53) remove the drum drive plate (2709). (...

Page 109

109 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (56) disconnect the harness and release it from the clamp. (57) remove 2 screws (m3). (58) remove the dc brower (4220)..

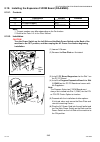

Page 110

110 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.18. System console 2.2.18.1. 3rd/4th paper feed module (1) open the release cover (9324). (2) clean the intermediate roller (3010). (3) remove 1 screw (h8). (4) remove the right side rear cover (9319) (5) remove 1 screw (j4). ...

Page 111

111 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (7) disconnect the harness . (8) remove 1 screw (j4). (9) remove 3rd paper feed module . Note: follow the instructions for steps (10)~(17) of the 1st paper feed module. (10) remove the 4th paper feed module , by following the step...

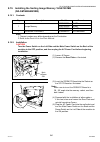

Page 112

112 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.18.2. Drive motor, lift motor 2, cst pc board (1) remove 2 screws (h8). (2) remove the rear cover (9301). (3) disconnect the harness on the system console drive motor. (4) remove 4 screws (j4). (5) remove 1 screw (21). (6) rem...

Page 113

113 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (11) disconnect 2 harnesses . (12) remove 6 screws (21). (13) remove 2 lift motor 2 (4023) assemblies. (14) release the harness from the clamp. (15) remove 2 screws (5m). (16) remove the lift motor 2 (4023) (17) disconnect all har...

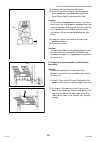

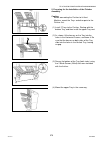

Page 114

114 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.2.19. 3000-sheet tray (lct) (1) remove 2 screws (21). (2) remove the front guide (9142). (3) clean the feed roller (9129). (4) remove the snap ring (h6). (5) remove the feed roller (9129). (6) remove 4 screws (j2). (7) remove th...

Page 115

115 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (8) remove the snap ring (h6). (9) remove the guide bracket (9112). (10) remove the pickup roller (9107). (11) remove 3 screws (j3). (12) remove the reinforcement bracket (9101). (13) remove the paper feed roller (9111). (14) disc...

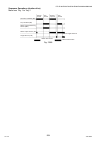

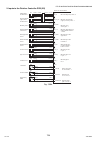

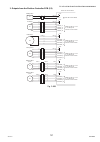

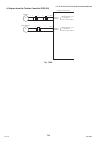

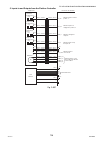

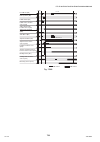

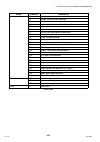

Page 116: 2.3.

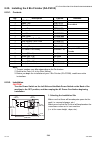

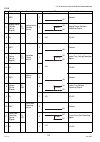

116 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.3. Screw identification template note: for dp-3510/3520/4510/4520/6010/6020 only part no. Figure remark ref. No. Screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw (see no...

Page 117

117 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: for dp-3510/3520/4510/4520/6010/6020 only part no. Figure remark ref. No. Xyn3+f4fj 5m xyc3+ff8fj b2 xtw3+8sfj-tp c8 screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw...

Page 118

118 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: for dp-3510/3520/4510/4520/6010/6020 only part no. Figure remark ref. No. Screw (see note) screw (see note) black shoulder screw (see note) screw (see note) screw (see note) screw (see note) shoulder screw (see note) shoulde...

Page 119

119 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: for dp-3510/3520/4510/4520/6010/6020 only part no. Figure remark ref. No. Screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw (see not...

Page 120

120 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: for dp-3510/3520/4510/4520/6010/6020 only part no. Figure remark ref. No. Screw (see note) blue screw (see note) screw (see note) shoulder screw (see note) screw (see note) screw (see note) shoulder screw (see note) screw (s...

Page 121

121 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: for dp-3510/3520/4510/4520/6010/6020 only part no. Figure remark ref. No. Screw (see note) screw (see note) screw (see note) screw (see note) screw (see note) screw screw screw screw screw screw screw screw screw xtw4+10pfj ...

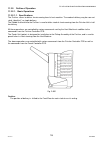

Page 122: 3.1.

122 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3 maintenance, adjustments and check points 3.1. Preventive maintenance preventive maintenance is performed at specific intervals and consists of machine cleaning and parts replacement. It is essential to perform these service act...

Page 123

123 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4 precautions for handling lasers the laser optical system employed by this photocopier is completely sealed by a protective housing and an external cover. Therefore, the laser beam will not stray or leak during photocopier operat...

Page 124: 3.2.

124 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.2. Required tools 3.2.1. Preventive maintenance method no. Tools no. Tools 1 soft cloth 7 pliers 2 isopropyl alcohol 8 cotton swab 3 phillips screwdriver (#2) 9 brush 4 stubby phillips screwdriver (#2) 10 ks-660 - conductive gre...

