1 panther 24 ktv / 24 kov / 28 ktv the boiler’s serial no. Is shown on the plate which is attached to the rear side of the control panel. The control panel is accessible after removing the front cover. In section “operating instructions” you will fi nd description of the boiler’s main functi- ons and...

2 1. The boiler and all associated equipment must be installed and used in accordance with the installation design, all applicable legal regulations and technical standards and with the manufacture’s instructions. 2. The boiler may be installed only in an environment for which it is designed. 3. Aft...

3 • in order to run and operate the boiler in accordance with the purpose for which it is designed in actual conditions of use (hereafter referred to only as use), it is necessary to abide also by additional conditions – the most essential ones of which (i.E. Those which must not be omit- ted) are f...

4 operating instructions operating instructions controls and signals main swich the main swich (fig. 1, position. 1) is used to swich the boiler on or off. The main swich underneath the boilers bottom edge, in the control panel centreline importent: the boiler must be put into operation and switched...

5 displaying heating water temperature after turning the boiler on with the main switch, the current heating water tem- perature will appear on the display. This status is indi- cated by the lit led under- neath the symbol . Displaying hot water temperature setting when hot water is running, only th...

6 equithermal mode – curve slope press the button – letter e with the characters (-) and (1) through to (9) attached will appear on the display. By pressing the buttons, select the re- quired equithermal curve. The curve’s slope grows with the growing number (e1 – see fig. 2. If you wish to turn the...

7 tlačítko mode tlak ov v systému teplota tuv teplota ov dodržujte tlak v rozmezí 1 - 2 bary 40, 42, 45, 48, 50, 52, 55, 58, 60 °c (- - vypnuto) 45, 50, 55, 60, 65, 70, 75, 80, 85 °c (- - vypnuto) potvrďte tlačítkem mode výrobní nastavení max. Výkon : 23 (27,5) kw teplota tuv: 50 °c teplota ov: 80 °...

8 loss of heating water pressure - f0 loss of heating water pressure (below 0.6 bar) in the system. The boiler is automatically shut down – the led underneath the symbol is fl ashing. Top up water in the heating system to increase the pressure to 1.2 – 2 bar. After water has been topped up, the boile...

9 starting the boiler up important: putting the boiler into operati- on and starting it up for the fi rst time must be done by an authorised service only! If you wish to start the boiler up after it has been put into operation, make sure that: 1. The boiler is connected to power supply 2. The gas val...

10 using the boiler without a room con- trol unit when running in this mode, the boiler maintains the selected heating water tem- perature. No room control unit is connec- ted, the terminals for its connection must be interconnected with a jumper (standard factory setting). Setting procedure: • turn...

11 summer is not selected (symbol --). You must set a temperature value (this tempe- rature will have no effect on the equithermal control mode). 2. Select the “equithermal mode – curve slope” and set the e6 symbol – see page 6. 3. Select the “equithermal mode – parallel shift” and set the symbol (p...

12 protection against freezing the boiler has a protection system which protects the boiler (but not the heating and the hot water distribution systems) against freezing. When the heating water in the boiler drops below 10˚c, the boiler pump is automati- cally switched on. When the heating water tem...

13 safety valve the boiler is equipped with a safety valve with an opening pressure 3 bar. Do not touch the safety valve! If the safety valve starts releasing heating water, always turn the boiler off, disconnect if from power supply and call an authorised service. If the heating system repeatedly l...

14 warranty and waranty conditions cleaning the boiler cover can be cleaned with a moist cloth and afterwards dried and po- lished with a dry cloth. Do not use abrasive detergents or solvents. Upozornění: before cleaning turn the boiler off with the main switch. Regular service to assure continuous ...

15 category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ii 2h3p version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B 11bs ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

16 category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ii 2h3p version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C 12 , c 32 , c 42 , c 52 , c 82 ignition . . . . . . . . . . . . . . . . . . . . . . . ...

17 category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ii 2h3p version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C 12 , c 32 , c 42 , c 52 , c 82 ignition . . . . . . . . . . . . . . . . . . . . . . . ...

18 connection dimensions - model 24 ktv (kov) 1. Heating water outlet g3/4“ 2. Hot water outlet g1/2“ 3. Gas inlet g3/4“´ 4. Hot water inlet g1/2“ 5. Heating water inlet g3/4“ fig. 6 740 410 320 205 185 Ø 60 Ø 60 358 19 66 24 74.5 65 116 65 89.5 214 Ø 124 Ø 102 205 185 Ø 45 1 2 3 4 5 95 146.5 půdory...

