Protherm 100 User Instructions

1

Protherm 100 e

Users’ Instructions

Introduction ........................................................................................................................... 2

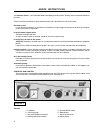

Controls and lighting ............................................................................................................. 2

Draining and filling ................................................................................................................ 3

Heating safety valve ............................................................................................................. 3

Servicing/maintenance ......................................................................................................... 3

Cleaning ............................................................................................................................... 3

Boiler casing ......................................................................................................................... 3

Installation Instructions

Introduction ........................................................................................................................... 4

Technical data ...................................................................................................................... 5

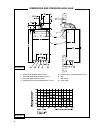

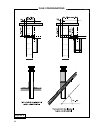

Dimensions ........................................................................................................................... 6

Pump capacity ...................................................................................................................... 6

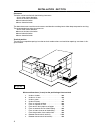

Boiler schematic ................................................................................................................... 7

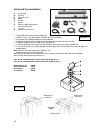

Installation section ................................................................................................................ 8

Terminal positions ................................................................................................................. 8

Heating and hot water system design ................................................................................... 9

Boiler installation ................................................................................................................ 10

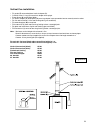

Horizontal flue installation ................................................................................................... 12

Vertical flue installation ....................................................................................................... 13

Flue configurations ............................................................................................................. 14

Electrical connection ........................................................................................................... 15

Commissioning ................................................................................................................... 16

Servicing Instructions

Routine cleaning and inspection ......................................................................................... 18

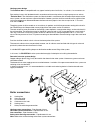

Replacement of parts ......................................................................................................... 19

Schematic wiring diagram ................................................................................................... 22

Fault finding ........................................................................................................................ 23

Conversion to LPG ............................................................................................................. 24

Mandatory warning for CE countries

WARNING

, these appliances were designed, approved and inspected to meet the requirements of the English

market. The identification plate located on the inside of the appliance

certifies the origin

where the product was

manufactured and the

country

for which it is intended.

If you see any exception to this rule, please contact your nearest stockist.

Thank you in advance for your assistance.

Note:

The boiler serial number is marked on the data label attached to the fascia behind

the front panel. Refer to the ‘Introduction’ section for a description of the basic functions

of the boiler. The ‘User’ section describes how to safely operate the boiler.