Page 125: 3.3.

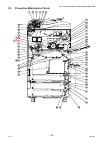

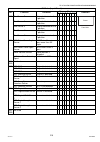

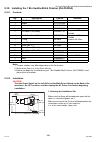

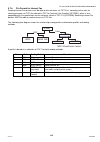

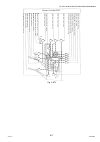

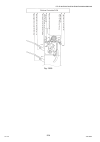

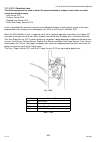

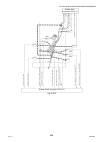

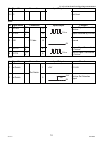

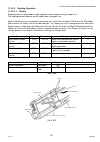

125 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.3. Preventive maintenance points 6 5 7 8 9 10 57 58 a 17 45 49 48 47 25 2 52 52 52 11 12 3 22 23 16 18 1 b 4 56 54 55 50 51 52 53 43 50 51 61 59 60 53 50 51 53 50 51 24 19 20 21 46 53 44 26 28 27.

Page 126

126 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 detail a detail b 37 33 34 31 35 39 40 41 42 32 38 29 30 36 13 14 15.

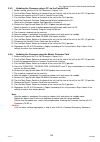

Page 127: 3.4.

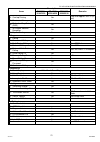

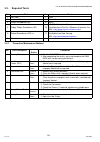

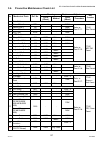

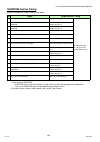

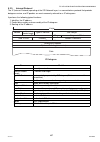

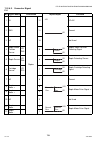

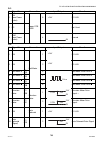

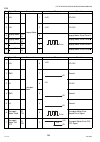

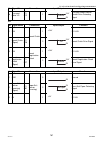

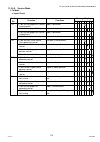

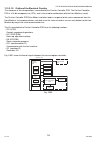

127 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.4. Preventive maintenance check list no. Mechanical parts ref. No. Cleaning replacement/adjustment ref. Counter cycle (sheet) method cycle (sheet) procedure main unit 1 ozone filter 1 4204 - - 240k refer to sect 2.2.1. F7-02 tot...

Page 128

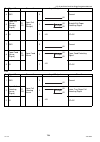

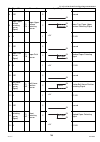

128 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 27 split lock washer 1825 - - 480k refer to sect 2.2.8. F7-02 opc drum count 28 separator 1826 - - 480k fuser unit 29 upper separator 2227 240k water 1 480k refer to sect 2.2.11. F7-02 fuser web count 30 lower separator 2228 240k ...

Page 129: 3.5.

129 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: 1. Clean all rollers and separation rubber with a soft cloth saturated with water. For stubborn toner accumulation, wipe with a soft cloth saturated with isopropyl alcohol first, then follow up with a soft cloth saturated wi...

Page 130

130 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2. Press the "function", "original size (ledger/a3)" and "3" keys simultaneously in that order to enter the service mode. 3. Enter the copy service mode f5-87 (adf) pm cycle and change to the desired value. 4. Press “function” and...

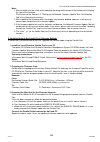

Page 131: 3.6.

131 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.6. Updating the firmware the quickest and most reliable way of updating the firmware is to use the network firmware program tool (fup) using ethernet lan port and a crossover cable. The network fup tool version must be 3.Xx or h...

Page 132

132 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (b). The pcl control program (3) and pcl font data (4) are written into the 8 mb in the slot 1. The firmware (3) and (4) are assigned as rom code (c). When using 8 mb flash memory card, the 8 mb program (c) can be written at once....

Page 133

133 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.6.2. Updating through a lan port (the quickest and most easiest method) the firmware code can be easily updated when the main unit is connected to a lan. The network firmware update tool can also be used by connecting to the mac...

Page 134

134 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4) upgrading the main unit's firmware code start the network firmware update tool and select the following firmware code folders in the c:\program files\panasonic\panasonic-fup\data folder, and then follow the display instructions...

Page 135

135 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.6.3. Updating the firmware using a pc via the parallel port 1. Before starting, print the f5 & f6 parameters (copier) lists. 2. Turn the main power switch on the back of the unit (not the side of the unit) to the off (o) positio...

Page 136

136 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.6.5. Creating a master firmware card a. Utilizing the firmware update kit 1) install the local firmware update tool to your pc the option cd-rom or the panasonic document management system cd-rom includes the local firmware upda...