19 deeeee connection dimensions - model 28 ktv 1 800 225 182.6 330 Ø 102 Ø 120 Ø 60 104.5 156 25 450 65 65 116 74.5 94.5 109.5 104.5 156 5 4 3 2 připojovací rozměry kotle useable pressure into heating system fig. 8 for description of connection points see 24 ktv (kov) fig. 7 flow through heating sys...

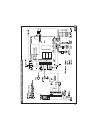

20 1*.Combustion gases thermostat 8. Pump 17. Reverse valve 1. Air manostat 9. Hot water fl ow detector 18. Safety valve 2*.Thrust breaker 10. Pressure sensor 19. Top-up valve 2. Fan 11. Draining valve 20. Bypass 3. Combustion gas collector 12. Heating water inlet 21. 3-way valve 4. Heating water hea...

21 the boilers are designed to run with he- ating water compliant with Čsn 07 7401 (which under no circumstances can be acidic, i.E. Its ph factor must be greater than 7 and must have a minimal carbona- te hardness). Requirements on utility water properties are defi ned in Čsn 83 0618 (on drinking wa...

22 the distance from fl ammable materials (e.G. Pvc, chipboard, polyurethane, syn- thetic fi bres, rubber and others) must be suffi cient so that the surface temperature of these materials does not exceed 80˚c. Important: surface temperature of upper parts (particularly the side walls and the cover) of...

23 delivery the protherm panther 24 ktv, 28 ktv and 24 kov boilers are supplied completely assembled and functionally tested. The delivery includes (fig. 12): 1. The boiler 2. Operatin and installation guide 3. Service book 4. List of service centres 5. Waranty certifi cate 6. An installation bar wit...

24 distribution pipes nominal pipe internal diameter is chosen in the usual way, using the pump charac- teristic. Distribution pipes are designed ac- cording to the requirements for the system performance, not according to the boiler’s maximum output. The system must allow suffi cient fl ow so that th...

25 thermostatic radiators valves if a room control unit is installed, at least one of the radiators in the reference room must be without a thermostatic valve. For better temperature comfort we recommend to leave all radiators in the reference room without a thermostatic valve. Hot water system pres...

26 after reconstructions, in unfavourable building dispositions, etc., it is possible to connect the boiler to the heating system, the hot water system as well as the gas mains by means of fl exible hoses, but only those designed for this purpose. Flexible components should be as short as possi- ble,...

27 expansion vessel before fi lling up the heating system, check pressure in the expansion vessel. The ini- tial pressure inside the expansion vessel should be by 0.2 bar higher than the assu- med pressure in the heating system. If the heating system is already fi lled up, it is necessary to shut the ...

28 filling up the heating system with water • make sure that the boiler gas supply valve is closed. • unscrew the automatic bleeding valve cap situated on the pump. • check and adjust the expansion vessel pressure according to the prescribed static pressure in the system. • connect the boiler to pow...

29 fig. 18 in the ktv models, combustion gases must always be removed and air supplied through a dual ducting specially designed for this purpose. Horizontal ducting sections must have a gradient allowing condensate to be dischar- ged to the outside space or to condensate removal components. This is...

30 method c 42 – connection to common dual chimneys. Air can be also supplied from free space (or from a space with plentiful air supply). Dual ducting from each boiler (individual routes) may be terminated in a common chimney; the chimney’s trans- portation suffi ciency is assessed from the data sta...

31 termination of horizontal ducting sections on the building‘s façade terminating horizontal sections on the building’s façade is a method which should be used only when there is no other way. Ducting routes may be terminated using the rules described in this operation and installation guide (or in...

32 permissible exhaust outlet locations fig. 21 - overhangs fig. 22 - façades fig. 23 - corners 2 m - in publicly accessible places 0,4 m - in other places - denotes space where an outlet can be located.

33 safety measures the distance between any fl ammable material and the combustion gases part of a separate ducting system must be such that the surface temperature of this material does not exceed 80˚c. Combustion gases outlets must not be located in: • places with the danger of explosion (as defi ne...

34 the room control unit must be connected to the boiler by a two-core cable. The re- commended copper wire cross-section is 0.5 to 1.5 sq.Mm. The room control unit connection cable must not run in parallel with power wires or cables. The terminal box for wiring the room control unit, which is facto...

35 electrical wiring dia gram - pr o therm p anther 24 k o v fig. 25.

36 electrical wiring dia gram - pr o therm p anther 24 ktv / 28 ktv fig. 26.

User and installation instruction 24 ktv / v .17 24 kov / v .17 28 ktv / v .17 w allhung combined boiler output 9,5 - 23 (11 - 27,5) kw equither mal control panther 2 0020003645 - v .2 6/2004.