Page 137

137 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 10. Turn the main power switch on the back and the power switch on the left side of the machine to the on position. 11. Use this master firmware card to update the firmware on other machines. 3.6.6. Erasing the master firmware car...

Page 138

138 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.6.8. Firmware emergency recovery the easiest method to recover the firmware in an emergency recovery routine is to either use the local firmware update tool software by selecting the independent file method, or using the master ...

Page 139: Dp-3510/4510/6010

139 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.6.9. Firmware version dp-3510/4510/6010 sc : pnl : spc : dp-sfdm a a v1xxxx pu destination code (copier) pu : usa/canada pb : uk destination code (fax) au : usa/canada ab : uk firmware version (v1xxxx) language code a : a-englis...

Page 140: Dp-3520/4520/6020

140 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 dp-3520/4520/6020 sc : pnl : spc : sfd m mk2 a a vxxxxx pu destination code (copier) pu : usa/canada pb : uk destination code (fax) au : usa/canada ab : uk firmware version (v1xxxx) language code a : a-english, c-french & spanish ...

Page 141: Dp-3530/4530/6030

141 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 dp-3530/4530/6030 sc : pnl : spc : sfd m25r a a vxxxxx pu destination code (copier) pu : usa/canada pb : uk destination code (fax) au : usa/canada ab : uk firmware version (v1xxxx) language code a : a-english, c-french & spanish b...

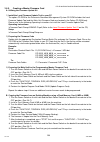

Page 142: 3.7.

142 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.7. Copy quality adjustment procedure (order) no. Part item adjustment when the following items are replaced or cleaned, perform adjustments in the correct order. Work optics clean drum unit clean toner density sensor clean tdc a...

Page 143

143 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: 1. Copy quality check 1) press the "function", "original size (ledger/a3)" and "3" keys simultaneously in that order to enter the service mode. 2) press the "6" and "start" keys to enter the f6 mode (adjust parameters). 3) p...

Page 144

144 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 9) press "52 lsu unit pwm adjust 1". 10) press "input" button and enter the value of the gray patch, as established in step (6). 11) press "ok" button 2 times. 12) perform the service modes f8-18 and f6-39 in the same manner as st...

Page 145

145 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4. Contrast adjusting 1) press the "function", "original size (ledger/a3)" and "3" keys simultaneously in that order to enter the service mode. 2) press the "2" and the "start" keys to enter the f2 mode. 3) set the exposure to the...

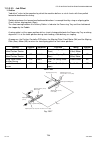

Page 146: 3.8.

146 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.8. Adjusting the printer registration, lsu image side to side when installing the system console option or replacing the lsu, the following lsu image side to side adjustment must be performed. The printer registration is adjuste...

Page 147: 3.9.

147 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 6. If the gap is less than 5 mm, input a (+) value. If more than 5 mm, input a (-) value. 7. Press "stop" key first and then press "function" + "clear" keys simultaneously to return to standby. 3.9. Quantum control in f8-14 to sta...

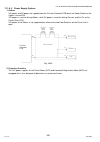

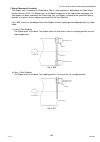

Page 148: Quantum Control Timing

148 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 quantum control timing quantum works in copy, print or fax mode. No trigger 1 when f8-09 is performed after performing f8-09 wait approximately 30 - 90 sec for the quantum to start *1 2 at 200, 400, 600, 800 and 1000 prints after ...

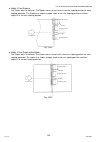

Page 149: 3.10. Calibrating The Lcd

149 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 3.10. Calibrating the lcd 1. Turn the main power switch on the back of the machine to the off (o) position and leave the power switch on the left side of the machine in the on (i) position. 2. Ensure that the f-rom card with firmw...

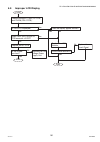

Page 150: 4 Troubleshooting

150 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4 troubleshooting 4.1. Initial troubleshooting flowchart start plug in the power cord, and then turn the power switches on. Does the lcd display function correctly? Does the original document feed through correctly? Does the recor...

Page 151: 4.2.

151 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.2. Improper lcd display replace the sc pcb. Is the trouble resolved? Replace the low voltage power supply unit. Is the trouble resolved? Check connectors: cn52 (sc pcb) and cn220 (pnl1 pcb). Is led/lcd displayed? Does the displa...

Page 152: 4.3.

152 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3. Printed copy quality problems 4.3.1. Black copy start yes no check the scanner mechanism. Is the ps normal? Is the spc pcb normal? Is the opc drum/developer unit operational? Replace the opc drum/developer unit. 1. Check all ...

Page 153

153 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.2. Blank copy start end check the scanner mechanism. Are there any foreign particles or stains in the charge unit? Is the opc drum/developer unit operational? Is the ps normal? No yes yes yes no no replace the opc drum/develop...

Page 154

154 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.3. Vertical white lines start end replace the recording paper. Yes no replace the opc/developer unit. Are there any foreign particles or stains blocking the laser beam path? No 1. Clean the corona wire with a soft, dry cloth. ...

Page 155

155 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.4. Ghost images start end yes no check the scanner mechanism. Is the opc/developer unit operational? No yes are the fuser and pressure roller surfaces clean? No yes is the recording paper damp? Are there any foreign particles ...

Page 156

156 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.5. Vertical dark lines start yes no check the scanner mechanism. Is the opc/developer unit operational? No yes are there any foreign particles or stains in the corona unit? Yes no replace the opc/developer unit. 1. Clean the c...

Page 157

157 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.6. Horizontal dark lines start yes no replace the opc/developer unit. 1. Clean the corona wire with a soft, dry cloth. 2. Replace the corona unit. Yes no check the scanner mechanism. Is the opc/developer unit operational? No y...

Page 158

158 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.7. Dark background is the lsu normal? No yes replace the lsu. Start yes no check the scanner mechanism. Is the opc drum/developer unit operational? No yes is the recording paper damp? Yes no replace the recording paper. Replac...

Page 159

159 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.8. Light print (1) pull the developer release lever (3823) out and turn it clockwise, then turn it counter-clockwise to reset. (2) ensure that the developer unit is installed properly by checking 2 guide pins are in the right ...

Page 160

160 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.9. Horizontal white lines end no yes clean or replace the rollers. Start yes no check the scanner mechanism. Is the opc drum/developer unit operational? No yes is the recording paper damp? Yes no replace the recording paper. R...

Page 161

161 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.10. Improper fusing (printed image does not bond to the paper) note: replace the entire fuser unit when the thermostat and/or the thermistor turn into an open-circuit. End is the fuser unit normal? No yes replace the fuser uni...

Page 162

162 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.11. Voids in solid areas 4.3.12. Black dots end no yes clean or replace the rollers. Start no yes is the recording paper damp? Replace the recording paper. Is the opc drum/developer unit operational? Yes no replace the opc dru...

Page 163

163 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.13. Recording paper creases start no yes is the recording paper damp? Replace the recording paper. End are the fuser and pressure roller surfaces soiled or are there any foreign particles or stains in the fuser unit? 2. Clean ...

Page 164

164 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.14. Poor printed copy quality start is the test pattern printout in copier f1 mode or fax service mode 3 normal? 1. Replace the spc pcb. 2. Replace the lsu. 3. Replace the hvps. 4. Replace the developer unit. End perform a rec...

Page 165

165 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.15. Document skewing end start is the lsu normal? Check the scanner mechanism. Check or replace lsu. No no yes yes is the test pattern printout in copier f1 mode normal? Copy mode sample.

Page 166

166 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.16. Abnormal printing start is the recording paper loaded in the paper tray properly? 1. Adjust the paper width guide. 2. Adjust the paper length guide. Is panasonic toner being used? Yes no is the recording paper size and thi...

Page 167

167 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.3.17. Scanned copy quality problems start no yes is the xenon lamp abnormal? Replace the xenon lamp. End are the transmitting rollers dirty? Are there any foreign particles or paper pieces in the scanning area? Yes no remove the...

Page 168: 4.4.

168 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.4. Troubleshooting the lan interface 4.4.1. Checking network configuration start from the dos prompt, enter the following command-line utility: ipconfig /all locate a pc connected to the same subnet mask as the unit does the dis...

Page 169

169 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.4.2. Testing the tcp/ip network it is beyond the scope of this service manual to cover networking in detail, there are many excellent manuals on this subject, but we hope the information in this section will aid with your troubl...

Page 170

170 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2. Checking current configuration print the current unit internet parameters configuration. Locate a pc connected to the same subnet mask as the unit, then from the dos prompt, type the following command-line utility: "ipconfig /a...

Page 171

171 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 pinging the unit pinging the default gateway (default router ip address) pinging the smtp/pop server if for some reason, the physical connection is missing, the echo reply will not be received from the destination and the followin...

Page 172

172 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 if the physical destination is far and it's connected by wan (wide area network), the ping option command default value must be changed to compensate for the expected delayed response. E.G. 4. Tracing a packet route another useful...

Page 173

173 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5. Managing network route tables in the simplest case a router connects two network segments. In this model, the system used to join the two segments needs to know only about these segments. The routing table for router r1 in this...

Page 174

174 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 when the packet does not reach the specified destination even when the physical connection is properly made, check the registered persistent routes on the same subnet as the unit by typing "route print" in the dos command-line. Th...

Page 175

175 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 7. Testing unit using the telnet command telnet is a terminal emulation protocol. Telnet enables pcs and workstations to function as dumb terminals in sessions with hosts on internet works. From windows 98/me/2000/nt/xp, use the t...

Page 176: 4.5.

176 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.5. Error codes (for copier) the self-diagnostic functions detect troubles in the important components of the copier. When any trouble occurs, the copier stops. 4.5.1. User error codes (u code) note: uxx and a message will appear...

Page 177

177 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 u14 replace toner waste container 1. Toner waste container is full. (see sect. 3.5.4.) u15 no toner waste container 1. Toner waste container is not installed. 2. Toner waste container sensor is disconnected. 3. Toner waste contain...

Page 178

178 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.5.2. Jam error codes (j code) • j code log view mode (dp-3520/3530/4520/4530/6020/6030) the 5 most recent j codes can be displayed on the panel display by pressing “function” and “3” keys in standby mode. Note: if the machine is...

Page 179

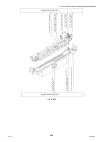

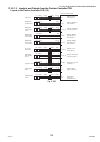

179 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 • jam sensor location of printer • jam sensor location of i-adf exit sensor inverting exit sensor inverting paper sensor inverting paper path sensor adu entrance sensor registration sensor timing sensor paper path sensor 2nd paper...

Page 180

180 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 jam error codes (j code) table code contents section j00 the registration sensor does not detect paper within a predetermined time after the paper starts feeding. (sheet bypass) c j01 the 1st paper path sensor does not detect pape...

Page 181

181 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 j33 the registration sensor detects paper during non-printing mode. C j40 the fuser unit paper exit sensor does not detect paper within a predetermined time after the registration sensor is activated. C, d j41 the fuser unit paper...

Page 182

182 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 j82 the adu exit sensor does not detect paper within a predetermined time after adu middle sensor is activated. F j83 the adu entrance sensor keeps detecting paper after a predetermined time has lapsed. F j84 the adu intermediate ...

Page 183

183 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.5.3. Mechanical error codes (e code) j78 j71 1. The adf registration sensor 3 does not detect paper after the face page is scanned, during 2-sided scanning. 2. The adf selection sensor keeps detecting paper during 2-sided scanni...

Page 184

184 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 e2: lift dc motor error code function check points e2- 01 e2- 02 lift motor rotation (1st paper tray) lift motor rotation (2nd paper tray) 1. Level sensor connector is disconnected. 2. Level sensor is defective. 3. Lift mechanism ...

Page 185

185 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 e3- 03 toner density sensor gain 1. Sensor connector is disconnected. 2. Sensor is defective. 3. Spc pcb connector is disconnected. 4. Spc pcb is defective. E3- 10 high voltage power supply leak (1) - grid charge voltage 1. Hvps c...

Page 186

186 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 e3- 25 drum motor rotation 1. Drum drive gear is defective. 2. Drum drive mechanism is defective. 3. Drum unit is defective. 4. Drum motor connector is disconnected. 5. Drum motor is defective. 6. Drv pcb connector is disconnected...

Page 187

187 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 (1) remove the drum unit. (see sect 2.2.8.) (2) turn the toner waste screw gear towards the arrow direction until you hear a click. E4: fuser unit error code function check points e4- 01 fuser warm-up temperature 1. Fuser thermist...

Page 188

188 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 e5: system error code function check points e5- 01 vp (+24v, printer) 1. Spc pcb connector is disconnected. 2. Spc pcb is defective. E5- 05 vp (+24v, scanner) e5- 11 printer engine communication abnormal 1. Spc pcb connector is di...

Page 189

189 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: these error codes will appear only when the optional accessories are installed. Refer to the appropriate optional unit service manual. E7: optional unit error code function check points e7- 20 finisher paper transport motor ...

Page 190

190 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 e13: out of toner code function check points e13 toner sensor 1. Toner bottle is not installed correctly. 2. Out of toner. 3. Toner sensor is disconnected. 4. Toner sensor is defective. 5. Spc pcb connector is disconnected. 6. Spc...

Page 191: 4.6.

191 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.6. Information codes table (for facsimile) fax information codes code mode phase description of problem cause 012 rcv c, d the length of the received document is over 2 m. Transmitter document jam. 030 xmt b read point sensor do...

Page 192

192 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 405 xmt b transmitter received ftt after it transmitted tcf at 2400 bps. Received rtn after communicating at 2400 bps. Line quality is poor. (tcf is damaged due to line noise) receiver is defective. (modem, mjr pcb, etc.) fxb pcb ...

Page 193

193 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 418 rcv c receiver transmitted pin in response to pri-q from transmitter. (transmitting operator requests voice contact) line quality is poor. (there are excessive errors in received data) fxb pcb or mjr pcb is defective. 420 rcv ...

Page 194

194 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 503 xmt/ rcv(v.34) b, c, d cs of modem is not able to turn on during training. Fxb pcb is defective. Line is disconnected. 504 rcv/v.34 (polling) b polling is rejected from the remote station. No polling original is set. 505 xmt/v...

Page 195

195 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 634 xmt redial count over with no response or busy tone was not detected. Note: u.S.A. And canadian models will redial only once if a busy tone is not detected. 638 xmt power turned off with applicable data in memory or during com...

Page 196

196 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 726 xmt pop lan received an error response from the dns server. Incorrect pop server address is set. Incorrect smtp server address is set. 727 xmt lan received an error or no response from the remote internet fax. (smtp direct xmt...

Page 197: 4.7.

197 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.7. Diagnostic codes (for facsimile) the 13-digit diagnostic code is provided for the service engineer to analyze how the communication was performed. The code is recorded on the journal. Journal example 1st digit: manufacturer c...

Page 198

198 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2nd digit -: not used/defined 3rd digit -: not used/defined fax diagnostic codes data definition id (tsi, csi, cig) rtn dcn stop button 0 - - - - 1 received - - - 2 - received - - 3 received received - - 4 - - received - 5 receive...

Page 199

199 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4th digit -: not used/defined 5th digit -: not used/defined fax diagnostic codes data definition scanning rate resolution 0 20 ms/line std 1 5 ms/line std 2 10 ms/line std 3 - std 4 40 ms/line std 5 - std 6 - std 7 0 ms/line std 8...

Page 200

200 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 6th digit -: not used/defined 7th digit -: not used/defined fax diagnostic codes data definition polling xmt/rcv selective comm. Password comm. 0 - rcv off off 1 yes rcv off off 2 - xmt off off 3 yes xmt off off 4 - rcv on off 5 y...

Page 201

201 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 8th digit -: not used/defined 9th digit -: not used/defined fax diagnostic codes data definition advanced comm. Cover sheet xmt 0 - - 1 report xmt - 2 check & call - 3 - - 4 memory transfer - 5 - - 6 - - 7 - - 8 - yes 9 report xmt...

Page 202

202 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 10th digit -: not used/defined 11th digit -: not used/defined fax diagnostic codes data definition coding ecm 0 mh - 1 mr - 2 mmr - 3 jbig - 4 - - 5 - - 6 - - 7 - - 8 mh yes 9 mr yes a mmr yes b jbig yes c - yes d - yes e - yes f ...

Page 203

203 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 12th digit -: not used/defined 13th digit -: not used/defined fax diagnostic codes data definition modem speed modem speed (v.34) 0 2400 bps - 1 4800 bps 2400 bps 2 7200 bps 4800 bps 3 9600 bps 7200 bps 4 tc 7200 bps 9600 bps 5 tc...

Page 204: 4.8.

204 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.8. Troubleshooting (for printer) 4.8.1. Checking the basics 4.8.2. Document does not print properly this section explains how to solve problems including error messages or unexpected printing results. If the printing system is n...

Page 205

205 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 4.8.3. Error message appears on the pc 4.8.4. Error message appears on the unit 4.8.5. System error (cd drive related error during installation) error message possible solution(s) network print dll error. • check if the panasonic ...

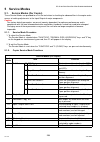

Page 206: 5 Service Modes

206 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5 service modes 5.1. Service modes (for copier) these service modes are provided to assist the technician in checking for abnormalities in the copier and a means of making adjustments to the input/output of major components. Cauti...

Page 207

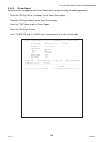

207 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 f5 / f6 information list (sample) * * * * * * * * * * - f 5 / f 6 i n f o r m a t i o n l i s t - * * * * * * d a t e m m m - d d - y y y y * * * t i m e 1 2 : 0 1 * * * p . 0 1 f5-00 country version usa/can f5-50 auto contrast ad...

Page 208

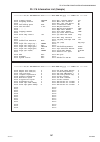

208 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2.Firmware version sc : bav001xxpu 1.Machine information machine name : dp-6030 mac address : 080023006fa1 serial number : sc boot : m30 pnl : aat00001pu spc : 60cpm t40000 finisher : 0702 fax modem : pdl font1 : cav00001b sc2 : c...

Page 209

209 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 f7 total counter list (sample) f7-01 key operator id code : 0000 f7-02 maintenance count total count : 295 pm count : 295 scanner pm count : 61 adf count : 26 opc drum count : 295 process unit count : 295 adf pm count : 50 fuser w...

Page 210

210 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.1.3. F4 mode: input/output status test set the machine to service mode and press "4" key on the keypad. ↓ press the "start" key. ↓ enter the number to activate the test then press "start" key. ↓ press "stop" key to cancel the te...

Page 211

211 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 002 upper limit sensor (2nd paper tray) upper limit is detected. 1 np sensor (2nd paper tray) paper is not detected. 1 paper remaining sensor 3 (2nd paper tray) sensor is activated. 1 paper remaining sensor 2 (2nd paper tray) sens...

Page 212

212 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 005 charge corona cleaning end detect sensor cleaner is not detected. 0 charge corona cleaning home position sensor cleaner is detected. 1 inverting cover sensor cover is open. 1 paper exit sensor paper is detected. 0 inverting pa...

Page 213

213 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 010 paper path sensor (3rd paper tray) paper is detected. 1 upper limit sensor (3rd paper tray) upper limit is detected. 1 np sensor (3rd paper tray) paper is not detected. 1 paper remaining sensor 3 (3rd paper tray) sensor is act...

Page 214

214 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 015 stapler home position sensor home position is detected. 1 entrance paper path sensor paper is detected. 0 buffer paper path sensor paper is detected. 0 exit paper path sensor paper is detected. 0 buffer entrance sensor paper i...

Page 215

215 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 020 size sensor b original detected on the b position. 1 size sensor a original detected on the a position. 1 size sensor z original detected on the z position. 1 size sensor y original detected on the y position. 1 size sensor x ...

Page 216

216 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 2. Output check press the "start" key to start and press the "stop" key to reset. F4 mode (output check) no. Item function remark 040- 049 not used 050 main motor activate the main motor after pressing start key. 051 toner bottle ...

Page 217

217 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 070 paper feed roller clutch (2nd paper tray) when cn710-2 signal level changes to 0v from +24v, clutch operates. 1 minute 071 paper feed solenoid (2nd paper tray) when cn710-4 signal level changes to 0v from +24v, solenoid operat...

Page 218

218 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 101 adu paper feed clutch when cn716-4 signal level changes to 0v from +24v, clutch operates. 1 minute 102 inverting motor rotating in forward direction inverting motor rotates in the forward direction. 103 inverting motor rotatin...

Page 219

219 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 161 adf paper feed motor rotating (100% of rotating speed) adf paper feed motor rotates at 100% of rotating speed. 162 adf paper feed motor rotating (400% of rotating speed) adf paper feed motor rotates at 400% of rotating speed. ...

Page 220

220 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.1.4. F5 mode: function parameters (for copier) set the machine to service mode and press "5" key on the keypad. ↓ press the "start" key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select anothe...

Page 221

221 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 07 language default 0 : english (american) 1 : french 3 : german 4 : swedish 5 : italian 6 : dutch 7 : portugal 8 : spanish 9 : norway 10 : danish 11 : finnish 13 : english 17 : polish 18 : hungary 19 : japanese 20 : czech 21 : gr...

Page 222

222 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 16 paper size tray 3 (sys1) 0 : none 1 : a3 2 : b4 3 : a4 4 : a4r 5 : b5 6 : b5r 7 : a5 9 : 8 x 13 10 : 8.5 x 13 11 : ledger 12 : legal 13 : letter 14 : letter r 15 : invoice 0 17 paper size tray 4 (sys2) same as f5-16 same as f5-...

Page 223

223 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 35 not used 36 display dd key 0 : no 1 : yes 0 (for usa / canada) 1 (for europe) 37 corona wire cleaning 0 : 1000 1 : 3000 2 : 10000 3 : 0 2 38 2-sided mode default 0 : no 1 : 1 to 2 2 : 2 to 2 3 : b to 2 0 39 staple position sett...

Page 224

224 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 53 2-sided auto shift 0 : no 1 : auto sft 0 54 margin reduction 0 : no 1 : yes 0 55 margin value default 0 : 5 mm 1 : 10 mm 2 : 15 mm 3 : 20 mm 1 56 edge value default 0 : 5 mm 1 : 10 mm 2 : 15 mm 3 : 20 mm 0 57 book value default...

Page 225

225 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 70 pm (preventive maintenance) cycle 0 : no 1 : 1.5 k 2 : 2.5 k 3 : 5 k 4 : 10 k 5 : 15 k 6 : 20 k 7 : 30 k 8 : 40 k 9 : 60 k 10 : 80 k 11 : 90 k 12 : 120 k 13 : 150 k (dp-60xx) 14 : 200 k (dp-60xx) 15 : 240 k (dp-60xx) 12 (dp-35x...

Page 226

226 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 83 digital skyshot mode 0 : no 1 : freeshp 2 : parallel 1 84 paper tray priority 0 : l > s > c > b 1 : c >s > l > b 2 : l > c > s > b 0 85 side void setting (adf) 0 : none 1 : yes 0 86 not used 87 pm cycle (adf) 0 : no 3 : 120 k 4...

Page 227

227 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.1.5. F6 mode: adjust parameters (for copier) set the machine to service mode and press "6" key on the keypad. ↓ press the "start" key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another ...

Page 228

228 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 14 side adjust (tray 4) adjustment of lsu side-side (4th tray). -8 - +7 0.5mm 15 side adjust (lct) adjustment of lsu side-side (lct). -8 - +7 0.5mm 16 side adjust (adu) adjustment of lsu side-side (adu). -8 - +7 0.5mm 17 grid stan...

Page 229

229 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 41 paper loop (bypass) individual fine adjustment for sheet bypass -99 - +99 42 paper loop (tray 2, cop) individual fine adjustment for tray 2 -99 - +99 43 paper loop (2-sided) adjustment for the length of the loop formed before t...

Page 230

230 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 70-74 not used 75 adj. Read ad enable (factory use only) adjustment of read timing. -2 - +2 76 adj. Read lsi sampling (factory use only) adjustment of read timing. 0 - +3 77 adj. Read lvds clock (factory use only) adjustment of re...

Page 231

231 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.1.6. F7 mode: electronic counter set the machine to service mode and press "7" key on the keypad. ↓ press the "start" key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number,...

Page 232

232 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 f7 electronic counters 03 paper feed count 00 sheet bypass count total count of paper fed from the sheet bypass. 01 1st paper tray count total count of paper fed from the 1st paper tray. 02 2nd paper tray count total count of pape...

Page 233

233 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.1.7. F8 mode: service adjustment set the machine to service mode and press "8" key on the keypad. ↓ press the "start" key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number,...

Page 234

234 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 19 move mirror to lock a) press the start key to move the mirror unit to the locked position for transporting the copier. B) when the mirror unit is locked, the machine will not accept any numerical key input. Note: the locking op...

Page 235

235 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.1.8. F9 mode: unit maintenance set the machine to service mode and press "9" key on the keypad. ↓ press the "start" key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number, s...

Page 236

236 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 f9 unit maintenance 06 ram initialize 00 parameter initialize resets the fax and function parameters to default values. Note: turn the power switch on the left side of the machine to the off and back to the on position to enable t...

Page 237: 5.2.

237 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.2. Service modes (for facsimile) caution: the factory default parameters are preset (country dependent) for optimum performance and in compliance with the local telecommunication regulations/standards, and do not need to be chan...

Page 238

238 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.2.3. Fax service mode 1 (function parameter setting) use the following procedure to change the function parameters. Select the "01 function param. Setting" on the touch panel display. ↓ select the desired code number on the touc...

Page 239

239 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 005 destination code 000 : austria 001 : u.K. 002 : canada 003 : denmark 004 : taiwan 005 : finland 006 : germany 007 : netherlands 008 : italy 009 : spanish 010 : hong kong 011 : australia 012 : switzerland 013 : norway 015 : por...

Page 240

240 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 012 dtmf level 00 = 0 dbm ~ 15 = -15 dbm selects the dtmf output level, 0 to -15 dbm in 1 dbm steps. 013 g3 rx eql 1 = 0db 2 = 4db 3 = 8db 4 = 12db selects the cable equalizer for g3 reception mode, 0db, 4db, 8db or 12db. 014 g3 t...

Page 241

241 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 026 non- standard 1 = off (invalid) 2 = on (valid) selects own mode (panafax mode). 027 short protocol b 1 = off (invalid) 2 = on (valid) selects the short protocol mode. 028 short protocol d 1 = off (invalid) 2 = on (valid) selec...

Page 242

242 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 046 on-hook time 0 = 0 sec. ~ 90 = 90 sec. Selects the on-hook time between sequential communication calls in 1 second step intervals. 047 response wait 1 = 1 sec. ~ 90 = 90 sec. 20 ~ 150 sec. (for france only) selects the waiting...

Page 243

243 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 068 nyse fax forward (usa and canada only) 1 = off 2 = on selects whether the machine will forward the incoming and outgoing faxes to a specified station. Note: once this parameter is activated, fax forwarding via fax parameter 05...

Page 244

244 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 083 not used 084 line as no paper 1 = ring (ring) 2 = busy (keep line busy) selects whether to ring or send a busy tone to the remote station when the recording paper runs out or the unit cannot receive because of any trouble. 085...

Page 245

245 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note 1: continuous polling (station mode) this feature allows you to store or add documents into a polled file in memory. To enable the continuous polling feature set function parameter no. 003 to "2:station". The last program key...

Page 246

246 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 5.2.4. Fax service mode 3 (printout of lists, reports and test results) from this service mode you can print the function parameter list, page memory test, printer report, all document file, protocol trace and the toner order form...

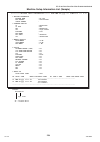

Page 247

247 jan 2006 ver. 5.2 dp-3510/3520/3530/4510/4520/4530/6010/6020/6030 note: 1. The contents of the function parameter list may vary depending on the country’s regulations. 2. “ * ” mark will be shown on the left side of number when setting was changed from default. Function parameter list (sample) *...

Page 248